READ THRU THESE SUB LINKS

http://www.estes-park-information.com/vapor-lock.html

http://en.wikipedia.org/wiki/Vapour_lock

viewtopic.php?f=55&t=211&hilit=inside+fuel+pump

viewtopic.php?f=55&t=5365&p=16067&hilit=inside+fuel+pump#p16067

http://garage.grumpysperformance.com/index.php?threads/vacuum-gauge-help.9453/#post-34623

If you have not experiences vapor lock issues before this,its most likely because youve only dealt with high pressure fuel injection cars not carburetors, but are now recently dealing with an older carburetor equipped muscle car in hot weather, what may have (CHANGED) is either the fuel itself or the fuel pump may be dealing with wear or heat related issues, but in almost every case Ive investigated vapor lock is aggravated by the use of a fuel system thats not using a return style fuel pressure regulator.

vapor lock is basically a fuel delivery condition caused by both heat and low fuel pressure where fuel turns to vapor in the carburetor or fuel lines , and the car won,t start as a result and the fuel pump won,t pump fuel effectively as a result.

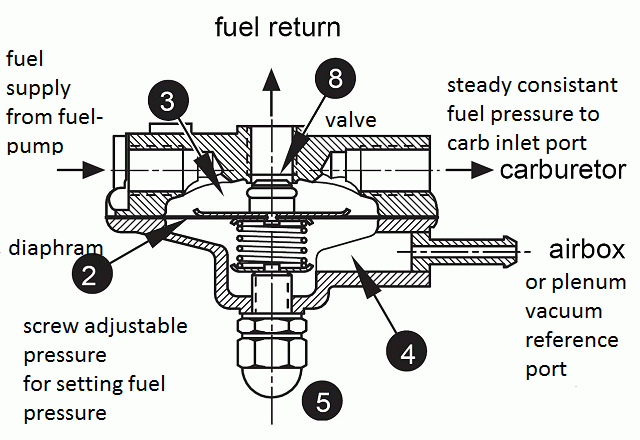

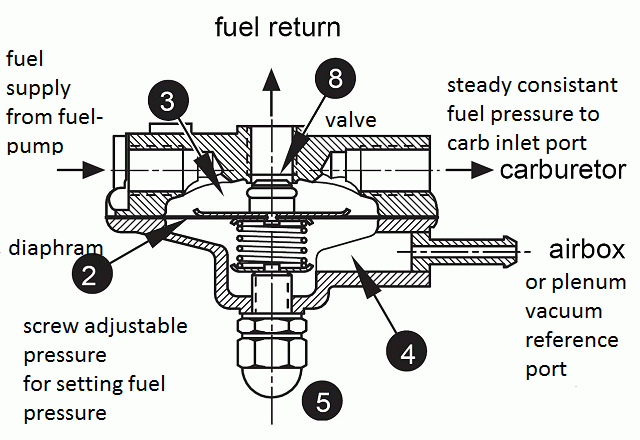

a return style fuel pressure regulator , like those used on most EFI systems generally help avoid vapor lock issues, for two reasons, first the higher pressure used, but more importantly, the basic design has a constant flow of fresh fuel coming up from the tank, and some routed back to the tank this tends to limit the heat level absorbed by the fuel, unlike the common carburetor dead head systems used on many early cars with carbs

recent changes in fuel formulas to reduce emissions by adding ethanol up to 10% by volume, have changed the temperature tolerance and made the seals in the fuel system,more subject to wear, or degrading over time, issues.

some fuel filters mounted in the engine compartment tend to aggravate the problem

the simplest way to control or avoid vapor lock conditions, is a two step approach, first you want to have a constantly replaced, fuel flow volume, this is easily accomplished if you select a fuel pump that supplies fuel at about 7 psi-12 psi and has a rated flow of at least 100 gallons per hour (most of the better quality performance fuel pumps will do this,)

but having a bye-pass fuel pressure regulator connected after the carb inlet port, the pump will thus force room temp, liquid fuel up the fuel lines and into the carb inlet, and past the carb inlet port too the fuel pressure regulator , where a spring in the fuel pressure regulator opens any time fuel pressure exceeds an adjustable back pressure you set at about 4.5 psi-5 psi, thus its constantly flushing a significant volume of the fuel past the carb inlet port and back too the fuel tank through the return line, this mandates the fuel does not have time to absorb much heat and its under constant pressure so theres zero chance for fuel vapor to build up displacing liquid fuel delivered to the fuel bowls.

they make effective slip on thermal insulation.

that can be slipped over fuel lines to reduce the potential for heat absorbsion in the engine compartment.

https://www.summitracing.com/parts/...eld-products...

phenolic spacers work well just don,t get the cheap plastic knock off versions that warp and leak, and be aware that the dual plane intakes tend to work best with the 1"and 2" four hole designs but single planes tend to work best with the larger single open plenum designs

http://www.summitracing.com/parts/SUM-G1404/

http://garage.grumpysperformance.com/index.php?thr...

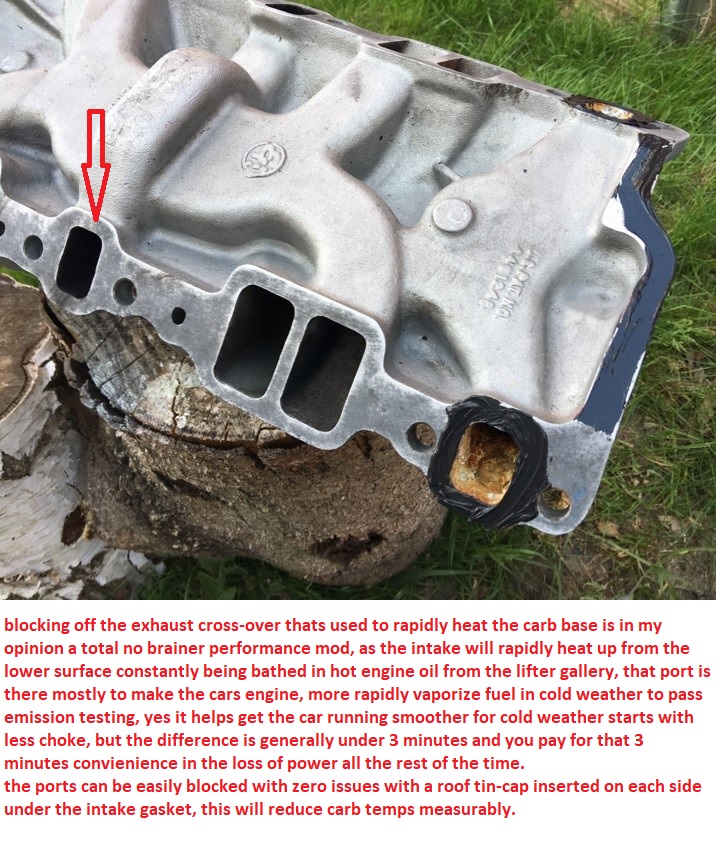

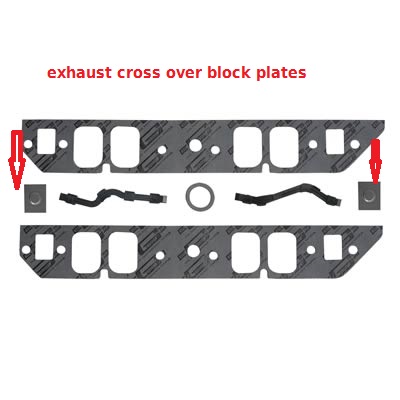

you must also restrict heat build-up potential in the carb fuel bowls, this is generally done with a very poor thermal conductive spacer between the carb base and the intake manifold.

yes the diagrams a bit confusing,pressure is a measurement of RESISTANCE to flow, the pump puts out , flow volume, theres no pressure until theres a resistance or restriction to flow,

potentially 6 -7 psi the true pressure is regulated to what ever the fuel pressure regulator is set too, IE, if the bye-pass spring setting is at 4.5 psi thats a high as the pressure ever gets, the fuel pressure potentially exceeding this forced the regulator to open,the spring resistance is over come and the fuel flows back too the tank, thus running out through the bye-pass, into the return line, limiting pressure.

THERES A GREAT DEAL OF RELATED INFO IN THE LINKS AND SUB LINKS

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=635

viewtopic.php?f=87&t=7770&p=26981&hilit=ethanol#p26981

viewtopic.php?f=87&t=2141&p=25201&hilit=ethanol#p25201

viewtopic.php?f=55&t=58&p=23610&hilit=+1206#p23610

viewtopic.php?f=52&t=462&p=22497&hilit=+1206#p22497

viewtopic.php?f=99&t=6461&p=20458&hilit=+1206#p20458

viewtopic.php?f=52&t=5537&p=16750&hilit=+1206#p16750

viewtopic.php?f=80&t=8505&p=32253&hilit=filter+drain#p32253

viewtopic.php?f=55&t=5378&p=16106&hilit=+1206#p16106

viewtopic.php?f=55&t=1038&p=14928&hilit=+1206#p14928

viewtopic.php?f=52&t=4664&p=12584&hilit=+1206#p12584

viewtopic.php?f=55&t=2953&p=7745&hilit=+1206#p7745

viewtopic.php?f=55&t=2857&p=7402&hilit=+1206#p7402

Vapor lock occurs when the gasoline in your engine turns into vapor, this is usually restricted to carburetor equipped engines, because they use a fairly low 5-7psi fuel pressure and due to the fuel lines, or fuel pump being located where the engine heat is rather high like near headers or exhaust pipes. the symptoms, commonly include,a condition where the engine runs ok until it heats up, then , your engine starts missing and has a general lack of power when the engines reved ,once it reaches operating temps,hard re-starting after brief cool down, lack of passing power and general lack of torque, due to intermittent fuel supply This can happen in cars equipped with carburetors or low pressure fuel injection due to high heat in the carburetor or fuel lines or high altitude, where gas turns to vapor at a lower temperature, more easily than normal. Often it's a combination of both heat and altitude. Essentially, your engine is no longer getting enough liquid fuel to the carburetor, or throttle body.

A FUEL SYSTEM THAT'S PROPERLY CONFIGURED WITH A RETURN STYLE OR BYE_PASS FUEL PRESSURE REGULATOR IS FAR LESS LIKELY TO BE TROUBLED BY THIS AS THERE'S CONSTANTLY FRESH COOL FUEL REACHING THE CARB AND HOT FUEL RETURNED TO THE TANK

READ THESE THREADs

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=9305

viewtopic.php?f=55&t=4381&p=11507&hilit=ethanol#p11507

DON,T CONFUSE this with, running out of fuel or a defective fuel pump,or having the carburetors float level not correctly adjusted(to low or to high) causing carburetor flooding or fuel starvation that can happen when the floats are too high or too low or the fuel pump is flooding the carburetor if the fuel pressure exceeds about 5.5 -6 psi which occasionally does happen if you don,t know the difference in the symptoms

Don,t confuse this with a similar symptom,caused by a partially plugged catalytic converter, where once the engine reaches a higher rpm level the power drops off as the exhaust becomes a major restriction to exhaust flow rates, and returns once the rpm level drops reducing the exhaust flow

keep in mind that a return style fuel pressure regulator set at about 5 psi matched with a fuel pump that provides at least 7 psi results in a constant flow of new fresh cooler fuel reaching the regulator from the fuel tank and heated fuel bleeding off back down the return line to the fuel tank, so this type system seldom has a tendency to have vapor lock occur, but systems using the dead head style fuel pressure regulators frequently have it happen as fuel is relatively stationary in the fuel lines allowing engine heat to bake fuel lines and cause vapor to form

READ THESE RELATED THREADS

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=211

you'll want to check the, fuel tanks at least 1/4 filled,and the carburetors float levels are correct and the fuel pressure,is at between 4psi-5.5 psi and theres adequate flow at the carburetor inlet port as the first steps in diagnosing the problem

viewtopic.php?f=55&t=211

vapor lock,is rare to almost non-existent, in fuel injected cars due to the combination of higher fuel pressure and constant cooling flow of fuel back to the tank thru the return style fuel pressure regulator most fuel injection systems use.

Symptoms include power loss, a feeling that the car is about to stall, a rough engine, or the car cranks but won't start.

you can cure vapor lock by installing the correctly designed fuel supply system, if the fuel is kept under a set pressure than all fuel/vapor is prevented from forming in the line by the simple process of keeping the fuel from heating excessively by keeping it moving slowly thru the lines until its used, fuel pressure should be about 6-9 psi up to the fuel pressure regulator and at about 5 psi between the carb inlet and regulator, so you don't have that problem, use of a return style fuel pressure regulator mounted as close to the carburetor as you can reasonably mount it and if possibly running the fuel lines where they are not near a hot exhaust component, keeps a constant exchange flow of fuel in the lines with fresh lower temp fuel from the tank.

vapor lock is basically the result of fuel brought to its boiling point pressurizing the line between the tank and carb and preventing fuel flow, keep the fuel in constant rotation thru the fuel system and back to the fuel tank with a RETURN STYLE FUEL PRESSURE REGULATOR AND RETURN LINE and the FUEL NEVER HAS TIME TO ABSORB THE HEAT TO BOIL AND CAUSE A PROBLEM.

that's also why its a good idea to keep your fuel tank at least 1/3rd full as most modern cars use electric in the tank fuel pumps that are cooled by sloshing fuel in the tank

Vapor lock is rare with today's fuel injection systems. Vapor lock occurs when the vapor pressure of the fuel is higher than the surrounding environment. In older engines with "sucking" fuel pumps at the engine, the pressure in the fuel line to the tank was reduced by the sucking action of the fuel pump drawing fuel form a fuel tank nearly twenty feet away, and when heated, the gasoline actually boiled creating a vapor of gasoline which the fuel pump could not handle, thus the name "vapor lock"., as pressure is reduced in the fuel line the boiling point of the fuel is reduced.

gasoline in some blends will boil as low as about 120F if the fuel line pressure is low enough and a fuel pump can,t SUCK vapor efficiently, pumps PUSH FUEL FAR MORE EFFICIENTLY than THEY PULL FUEL SO AN ELECTRIC PUMP MOUNTED LOWER THAN AND NEAR THE TANK IS ABOUT IDEAL

Today's fuel pumps are in the fuel tank where they push the fuel under pressure to the engine systems. Excessive fuel which is not used is sent back to the fuel tank. This causes a constant flow of pressurized, cool fuel in the lines to the engine system, be it fuel injection or carburetor. As a result you would have to heat the fuel line with a propane torch to get the fuel to boil and even then it would be cooled by the flowing fuel circulating from the tank to the engine and back again to the tank. Vapor lock as we once knew it is a thing of the past.

http://www.chevyhiperformance.com/tech/ ... index.html

viewtopic.php?f=55&t=635

http://web.archive.org/web/200701062316 ... 1.htm#FPHP

http://www.vw-resource.com/vapor_lock.html

viewtopic.php?f=32&t=596&p=793&hilit=+filter+fuel+drain#p793

QUOTE

Vapor Lock

~~~

Have you ever had this problem? You are driving home from work late in the afternoon. It's 90oF (32oC) outside and there's lots of traffic, so accelerating and decelerating a lot. The engine is working, and you know it's getting hot.

Then, about 4-5 miles from home, the engine suddenly starts surging and then decides to take a rest altogether. As you pull off the road you think to yourself, "This couldn't be an electrical problem - the engine wasn't actually cutting out, just surging."

Alternately, you drive to the store on a hot day (far enough so that the engine gets thoroughly hot); when you return from the store to the car, it won't start! What's up with that!?

So you lift the engine lid and notice right off that there is no fuel in that small fuel filter in the line between the fuel pump and the carburetor (if you have such a filter -- we actually recommend that you don't have a filter here). So right away you know the problem (right?) - vapor lock! Every VW we have had has done this when it got hot. They seem to be especially touchy both when they're hot and when it's getting close to "Tender Loving Care" time, when timing or valves may be a bit off the numbers.

The usual problem is that the whole engine gets thoroughly hot, and when you switch off, there is a 'heat soak' period when the temperature in the tinware and engine compartment rises because the residual heat in the cylinder/heats isn't getting blown away by the fan. The heads run at about 265-285oF (130-140oC) and can run up to about 355oF (180oC) on a really hard run which is pretty hot.

This causes the metal fuel line around the tinware, the fuel pump, and the carburetor to all heat up somewhat, causing either excess vaporization of the fuel in the carburetor, or and actual vapor lock in the fuel line or fuel pump.

As a result, starting is sometimes hard. With hot fuel in the carburetor, the least reduction in pressure (through the carburetor throat) causes instant vaporization, perhaps of fuel in the float bowl too (which breathes into the top of the carburetor throat), and of course a vapor lock in the fuel line or pump is even worse, because it will result in an empty fuel bowl in the carburetor - the car uses that fuel and stalls because it can't get any more. Then it takes a lot of cranking to fill the fuel bowl, once the vapor lock itself is cleared.

In summary, following is the cause and the cure for vapor lock -

Cause: The engine overheats, causing the fuel line, fuel pump and carburetor to heat up.

Result: Excess vaporization of fuel in the carburetor and/or actual vapor lock in the fuel line or fuel pump.

Cure:

1. Wrap the fuel lines on both sides of the pump with aluminum foil.

Note: This is a precaution if your car is prone to vapor lock. It won't help much once the problem has

already occurred.

# Pour a little water over the fuel pump to cool and re-condense the fuel, being careful not to splash the distributor. If no water is readily available, hopefully there is some in the windshield washer bottle. It doesn't take much.

# Hold the throttle open just a bit with the accelerator pedal while you crank. Don't move the throttle at all while cranking, or the accelerator pump with flood the carburetor. The reason for cracking the throttle open it to avoid using the idle jet alone, as this runs the car richer than the main jet, and a rich-hot mixture makes the car flood easily.

# When the engine catches, hold the throttle still until it clears the excess fuel (revs up smoothly).

Away you go!

~~~

Other things to check if vapor lock has become a regular problem:

* Is the heat riser under the inlet manifold getting too hot? It should be hot enough to keep the manifold above it warm, but if the heat riser is providing excessive manifold heat, it can also be overheating the fuel line which runs close to it on the way to the fuel pump. There are "small hole" heat riser gaskets available (you'll have to look for them though) which can reduce the heat flow through the heat riser if it's running finger sizzling hot.

* Is the carburetor running lean? Many new H30/31 and 34PICT/3 carburetors are supplied with lean jetting as an emissions thing, which makes the engine harder to tune, and causes higher engine temperatures. There is information elsewhere in these articles about suggested jetting for various distributor, engine size and carburetor size options.

* Is the carburetor pre-warmer working properly? The paper tube up to the carburetor inlet is supposed to draw air from near one cylinder head to speed up the engine warm-up process, but if it's stuck full on (breathing hot air) the engine will run hotter than it needs to, which will worsen any potential vaporization problem. There are two actuating mechanisms - the earlier engines (up to about '71-'72) have a pull-wire operated by the right hand cooling flap assembly, and later engines have a vacuum line from the manifold directly under the carburetor, up to a temperature switch in the air cleaner and another vacuum line from that switch to the vacuum canister on the side of the air cleaner inlet. The early type is just on-off, depending on whether the flaps mechanism (controlled by the thermostat) is open or shut, but the later type may hold a partial position, depending on the temperature inside the air cleaner. Of course if your engine has no cooling flaps (tsk tsk) or if it has no vacuum lines connected, or an aftermarket air cleaner, then the carburetor inlet will be breathing full cold all the time - a potential icing problem, but not an excess-heat problem.

* Is any of the tinware missing?. If the engine is missing any of the tinware which controls the flow of cooling air around the heads and cylinders, it WILL run hot, and this will worsen any vapor lock problems.

* Is the engine tuned properly?. If the car is out of tune it has to work harder to provide the power to drive the car, so it may run hotter. Keeping the car well tuned keeps the engine temperatures in the normal range, minimizing any vapor lock problems.

~~~

Notes from Rob on the Subject of Vapor Lock -

My '68 Bug definitely doesn't like the heat as much as my '70 Bug - he started getting vapour locks before we even got there, and was troublesome all the way home. Luckily I had a bottle of water with me and was able to pour a little over the fuel pump and carby, and get him going each time.

I think the problem is that the heat riser is working TOO well, and cooking the inlet manifold and carb plus the fuel pump.

I'm going to make a block-off washer for one side of the heat riser, and see what effect that has. It's only about 20 minutes to install it and will be a good test of the theory. I can always drill a tiny hole in it if I find the carby freezing up. He already has a "small hole" washer in one side, but the inlet manifold still gets finger burning hot, and it only needs to be slightly warm to keep the fuel in suspension.

I cut a washer out of flat metal sheet, and it only took about 20 minutes to remove the rear tinware, pull the two heat riser bolts and slide the old washer out before putting the new washer in. I found that you can use the tinware to "lever" on if you are careful - I used a piece of flat steel so I was spreading the load, and it only took a little levering.

I've only had a couple of short runs so far, but the manifold under the carburetor is not completely cold, so it looks like it might work OK. If not, I'll remove the seal and put a 1/16" hole in it and work up from there.

The manifold has always been too hot to touch on my '68 Bug and it only needs to be warm ( above freezing) to keep the fuel in suspension. He seems to have a littel more power now too - and a hot inlet WOULD be less dense, so that makes sense.

http://www.wisegeek.com/what-is-vapor-lock.htm

Vapor locking primarily happens in cars with carbureted engines, but since electronic fuel injection replaced carburetors in the 1980s, most car owners don’t have to deal with vapor lock anymore. Carburetors and electronic fuel injection are two different methods of delivering the proper amounts of fuel to the engine. Fuel injection is more advanced, and requires a computer to tell the injectors how much gasoline to squirt into the engine. A carburetor, on the other hand, is a mechanical device that uses the engine’s natural vacuum, allowing specific amounts of fuel to be sucked into the combustion chambers. The amount of fuel that is delivered to the engine can be changed using simple mechanical adjustments on the carburetor.

Most carbureted engines have a mechanical in-line fuel pump, which means that the simple mechanical pump is placed on the fuel line, usually next to the engine. The mechanical fuel pump’s proximity to the engine means that the engine’s heat causes the fuel in the line to become very hot. When the fuel becomes too hot, it turns into a vapor, just as water begins to turn to steam when it boils. This process is hastened by the vacuum created in the line as the fuel is sucked into the engine.

When the fuel turns into vapor, the mechanical fuel pump can no longer move it along the lines. As a result, some or all of the fuel stops getting into the combustion chambers, and the car either begins to run very roughly or dies completely. If the driver attempts to restart the car, it will probably not start, or will continue having problems. This is known as vapor lock.

Vapor lock does not usually happen in fuel-injected engines for several reasons. First of all, most electric fuel pumps are located at or in the fuel tank. Because the fuel tank is usually located too far away from the engine to be affected by its heat, gasoline is not likely to turn to vapor there. As a result, the fuel pump can push the fuel along without any problems, avoiding one of the major causes of vapor lock.

Another reason why vapor lock does not often happen in fuel-injected engines is because the fuel lines are usually pressurized. The high pressure that the fuel is under prevents it from turning into vapor quite as easily, unlike the carbureted system that actually produces negative pressure, also known as vacuum, in the lines.

More efficient engine cooling systems also contribute to the decreased likelihood of vapor lock occurring in modern cars. The cooling fans in older cars usually ran off of the momentum of the engine, which meant that when cars were at a disadvantage when they sat idling in traffic for long periods of time: The lack of motion meant less air flowing through the engine compartment, and the fan — stuck at the idling speed of the engine — was unable to cool the engine sufficiently. As a result, the engines in older cars tend to run hotter in heavy traffic, making vapor lock more likely to occur.

Modern cars, on the other hand, typically have electric cooling fans. These fans are linked to a sensor that detects the engine’s temperature, and tells the fan whether to speed up or slow down. As a result, the internal combustion engines in modern cars are less likely to overheat than those in older models, making vapor lock much less common than it used to be.

All of the problems that cause vapor lock are easily corrected, even on older cars. Older cars can often be retrofitted with the newer technology that reduces the likelihood of the fuel lines overheating. For instance, even on a carbureted engine, a low-pressure electric fuel pump can be installed near the fuel tank, which will keep the fuel moving along the lines even if it starts to heat up in the engine compartment.

Another easy remedy for vapor lock in older cars is to install an electric fan in the engine compartment. Many auto parts stores carry aftermarket cooling fans, which can be installed on any car. Some cooling fans can be connected to the existing engine temperature sensor, mimicking the behavior of the cooling fans in modern cars.

Finally, vapor lock can be prevented in any car by protecting the fuel lines from the heat of the engine. There are two ways to do this. One way is to install heat shields between the engine and the fuel lines, which will divert most of the heat away from the lines. Fuel lines can also be insulated to prevent the fuel from getting to the temperatures at which vapor lock occurs.

READ THESE related threads

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1030

viewtopic.php?f=55&t=109

viewtopic.php?f=55&t=231

viewtopic.php?f=55&t=6442&p=20373&hilit=brass+roof#p20373

viewtopic.php?f=55&t=4381

viewtopic.php?f=56&t=495&p=8333&hilit=+back+pressure#p8333

http://www.centuryperformance.com/fueli ... g-140.html

http://www.estes-park-information.com/vapor-lock.html

http://en.wikipedia.org/wiki/Vapour_lock

viewtopic.php?f=55&t=211&hilit=inside+fuel+pump

viewtopic.php?f=55&t=5365&p=16067&hilit=inside+fuel+pump#p16067

http://garage.grumpysperformance.com/index.php?threads/vacuum-gauge-help.9453/#post-34623

If you have not experiences vapor lock issues before this,its most likely because youve only dealt with high pressure fuel injection cars not carburetors, but are now recently dealing with an older carburetor equipped muscle car in hot weather, what may have (CHANGED) is either the fuel itself or the fuel pump may be dealing with wear or heat related issues, but in almost every case Ive investigated vapor lock is aggravated by the use of a fuel system thats not using a return style fuel pressure regulator.

vapor lock is basically a fuel delivery condition caused by both heat and low fuel pressure where fuel turns to vapor in the carburetor or fuel lines , and the car won,t start as a result and the fuel pump won,t pump fuel effectively as a result.

a return style fuel pressure regulator , like those used on most EFI systems generally help avoid vapor lock issues, for two reasons, first the higher pressure used, but more importantly, the basic design has a constant flow of fresh fuel coming up from the tank, and some routed back to the tank this tends to limit the heat level absorbed by the fuel, unlike the common carburetor dead head systems used on many early cars with carbs

recent changes in fuel formulas to reduce emissions by adding ethanol up to 10% by volume, have changed the temperature tolerance and made the seals in the fuel system,more subject to wear, or degrading over time, issues.

some fuel filters mounted in the engine compartment tend to aggravate the problem

the simplest way to control or avoid vapor lock conditions, is a two step approach, first you want to have a constantly replaced, fuel flow volume, this is easily accomplished if you select a fuel pump that supplies fuel at about 7 psi-12 psi and has a rated flow of at least 100 gallons per hour (most of the better quality performance fuel pumps will do this,)

but having a bye-pass fuel pressure regulator connected after the carb inlet port, the pump will thus force room temp, liquid fuel up the fuel lines and into the carb inlet, and past the carb inlet port too the fuel pressure regulator , where a spring in the fuel pressure regulator opens any time fuel pressure exceeds an adjustable back pressure you set at about 4.5 psi-5 psi, thus its constantly flushing a significant volume of the fuel past the carb inlet port and back too the fuel tank through the return line, this mandates the fuel does not have time to absorb much heat and its under constant pressure so theres zero chance for fuel vapor to build up displacing liquid fuel delivered to the fuel bowls.

they make effective slip on thermal insulation.

that can be slipped over fuel lines to reduce the potential for heat absorbsion in the engine compartment.

https://www.summitracing.com/parts/...eld-products...

phenolic spacers work well just don,t get the cheap plastic knock off versions that warp and leak, and be aware that the dual plane intakes tend to work best with the 1"and 2" four hole designs but single planes tend to work best with the larger single open plenum designs

http://www.summitracing.com/parts/SUM-G1404/

http://garage.grumpysperformance.com/index.php?thr...

you must also restrict heat build-up potential in the carb fuel bowls, this is generally done with a very poor thermal conductive spacer between the carb base and the intake manifold.

yes the diagrams a bit confusing,pressure is a measurement of RESISTANCE to flow, the pump puts out , flow volume, theres no pressure until theres a resistance or restriction to flow,

potentially 6 -7 psi the true pressure is regulated to what ever the fuel pressure regulator is set too, IE, if the bye-pass spring setting is at 4.5 psi thats a high as the pressure ever gets, the fuel pressure potentially exceeding this forced the regulator to open,the spring resistance is over come and the fuel flows back too the tank, thus running out through the bye-pass, into the return line, limiting pressure.

THERES A GREAT DEAL OF RELATED INFO IN THE LINKS AND SUB LINKS

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=635

viewtopic.php?f=87&t=7770&p=26981&hilit=ethanol#p26981

viewtopic.php?f=87&t=2141&p=25201&hilit=ethanol#p25201

viewtopic.php?f=55&t=58&p=23610&hilit=+1206#p23610

viewtopic.php?f=52&t=462&p=22497&hilit=+1206#p22497

viewtopic.php?f=99&t=6461&p=20458&hilit=+1206#p20458

viewtopic.php?f=52&t=5537&p=16750&hilit=+1206#p16750

viewtopic.php?f=80&t=8505&p=32253&hilit=filter+drain#p32253

viewtopic.php?f=55&t=5378&p=16106&hilit=+1206#p16106

viewtopic.php?f=55&t=1038&p=14928&hilit=+1206#p14928

viewtopic.php?f=52&t=4664&p=12584&hilit=+1206#p12584

viewtopic.php?f=55&t=2953&p=7745&hilit=+1206#p7745

viewtopic.php?f=55&t=2857&p=7402&hilit=+1206#p7402

Vapor lock occurs when the gasoline in your engine turns into vapor, this is usually restricted to carburetor equipped engines, because they use a fairly low 5-7psi fuel pressure and due to the fuel lines, or fuel pump being located where the engine heat is rather high like near headers or exhaust pipes. the symptoms, commonly include,a condition where the engine runs ok until it heats up, then , your engine starts missing and has a general lack of power when the engines reved ,once it reaches operating temps,hard re-starting after brief cool down, lack of passing power and general lack of torque, due to intermittent fuel supply This can happen in cars equipped with carburetors or low pressure fuel injection due to high heat in the carburetor or fuel lines or high altitude, where gas turns to vapor at a lower temperature, more easily than normal. Often it's a combination of both heat and altitude. Essentially, your engine is no longer getting enough liquid fuel to the carburetor, or throttle body.

A FUEL SYSTEM THAT'S PROPERLY CONFIGURED WITH A RETURN STYLE OR BYE_PASS FUEL PRESSURE REGULATOR IS FAR LESS LIKELY TO BE TROUBLED BY THIS AS THERE'S CONSTANTLY FRESH COOL FUEL REACHING THE CARB AND HOT FUEL RETURNED TO THE TANK

READ THESE THREADs

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=9305

viewtopic.php?f=55&t=4381&p=11507&hilit=ethanol#p11507

DON,T CONFUSE this with, running out of fuel or a defective fuel pump,or having the carburetors float level not correctly adjusted(to low or to high) causing carburetor flooding or fuel starvation that can happen when the floats are too high or too low or the fuel pump is flooding the carburetor if the fuel pressure exceeds about 5.5 -6 psi which occasionally does happen if you don,t know the difference in the symptoms

Don,t confuse this with a similar symptom,caused by a partially plugged catalytic converter, where once the engine reaches a higher rpm level the power drops off as the exhaust becomes a major restriction to exhaust flow rates, and returns once the rpm level drops reducing the exhaust flow

keep in mind that a return style fuel pressure regulator set at about 5 psi matched with a fuel pump that provides at least 7 psi results in a constant flow of new fresh cooler fuel reaching the regulator from the fuel tank and heated fuel bleeding off back down the return line to the fuel tank, so this type system seldom has a tendency to have vapor lock occur, but systems using the dead head style fuel pressure regulators frequently have it happen as fuel is relatively stationary in the fuel lines allowing engine heat to bake fuel lines and cause vapor to form

READ THESE RELATED THREADS

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=211

you'll want to check the, fuel tanks at least 1/4 filled,and the carburetors float levels are correct and the fuel pressure,is at between 4psi-5.5 psi and theres adequate flow at the carburetor inlet port as the first steps in diagnosing the problem

viewtopic.php?f=55&t=211

vapor lock,is rare to almost non-existent, in fuel injected cars due to the combination of higher fuel pressure and constant cooling flow of fuel back to the tank thru the return style fuel pressure regulator most fuel injection systems use.

Symptoms include power loss, a feeling that the car is about to stall, a rough engine, or the car cranks but won't start.

you can cure vapor lock by installing the correctly designed fuel supply system, if the fuel is kept under a set pressure than all fuel/vapor is prevented from forming in the line by the simple process of keeping the fuel from heating excessively by keeping it moving slowly thru the lines until its used, fuel pressure should be about 6-9 psi up to the fuel pressure regulator and at about 5 psi between the carb inlet and regulator, so you don't have that problem, use of a return style fuel pressure regulator mounted as close to the carburetor as you can reasonably mount it and if possibly running the fuel lines where they are not near a hot exhaust component, keeps a constant exchange flow of fuel in the lines with fresh lower temp fuel from the tank.

vapor lock is basically the result of fuel brought to its boiling point pressurizing the line between the tank and carb and preventing fuel flow, keep the fuel in constant rotation thru the fuel system and back to the fuel tank with a RETURN STYLE FUEL PRESSURE REGULATOR AND RETURN LINE and the FUEL NEVER HAS TIME TO ABSORB THE HEAT TO BOIL AND CAUSE A PROBLEM.

that's also why its a good idea to keep your fuel tank at least 1/3rd full as most modern cars use electric in the tank fuel pumps that are cooled by sloshing fuel in the tank

Vapor lock is rare with today's fuel injection systems. Vapor lock occurs when the vapor pressure of the fuel is higher than the surrounding environment. In older engines with "sucking" fuel pumps at the engine, the pressure in the fuel line to the tank was reduced by the sucking action of the fuel pump drawing fuel form a fuel tank nearly twenty feet away, and when heated, the gasoline actually boiled creating a vapor of gasoline which the fuel pump could not handle, thus the name "vapor lock"., as pressure is reduced in the fuel line the boiling point of the fuel is reduced.

gasoline in some blends will boil as low as about 120F if the fuel line pressure is low enough and a fuel pump can,t SUCK vapor efficiently, pumps PUSH FUEL FAR MORE EFFICIENTLY than THEY PULL FUEL SO AN ELECTRIC PUMP MOUNTED LOWER THAN AND NEAR THE TANK IS ABOUT IDEAL

Today's fuel pumps are in the fuel tank where they push the fuel under pressure to the engine systems. Excessive fuel which is not used is sent back to the fuel tank. This causes a constant flow of pressurized, cool fuel in the lines to the engine system, be it fuel injection or carburetor. As a result you would have to heat the fuel line with a propane torch to get the fuel to boil and even then it would be cooled by the flowing fuel circulating from the tank to the engine and back again to the tank. Vapor lock as we once knew it is a thing of the past.

http://www.chevyhiperformance.com/tech/ ... index.html

viewtopic.php?f=55&t=635

http://web.archive.org/web/200701062316 ... 1.htm#FPHP

http://www.vw-resource.com/vapor_lock.html

viewtopic.php?f=32&t=596&p=793&hilit=+filter+fuel+drain#p793

QUOTE

Vapor Lock

~~~

Have you ever had this problem? You are driving home from work late in the afternoon. It's 90oF (32oC) outside and there's lots of traffic, so accelerating and decelerating a lot. The engine is working, and you know it's getting hot.

Then, about 4-5 miles from home, the engine suddenly starts surging and then decides to take a rest altogether. As you pull off the road you think to yourself, "This couldn't be an electrical problem - the engine wasn't actually cutting out, just surging."

Alternately, you drive to the store on a hot day (far enough so that the engine gets thoroughly hot); when you return from the store to the car, it won't start! What's up with that!?

So you lift the engine lid and notice right off that there is no fuel in that small fuel filter in the line between the fuel pump and the carburetor (if you have such a filter -- we actually recommend that you don't have a filter here). So right away you know the problem (right?) - vapor lock! Every VW we have had has done this when it got hot. They seem to be especially touchy both when they're hot and when it's getting close to "Tender Loving Care" time, when timing or valves may be a bit off the numbers.

The usual problem is that the whole engine gets thoroughly hot, and when you switch off, there is a 'heat soak' period when the temperature in the tinware and engine compartment rises because the residual heat in the cylinder/heats isn't getting blown away by the fan. The heads run at about 265-285oF (130-140oC) and can run up to about 355oF (180oC) on a really hard run which is pretty hot.

This causes the metal fuel line around the tinware, the fuel pump, and the carburetor to all heat up somewhat, causing either excess vaporization of the fuel in the carburetor, or and actual vapor lock in the fuel line or fuel pump.

As a result, starting is sometimes hard. With hot fuel in the carburetor, the least reduction in pressure (through the carburetor throat) causes instant vaporization, perhaps of fuel in the float bowl too (which breathes into the top of the carburetor throat), and of course a vapor lock in the fuel line or pump is even worse, because it will result in an empty fuel bowl in the carburetor - the car uses that fuel and stalls because it can't get any more. Then it takes a lot of cranking to fill the fuel bowl, once the vapor lock itself is cleared.

In summary, following is the cause and the cure for vapor lock -

Cause: The engine overheats, causing the fuel line, fuel pump and carburetor to heat up.

Result: Excess vaporization of fuel in the carburetor and/or actual vapor lock in the fuel line or fuel pump.

Cure:

1. Wrap the fuel lines on both sides of the pump with aluminum foil.

Note: This is a precaution if your car is prone to vapor lock. It won't help much once the problem has

already occurred.

# Pour a little water over the fuel pump to cool and re-condense the fuel, being careful not to splash the distributor. If no water is readily available, hopefully there is some in the windshield washer bottle. It doesn't take much.

# Hold the throttle open just a bit with the accelerator pedal while you crank. Don't move the throttle at all while cranking, or the accelerator pump with flood the carburetor. The reason for cracking the throttle open it to avoid using the idle jet alone, as this runs the car richer than the main jet, and a rich-hot mixture makes the car flood easily.

# When the engine catches, hold the throttle still until it clears the excess fuel (revs up smoothly).

Away you go!

~~~

Other things to check if vapor lock has become a regular problem:

* Is the heat riser under the inlet manifold getting too hot? It should be hot enough to keep the manifold above it warm, but if the heat riser is providing excessive manifold heat, it can also be overheating the fuel line which runs close to it on the way to the fuel pump. There are "small hole" heat riser gaskets available (you'll have to look for them though) which can reduce the heat flow through the heat riser if it's running finger sizzling hot.

* Is the carburetor running lean? Many new H30/31 and 34PICT/3 carburetors are supplied with lean jetting as an emissions thing, which makes the engine harder to tune, and causes higher engine temperatures. There is information elsewhere in these articles about suggested jetting for various distributor, engine size and carburetor size options.

* Is the carburetor pre-warmer working properly? The paper tube up to the carburetor inlet is supposed to draw air from near one cylinder head to speed up the engine warm-up process, but if it's stuck full on (breathing hot air) the engine will run hotter than it needs to, which will worsen any potential vaporization problem. There are two actuating mechanisms - the earlier engines (up to about '71-'72) have a pull-wire operated by the right hand cooling flap assembly, and later engines have a vacuum line from the manifold directly under the carburetor, up to a temperature switch in the air cleaner and another vacuum line from that switch to the vacuum canister on the side of the air cleaner inlet. The early type is just on-off, depending on whether the flaps mechanism (controlled by the thermostat) is open or shut, but the later type may hold a partial position, depending on the temperature inside the air cleaner. Of course if your engine has no cooling flaps (tsk tsk) or if it has no vacuum lines connected, or an aftermarket air cleaner, then the carburetor inlet will be breathing full cold all the time - a potential icing problem, but not an excess-heat problem.

* Is any of the tinware missing?. If the engine is missing any of the tinware which controls the flow of cooling air around the heads and cylinders, it WILL run hot, and this will worsen any vapor lock problems.

* Is the engine tuned properly?. If the car is out of tune it has to work harder to provide the power to drive the car, so it may run hotter. Keeping the car well tuned keeps the engine temperatures in the normal range, minimizing any vapor lock problems.

~~~

Notes from Rob on the Subject of Vapor Lock -

My '68 Bug definitely doesn't like the heat as much as my '70 Bug - he started getting vapour locks before we even got there, and was troublesome all the way home. Luckily I had a bottle of water with me and was able to pour a little over the fuel pump and carby, and get him going each time.

I think the problem is that the heat riser is working TOO well, and cooking the inlet manifold and carb plus the fuel pump.

I'm going to make a block-off washer for one side of the heat riser, and see what effect that has. It's only about 20 minutes to install it and will be a good test of the theory. I can always drill a tiny hole in it if I find the carby freezing up. He already has a "small hole" washer in one side, but the inlet manifold still gets finger burning hot, and it only needs to be slightly warm to keep the fuel in suspension.

I cut a washer out of flat metal sheet, and it only took about 20 minutes to remove the rear tinware, pull the two heat riser bolts and slide the old washer out before putting the new washer in. I found that you can use the tinware to "lever" on if you are careful - I used a piece of flat steel so I was spreading the load, and it only took a little levering.

I've only had a couple of short runs so far, but the manifold under the carburetor is not completely cold, so it looks like it might work OK. If not, I'll remove the seal and put a 1/16" hole in it and work up from there.

The manifold has always been too hot to touch on my '68 Bug and it only needs to be warm ( above freezing) to keep the fuel in suspension. He seems to have a littel more power now too - and a hot inlet WOULD be less dense, so that makes sense.

http://www.wisegeek.com/what-is-vapor-lock.htm

Vapor locking primarily happens in cars with carbureted engines, but since electronic fuel injection replaced carburetors in the 1980s, most car owners don’t have to deal with vapor lock anymore. Carburetors and electronic fuel injection are two different methods of delivering the proper amounts of fuel to the engine. Fuel injection is more advanced, and requires a computer to tell the injectors how much gasoline to squirt into the engine. A carburetor, on the other hand, is a mechanical device that uses the engine’s natural vacuum, allowing specific amounts of fuel to be sucked into the combustion chambers. The amount of fuel that is delivered to the engine can be changed using simple mechanical adjustments on the carburetor.

Most carbureted engines have a mechanical in-line fuel pump, which means that the simple mechanical pump is placed on the fuel line, usually next to the engine. The mechanical fuel pump’s proximity to the engine means that the engine’s heat causes the fuel in the line to become very hot. When the fuel becomes too hot, it turns into a vapor, just as water begins to turn to steam when it boils. This process is hastened by the vacuum created in the line as the fuel is sucked into the engine.

When the fuel turns into vapor, the mechanical fuel pump can no longer move it along the lines. As a result, some or all of the fuel stops getting into the combustion chambers, and the car either begins to run very roughly or dies completely. If the driver attempts to restart the car, it will probably not start, or will continue having problems. This is known as vapor lock.

Vapor lock does not usually happen in fuel-injected engines for several reasons. First of all, most electric fuel pumps are located at or in the fuel tank. Because the fuel tank is usually located too far away from the engine to be affected by its heat, gasoline is not likely to turn to vapor there. As a result, the fuel pump can push the fuel along without any problems, avoiding one of the major causes of vapor lock.

Another reason why vapor lock does not often happen in fuel-injected engines is because the fuel lines are usually pressurized. The high pressure that the fuel is under prevents it from turning into vapor quite as easily, unlike the carbureted system that actually produces negative pressure, also known as vacuum, in the lines.

More efficient engine cooling systems also contribute to the decreased likelihood of vapor lock occurring in modern cars. The cooling fans in older cars usually ran off of the momentum of the engine, which meant that when cars were at a disadvantage when they sat idling in traffic for long periods of time: The lack of motion meant less air flowing through the engine compartment, and the fan — stuck at the idling speed of the engine — was unable to cool the engine sufficiently. As a result, the engines in older cars tend to run hotter in heavy traffic, making vapor lock more likely to occur.

Modern cars, on the other hand, typically have electric cooling fans. These fans are linked to a sensor that detects the engine’s temperature, and tells the fan whether to speed up or slow down. As a result, the internal combustion engines in modern cars are less likely to overheat than those in older models, making vapor lock much less common than it used to be.

All of the problems that cause vapor lock are easily corrected, even on older cars. Older cars can often be retrofitted with the newer technology that reduces the likelihood of the fuel lines overheating. For instance, even on a carbureted engine, a low-pressure electric fuel pump can be installed near the fuel tank, which will keep the fuel moving along the lines even if it starts to heat up in the engine compartment.

Another easy remedy for vapor lock in older cars is to install an electric fan in the engine compartment. Many auto parts stores carry aftermarket cooling fans, which can be installed on any car. Some cooling fans can be connected to the existing engine temperature sensor, mimicking the behavior of the cooling fans in modern cars.

Finally, vapor lock can be prevented in any car by protecting the fuel lines from the heat of the engine. There are two ways to do this. One way is to install heat shields between the engine and the fuel lines, which will divert most of the heat away from the lines. Fuel lines can also be insulated to prevent the fuel from getting to the temperatures at which vapor lock occurs.

READ THESE related threads

viewtopic.php?f=55&t=211

viewtopic.php?f=55&t=635

viewtopic.php?f=55&t=1030

viewtopic.php?f=55&t=109

viewtopic.php?f=55&t=231

viewtopic.php?f=55&t=6442&p=20373&hilit=brass+roof#p20373

viewtopic.php?f=55&t=4381

viewtopic.php?f=56&t=495&p=8333&hilit=+back+pressure#p8333

http://www.centuryperformance.com/fueli ... g-140.html

Last edited by a moderator: