NOT A TA

reliable source of info

I'm forced to pay flood insurance but not specific hurricane insurance.

Interesting bit I learned the hard way. Flood insurance only covers rising water from say a nearby river, not falling water from say a hole ripped in a roof or broken pipe.

Loves302Chevy, Here's what he wrote.

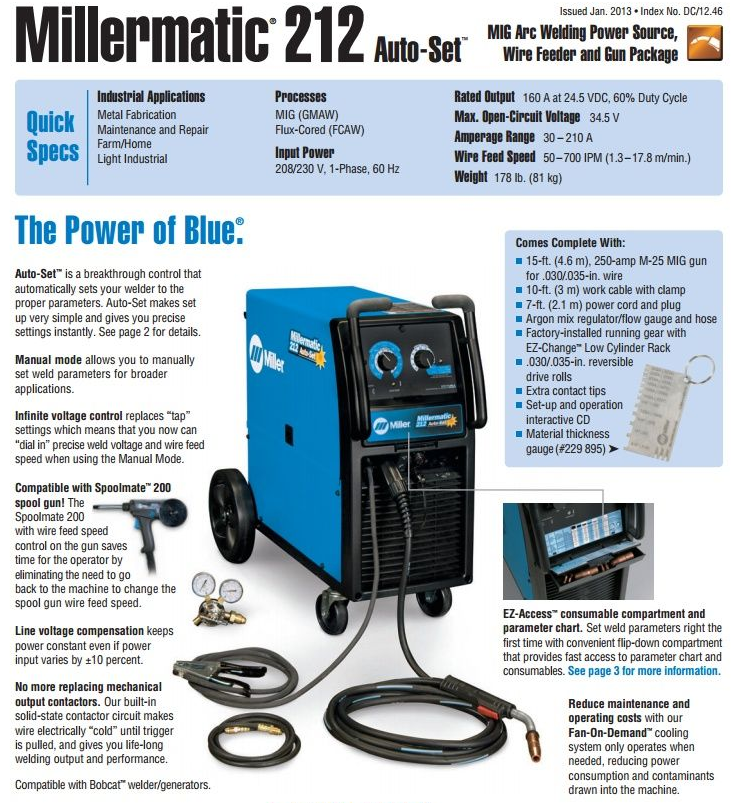

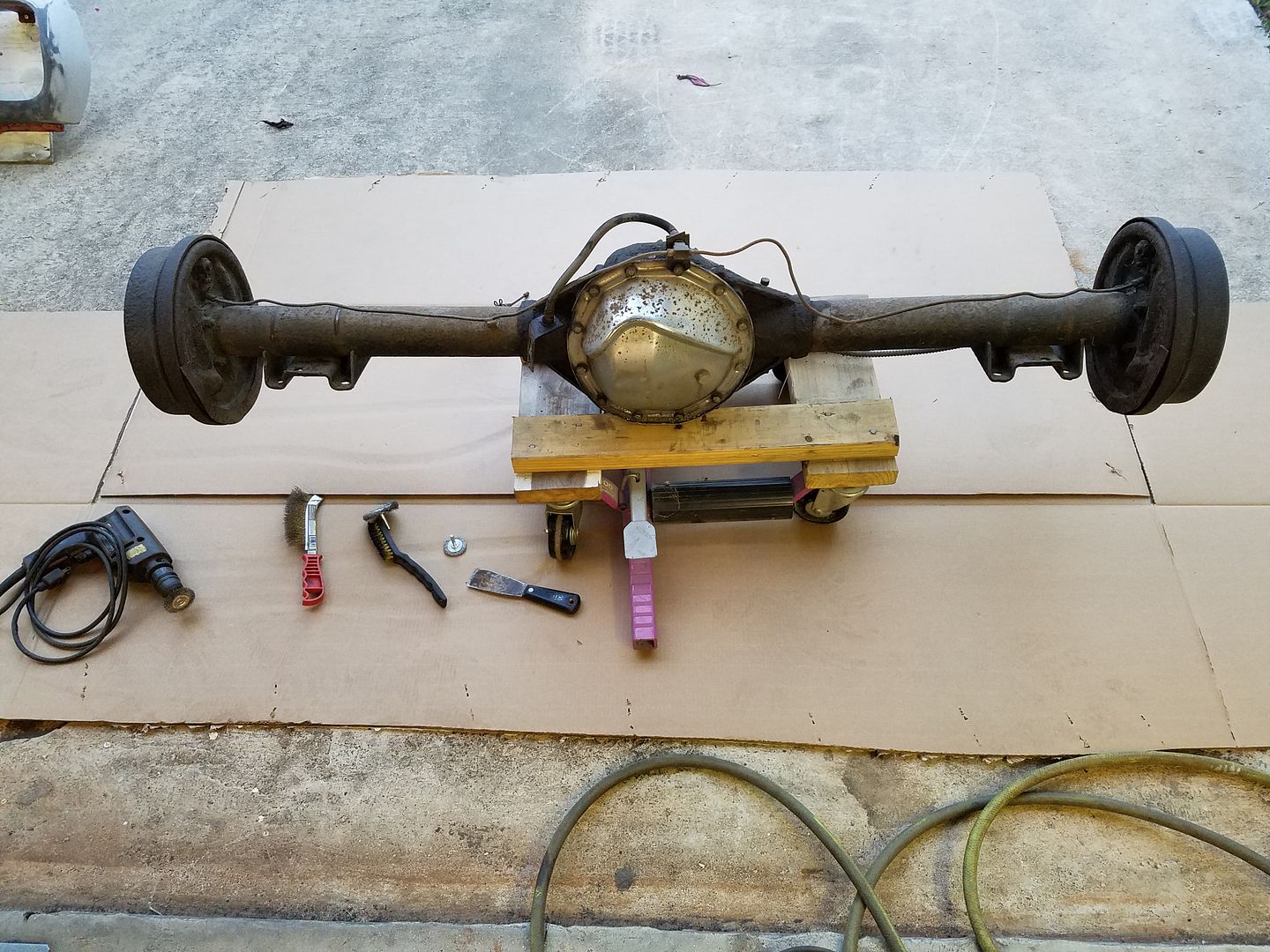

"Got them all set up for welding. I used a crayon as that was what I had on hand. It went very well except for the crayon part. It almost immediately washed off with the wd-40 despite being far away from the holes. I think a scribe would work a bit better."

Well he may not be an experienced mechanic but the pics he sent looked like prep and alignment/clamping was done nicely AND he knew what a scribe is. He's going to have a bud do the actual welding. There's a lot of guys that have grown up who never had the opportunity to learn but want to build a car. Everyone's gotta start somewhere with what ever they have handy. You wouldn't believe how many guys think you can rebuild a car with a 3/8" socket set, hammer, drill, adjustable wrench, and a couple screwdrivers. That's why I'm listing tools required and writing such detailed instructions based on the most basic tools. There's a lot we take for granted while a new guy doesn't even know the correct way to put an open end wrench on a bolt or that he should use a box end or socket when possible instead of the open end wrench to start with..

Interesting bit I learned the hard way. Flood insurance only covers rising water from say a nearby river, not falling water from say a hole ripped in a roof or broken pipe.

That guy should probably not be working on cars.

Loves302Chevy, Here's what he wrote.

"Got them all set up for welding. I used a crayon as that was what I had on hand. It went very well except for the crayon part. It almost immediately washed off with the wd-40 despite being far away from the holes. I think a scribe would work a bit better."

Well he may not be an experienced mechanic but the pics he sent looked like prep and alignment/clamping was done nicely AND he knew what a scribe is. He's going to have a bud do the actual welding. There's a lot of guys that have grown up who never had the opportunity to learn but want to build a car. Everyone's gotta start somewhere with what ever they have handy. You wouldn't believe how many guys think you can rebuild a car with a 3/8" socket set, hammer, drill, adjustable wrench, and a couple screwdrivers. That's why I'm listing tools required and writing such detailed instructions based on the most basic tools. There's a lot we take for granted while a new guy doesn't even know the correct way to put an open end wrench on a bolt or that he should use a box end or socket when possible instead of the open end wrench to start with..