You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Camshaft opinion

- Thread starter Thunderbolt

- Start date

Loves302Chevy

"One test is worth a thousand expert opinions."

http://www.superchevy.com/how-to/en...chevy-mini-blower-test-danger-mouse-part-ten/

Part 10 has everything you want to know.

Part 10 has everything you want to know.

Maniacmechanic1

solid fixture here in the forum

He has double hump heads.I say your compression is too low. You are only starting with 8.7 STATIC, which gives you only 7.26 DCR with a cranking pressure of 144 psi.

And I'll bet that the Felpro .040" gasket brought it down even lower. Anyone else agree?

View attachment 11353

I was going to retract this because I remembered about the blower. But I will leave it since I already ran the calculator.

They should be 64 CC combustion chambers.

They ran pretty decent in the day.

A friend had a 1970-1/2 Camaro LT1.

He street raced it daily for years.

Factory Turbo 400 Transmission & original with a shift kit. High RPM shift points at 6,000 rpm auto mode. Full manual control put into Low 1.

3.73 Posi in the 1 year only 1970 2nd Gen 12-bolt.

He spanked many on the streets.

Knocked down Big Block Chevy 454's.

Mopar 440 6-packs.

Put the power down & was 100 % reliable.

Static Compression I know is higher.

Wind up like a Snap On Air ratchet at 200 psi shop line pressure.

Doesn't help when it's NOT correct. Just creates confusion.Racer slang.

At the strip at night gathering we SHORTCUT speak.

Saves time.

.

Last edited:

keep in mind as heat and boost pressure rise the fuel octane must keep pace and increase or youll have detonation damage result rather quickly

http://garage.grumpysperformance.com/index.php?threads/detonation-issues.14434/#post-74620

http://garage.grumpysperformance.co...octane-for-compression-ratio.2718/#post-68131

http://garage.grumpysperformance.com/index.php?threads/octane-boosters.613/#post-12677

http://garage.grumpysperformance.com/index.php?threads/detonation-issues.14434/#post-74620

http://garage.grumpysperformance.co...octane-for-compression-ratio.2718/#post-68131

http://garage.grumpysperformance.com/index.php?threads/octane-boosters.613/#post-12677

.

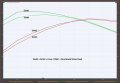

Sim01 = Baseline

For Simo2 .......

Added Blower

Went from 650 cfm to 850 cfm carburetor

Changed the intake from dual to single plane

For Sim03 ........

Changed from the default Dynomation6 heads (flow posted above) to the Brodix IK200 heads posted below.

Dynomation6 has included several specific blowers of which the Weiand 177 is included (2.9 Liters/Rev) shown

below. The 3 GREEN squares show that it is not being pushed into a Surge, Choke or Overspeed condition. The

squares will turn YELLOW when there is a possible problem and RED when you have definite problem.

Flow number for the Brodix IK200 heads.

The double hump Chevy heads are obviously a problem since the Torque drop off so quickly after 3000 rpm in

Sim01 and Sim02. Sim03 gets better and holds on until about 4000 rpm, where it looks like the Crane 274H06

runs out.

A camshaft with more duration is not only going to help with the breathing, but will also reduce your DCR and

help with detonation issues.

.

Sim01 = Baseline

For Simo2 .......

Added Blower

Went from 650 cfm to 850 cfm carburetor

Changed the intake from dual to single plane

For Sim03 ........

Changed from the default Dynomation6 heads (flow posted above) to the Brodix IK200 heads posted below.

Dynomation6 has included several specific blowers of which the Weiand 177 is included (2.9 Liters/Rev) shown

below. The 3 GREEN squares show that it is not being pushed into a Surge, Choke or Overspeed condition. The

squares will turn YELLOW when there is a possible problem and RED when you have definite problem.

Flow number for the Brodix IK200 heads.

The double hump Chevy heads are obviously a problem since the Torque drop off so quickly after 3000 rpm in

Sim01 and Sim02. Sim03 gets better and holds on until about 4000 rpm, where it looks like the Crane 274H06

runs out.

A camshaft with more duration is not only going to help with the breathing, but will also reduce your DCR and

help with detonation issues.

.

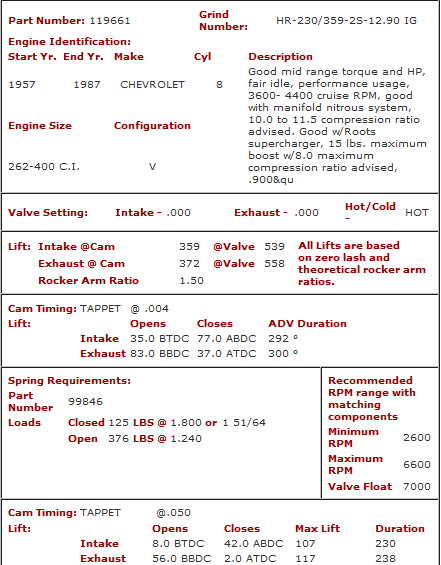

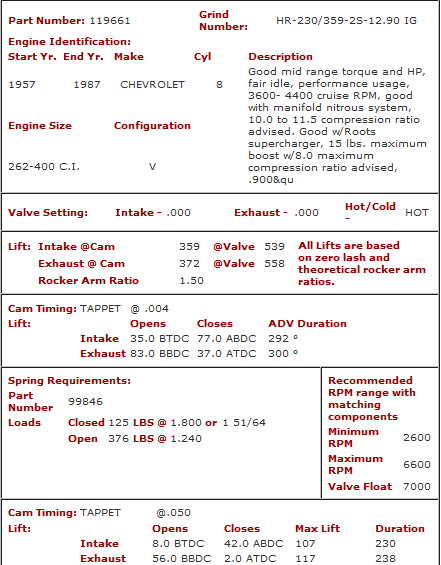

RICK, just for giggles ,why not try to maximize the result with two changes

the larger port vortec heads and a crane 119661 hydraulic roller cam

https://paceperformance.com/i-62556...haust-runner-65cc-chamber-up-to-530-lift.html

25534446 is the new improved version the older numbers been discontinued

INTAKE EXHAUST

Lift Volume Lift Volume

0.200 128.6 0.200 100.8

0.300 188.4 0.300 138.6

0.400 234.8 0.400 154.4

0.500 257.2 0.500 152.5

0.600 263.2 0.600 163.8

0.700 269.1 0.700 167.0

btw the port flow can rather easily be boosted enough to mater with mild port and bowl clean-up work on those larger port vortec heads

the larger port vortec heads and a crane 119661 hydraulic roller cam

https://paceperformance.com/i-62556...haust-runner-65cc-chamber-up-to-530-lift.html

25534446 is the new improved version the older numbers been discontinued

INTAKE EXHAUST

Lift Volume Lift Volume

0.200 128.6 0.200 100.8

0.300 188.4 0.300 138.6

0.400 234.8 0.400 154.4

0.500 257.2 0.500 152.5

0.600 263.2 0.600 163.8

0.700 269.1 0.700 167.0

btw the port flow can rather easily be boosted enough to mater with mild port and bowl clean-up work on those larger port vortec heads

obviously somethings not correct with the softwares prediction,

you can,t logically and significantly boost air flow rated flow through the engine,

on both intake and exhaust, and get a reduction in power,

unless the supercharger, and exhaust scavenging is already maxed out, well,

before the increase potential for greater air flow is being added is available,

which I strongly suspect here.

notice the torque peak falls at only about 4000 rpm thats a strong indication thats what has happened

swap the same combo components from using a small roots style to a mid capacity centrifugal blower and ID bet the result is far better.

yeah I know.. no longer the same build And far too expensive!

you can,t logically and significantly boost air flow rated flow through the engine,

on both intake and exhaust, and get a reduction in power,

unless the supercharger, and exhaust scavenging is already maxed out, well,

before the increase potential for greater air flow is being added is available,

which I strongly suspect here.

notice the torque peak falls at only about 4000 rpm thats a strong indication thats what has happened

swap the same combo components from using a small roots style to a mid capacity centrifugal blower and ID bet the result is far better.

yeah I know.. no longer the same build And far too expensive!

Last edited:

Maniacmechanic1

solid fixture here in the forum

I think you lost him Grumpy and Rick.

Alot of theses guys want to use what they have for parts.

We all know all aftermarket new race oriented is best.

Stock parts used.

Block and stock heads.

Where we are at today.

Comes down to budget money $$$.

Alot of theses guys want to use what they have for parts.

We all know all aftermarket new race oriented is best.

Stock parts used.

Block and stock heads.

Where we are at today.

Comes down to budget money $$$.

Maniacmechanic1

solid fixture here in the forum

Keep trying.

Think everyone weighs against 1000 Hp Dodge Death Bullet.

Come to realize like me can not affford.

Look at what you have present.

Improve it.

Run it.

Thinking many 1000 Hp will blow up.

Pass on by my Strategy.

Unless Big shot of Nitrous hit.

Only when really needed.

Think everyone weighs against 1000 Hp Dodge Death Bullet.

Come to realize like me can not affford.

Look at what you have present.

Improve it.

Run it.

Thinking many 1000 Hp will blow up.

Pass on by my Strategy.

Unless Big shot of Nitrous hit.

Only when really needed.

Loves302Chevy

"One test is worth a thousand expert opinions."

He has double hump heads.

They should be 64 CC combustion chambers.

They ran pretty decent in the day.

A friend had a 1970-1/2 Camaro LT1.

He street raced it daily for years.

Factory Turbo 400 Transmission & original with a shift kit. High RPM shift points at 6,000 rpm auto mode. Full manual control put into Low 1.

3.73 Posi in the 1 year only 1970 2nd Gen 12-bolt.

He spanked many on the streets.

Knocked down Big Block Chevy 454's.

Mopar 440 6-packs.

Put the power down & was 100 % reliable.

Static Compression I know is higher.

Wind up like a Snap On Air ratchet at 200 psi shop line pressure.

Yes, I am familiar. I had a set of 186's with a lot of work done to them. They work better than most people would admit.

Maniacmechanic1

solid fixture here in the forum

Gave up on the Horsepower Race Mike.Yes, I am familiar. I had a set of 186's with a lot of work done to them. They work better than most people would admit.

Need to make the engine expendable.

Blows up it Blows thinking required. Be ready to build another.

Can not do that myself.

It must last at least 10,000 miles for me Raced hard.

Thunderbolt

Well-Known Member

It was really interesting to see the differences with cams and head flow, especially since i plan to build another motor to replace this old 350 in the future.

So to review just a little, Sim04 should have been significantly better than Sim03, but that did

NOT happen. For the reasons that will be evident below.

To improve Sim04 and get the results of Sim05, the following 4 changes were made ...........

- Changed to the next higher capacity Weiand blower (177 to 256) which has increased the capacity

from 2.9 Liters/Rev to 4.2 Liters/Rev

- Changed the belt ratio from 1.72 to 1.8. Does not sound like much, but the difference in peak torque

was about 25 lb/ft. Any ratio outside of 1.8 was considerably different, that means I tried 1.6 and 2.0.

- Not that it's possible, but to smooth out the Sim05 curve I added an intercooler Efficency of 50%. The

effects of this change was predominately in the 2500 to 3500 rpm range. Above that had little effect

on smoothness.

- The boost limit was changed from 10 psi to 16 psi.

Once again this proves it's a system and every parameter has an effect.

NOT happen. For the reasons that will be evident below.

To improve Sim04 and get the results of Sim05, the following 4 changes were made ...........

- Changed to the next higher capacity Weiand blower (177 to 256) which has increased the capacity

from 2.9 Liters/Rev to 4.2 Liters/Rev

- Changed the belt ratio from 1.72 to 1.8. Does not sound like much, but the difference in peak torque

was about 25 lb/ft. Any ratio outside of 1.8 was considerably different, that means I tried 1.6 and 2.0.

- Not that it's possible, but to smooth out the Sim05 curve I added an intercooler Efficency of 50%. The

effects of this change was predominately in the 2500 to 3500 rpm range. Above that had little effect

on smoothness.

- The boost limit was changed from 10 psi to 16 psi.

Once again this proves it's a system and every parameter has an effect.

busterrm

solid fixture here in the forum

I agree with Rick, I have done a lot of reading lately about Turbo and Super charged engines, there is a direct science related to camshaft dynamics! I believe you would best serve yourself by putting in a cam with more duration, even more on exhaust side and also shorter overlap! Longer overlap and you’ll being pushing some of the charge right out the exhaust and getting less fuel mileage like Rick stated above!It will work, but will it work well enough to satisfy you?

With the the smaller LSA of 106° of your present cam, compared to the 114° LSA that Grumpy suggested,

the fuel mileage will be less. Some of your fuel/air mixture will be going out the exhaust valve during overlap.

That's just one consideration you have to make.

What static and dynamic compression ratio will you have with the present camshaft?

Maniacmechanic1

solid fixture here in the forum

You can quadruple power today with Twin Turbo charging.

Use a boost cam.

Run 60 psi boost.

Well over 4000 hp.

Recent 100 psi boost was done in a 4 cylinder Mitsubishi Evo.

Ran 6's at the track 1/4 mile.

Embarrassed all but the True Street Outlaw guys on Tv with Big Chief and his Twin Turbo Ponch V8.

Use a boost cam.

Run 60 psi boost.

Well over 4000 hp.

Recent 100 psi boost was done in a 4 cylinder Mitsubishi Evo.

Ran 6's at the track 1/4 mile.

Embarrassed all but the True Street Outlaw guys on Tv with Big Chief and his Twin Turbo Ponch V8.