2Loose

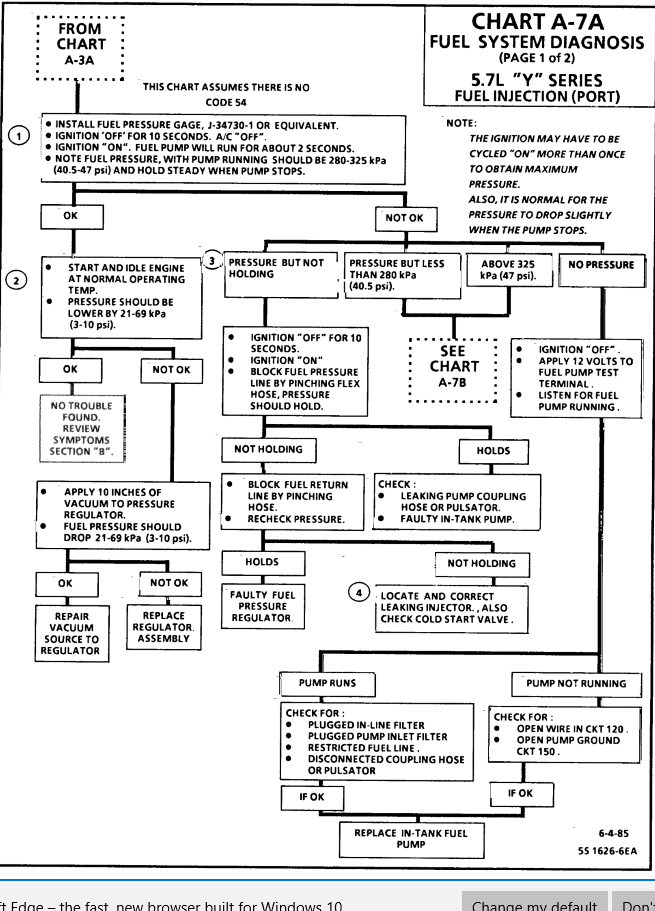

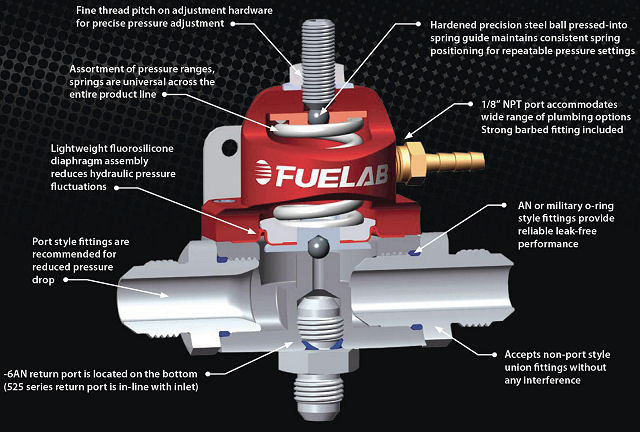

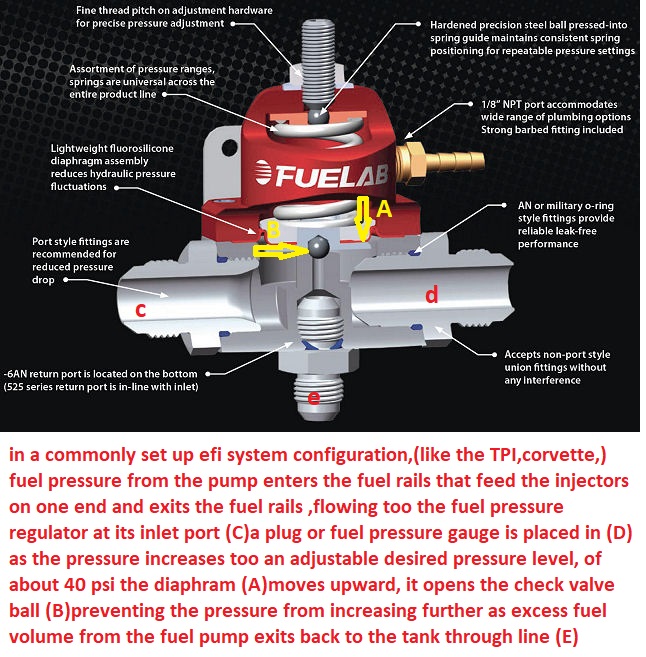

reliable source of info

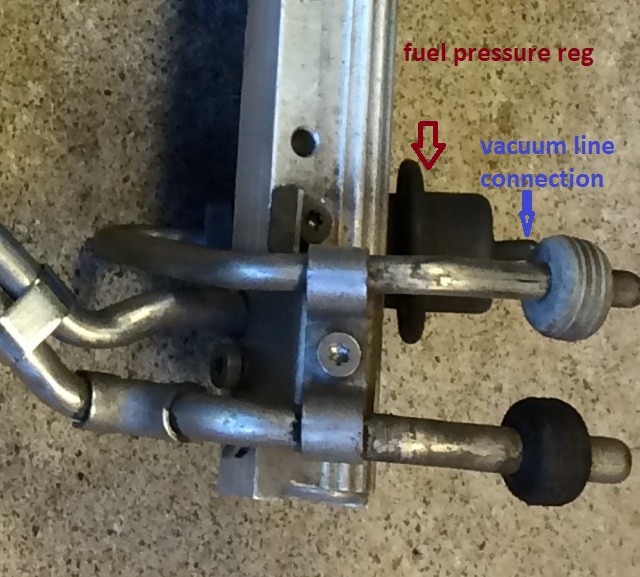

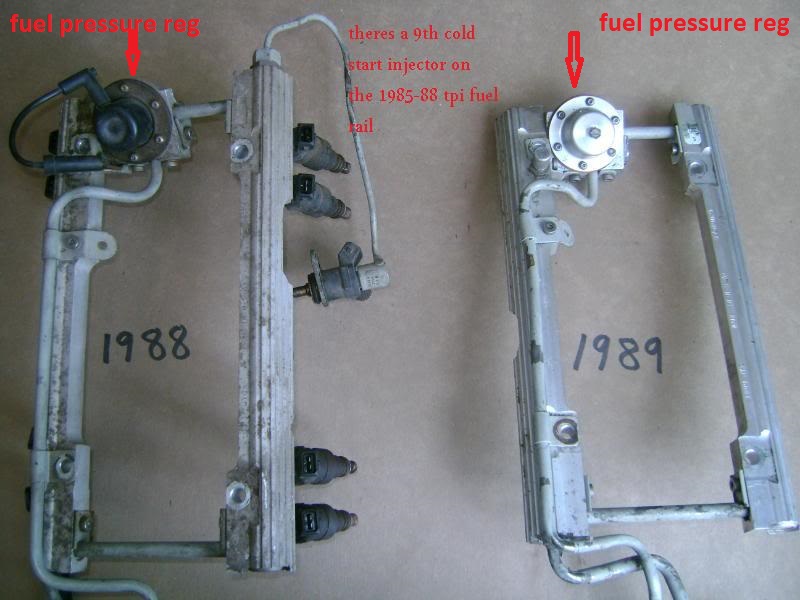

Fitting together the fuel and exhaust systems

Had to pull off this right side header to get a drill in

for the last two fuel line mounts....

The header is going to be close...

Yes, I'm going to need some insulation for those fuel lines

to protect them from the exhaust heat

Or, wrap the exhaust system to keep the heat away from the fuel lines...

More Later....

Had to pull off this right side header to get a drill in

for the last two fuel line mounts....

The header is going to be close...

Yes, I'm going to need some insulation for those fuel lines

to protect them from the exhaust heat

Or, wrap the exhaust system to keep the heat away from the fuel lines...

More Later....