EVER CONSIDER BUILDING, RATHER THAN BUYING A TRANSMISSION HOLDING FIXTURE?

http://nastyz28.com/forum/threads/home-made-transmission-fixture.234676/

THERE'S A GREAT DEAL OF RELATED INFO IN THESE THREAD's

http://garage.grumpysperformance.com/index.php?threads/tbucket-200-4r-transmission-project.7230/

http://garage.grumpysperformance.co...ience-converting-a-4l80e-to-full-manual.5579/

http://garage.grumpysperformance.com/index.php?threads/4l80e.11645/#post-54467

https://www.ebay.com/i/132415307603?chn=ps

IF your planing on rebuilding a transmission, it helps a good deal to have a decent work bench AND a transmission holding fixture,

you can buy a transmission holding bracket off ebay for between about $130-$300 but if you own a decent welder and can fabricate and weld this is certainly within the range of projects most of us could design and build

just a bit of info, if you want a new transmission,core for spare parts,

I called the local "U-PULL-AUTO-PARTS"

and the salvage yard quoted me $220

for ANY AUTO TRANSMISSION I CARE TO PULL

and I asked again, any auto trans regardless of make/model/year?

and was told yes..

but that trans does not come with a warantee its looked at as a core

so Id be looking for a car/truck, source ,that had been in an accident as it had to be running to be driving,

if the car/truck you pull it out of,

is undamaged it MIGHT be in the salvage yard,

because the trans failed.

Id also look to see if theres indications,

the car/truck had been under water or in a fire,

that might have damaged the transmission

I didn't tack weld the nuts to each side of the tubing, but I suppose you could. The 2.5in distance from tube to plate could also be increased - I kept it as short as possible since the weight is hanging out there. But reality is the transmission isn't really that heavy. This is overbuilt because that's what I h

http://nastyz28.com/forum/threads/home-made-transmission-fixture.234676/

THERE'S A GREAT DEAL OF RELATED INFO IN THESE THREAD's

http://garage.grumpysperformance.com/index.php?threads/tbucket-200-4r-transmission-project.7230/

http://garage.grumpysperformance.co...ience-converting-a-4l80e-to-full-manual.5579/

http://garage.grumpysperformance.com/index.php?threads/4l80e.11645/#post-54467

https://www.ebay.com/i/132415307603?chn=ps

IF your planing on rebuilding a transmission, it helps a good deal to have a decent work bench AND a transmission holding fixture,

you can buy a transmission holding bracket off ebay for between about $130-$300 but if you own a decent welder and can fabricate and weld this is certainly within the range of projects most of us could design and build

just a bit of info, if you want a new transmission,core for spare parts,

I called the local "U-PULL-AUTO-PARTS"

and the salvage yard quoted me $220

for ANY AUTO TRANSMISSION I CARE TO PULL

and I asked again, any auto trans regardless of make/model/year?

and was told yes..

but that trans does not come with a warantee its looked at as a core

so Id be looking for a car/truck, source ,that had been in an accident as it had to be running to be driving,

if the car/truck you pull it out of,

is undamaged it MIGHT be in the salvage yard,

because the trans failed.

Id also look to see if theres indications,

the car/truck had been under water or in a fire,

that might have damaged the transmission

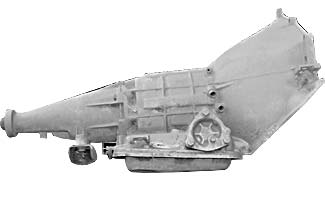

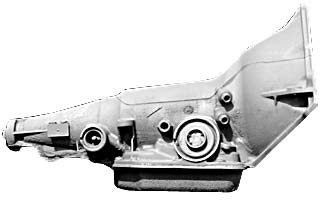

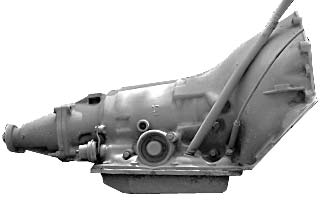

Ok guys, I was looking in my shop the other day and saw my three TH400's sitting on the floor. I grabbed one and monted it to my engine stand by the bellhousing. I called up my transmission builder and told him to come over and take a look. He said that's a great way to mount the trans, but if you want to rebuild it you have to use a transmission fixture. He looked at my welder and some steel I had laying around and said,"Dude, you should build one."

This is what one looks like if you buy it.

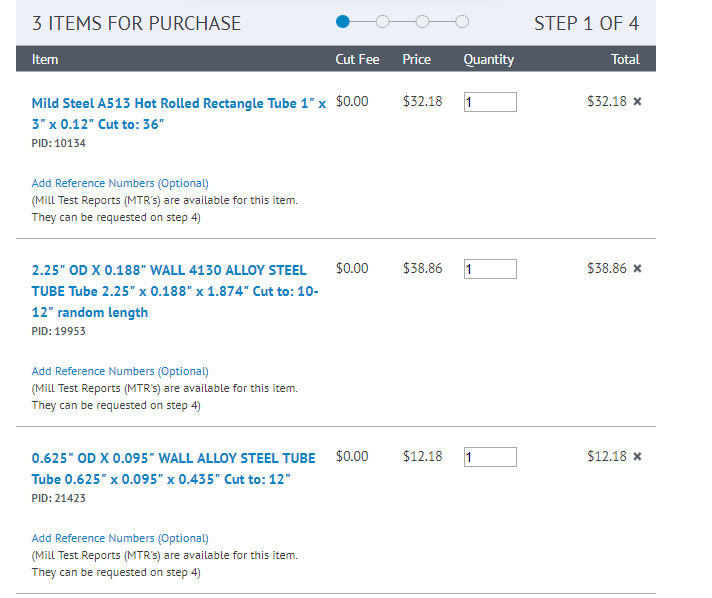

So I woke up the other day, grabbed my coffee and went out in the shop. I looked under my bench and located some scrap 1.5"x3" eighth in thick rectangular tubing. I looked at my trans and got some measurements. I cut the ends at 45* angles, but you could probably just square the ends.

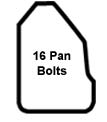

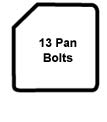

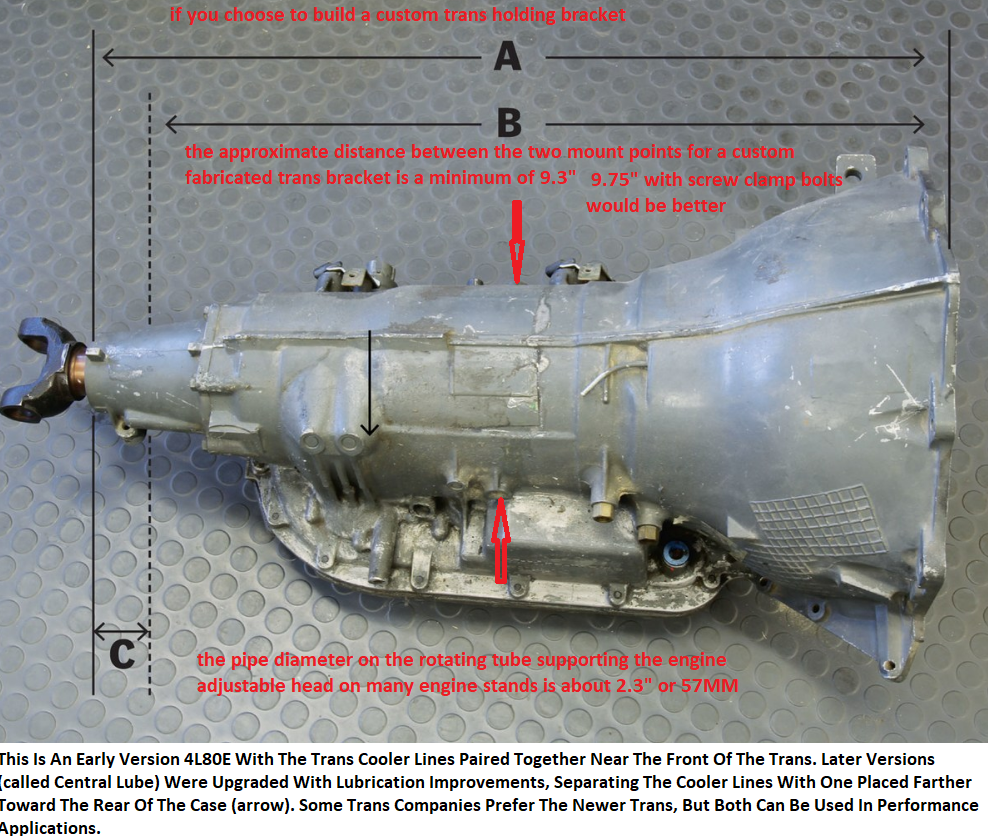

The inner width between the legs is 9 5/8" wide. The legs are 12 1/4" long. and the overall width of the top piece is 15 5/8". Now it really doesn't matter what you overall width is, just that you maintain the 9 5/8" inner width, so you can slide the fixture over your trasnmission as shown below.

As you can see, the fixture slides over the top of the transmission with ease. Now, you have to make a way to hold the transmission in place on the fixture. So, I proceeded to drill some 1/2" holes into the sides of the fixture, 1" in from the end of the tubing. Then I bought some 5" long 1/2" bolts to go into the side of the transmission. I also bought some square nuts and welded them to the back side of the fixture legs.

Now I had to figure out a way to mount the fixture to my HF engine stand. I was debating about making a mounting plate to bolt to the engine plate, but I decided to get some 2" black iron pipe. The OUTER diameter of the pipe if 2 3/8", and that's the same as the INNER diameter of the top post of the engine stand. I cut a piece of the pipe 11" long, I then proceeded to notch the end to fit OVER the rectangular tubing. I clamped the rectangular tubing to my work bench, using the 1/4" thick top plate as a reference edge. I then slid the pipe over the side of the tubing, making the CUT out part 4 1/4" from the TOP of the fixture. I then squared the end up with the edge of the bench top. I then burned it in using my Lincoln 140T welder.

Absolutely! Here you go...could you post the measurements/ materials and info used on the custom made, trans hold bracket so others could fabricate a duplicate?

I didn't tack weld the nuts to each side of the tubing, but I suppose you could. The 2.5in distance from tube to plate could also be increased - I kept it as short as possible since the weight is hanging out there. But reality is the transmission isn't really that heavy. This is overbuilt because that's what I h

Last edited: