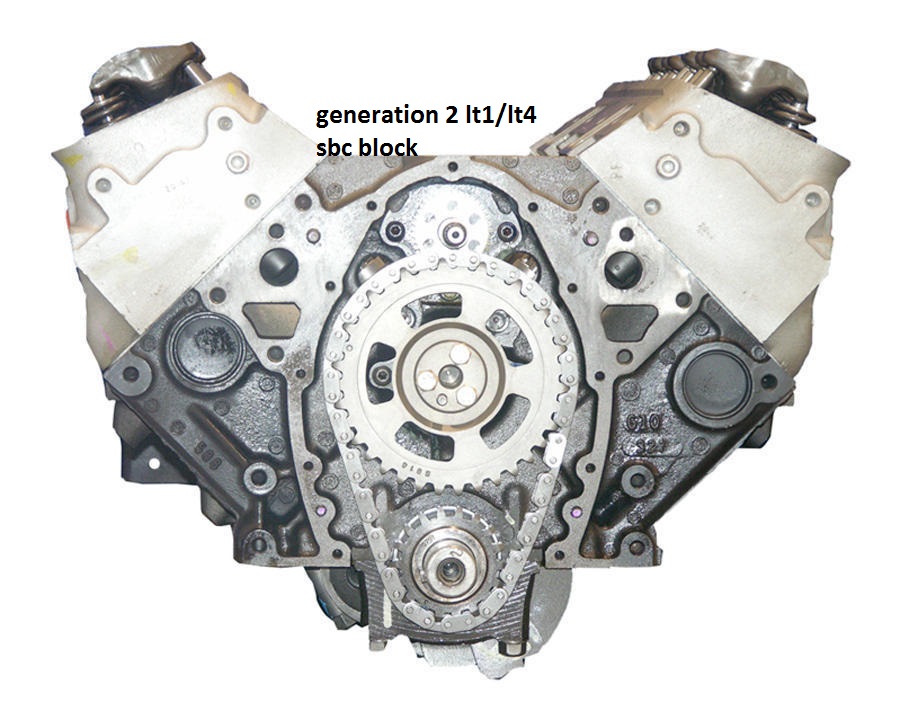

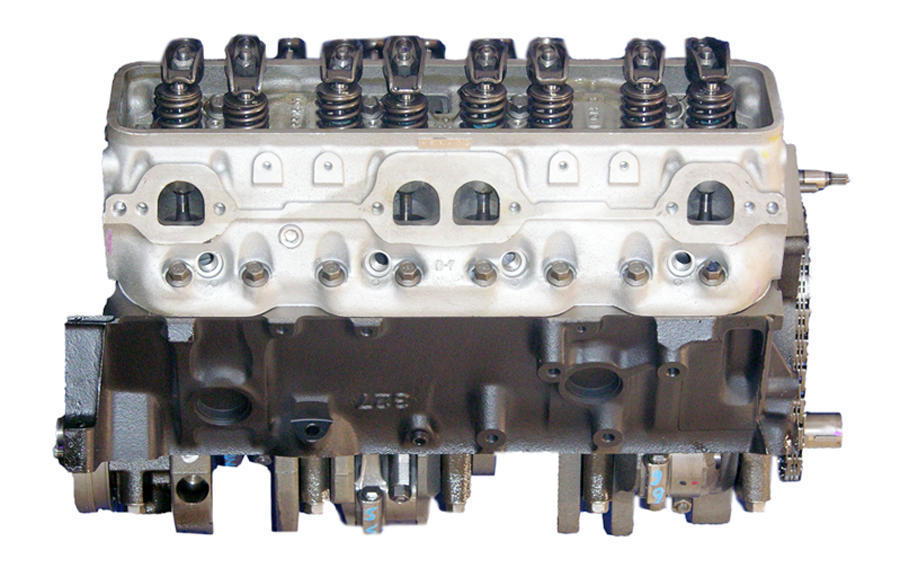

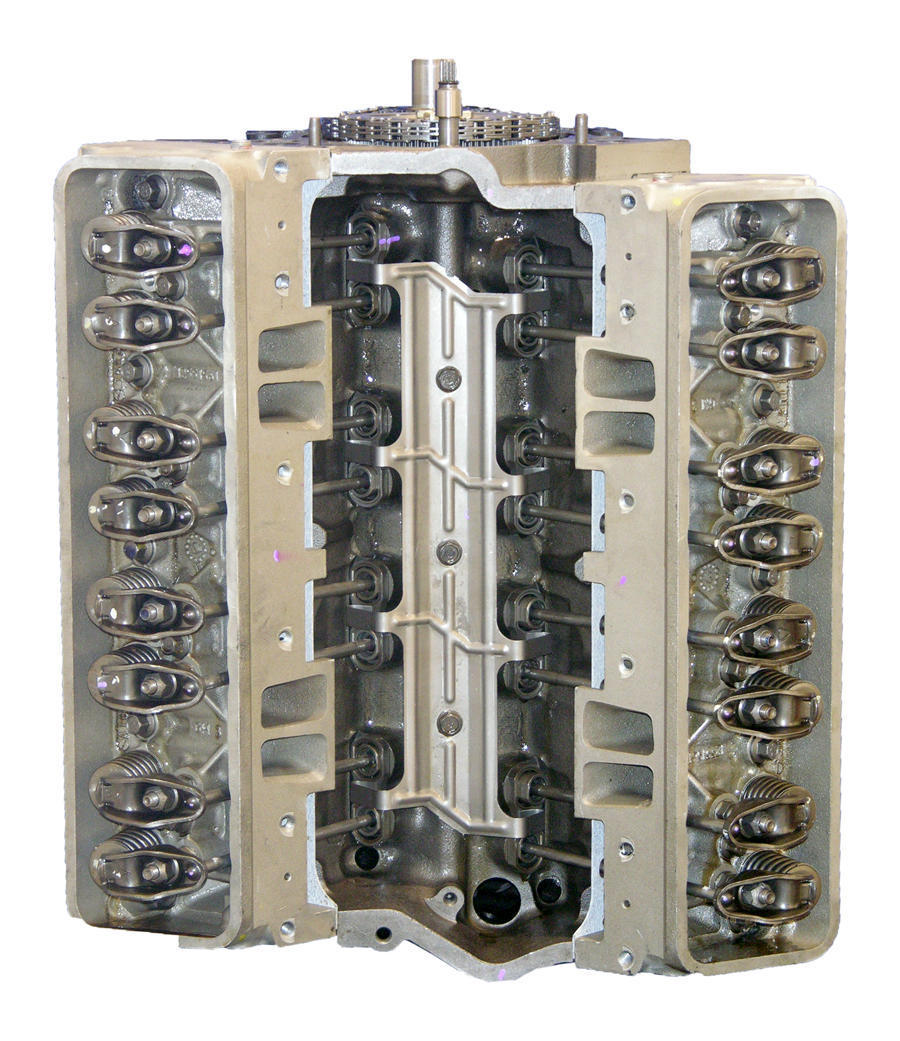

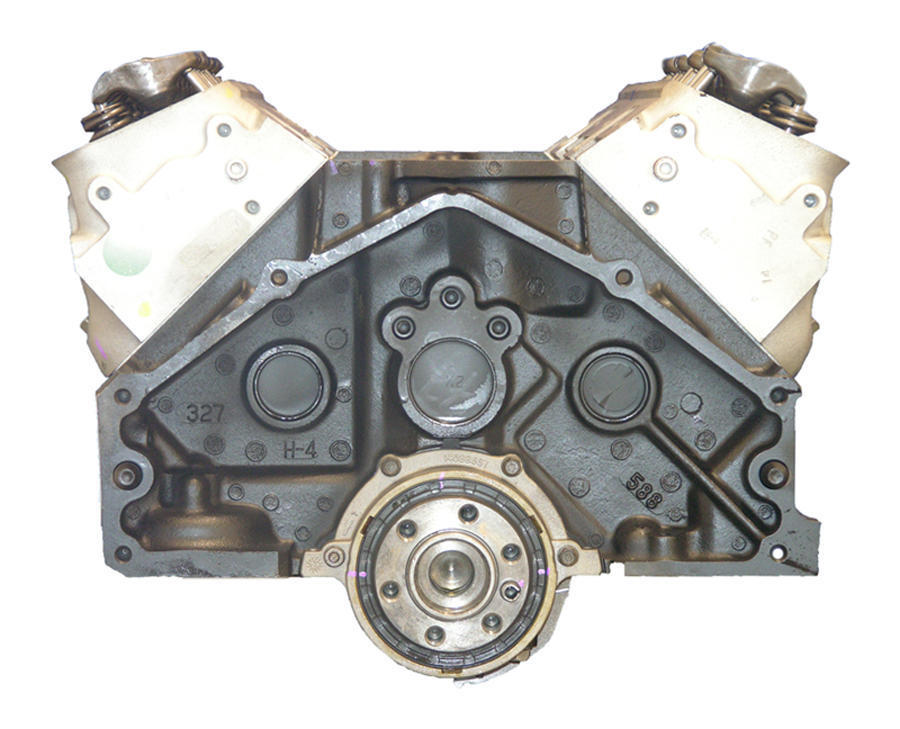

yes the first gen sbc heads, will work on that block, but of course you'll want to match the heads you select,

to the intended rpm/power range and application and match the cam timing, compression ratio, and drive train gearing, etc.

so lets discus the current car/truck weight, transmission, tire size, rear gear ratio and what your intended goals and budget limitations are, as a start point.

the last thing you'll want to do is select parts that may cripple or restrict the engine performance by mis-matching components or selecting parts on price alone, we all work on limited budgets,

but its will pay big dividends in power produced too carefully select matched components

and generally the biggest mistake is mis-matching heads, intake and cam combos or scrimping on the quality of the components used,

a couple extra hours or even days spent in detailed of research may prove critical, in fact anything less than buying and reading through several books and reading a couple dozen links and all the sub-links is very likely to leave you missing valuable and critical info youll need later, and thats usually going to cost you wasted time and cash.

the big mistake's most people make is in not selecting the correct cam, to match the displacement and compression and drive train gearing or selecting a restrictive cylinder head or intake that does not match the intended power range

youll want to take the time to do the math and compare components, lets for a second assume your,debating these two heads,

if you compare the 195cc vs 210cc AFR heads, all the way

theres a significant improvement in flow and a negligible decrease in port flow speed

theres always a compromise made between cost and potential power,

and obviously you want to match components to the intended power and rpm range,

but having seen a bunch of 383 builds use both AFR heads,

I think the 210cc choice here, is a no brainer if you can afford the price.

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

Potential HP based on Airflow (Hot Rod, Jun '99, p74):

Airflow at 28" of water x 0.257 x number of cylinders = potential HP

or required airflow based on HP:

HP / 0.257 / cylinders = required airflow

if we compare the head air flow rates between a 195cc and 210cc head on a 383-406 SBC and assuming a decent roller cam with the lift and duration,required, and intake that allows the heads to flow at their full potential,

195cc Street Head Flow Chart

.200 .300 .400 .500 .550

Int 146 201 247 275 280

Exh 119 166 197 213 218

210cc Race Ready Head Flow Chart

.200 .300 .400 .500 .550 .600 .650

Int 145 199 255 292 301 309 311

Exh 110 158 192 210 214 220 222

if you compare peak intake rated flow at .550 lift

280 cfm vs 301 cfm (about a 9% increase) youll see why

thats in theory potentially a 43 hp gain

yes allthe linked info below looks over whelming but ,

youll be amazed at the detailed info and,

the mistakes you can avoid by reading carefully and asking detailed questions, thus saving money and time

http://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/

http://garage.grumpysperformance.com/index.php?threads/semi-fool-proof-cam-sellection.82/

http://garage.grumpysperformance.com/index.php?threads/first-hotrod-build.12902/#post-67005

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-48785

http://garage.grumpysperformance.com/index.php?threads/matching-parts-and-a-logical-plan.7722/

http://garage.grumpysperformance.com/index.php?threads/what-to-look-for-in-a-good-engine-combo.9930/

http://garage.grumpysperformance.com/index.php?threads/another-383-build.12786/

http://garage.grumpysperformance.com/index.php?threads/383-information-overload.11137/

http://garage.grumpysperformance.com/index.php?threads/a-383-build.10991/

http://garage.grumpysperformance.com/index.php?threads/impersonator.9600/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.com/index.php?threads/valve-seat-angles-and-air-flow.8460/

http://garage.grumpysperformance.com/index.php?threads/tbucket-engine-project-dart-shp.3814/

a tip..never use a torque wrench to break loose bolts, own and use a 24"-25" breaker bar

a semi decent value

https://www.harborfreight.com/12-in-drive-25-in-breaker-bar-62729.html?_br_psugg_q=breaker+bars

before removing main caps stamp /number them and place an indication which side faces the front

placing all the stamped numbers offset to one end of those main caps helps and yes even mark the rear main in a similar matter even if its obvious where it goes to help indicate which side on the other main caps face forward

https://www.harborfreight.com/14-in...JbTfxfVMYFOapuwWwxF6MpH4wpRnt0Z8aAs3REALw_wcB

and yes remove the casting flash and use gyptal to paint the interior surfaces to reduce chances of crud getting caught in the oil flow and replace the freeze plugs with brass once and use sealant

read related threads

heres a short list REMEMBER the object or goal in building and maintaining the lubrication system is too maintain a 100% dependable pressurized cooling flow of lubricant to the bearings, rockers ,valves etc. your most important tool, is your ability to think about how things are supposed to...

garage.grumpysperformance.com

there's two ways ,...... you can use the correct tool, which is ADVISABLE! use this oil pump(link below) in most stock SBC builds, as it produces a 10% increase in oil volume and standard pressure which is just fine , but obviously check your bearing clearances and oil pump to oil pan floor...

garage.grumpysperformance.com

"OK GRUMPYVETTE< I have dumb question? What is a windage tray and whats it for?" windage trays don,t provide a huge boost in horse power, the purpose is mostly in providing much improved oil control, thus they can, if properly designed provide a much more consistent oil supply, and enhanced...

garage.grumpysperformance.com

READ THRU THESE SUB LINKS CAREFULLY theres a great deal of info here to look thru. pay attention to filter construction and the filter materials and total filter medium area, when discussing oil filters keep in mind their intended function, which is mostly too efficiently trap and remove...

garage.grumpysperformance.com

Last edited: 1 minute ago