So I was reading another link and found this:

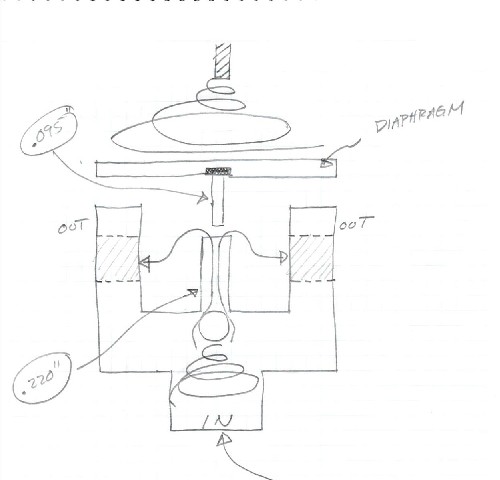

Your hand drawing is correct. It's exactly what I found inside.

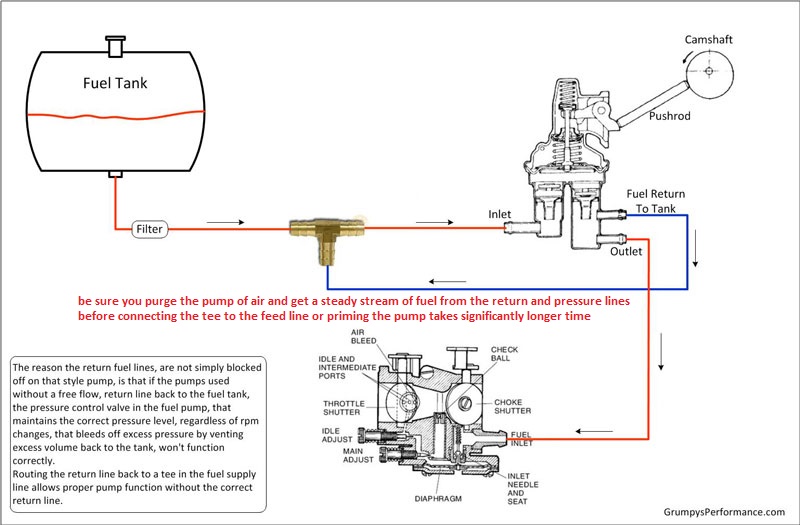

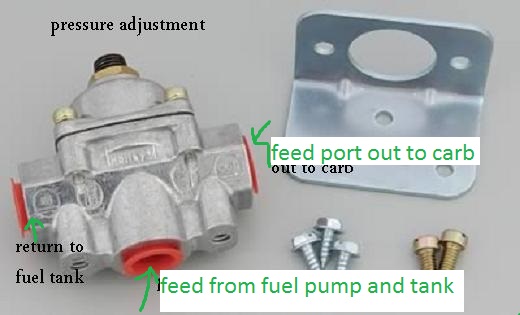

It gets confusing when you look at your last (black) diagram and compare it to the labeled regulator picture.

The way the regulator is drawn would make almost anyone hook it up as shown.

That is why I took the regulator apart today - to see if it could be used in reverse. It can't.

Do you think you should correct that black diagram to make it less confusing?

Or at least always attach the labeled regulator picture showing how to properly hook up that regulator.

Now it makes sense how it works after looking at the labeled regulator picture.

yeah. a good quality and properly adjusted, adjustable fuel pressure regulator is generally going to potentially provide,

just enough more consistent fuel delivery volume to be worth a few extra hp, but its major benefit is in the fact in many cases,

it can easily result in 30- plus hp over a improperly functioning O.E.M, fp regulator. (not all that rare)

keep in mind theres a huge difference between replacing a fully functional O.E.M. fuel pressure regulator ,

with an aftermarket adjustable regulator ,

which may or may not provide any benefits and replacing,

a mal functional, O.E.M. fuel pressure regulator with an aftermarket adjustable regulator ,

https://www.thedailystar.net/shift/...ure-regulator-will-improve-performance-111412

http://www.ws6.com/mod-7.htm

Dyno Comparisons -- Adjustable Fuel Pressure Regulator Settings

Here, the dyno shows a

16.6 horsepower and

14.6 ft/lbs torque difference between the stock fuel pressure (46psi) and 36psi with the LG Motorsports adjustable regulator. Actually, it was still making more power at 35psi than 36psi, but until I can measure my O2 sensors, I did not want to lean it out any further. The average gain here was

13.9 horsepower and

15.4 ft/lbs torque. Check out the Dynojet

Race Routine between the stock and 36psi fuel pressure.

Something new: Dynojet is currently Beta testing their new WinPEP software for the dyno. With this software, they have the ability to graph up to 12 graphs at once. Check out the Dynojet

WinPEP Graph of all the power between the stock and 35psi fuel pressures.

NOTE: One thing that I have found after some time with this mod is that the stock computer is quite smart. After lowering fuel pressure to achieve a better air/fuel ratio, the computer sees this at part throttle and adds injector pulsewidth to compensate. Basically, horsepower fell back off to where I started from. While normal trains of thought tell us that since O2 values are not measured during wide open throttle, that fuel pressure should have a long lasting effect here. Actually, it does not. The computer uses the last known long term fuel trim integer at WOT, which is to add fuel since at part throttle it has adjusted for being too lean.

related threads

http://garage.grumpysperformance.co...ss-fuel-pressure-regulators.12776/#post-65998

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

http://garage.grumpysperformance.co...eplacing-a-c-4-fuel-pump.33/page-2#post-75720

http://garage.grumpysperformance.com/index.php?threads/c4-corvettes-fuel-system-info.67/#post-37351

http://garage.grumpysperformance.co...-big-a-fuel-pump-do-you-need.1939/#post-35934

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-drop.10624/#post-45703

http://garage.grumpysperformance.co...l-line-sizing-return-vs-feed.3067/#post-44732

http://garage.grumpysperformance.co...ed-flow-and-its-limitations.11100/#post-49467

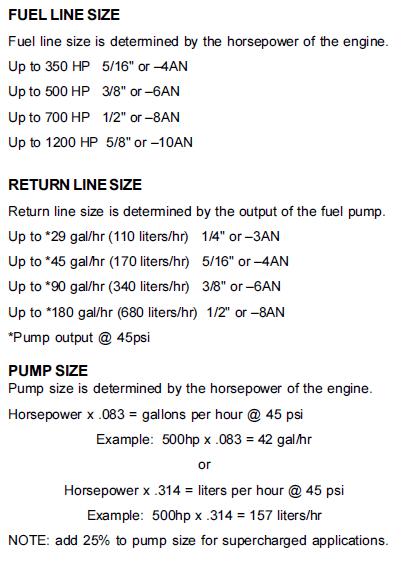

your carburetor inlet fuel pressure should be a consistent 5 psi-5.5 psi in most cases, once you get over 6 psi you'll find the carburetor float bowls tend to flood and under 3 psi the carburetor can run lean under hard acceleration.

EFI works at higher pressures

I don't plan on using one of those regulators because of the small .220" passage. Even though it should be connected

as close as possible to the carb, and my Quadrajet carb will have a .130" MAX needle & seat (I don't know what a Holley

carb has, or what their 2 needles & seats would be equivalent to), but for $19.77 I will try that Carter M6626 mechanical

fuel pump first. That might be all I need to do.

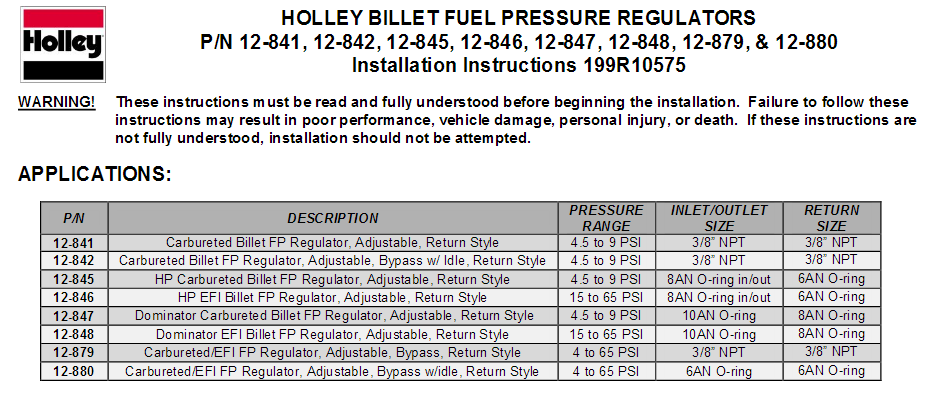

for some reason no one reads instructions and thinks the fuel return lines, supposed to be located at the bottom of the regulator and fuel should flow strait thru the regulator from side to side...WRONG! the fuel feeds up from the bottom center, and for some reason i always seem to get more consistent results with the lines hooked up as posted in the picture

BE AWARE THE FUEL PRESSURE REGULATOR MUST BE HOOKED TO AN UNRESTRICTED FLOW RETURN LINE BACK TO THE TANK TO ALLOW THE FUEL PRESSURE REGULATOR TO FUNCTION AND YOU MUST VERIFY THAT RETURN LINE IS UNRESTRICTED, IF THE RETURN LINES BLOCKED THE REGULATOR WON,T FUNCTION, BUT THE FUEL PRESSURE GAUGE MUST BE ON THE SAME SIDE OF THE FUEL PRESSURE REGULATOR THAT FEEDS THE CARBURETOR, the FEED FROM THE FUEL PUMP FEEDS THE LOWER CENTER PORT, THE LEFT SIDE IN THIS DIAGRAM FLOWS UNRESTRICTED BACK TO THE FUEL TANK, THE RIGHT SIDE FEEDS THE CARB AND FUEL PRESSURE GAUGE