answers in red

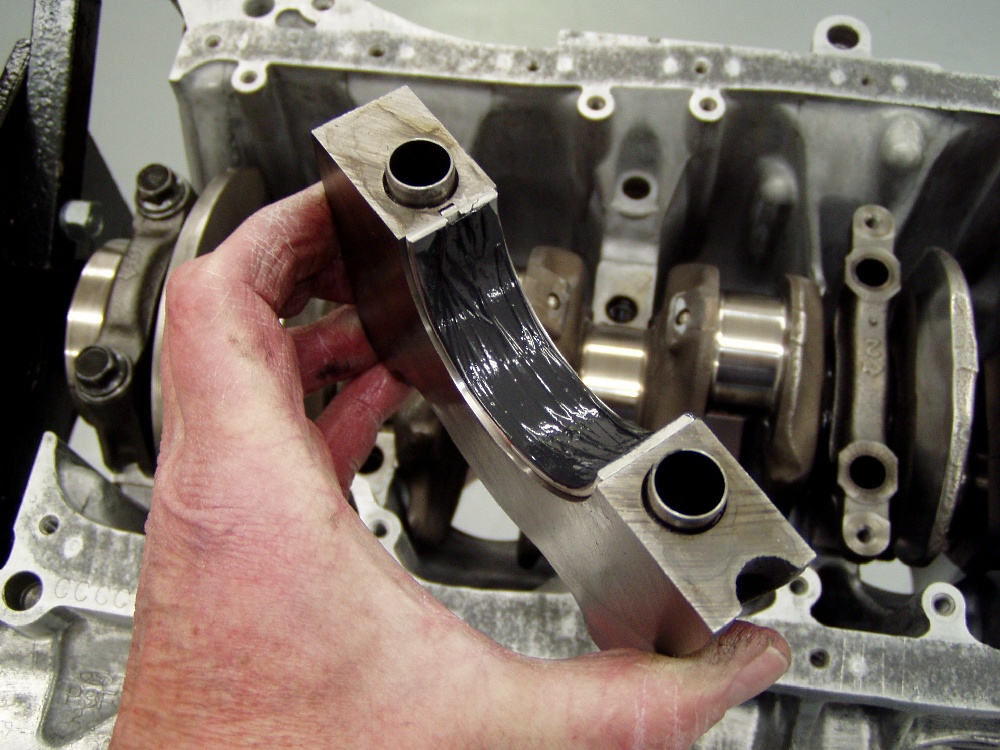

Preferences on bearings? I'm looking at king xp series bearings and the machinist uses clevite h series. He installed clevite cam bearings. I feel brands probably don't matter as long as its the right material for the application.

CLEVITE H SERIES

The internet is flooded with answers for these next questions but being only a few chime in on this thread its limits the amount of bs.

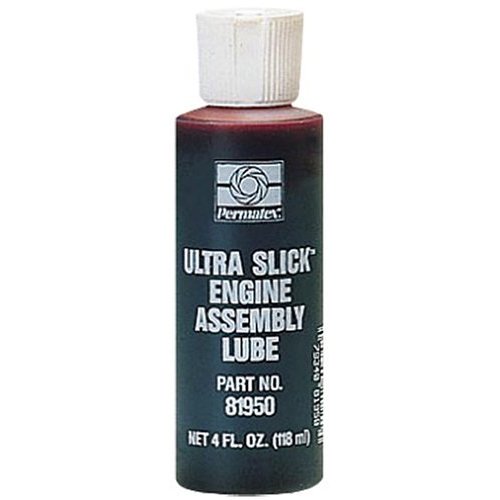

Preference on assembly lube?

50% marvel mystery oil

and 50% crane moly lubes

what Ive used for decades

but this works

I'm worried about long term sitting.,

either works but I prefer the top combo

this stuff is pretty much interchangeable

Sealant on core/freeze plugs, cam plug or not? Brand and type if so?

see above

All oil galley plugs are threaded. Which loctite should I use?

Also planning to install valley vents and possibly some super magnets. Which epoxy for the magnets?

IVE typically used these magnets in an engine, one in the rear oil drain on each cylinder head, one near each lifter gallery drain and 4 in the oil pan sump

proper magnets trap metallic debris

SmCo Samarium Cobalt Disc Magnets

http://www.magnet4less.com/

many magnets lose their magnetic pull if heated to 200F

these below won,t

proper magnets trap metallic debris

SmCo Samarium Cobalt Disc Magnets

http://www.magnet4less.com/

Cleaning tips? What does everyone use to scrub the cylinders when washing? I don't fancy the cylinder brush I see for that purpose.

READ THROUGH THESE THREADS

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://www.homedepot.com/p/Simpson-Hond ... 177499-_-N

heres one area where harbor freight has a few real good items, the cheap long reach air gun nozzles and brushes come in very handy cleaning oil passages

http://www.harborfreight.com/cpi/ctaf/d ... mber=95100

http://www.harborfreight.com/cpi/ctaf/d ... mber=97014

http://www.harborfreight.com/Air-Blow-G ... 68260.html

http://www.harborfreight.com/cpi/ctaf/d ... mber=95947

Last edited: