Came across this info while doing some research and thought I'd share.

http://www.hobracing.com/tech/tpi_flow.asp

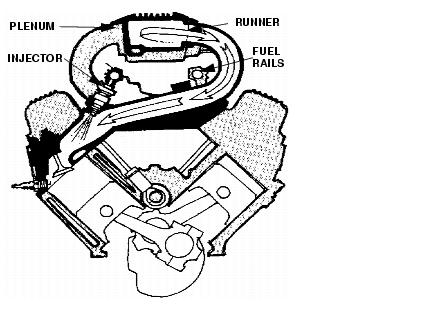

TPI Intakes and runners

The following airflow tests were performed on the University of Northwestern Ohio's SuperFlow SF600 Flow Bench. All CFM values are corrected for airflow at 28 inches of water. Injector flow rates are flowed at 43.5 PSI on an injector flow bench using test fluid with same density as gasoline.

AirFlow

Stock TPI/LT1 48mm Throttle Body w/o airfoil -- 783.0 cfm

Stock TPI/LT1 48mm Throttle Body w/ airfoil -- 821.9 cfm

TPI/LT1 52mm Throttle Body w/o airfoil -- 848.9 cfm

TPI/LT1 52mm Throttle Body w/ airfoil -- 898.8 cfm

Stock 98 Camaro 3800 II Throttle Body -- 554.3 cfm

Stock TPI Bosch MAF sensor w/ screens -- 517.8 cfm

Stock TPI Bosch MAF sensor w/o screens -- 658.4 cfm

Stock 87 GN 3.8L Turbo AC MAF sensor w/ screen -- 584.2 cfm

Stock 86 2.8L AC 5-wire MAF sensor w/ screen -- 576.2 cfm

Stock 96-up AC 3100 V6 MAF sensor w/ screen -- 616.4 cfm

Stock 96-up AC 3100 V6 MAF sensor w/o screen -- 670.7 cfm

Stock 94-up LT1 MAF Sensor w/o screen -- 719.0 cfm

Stock 85-87 Firebird TPI airbox mid piece -- 499.3 cfm

Stock 4.3/5.0/5.7 2bbl TBI complete -- 574.1 cfm (dry)

Stock 4.3/5.0/5.7 2bbl TBI w/o injectors -- 584.7 cfm

Stock 3800 vin L throttle body w/ screen -- 419.1 cfm

Stock 3800 vin L throttle body w/o screen -- 444.8 cfm

4bbl MPFI Holley Throttle Body -- 1287.6 cfm

Another source sent in these flow numbers

Flow and HP ratings for Throttle-bodies:

Flow (cfm) Max. NA HP

Stock 668 300

Stock w/airfoil 710 350

52MM w/airfoil 835 400

54MM (AS&M) 900 450

58MM 1050 500

TPI Intakes and runners flow rates

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

the stock TPI has a hard time flowing 230cfm even with minor port work, look here

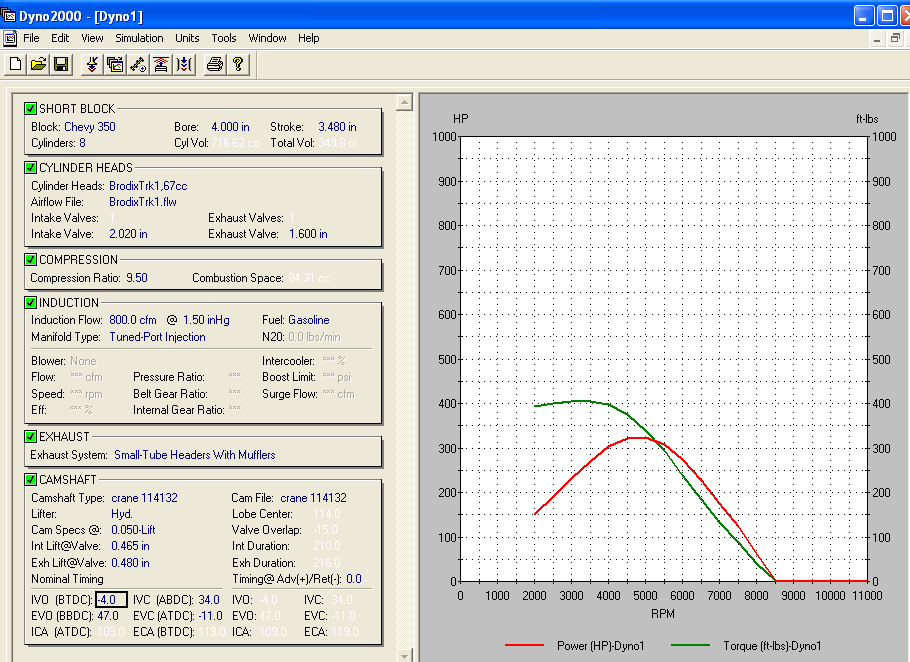

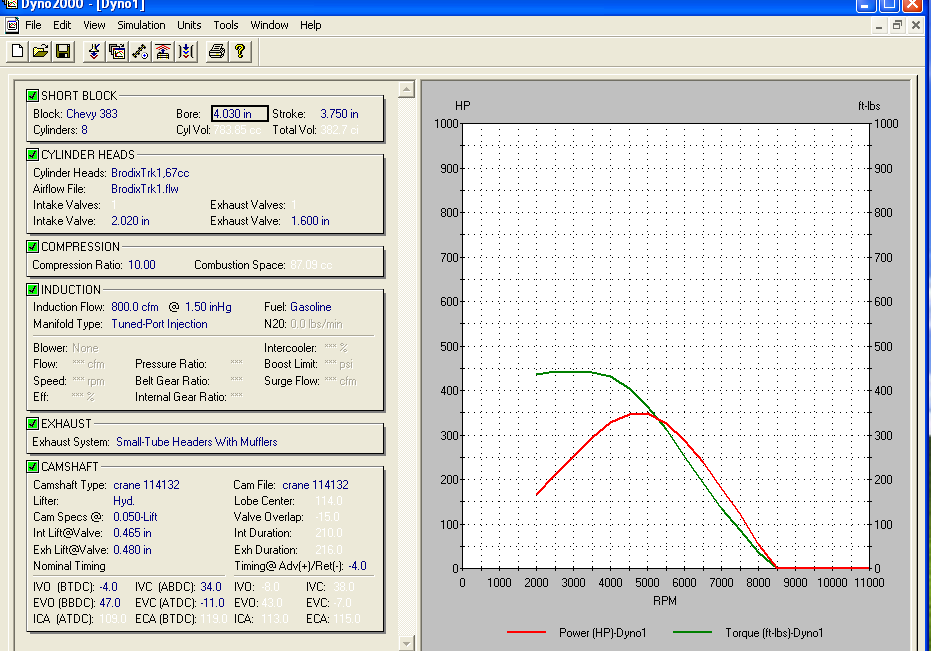

most of this info is right off the accel,holley,edelbrock, and TPIS sites, add a little math and the results become much clearer!!!

Intake....... length ....... port in -- out

Stock GM Base--- 6.375"------ 1.47"- 1.96x1.2

TPiS base------ -6.125"------ 1.75"- 2.09x1.28

Accel base----- -6.125"------ 1.75"- 2.09x1.28

Holley base------- 6” runner 2.3”- 1.9”x 1.23 (2.337 sq inches)

Runners

Stock TPI----- -- 7.250"------1.470" round(1.70 sq inchs)

SLP ----------- - 6.625"------1.600" round (2.01 sq inchs)

Accel LTR------- 6.625"------1.615" round (2.05 sq inchs)

TPiS----------- 7.625"------1.660" round (2.168 sq inchs)

Mini ram -----3.5”

LT1 ----------3”

Runners (measured individually)

Stock....................203.17 cfm

ACCEL................242.02 cfm

Extrude/ACCEL...275.83 cfm

Super Ram............289.18 cfm

Intake manifold with 3/8 inch radiused intlet.............................222.45 cfm

Holley stealth ram ………..275cfm

Stock intake manifold with runner

Stock....................198.72 cfm

ACCEL................213.52 cfm

Extrude/ACCEL....217.11 cfm

Super Ram............220.67 cfm

Holley stealth ram …..275cfm

ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet.........251.51 cfm

ACCEL Hi-Flow intake manifold with runner

Stock....................215.83 cfm

ACCEL................232.53 cfm

Extrude/ACCEL....243.21 cfm

Super Ram............240.24 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with 3/8 inch radiused inlet ...............275.83 cfm

Extrude-Honed ACCEL Hi-Flow intake manifold with ACCEL runner ..............266.94 cfm

Edelbrock Performer RPM manifold (Stock)..........286.51 cfm

Edelbrock Victor Jr. ............275.24 cfm

HOLLEY STEALTH RAM

the HOLLEY STEALTH RAM FLOWS at 275cfm out of the box, and has the potential when matched to the correct heads and cam to totally out flow most other intakes available,can easily reach 300cfm with minor port work and costs much less

Stock…………………………… 275cfm

Ported…………………………..300cfm

Runner lengths

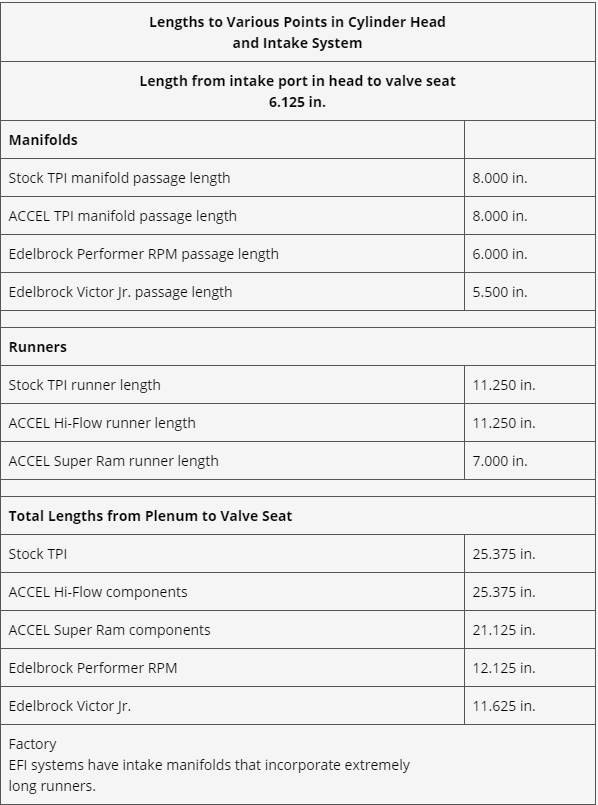

Stock tpi manifold 8” runners 11.25”, cylinder head 6” total 25.25”

Accel super ram manifold 8” runners 7” cylinder head 6” total 21”

Holley stealth ram manifold 6.26” ” cylinder head 6” total 12.26”

Edelbrock performer RPM runners 6” ” cylinder head 6” total 12”

Edelbrock vic jr , runner length 5.5” ” ” cylinder head 6” total 11.5”

while several guys brought up valid points to check, Ive found that the one most commonly over looked in my experience is that the stock exhaust system, is highly restrictive, and the stock fuel delivery system is not adequate,for the potential power, the heads and intake, allowable air flow potential, are all restrictive, and the stock cam timing and lift is already near max as it was designed to produce about 260 hp,and operate at under 5700 rpm, if you try too add an additional 100-200 hp, and 1000rpm-2000rpm to the engines power band, and too the engines output youll quickly find this to be a factor.

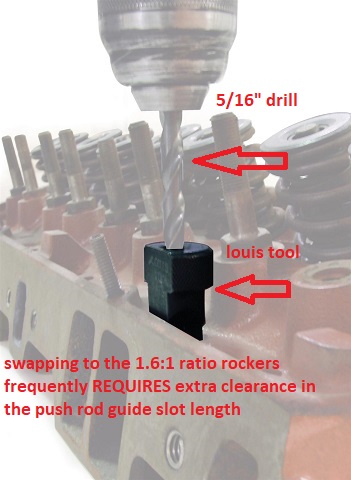

heres a bit of advice! so many times I get called over to help in some project, only to find the problems the guys hoping I can solve could have been avoided entirely ,

if the guy whos at this point is going partially insane, had only bothered to carefully read the details or installation instructions.

many times youll see the guy ordered the wrong part number, and theres a very similar component that exactly matches the concept ,

hes currently waist deep into, only to find the component he ordered is not compatible with the rest of the parts, hes working with.

Ive seen guys order high impedance injectors that are installed on a controller designed for low impedance injectors

http://fuelinjectorclinic.com/faqs

You can

measure the resistance across the two electrical terminals of the

injector. If the resistance is between 1.5 and 4.0 Ohm you have low

impedance injectors. If the resistance is between 8 and 16 Ohm you have high

impedance injectors.

https://www.hotrod.com/articles/hrdp-1211-low-impedance-vs-high-impedance-fuel-injectors/

Low impedance (peak and hold)

injectors have a resistance of

between 2 and 4 ohms.

High impedance(saturated)

injectors have a resistance of

between 10 and 14 ohms.

Low impedance and

high impedance injectors cannot be used interchangeably without modification of the

injector drivers.

What are the differences between low impedance/peak & hold and high impedance/saturated injectors?

The older fat body style low impedance injectors (1.5 to 4.0 Ohm) used to have faster open and close times due to the type of electrical signal pattern emitted by an ECU equipped with proper P&H signal transmitters. This “Peak and Hold” injector signal typically uses a high (4 amp) initial current to open the injector, and which reduces to a lower (1 amp) current to keep the injector open until the pulse ends. Since this method put less total current into the coil, the coil heated up less and was therefore more reliable. Since the “hold” or lower current part of the signal has created a weaker magnetic field, the injector will also close more quickly.

High impedance injectors (10 to 16 Ohm) are triggered by a low (typically around 1.2 amps) constant current signal and kept open by the same constant (saturated) current for the entire cycle. Most OEM injectors today are high impedance injectors being driven by saturated injector signals from the ECU since car manufacturers are most interested in the simpler saturated signal which is more cost effective to produce when building ECU’s, especially where there is no apparent loss of drivability or performance.

https://www.summitracing.com/parts/...MIsMryyOf_3gIVjoTICh1o7wzhEAQYAiABEgKO9fD_BwE

https://www.summitracing.com/parts/...MInIGXief_3gIVy-DICh1rpgH3EAYYAiABEgJLafD_BwE