I just had a 383 built by a crate engine supplier. The following is a list of the that was suggested to me. Originally with procom heads but now upgraded to AFR. If I had to do it again I should have waited, gained some more knowledge and built it myself. And yes I should have gone forged pistons.

The motor is going to my daily driver 1968 el camino with built performance 700r4, 373 gears in ford 9, and will be 90% street driven and 10% track use. The car is not lightened so it is around 3600 with me in it. My goal was max shift at 6000 rpm with max hp at 5500.

Quickfuel 750

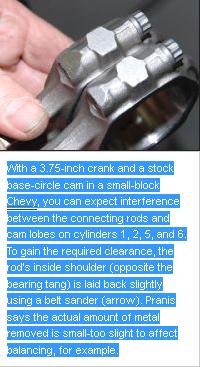

Scat 9000 crankshaft

pistons Speedpro 860 cp Flat top 5 cc valve reliefs

Scat i beam rods

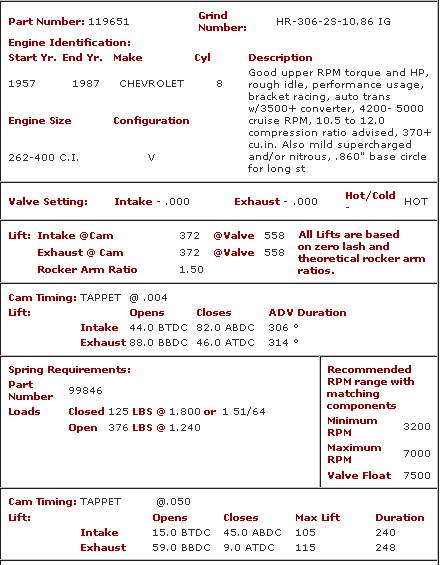

Camshaft hyd roller compcam Xr276Hr 224/230 @050, 276/282@.006 110 Lobe sep, Intake centerline 106

Heads AFR 195 -75 CC runners Should be around 9.8/1

Intake -Edelbrock air gap

Rockers Comp rollers

Timing -Double roll -3023

Oil pump- Melling high volume

Question will this combo give me 450 or so horsepower with lots of torque and would adding 1.6 rockers help.

I no almost nothing about cam choices but since read the David Vizards book on building small block chevys to gain some knowledge I have realized I know much less than I thought I did.

The motor is going to my daily driver 1968 el camino with built performance 700r4, 373 gears in ford 9, and will be 90% street driven and 10% track use. The car is not lightened so it is around 3600 with me in it. My goal was max shift at 6000 rpm with max hp at 5500.

Quickfuel 750

Scat 9000 crankshaft

pistons Speedpro 860 cp Flat top 5 cc valve reliefs

Scat i beam rods

Camshaft hyd roller compcam Xr276Hr 224/230 @050, 276/282@.006 110 Lobe sep, Intake centerline 106

Heads AFR 195 -75 CC runners Should be around 9.8/1

Intake -Edelbrock air gap

Rockers Comp rollers

Timing -Double roll -3023

Oil pump- Melling high volume

Question will this combo give me 450 or so horsepower with lots of torque and would adding 1.6 rockers help.

I no almost nothing about cam choices but since read the David Vizards book on building small block chevys to gain some knowledge I have realized I know much less than I thought I did.