2Loose

reliable source of info

I've replaced many dozens of alternators and generators over the last 60 years, and this one has me bugged !!

Background, built up a pro street style '58 Chevy pickup in the mid nineties, put it on the road in '98 with a built 502 and solid th400, not much in the way of electrical demand, so just put a pretty standard output alternator, single wire job, on it and it worked just fine for many years...

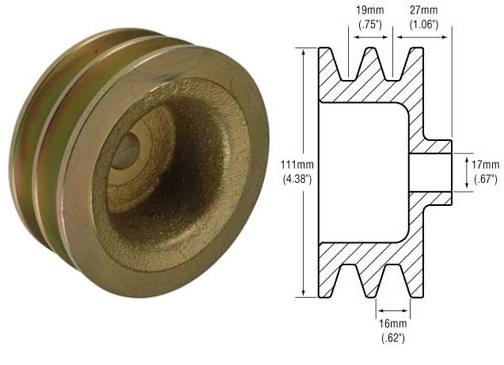

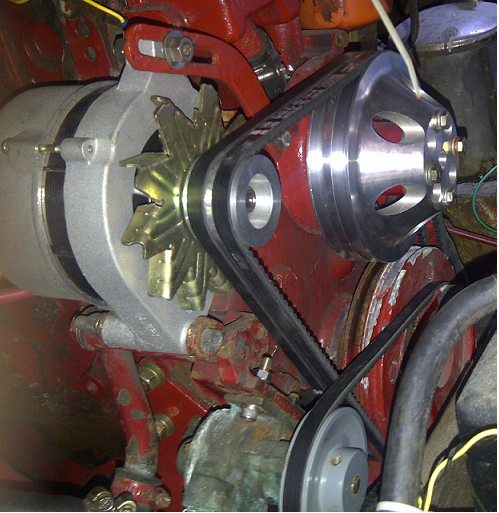

Then the adjustment bracket broke off and the alternator fan self destructed against the rest of the motor. I had a high output alternator on the shelf, so stuck that on after repairing the adjustment bracket. At idle, that alternator produced a lot of output, and the drag on the v-belt down at the motor pulley, was slipping and "screeching". The "screech" was accompanied by a corresponding drop in voltage output, convincing me that the high output alternator was dragging hard enough to cause slippage at the motor pulley. That belt also wrapped around the water pump pulley, so there was only a 1/4 wrap contact of that v-belt at the motor pulley, a quarter wrap at the water pump pulley, and nearly a 3/4 wrap at the alternator. Plus, I think as the new belt wore a bit, it would bottom out on the motor pulley and lose some of it's "grip", and with that heavy load at the alternator at idle, cause the belt to slip at the motor pulley. Put a new v-belt on, and it was fine for a couple of weeks, but as that v-belt wore in it would start slipping at the motor pulley, as indicated by the "screech" accompanied by the drop in voltage.

So I picked up a new Napa standard output single wire alternator and installed it, and got no output! Hmmmm!! Checked out the system, tried an additional ground from the alternator to the block, still no output. Put the high output alternator back on, it had output, and belt screeching, so I took the alternator back to the store and traded it for another one. Guess what, still no output from the second new alternator. Yes, it is a single wire unit, specs include 50 amps, 646 watts, 14.5 volt set point, alternator turn on speed 2,500 rpm, am really puzzled as to what is happening here. The truck had been sitting in the shop for awhile, the battery is showing only 10.5 volts, maybe it needs more to "activate" the alternator ??

Will put the charger on the battery and charge it up for awhile, see if that makes a difference, but I don't remember that ever being a problem in the past, and I have a long history working on these things....

-Willy

Reference my other thread

My Page: '58 truck

Background, built up a pro street style '58 Chevy pickup in the mid nineties, put it on the road in '98 with a built 502 and solid th400, not much in the way of electrical demand, so just put a pretty standard output alternator, single wire job, on it and it worked just fine for many years...

Then the adjustment bracket broke off and the alternator fan self destructed against the rest of the motor. I had a high output alternator on the shelf, so stuck that on after repairing the adjustment bracket. At idle, that alternator produced a lot of output, and the drag on the v-belt down at the motor pulley, was slipping and "screeching". The "screech" was accompanied by a corresponding drop in voltage output, convincing me that the high output alternator was dragging hard enough to cause slippage at the motor pulley. That belt also wrapped around the water pump pulley, so there was only a 1/4 wrap contact of that v-belt at the motor pulley, a quarter wrap at the water pump pulley, and nearly a 3/4 wrap at the alternator. Plus, I think as the new belt wore a bit, it would bottom out on the motor pulley and lose some of it's "grip", and with that heavy load at the alternator at idle, cause the belt to slip at the motor pulley. Put a new v-belt on, and it was fine for a couple of weeks, but as that v-belt wore in it would start slipping at the motor pulley, as indicated by the "screech" accompanied by the drop in voltage.

So I picked up a new Napa standard output single wire alternator and installed it, and got no output! Hmmmm!! Checked out the system, tried an additional ground from the alternator to the block, still no output. Put the high output alternator back on, it had output, and belt screeching, so I took the alternator back to the store and traded it for another one. Guess what, still no output from the second new alternator. Yes, it is a single wire unit, specs include 50 amps, 646 watts, 14.5 volt set point, alternator turn on speed 2,500 rpm, am really puzzled as to what is happening here. The truck had been sitting in the shop for awhile, the battery is showing only 10.5 volts, maybe it needs more to "activate" the alternator ??

-Willy

Reference my other thread

My Page: '58 truck

Last edited by a moderator: