8

87vette81big

Guest

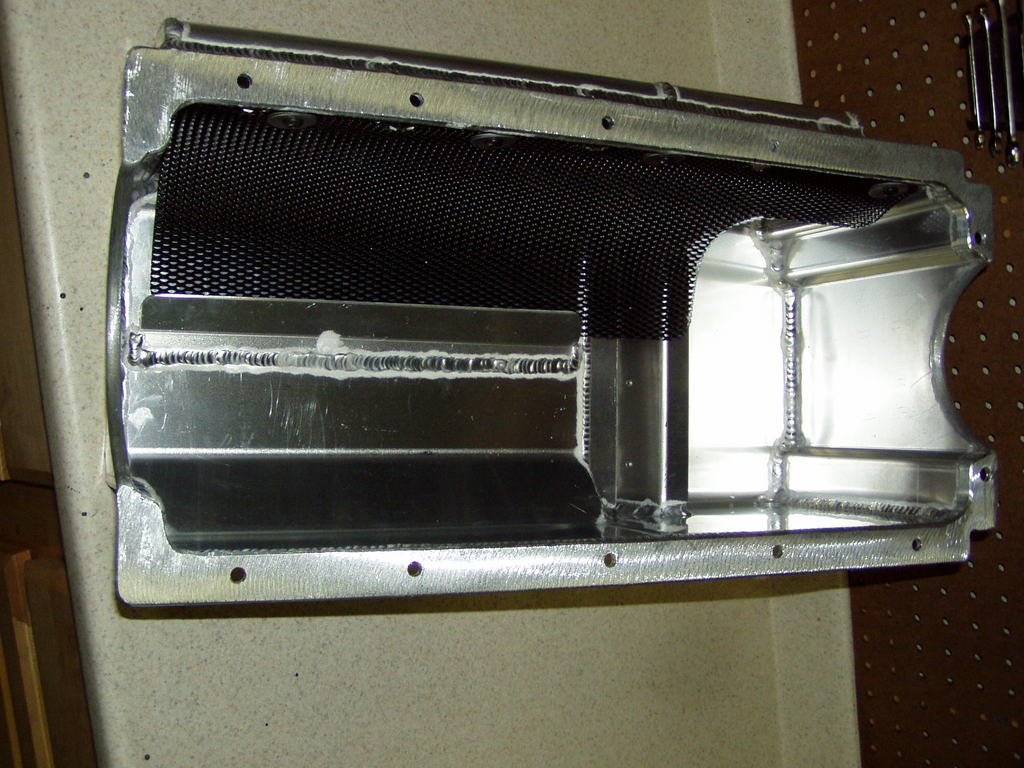

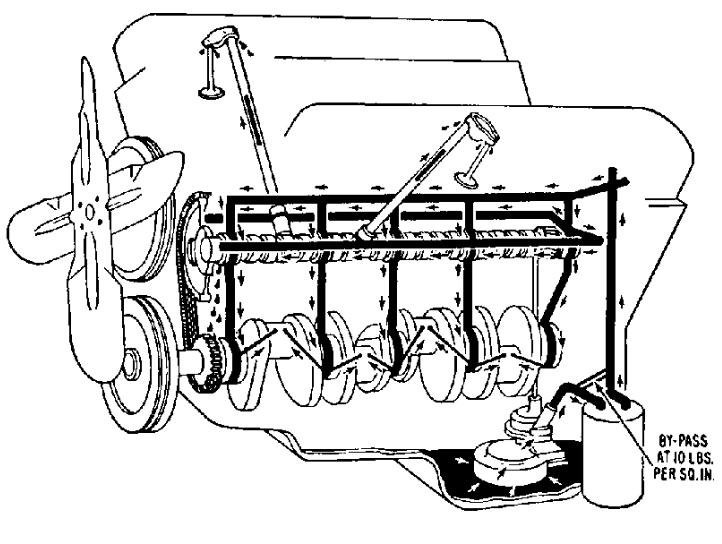

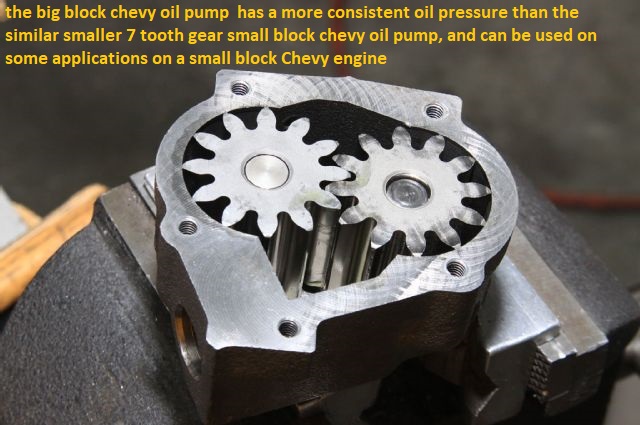

Without a Doubt in my mind the Bypass Valve is open 100% of the time in a Pontiac V8 with The stock oil pump, M54D & M54F 40-60-80psi oil pumps respective when on the gas WOT ABOVE 2600RPMS.WELL DESIGNED AND PROPERLY INSTALLED BAFFLED OIL PANS,WINDAGE TRAYS AND CRANK SCRAPERS GO A LONG WAY TO INCREASING ENGINE DURABILITY THRU BETTER MORE CONSISTENT OIL FLOW RATES

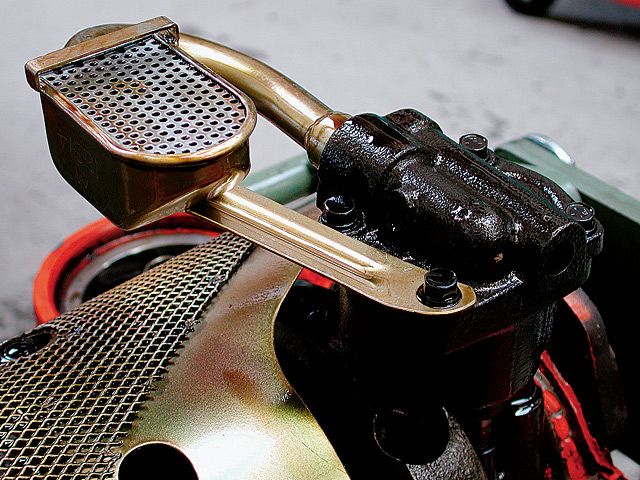

yes you can (and probably should) take the time to fabricate a windage screen similar too the one shown in the link above,

or in these link's

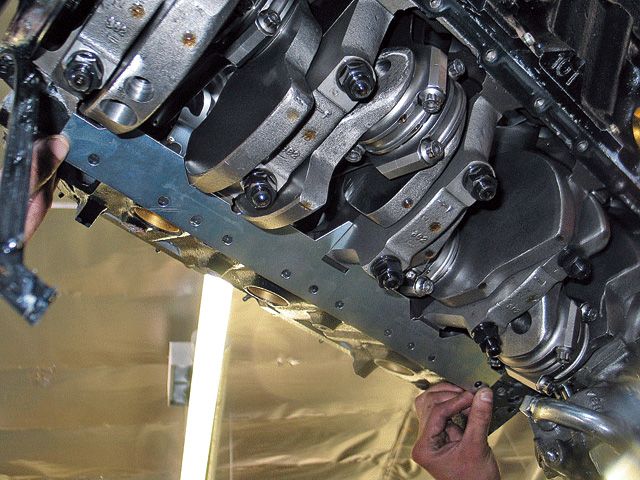

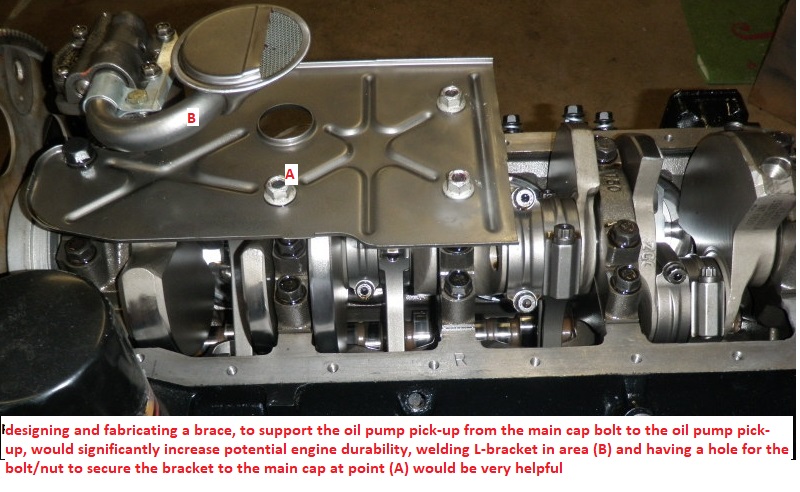

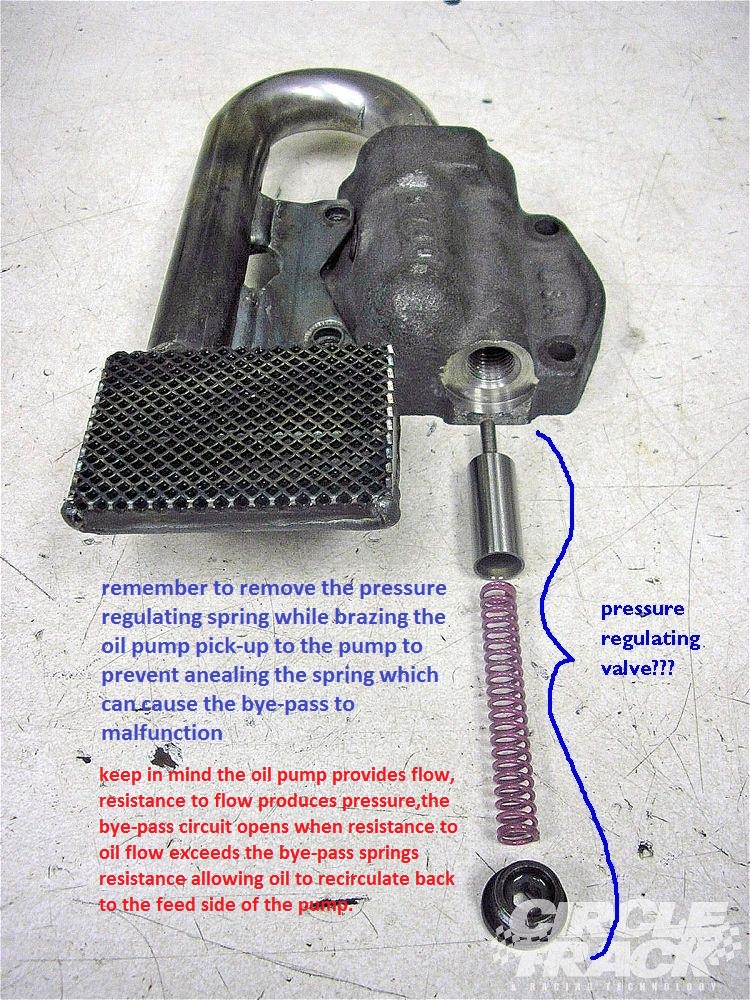

any time you allow an unsupported section of the oil pump pick-up to not have a welded or properly bolted external support bracing,

you can almost depend on constant flexing to eventually cause durability issues.

a good many engines benefit from having a bolt on external brace to the engines windage screen, if you think in three dimensions vs just two this can be done rather easily.

https://www.chevydiy.com/chevy-big-block-performance-lubrication-system-guide/

https://www.enginelabs.com/engine-tech/engine/useful-tips-installing-oil-pans-right-way/

one more in an ENDLESS LIST of reasons any serious shop needs to have access to a decent welder (A OXY-ACETYLENE TORCH in this case) a drill press and a dial caliper could allow you to fabricate a $1 l-bracket that could easily be the difference between a $10-$15K engine living a long trouble free life vs a very expensive self destructing engine , lesson in why adding a $1 brace would be almost mandatory

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/building-a-custom-wet-sump-oil-pan.65/

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

http://garage.grumpysperformance.com/index.php?threads/custom-windage-tray.10490/

http://www.colemanracing.com/Windage-Screen-P3831.aspx

http://www.musclecardiy.com/performance/how-to-build-racing-engines-sumps-and-oiling/#

http://www.hotrod.com/articles/ctrp-0603-oil-pan-design-windage-tech/

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

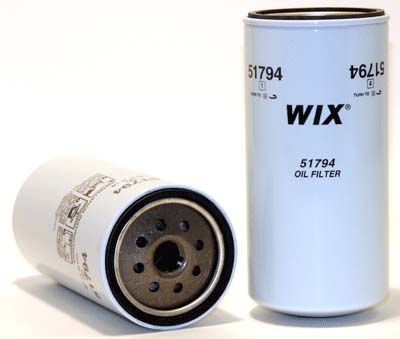

DUAL REMOTE MOUNT OIL FILTERS CAN MAKE EXTRA FILTRATION FAR EASIER TO INSTALL

PARTS DETAIL

Principal Application: Chevrolet and GMC Trucks (73-93)

Style: Spin-On Lube Filter

Service: Lube

Type: Full Flow

Media: Paper

Height: 7.822

Outer Diameter Top: 3.674

Outer Diameter Bottom: Closed

Thread Size: 13/16-16

By-Pass Valve Setting-PSI: None

Burst Pressure-PSI: 270

Max Flow Rate: 9-11 GPM

Nominal Micron Rating: 21

SAME HILDS TRUE SBC, BBC & LS-X.

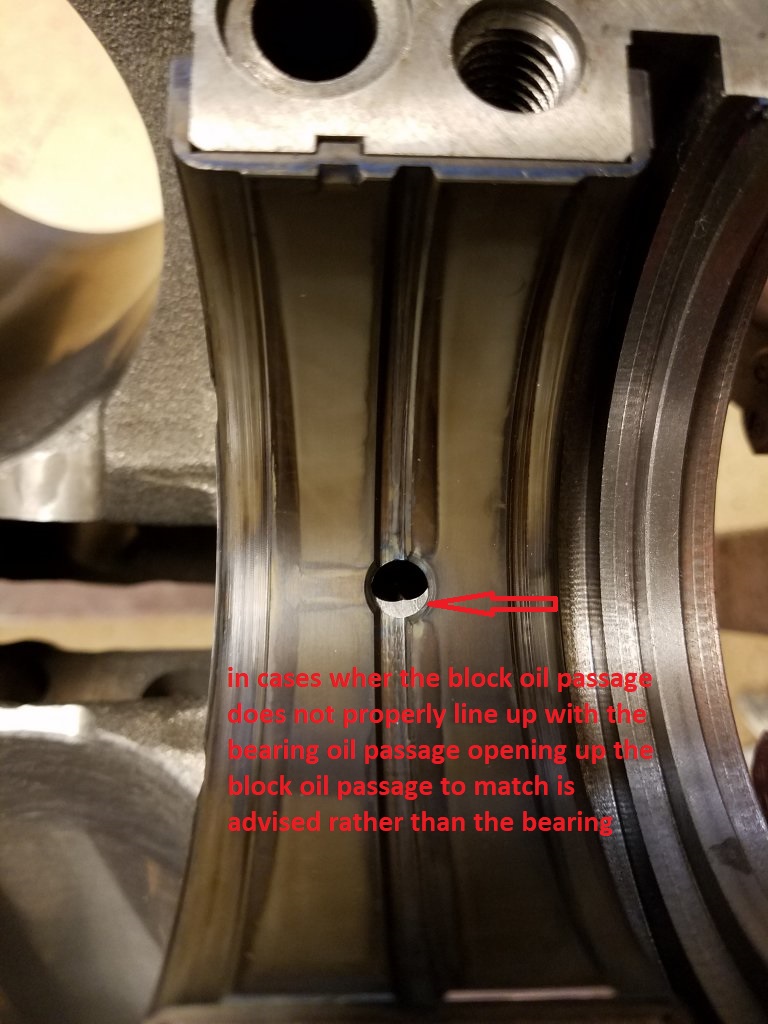

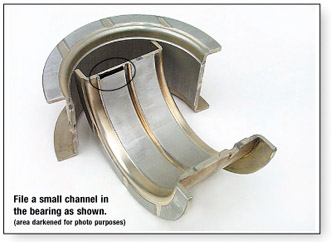

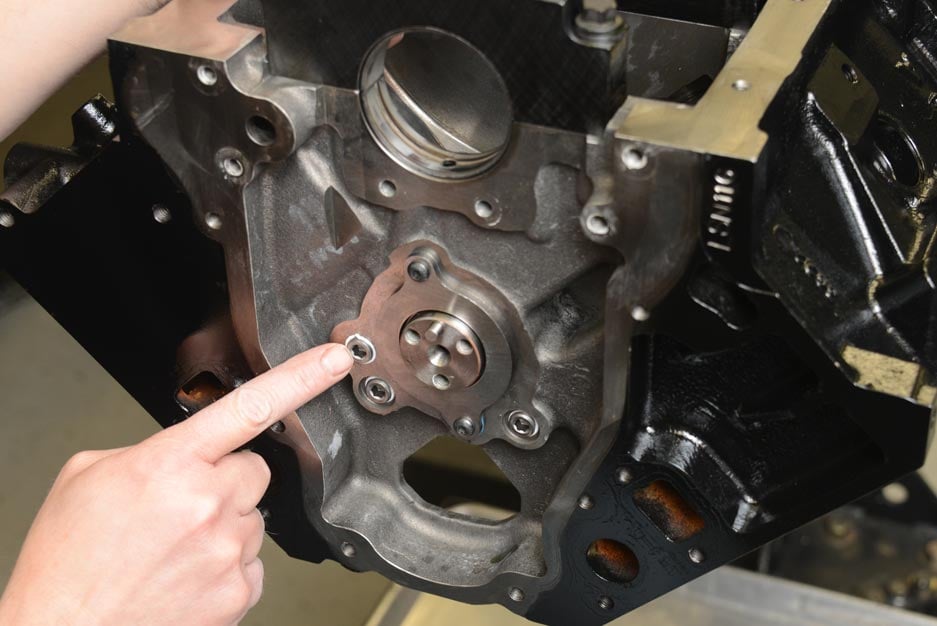

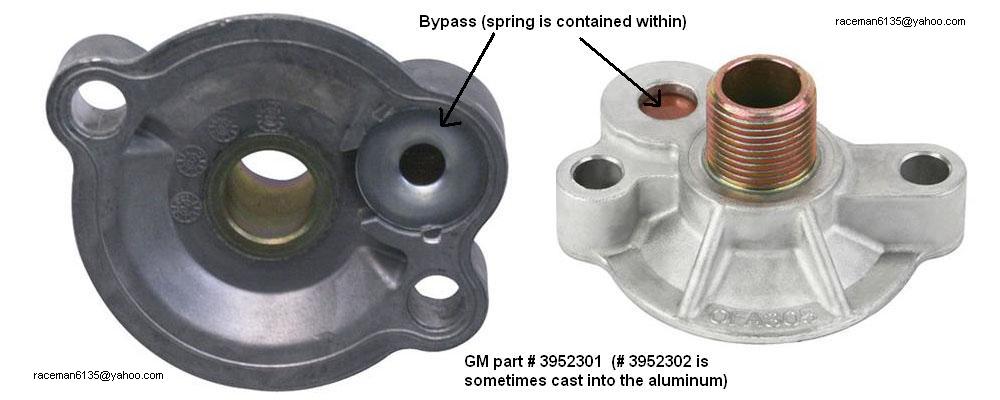

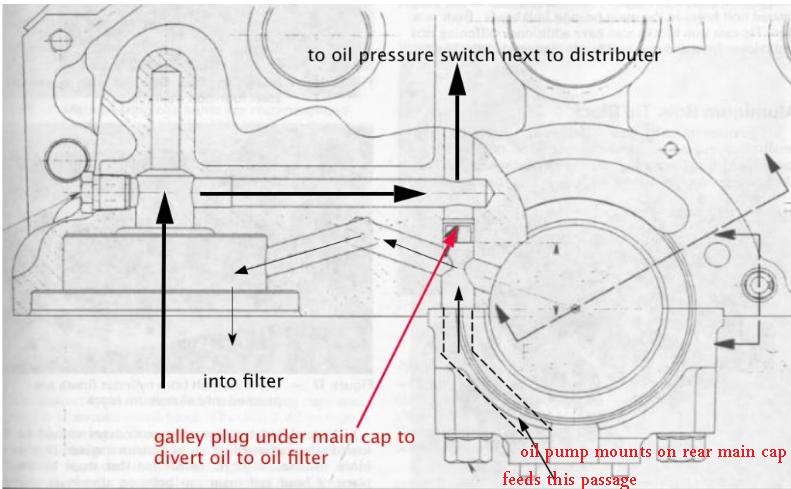

opening and smoothing the recessed area and porting the oil passage entrance reduces the restriction to oil flow

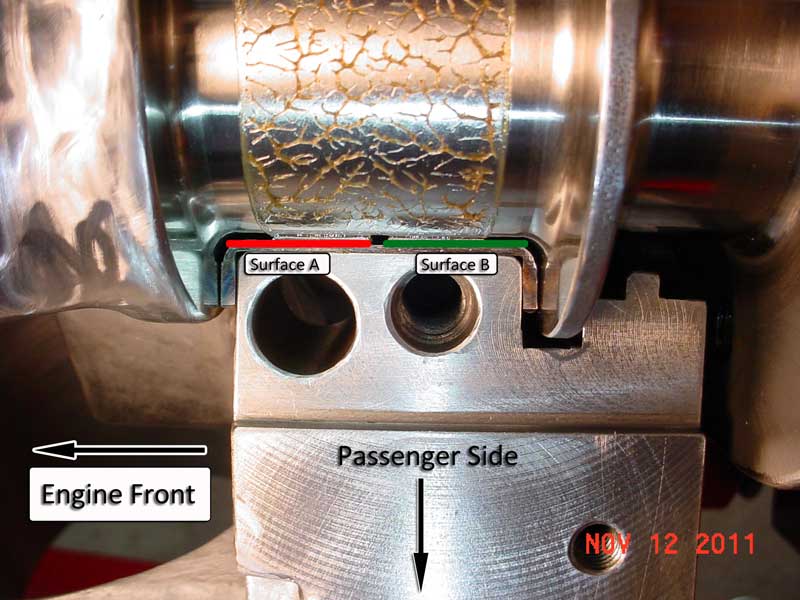

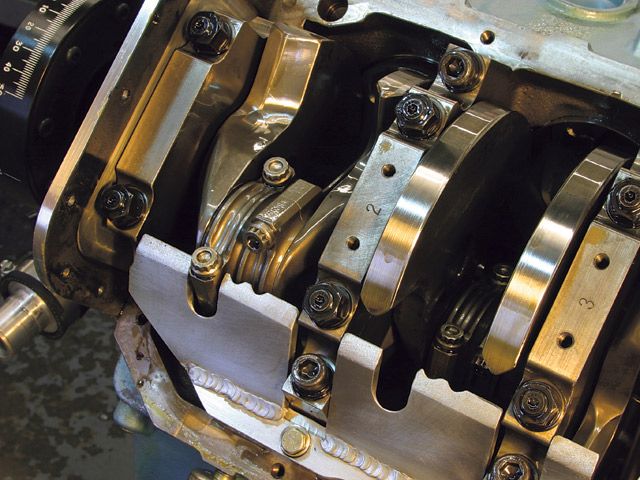

notice the open slot between the rear main cap supporting the oil pump and bearing shell support and the area supporting the rear main seal, this prevents PRESSURIZED oil from the bearings reaching the rear main seal.

the as cast recess in the rear main cap where the oil pump mounts can be rather restrictive and shallow, so a bit of careful mill or grinding work to open up and add some depth certainly helps oil flow if its done carefully

in my opinion , and experience and from lots of G.M. engine, race testing.

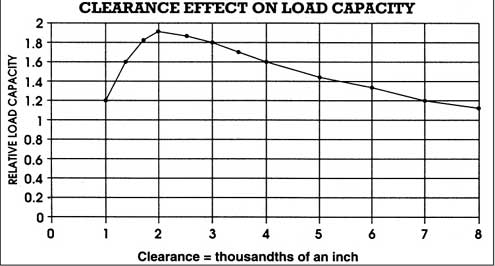

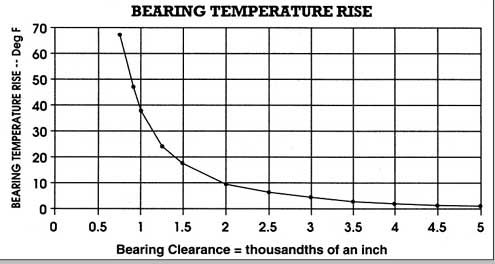

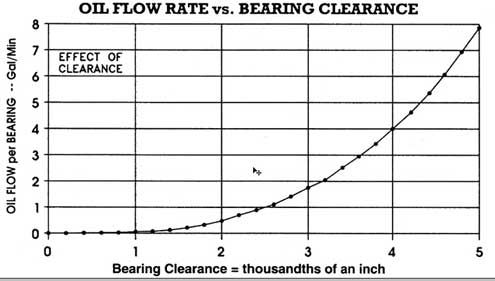

theres no need for oil pressure to exceed about 65 psi,

it takes power to spin the oil pump against that extra resistance, it induces extra wear on the distributor and cam gears,

and it does nothing to reduce bearing wear or increase cooling on the bearing surfaces,if your engine shows more than about 70 psi, you should open some bearing clearances marginally

(maybe an extra half thousandth on the mains) to increase oil flow volume reaching the main bearings, and use a lower resistance oil pump bye-pass spring.

extra oil flow volume cooling the bearings and valve train will do more for durability than oil pressure exceeding 65-70 psi

OIL PRESSURE read on the oil pressure gauge is a MEASURE of RESISTANCE to oil flow, you can REDUCE the pressure the gauge reads by either increasing the engine clearances or REDUCING the oil viscosity (thickness) so it flows thru the clearances faster with less resistance.(OR INSTALLING A SLIGHTLY WEAKER OIL PUMP BYE_PASS SPRING,that limits the pump pressure before it allows some oil to re-circulate back through the bye-pass valve ,from the high pressure back to the low pressure side of the pump impellers, but only the max pressure you reach is limited by the bye-pass spring,in your oil pressure bye pass circuit and its that spring resistance determines the point where the bye-pass circuit, opens and limits max oil pressure, but the bye-pass circuit has zero to do with anything else, if its functioning correctly,

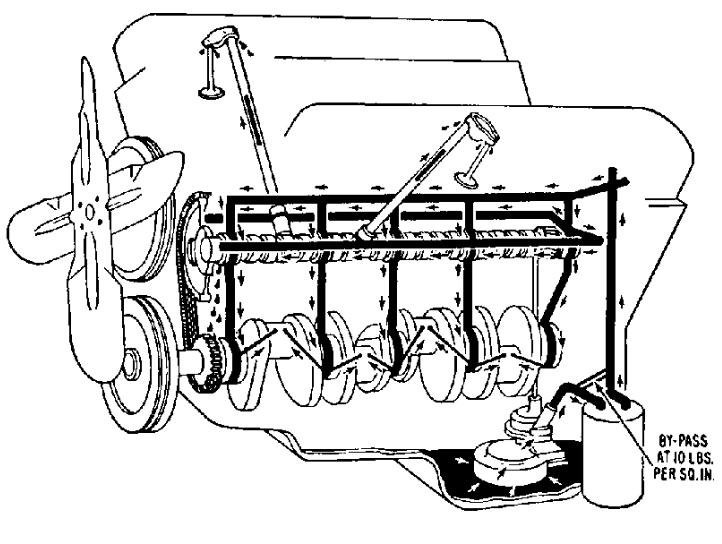

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

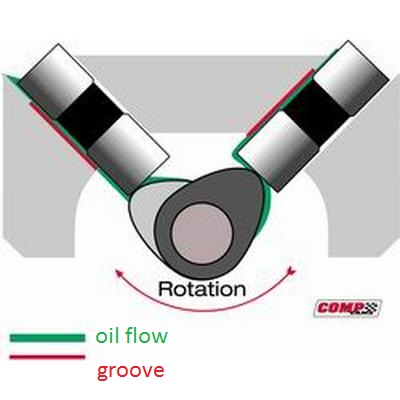

once oil exits the bearings or valve train it flows mostly by gravity back to the oil pan sump, but a properly designed windage screen and crank scraper correctly clearanced allows the spinning crank/rotating assembly to act like a directional pump that drags the vast majority of the oil flow back to the sump, by design.

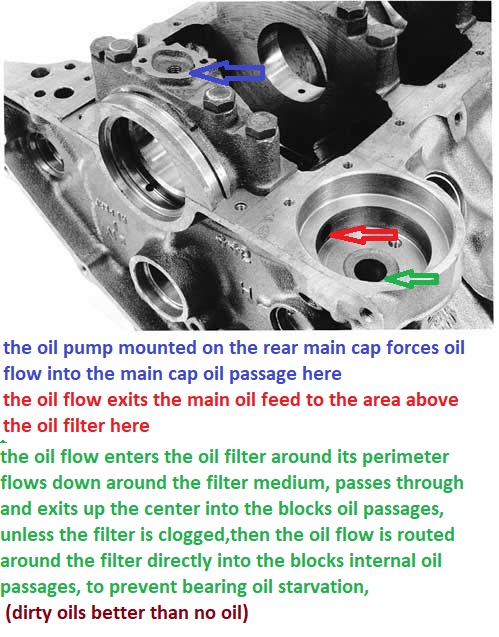

NO THE OIL PUMP, PUSHES OIL INTO THE BLOCK PASSAGES, THROUGH THE OIL FILTER ADAPTER ,THE BYE-PASS IS A SPRING LOADED BYE-PASS IN THE BLOCK THE OIL FILTER SCREWS ONTO, AND HAS NOTHING TO DO WITH OIL BYE-PASSING THE OIL FILTER

IF YOU DON,T WANT OIL TO OCCASIONALLY BYE-PASS THE FILTER INSTALL AN ADAPTER WITHOUT A BYE-PASS VALVE

ALL THAT OIL FILTER BYE-PASS VALVE DOES IS ROUTE OIL FLOW PAST THE OIL FILTER

IF IT BECOMES SO CLOGGED WITH TRASH THAT THERES

A 10 PSI DIFFERENCE IN THE RESISTANCE TO OIL FLOW THROUGH THE FILTER

VS AROUND IT INTO THE BLOCKS OIL PASSAGES, oil enters the area over the oil filter in the block and is forced into the outer holes in the oil filter perimeter down through the case and filter element and up through the central hollow screw retention stud into the blocks oil passages, if the resistance too flow is too great the oil filter bye-pass valve routes oil around the filter directly from oil pump to the blocks oil passages.

http://garage.grumpysperformance.co...-friction-and-pumping-losses.8966/#post-31978

THE OIL FILTER BYE-PASS MEARLY ALLOWS OIL TO BYE-PASS THE FILTER MEDIUM IF ITS MOSTLY CLOGGED OR OVERLY RESTRICTED

THIS HAPPENS MOSTLY IF YOU FAIL TO HAVE REGULAR OIL CHANGES OR REVE THE ENGINE WHILE THE OILS STILL COOL.

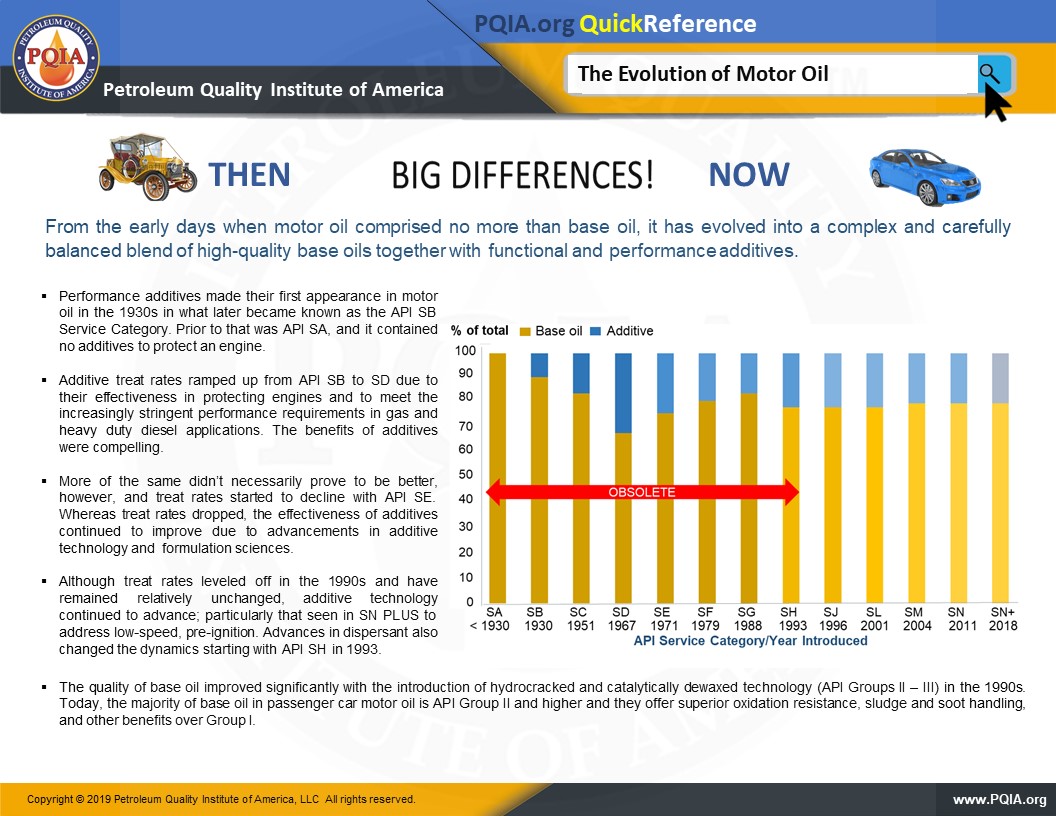

OIL THATS HOT HAS REDUCED VISCOSITY AND ITS EASIER TO PUSH THROUGH THE OIL FILTER

oil pumps have a pressure regulator circuit that prevents pressure increases past a springs resistance

grumpy, no mater how hard I tighten the distributor clamp on my intake manifold,

I will almost enviably, find its moved and will require re-timing. any ideas?

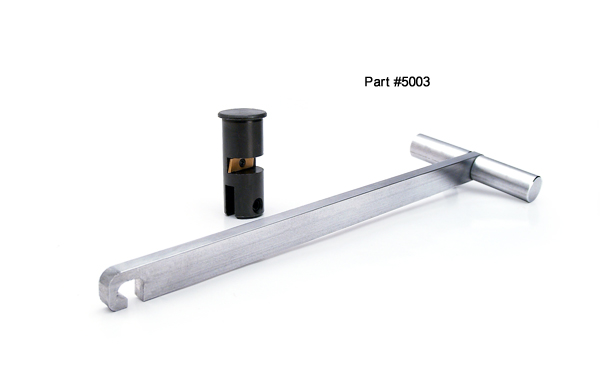

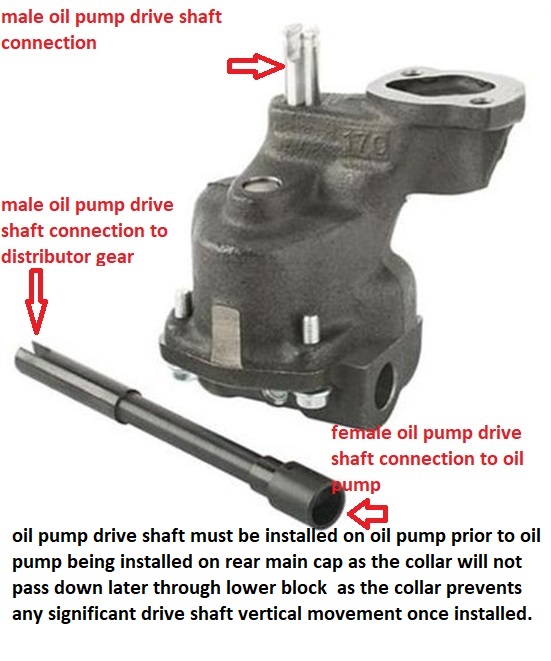

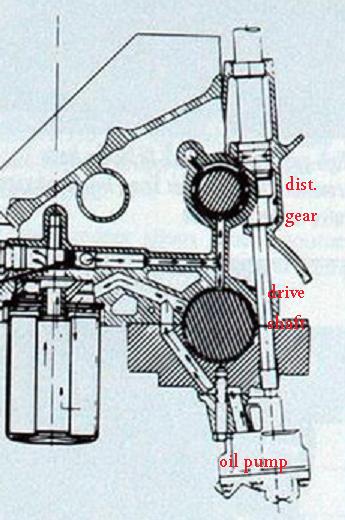

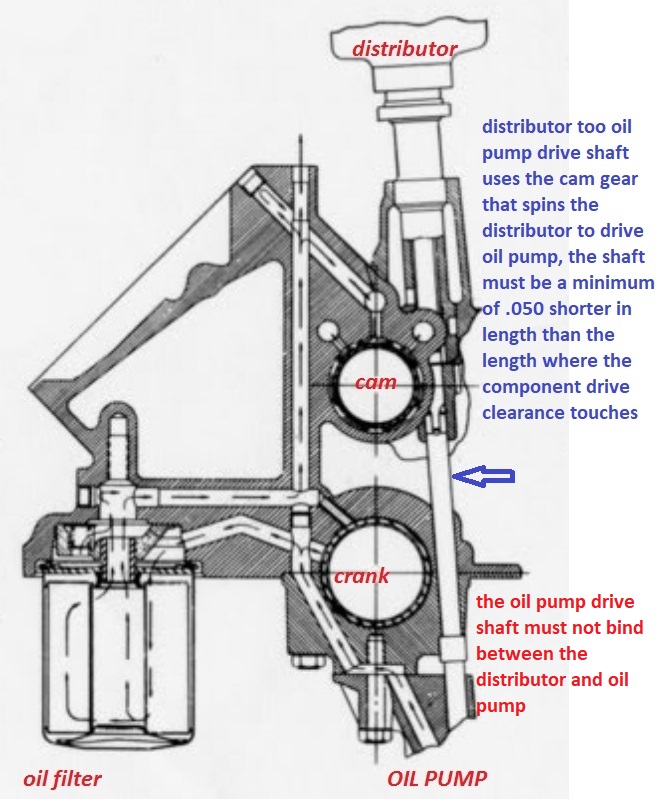

Ive seen this frequently, and almost always its a case where if you measure carefully, youll almost surely find,

the oil pump drive shaft is bottoming out solidly between the oil pump and the distributor gear is binding,

so the distributor is not firmly seated against the intake manifold surface.

the oil pump drive shaft length MUST BE about .050 SHORTER than the distance it would take to firmly seat it inside the distributor drive gear, the cam has a gear that spins the distributor and the oil pump drive shaft is driven by that distributor gear in the lower distributor that extends down to the oil pump drive.

this gear must not bind on the distributor too oil pump drive shaft when the distributor is seated firmly on the intake manifold and clamped into place there must be about .050 clearance minimum

related threads you should really read

http://garage.grumpysperformance.com/index.php?threads/oil-pump-drive-shafts.123/

http://garage.grumpysperformance.co...ibutors-wont-seat-on-intake.12538/#post-63636

http://garage.grumpysperformance.com/index.php?threads/oil-pump-drive-shafts.123/#post-19025

http://garage.grumpysperformance.co...ing-an-oil-pump-pick-up-tube.1800/#post-43110

http://garage.grumpysperformance.com/index.php?threads/distributor-gear-wear.1701/#post-4160

http://garage.grumpysperformance.co...butor-clamp-that-just-won-t-clamp-firmly.871/

http://garage.grumpysperformance.co...-allows-the-distrib-to-turn-even-tighten.873/

http://garage.grumpysperformance.com/index.php?threads/setting-timing-question.1411/#post-3131

Last edited by a moderator:

2/12

2/12 3/12

3/12 4/12

4/12

5/12

5/12 6/12

6/12 7/12

7/12 8/12

8/12 9/12

9/12 10/12

10/12 11/12

11/12 12/12

12/12 13/12

13/12