New

Hi Grumpy,

I caught your article on Journal measurements and would really appreciate your perspective on the followng questions. (background blather appears below the questions)

1) Shouldn't the journal in your article have looked shinier if it was a finish cut ? (see background below)

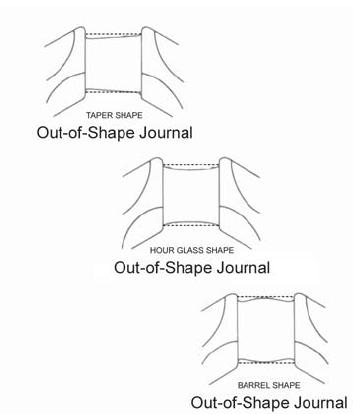

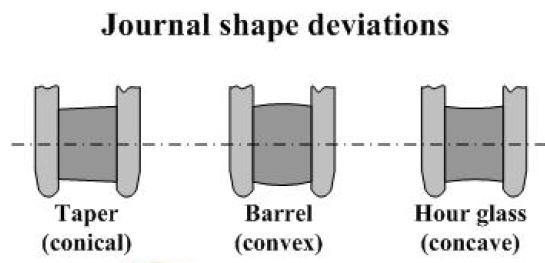

90% or more of the pictures were and are posted by other people on the internet , and merely used to illustrate, yes ideally a finish journal should be as close to mirror finished and glass smooth as you can get it, but level, from end to end except for the curved machined bevel,on each end ,its diameter concentric and even in its dimensions its intended and ideally standard size or standard under size, is critical

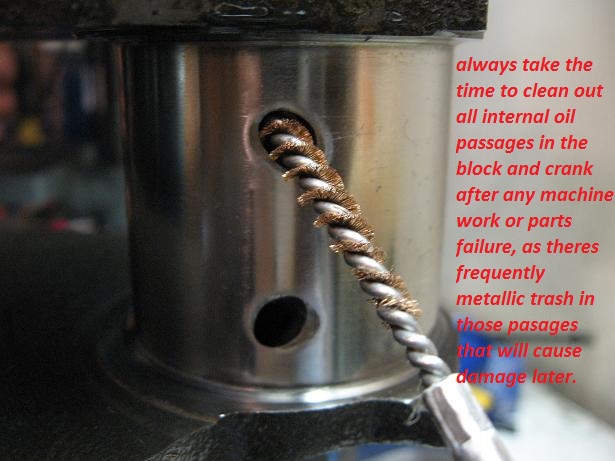

2) Is there a need to plasti-guage a daily driver crank (no racing) that's been resurfaced to a matching set of bearings ? I actually thought about plasti-gaging the journals rods from underneath (one location) but taking 6 measurements per makes removing the crank seem easier to do. I will definitely check for debris and burrs on future kits however.

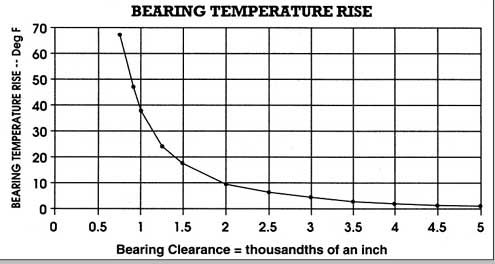

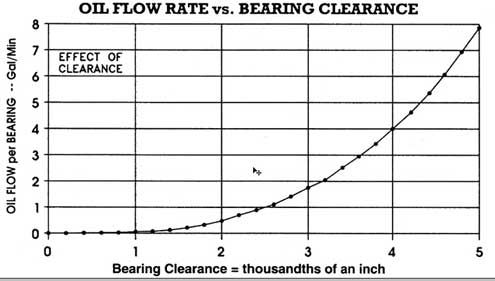

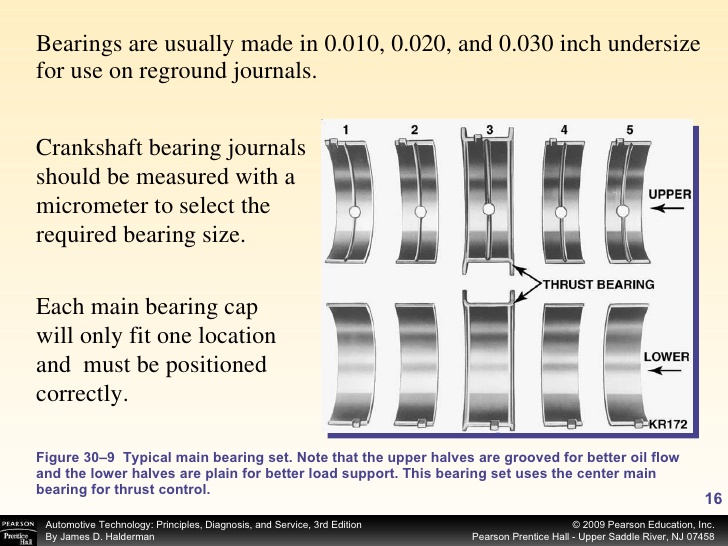

its always a good idea to verify machine work, theres always some machine shops that either do low quality or shoddy work, and you can,t expect an engine to operate correctly if the clearances or consistency of the bearing and lubrication surfaces are not correctly set, you would not bet the first or last guy to be told a crank was cut to a size that was not the true size or sold the wrong bearings for an application, you should always verify machine work, with both a precision measuring tool and plasti-gauge

MEASURE CAREFULLY

http://garage.grumpysperformance.com/index.php?threads/can-i-get-it-polished.9214/

http://garage.grumpysperformance.co...guess-on-clearances-and-journal-surface.9955/

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/rotating-assembly-bearings.9527/

3) Do you have any experience doing the crank kit right in the Caprice (without removing engine)

no I have always found it best too assemble an engine after placing it on a decent engine stand

if your going to assemble an engine you should buy or rent a decent engine stand, and a few basic tools

http://garage.grumpysperformance.co...g-with-a-local-machine-shop.14419/#post-74383

http://garage.grumpysperformance.co...haft-journal-surface-finnish.2728/#post-72043

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68850

4) I didn't understand from the graphs posted. What is a 180 'bearing' whatever vs a 270 ? and which is best and why ?

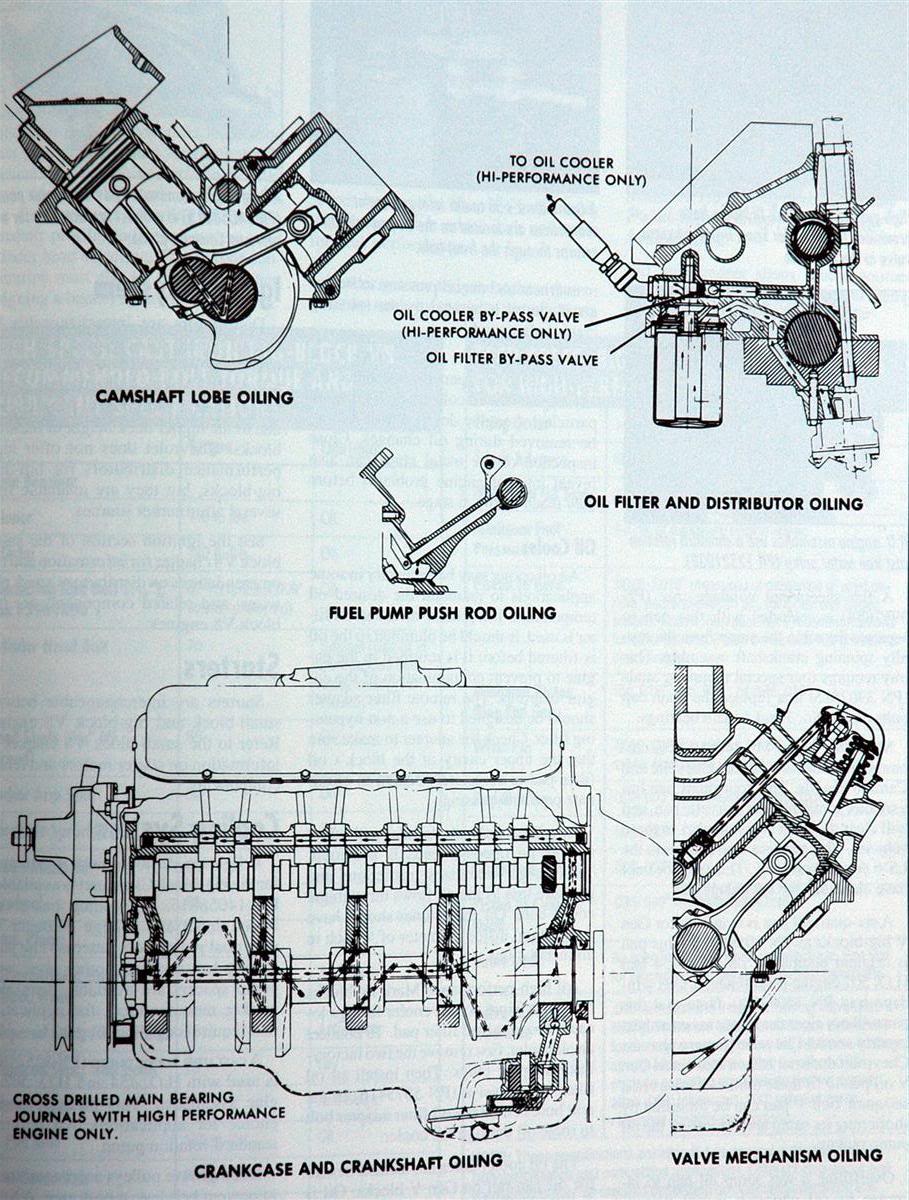

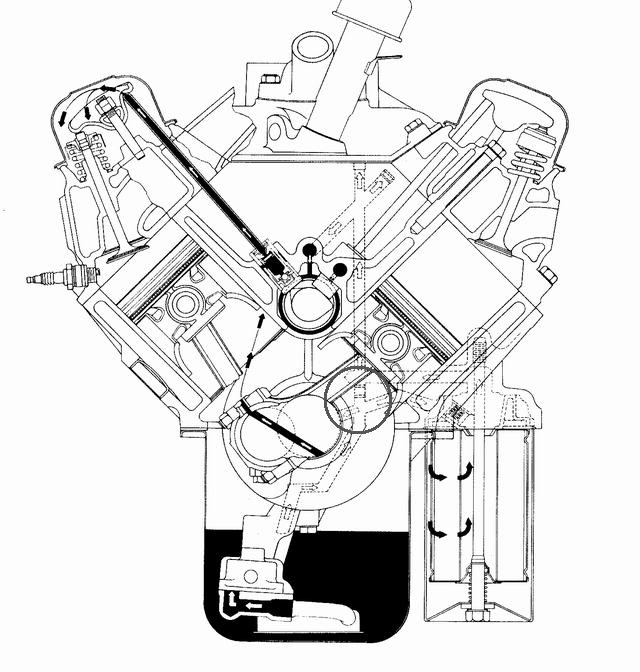

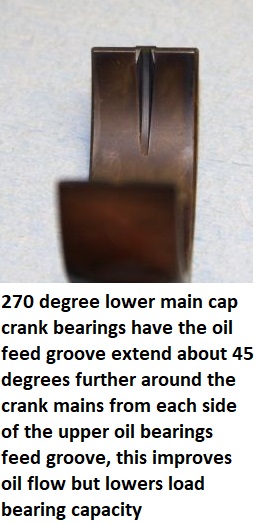

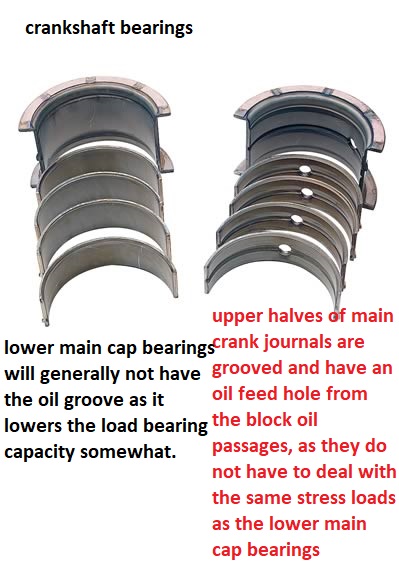

a 180 degree bearing has only the upper in the block grooved to improve oil flow,a 270 degree has the oil feed groove extend further 45 degrees on each lower bearing shell

the oil groove terminates before it gets to the bearing parting line. This style of main bearing has accounted for a 15 percent or more increase in hot idle oil pressure. So if you're looking to eliminate some of those unexplained low oil pressure gremlins contact your bearing manufacturer and ask about this style bearing and availability for the engine applications that you are building.

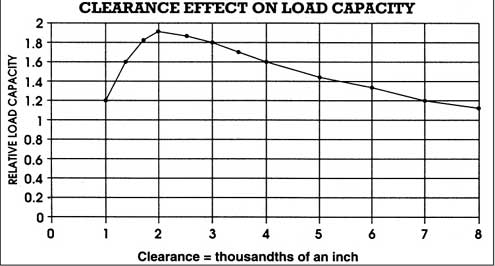

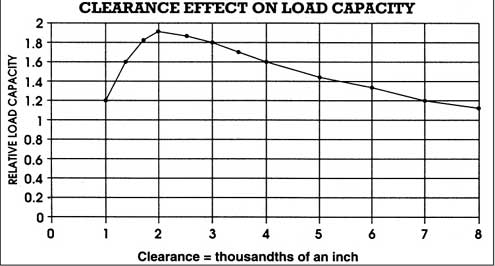

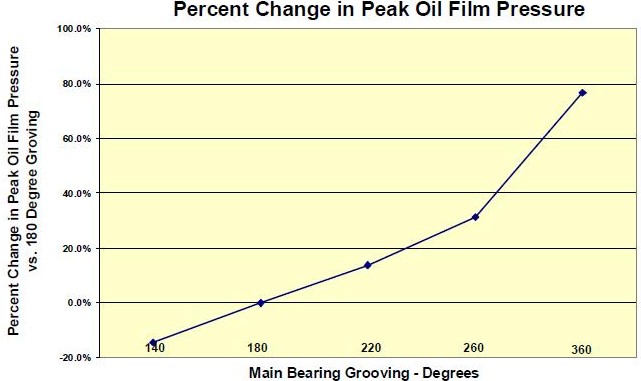

keep in mind only the upper main bearing shell should have an oil groove, having a 360 degree oil groove lowers the bearing ability to handle high rpm loads

THESE BEARINGS PICTURED ABOVE, with the full 360 degree grooves,LOOK GREAT BUT HAVE LOWER LOAD CAPACITY

a 180 degree bearing has only the upper in the block grooved to improve oil flow,a 270 degree has the oil feed groove extend further 45 degrees on each lower bearing shell

MAIN BEARINGS WITH 360 degree oil grooves

I've got my grandmothers 86 caprice that still looks really good and never fails to turn heads. Bone stock, but most of the cars been painted over 23 years I've owned it by a company that guarantees paint for life. More importantly this car has been just amazingly reliable over the years. Now that my son is ready to drive it (17) I'm noticing the engine shudders as second winds out so the bottoms loose with mileage just under 199K. I'm far from expert so did some googling and found your journal article.

I have done two crank shaft kits over the years - while the engines remained in the vehicles. 1975 and 1979 350 Chevy pickups. After reading the article I"ll have to say I don't recall checking nor deburing the oil passages - which would have been colossally easy to do. Will do so going forward. In both instances I pulled the crank had them resurfaced then bought bearings of matching thickness. The shop I turned the crank in 1990 has since closed so I'm checking out machine shops.

Note: The journal image in the article didn't look very shiny. Back during my 1990 crank kit install, I had the good fortune of comparing the journals of a crank that had been rough cut (per a racing engine builder) with my crank done by a shop owned by guys that raced engines. The difference was remarkable. I could easily see my pores, individual pores etc.. in the journals. They were mirrors. I installed it and drove my pickup daily to work 15 more years until gas hit $4/gallon then switched to the subject Caprice. Now my

Last edited: