Just another update:

Got the engine back together and installed in the truck a couple weeks ago. Took it to Coty's for a test and tune and break in for the rings.

After break in I checked for any blow by and could not see any evidence . With the rings opened up I thought I would see something..but all was good.

I turned on the learn feature on the Sniper software and plugged the laptop in for live tuning. I drove around varying the rpm and shifted through the gears for about 1 mile ... with an occasional blip of the throttle to bring in some boost.

All seemed great...

I then did a full on test hit bring the rpm's up to around 5900. Coty said the engine sounded amazingly more powerful than the

last build. I asked him to get in an do a full test hit while I stand back and listen.

The truck ran great until he was about 60% down the run....then it shut off.

I walked down to meet him and he said that the new fuel pump just quit. HMMMM.

My first thought was that I had set the software up with a ton of safety switches to trigger a shut down in case of any array of issues and one of them was triggered.

Well...that was the case...sort of...

Looking through the log...I seen where I had set a safety to first pull 20 degrees of timing, then shut off fuel... if the fuel pressure dropped below

50 psi. It worked!!!

So we traced the low pressure issue down to a blown fuse on the New fuel pump!

The Sniper has a harness with the 30 amp fuse and the relay built into it... That is what I used.

Issue was that the new MagnaFuel 750 PRO Tuner fuel Pump requires ( 2 ) separate power leads with a minimum 20 amp fuse and their

30/40 amp relay on each lead to supply the pump.

So... We installed the new dual relay set up and triggered them with the Relay in the Sniper harness so I did not have to cut any wires in the factory Sniper harness.... Problem solved!

I looked at the data that night form the st hits and seen the CL Comp values on the data log....But found that I had not had the learn table box checked

so it could learn .... But at least I could see where it was lean and where it was rich...

It rained hard for a few days so I could not get anymore testing in before last Saturday...Which is when we took our trucks to the annual

family reunion/mud bog.

Once there... I was allowed to use one of the fields to do some testing....This time I made sure the learn box was checked off.

What an amazing test!!! The engine performed perfect. The new relays worked , and the pump feed all the fuel I needed.

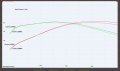

Here is a pic of the data log from one of the runs...

You can see where I have the pen pointed at the fuel flow...756.8 lb/hr

That is 114 GPH.

HP= GPH x 6.6 (weight of gal of E85) / .9 (BSFC)

Thats 838 HP. Not Bad.

You can also see on the left in the second box from the bottom that the Timing was pulled to 19.6 degrees...

I think there is more to be made....But I feel I am going to leave what ever is left on the table stay on the

table.....Cause it was a great feeling to drive the truck all day and get to drive it back on the trailer!!!!!! With NO issues!

When I got home and looked at the data logs... I seen a pattern of very lean spikes upon letting off he throttle ..then going very rich

trying to level out....

I seen in the software that my Minimum Injector Opening Time was set at 1.2 ......I upped it to 1.6 .....this should help with the lean spike

and keep things more even..

All in All....I am learning alot more with the software and it's capabilities ... I love that I found how to set all the safety switches...I'm

sure the engine appreciates it also!