rjs89ia

Well-Known Member

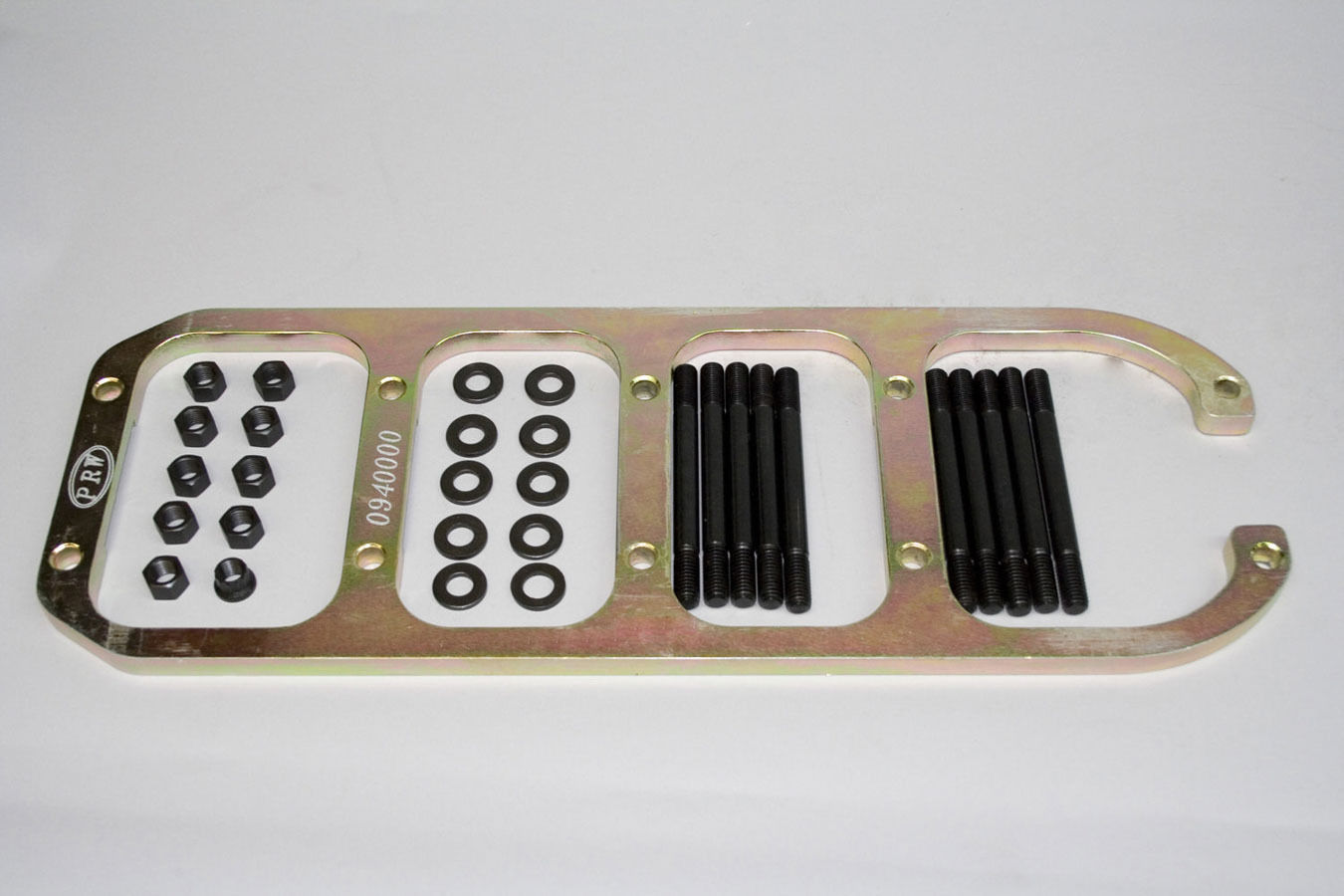

View attachment 8496

I read that you must grind these cooling passages deeper to maintain coolant flow on excessively milled heads.

Just 1/16" ought to do the job - compensate for the amount of material removed from the deck surface.

Do you think that will work? The sparkplug cooling holes have been welded completely shut. Grinding the groove now I wouldn't think would be much of a benefit because the water wouldn't flow. This has been one of my areas of concern on these heads as there isn't much talk about what to do after the holes have been filled. There are different points of view everywhere its talked about, you need them vs. you don't need them. I myself would like to have at least the exhaust side cooling hole BUT I have no idea how or where to redrill it or if I would trust the machine shop to do it. I guess I could talk to them about it but as time goes on there aren't to many people(machine shop wise) that have a clue how to modifiy these old heads whether they are really good or not.

Here's what I could find about it below.

As Told By Grumpy Jenkins:

"If the head is angle-milled very severely, the spark plug cooling holes may have to be filled and redrilled further outboard on the head. This isn't too critical on the drag racing heads as it is certainly possible to run the heads for a short time with no plug cooling at all. However, it would be smart to have at least the exhaust-side hole open if this is possible. There is plenty of material on the 492 head to move the cooling holes out a considerable distance. There is less material in this area on the 292 head. It is possible to break through the outside of the head when drilling the holes outboard of the stock location. A Grand National or short-track engine must have the exhaust side plug cooling holes in functional order to prevent detonation."

Here's another view of my head in better light. You can see how far down the heads were milled just by looking at the welds