Hey All,

My kids often rib me about how I spend months carefully plotting a long term vision months before I actually break ground. I know precisely where I want to go before I set the first stone.

…and so it goes for the corvette. The concept of where I want to take my 1969 L-46 corvette is slowly percolating.

In 1969, the L-46 put out 350HP/380TQ. The original L-46 powerplant is long gone. But nonetheless, puttering around with the iron lump that is in there, is kinda fun.

This has led me to the conclusion that I don’t need or even desire tons of power.

I have done the track days, exploded my trans and rebuilt it, did the centrifugal supercharger, the water/methanol injection… you name it…

I definitely do not want to do that with this car. This will be 90% restoration, 10% modification. The 10% modification will include: rack and pinion (I need a precise feel to my steering) and a TKO transmission (I need a comfortable cruise at 70MPH). Tho’ I

must admit, except on the highway, this close ratio is fun !

My plan is to match or improve on the L-46. This car will clearly be spending most of its time under 4,000 rpm. I doubt it will ever see the track, but it certainly will see some casual spirited countryside backroad driving.

I want to restore the engine bay’s original look (minus the AIR pump).

The plan is:

Carburetor

It will be a Quadrajet. I never really worked on those. I have done Holleys and AFBs. I always wanted a finely tuned Q that is nearly as smooth as FI. It also retains OEM looks. It can easily flow north of 750CFM. The small primaries will make for good throttle response… no real downsides that I can see other than the learning curve.

Intake

I will be going for a low-rise Edelbrock Performer intake or similar. The OEM L-46 is quite a lump of iron on the front end. A Performer intake (along with aluminum heads, see below) seems like a good compromise sacrificing some of the OEM look for substantial weight saving in a critical location. I also suspect 1969 OEM cannot match modern intakes in terms of overall flow performance.

Heads

OEM 186 iron heads are heavy, expensive, will need a lot of work and once again, cannot match aftermarket flow and weight saving. It is not worth seeing the camel humps on the end or the casting number underneath the valve covers. I suspect a pair of reasonable quality 195cc heads (blueprint seems to carry a nice, cost-effective pair) will do for my intended application.

Camshaft

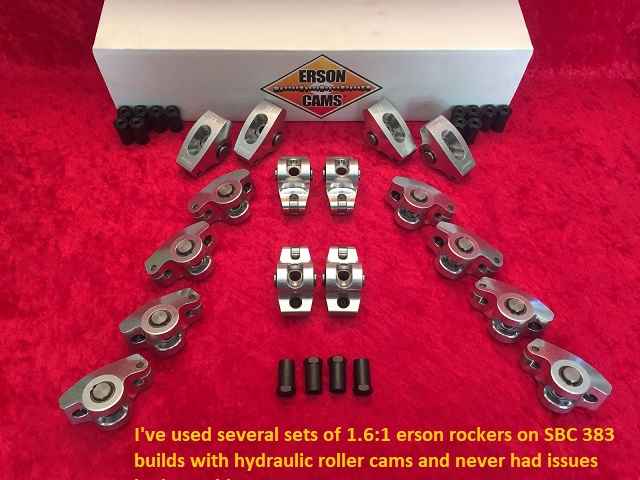

Here, I am clueless. I guess I have to worry about the vacuum at idle for the power brakes. I will probably go with a regular hydraulic cam swap on the block that I have and, when I do a rebuild, it makes sense to go hydraulic roller… with a 383.

Exhaust

Here I want to go with a preproduction (maybe ported) ram-horn exhaust manifolds. These manifolds are more restrictive than the full length headers that I have. But it is a big return to what was OEM. They are quieter. And OEM manifolds did support 370 gross HP @ 6,000 rpm on the 1970 LT1. (Tho that might be a factory exaggeration.) Again, I know I am losing some performance points, but for my application, ram-horns will probably be fine for a 350/383 CID striving to match or improve upon the original L-46.

Block

For now it is a 350. Soon I will rebuild a 383 out of the numbers matching 4-bolt that is in my basement.

My plan is to proceed in steps.

Right now I have good oil pressure and good compression. My short block seems healthy. I’ll keep that for the moment and start with an intake and cam swap. Then I’ll follow up with heads and an exhaust manifold conversion somewhere along the way. Finally, car running, I will independently rebuild a 383 and when the time comes, swap it in with a roller cam.

My questions are the following:

- What insight do you gentlemen have to share regarding my stepped-plan ?

- What would be good cam recommendations?

- How much can we improve on OEM considering the restrictions I have set down? What should I expect with the 350 and the 383?

MTIA !

D.

My kids often rib me about how I spend months carefully plotting a long term vision months before I actually break ground. I know precisely where I want to go before I set the first stone.

…and so it goes for the corvette. The concept of where I want to take my 1969 L-46 corvette is slowly percolating.

In 1969, the L-46 put out 350HP/380TQ. The original L-46 powerplant is long gone. But nonetheless, puttering around with the iron lump that is in there, is kinda fun.

This has led me to the conclusion that I don’t need or even desire tons of power.

I have done the track days, exploded my trans and rebuilt it, did the centrifugal supercharger, the water/methanol injection… you name it…

I definitely do not want to do that with this car. This will be 90% restoration, 10% modification. The 10% modification will include: rack and pinion (I need a precise feel to my steering) and a TKO transmission (I need a comfortable cruise at 70MPH). Tho’ I

must admit, except on the highway, this close ratio is fun !

My plan is to match or improve on the L-46. This car will clearly be spending most of its time under 4,000 rpm. I doubt it will ever see the track, but it certainly will see some casual spirited countryside backroad driving.

I want to restore the engine bay’s original look (minus the AIR pump).

The plan is:

Carburetor

It will be a Quadrajet. I never really worked on those. I have done Holleys and AFBs. I always wanted a finely tuned Q that is nearly as smooth as FI. It also retains OEM looks. It can easily flow north of 750CFM. The small primaries will make for good throttle response… no real downsides that I can see other than the learning curve.

Intake

I will be going for a low-rise Edelbrock Performer intake or similar. The OEM L-46 is quite a lump of iron on the front end. A Performer intake (along with aluminum heads, see below) seems like a good compromise sacrificing some of the OEM look for substantial weight saving in a critical location. I also suspect 1969 OEM cannot match modern intakes in terms of overall flow performance.

Heads

OEM 186 iron heads are heavy, expensive, will need a lot of work and once again, cannot match aftermarket flow and weight saving. It is not worth seeing the camel humps on the end or the casting number underneath the valve covers. I suspect a pair of reasonable quality 195cc heads (blueprint seems to carry a nice, cost-effective pair) will do for my intended application.

Camshaft

Here, I am clueless. I guess I have to worry about the vacuum at idle for the power brakes. I will probably go with a regular hydraulic cam swap on the block that I have and, when I do a rebuild, it makes sense to go hydraulic roller… with a 383.

Exhaust

Here I want to go with a preproduction (maybe ported) ram-horn exhaust manifolds. These manifolds are more restrictive than the full length headers that I have. But it is a big return to what was OEM. They are quieter. And OEM manifolds did support 370 gross HP @ 6,000 rpm on the 1970 LT1. (Tho that might be a factory exaggeration.) Again, I know I am losing some performance points, but for my application, ram-horns will probably be fine for a 350/383 CID striving to match or improve upon the original L-46.

Block

For now it is a 350. Soon I will rebuild a 383 out of the numbers matching 4-bolt that is in my basement.

My plan is to proceed in steps.

Right now I have good oil pressure and good compression. My short block seems healthy. I’ll keep that for the moment and start with an intake and cam swap. Then I’ll follow up with heads and an exhaust manifold conversion somewhere along the way. Finally, car running, I will independently rebuild a 383 and when the time comes, swap it in with a roller cam.

My questions are the following:

- What insight do you gentlemen have to share regarding my stepped-plan ?

- What would be good cam recommendations?

- How much can we improve on OEM considering the restrictions I have set down? What should I expect with the 350 and the 383?

MTIA !

D.

Last edited by a moderator: