GEAR PULLERS, for me, its a darn love/hate relationship, most of the time if your using the correct design and a quality tool everything goes smoothly and you don,t give it a second thought, but if you don,t know what your doing, if your using a cheap tool or the wrong tool, the potential to screw up expensive components is very high!

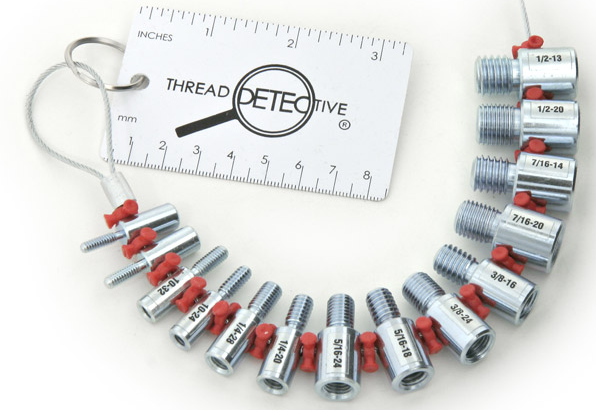

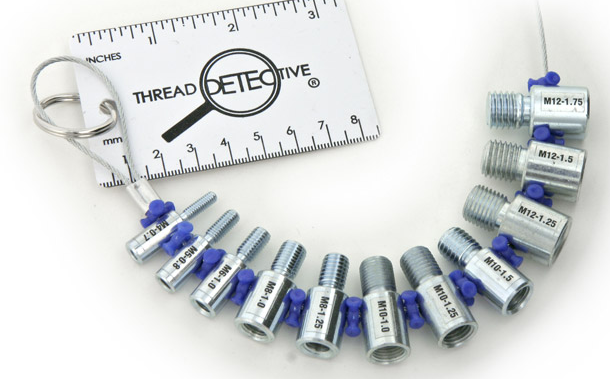

first bit of advice, Id strongly suggest you NEVER waste money on crappy imported Chinese gear pullers they are a total waste of money

EXAMPLE

http://www.atiracing.com/products/dampe ... ctions.htm

I bought this set mostly just to see if there was any chance they were serviceable (but at $23 I really knew better, and I was correct the first puller I used broke withing minutes of force being applied)

http://www.harborfreight.com/three-jaw- ... 69105.html

after you replace a front timing cover seal and before you re-install the damper,

Id suggest installing the new seal, timing chain cover and spraying the contact area on the crank and damper,

where it contacts the crank snout and outer damper to timing chain cover seal surfaces with a decent spray lube, I've always used,

moly spray but there are lots of option's

CAST right into the arms is the word (FORGED STEEL) they are NOT, they are a cheap brittle casting that breaks the first time a significant loads applied, I broke all three the first time I used them on applications that my old SEARS gear pullers smoothly and effectively removed with little effort.

http://www.summitracing.com/parts/pro-66514

or

http://www.summitracing.com/parts/shc-947626

heres a reasonably CHEAP but serviceable sets

Id strongly suggest you buy three jaw style pullers the two arm tend to bend and fold some types of metal pulleys rather than remove them.

http://www.zoro.com/g/Mechanical%20Jaw% ... /00059706/

two arm pullers can ocasionally damage dampers and gears

Three arm pullers are a bit less likely too damage dampers and gears

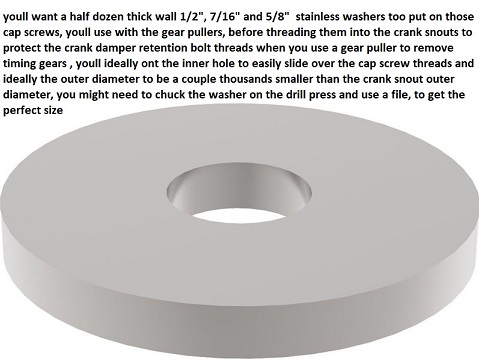

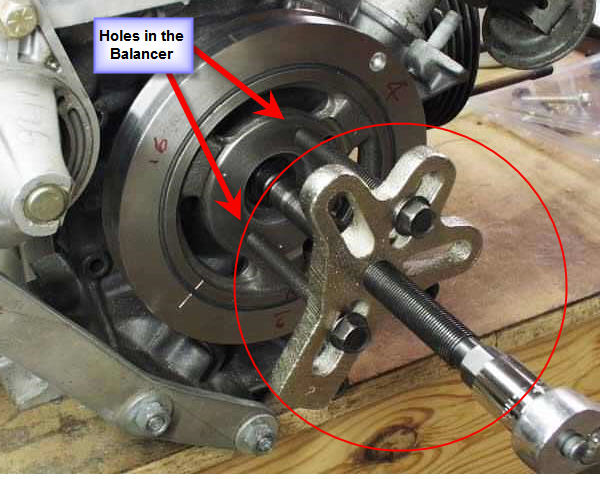

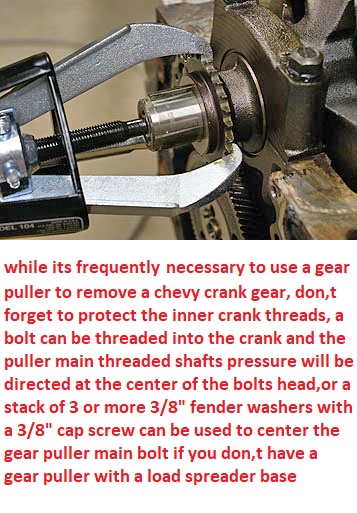

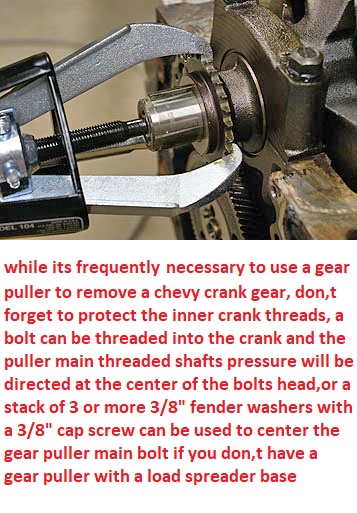

be aware the tools center screw shaft must not be allowed to damage crank threads, leaving a counter sunk crank bolt in the crank snout threads,after removing the retention washer and damper helps prevent crank thread damage, when using a gear puller to remove the crank timing chain gear,

http://www.jegs.com/i/ARP/070/234-2502/10002/-1?parentProductId=744916

http://www.zoro.com/i/G5310295/?category=5268

http://www.zoro.com/i/G5307382/?category=5268

http://www.sears.com/shc/s/p_10153_1260 ... Cookie=Yes

http://www.northerntool.com/webapp/wcs/ ... 3315_13315

https://www.mscdirect.com/browse/tn...-Separators/Pullers-Separators?navid=12104215

decent cheap pullers

http://www.stanleyproto.com/default.asp ... alog=PROTO

http://www.mytoolstore.com/otc/1020.html

keep in mind you NEVER want to center the threaded screw center section , of the puller into the end of a cranks threaded hole or the gear puller shaft will destroy the threaded section, UNLESS youve used a hardened center support between them.

http://www.stanleyproto.com/default.asp ... ement+Part

BTW check out local PAWN SHOPS I see snap-on and MAC gear pullers occasionally and buy any that are reasonably priced

use the correct tool, beating the damper onto the crank frequently damages both the damper and the thrust bearing in the engine

http://www.tavia.com/cat12.html#1

"You put the damper on the crankshaft after oiling the crank snout and inner damper as far as you can get it with a few soft taps of large plastic mallet.

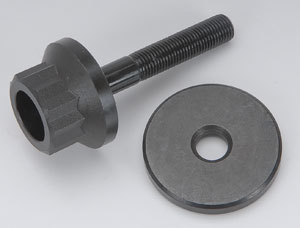

You thread grump's tool into the crankshaft as far as possible.OIL THE THREADS...with the roller bearing against the damper, the washer next, between the nut and roller bearing, then the nut,outer most, you turn the nut forcing the damper on, but be aware the damper generally slides on and the tool makes it fairly easy, so carefully watch as over tightening the tool once the damper bottoms against the cranks shoulder will brake the tool..........the picture depicts the tool set up for a sbc, you'll need to use the larger end and reverse it for the bbc

You then turn the real big nut, and the balancer walks on to the crankshaft

RELATED INFO

viewtopic.php?f=52&t=90

they also make combo puller/installers Proform 66514 - Proform

http://www.jegs.com/webapp/wcs/stores/servlet/product_10001_10002_43866_-1

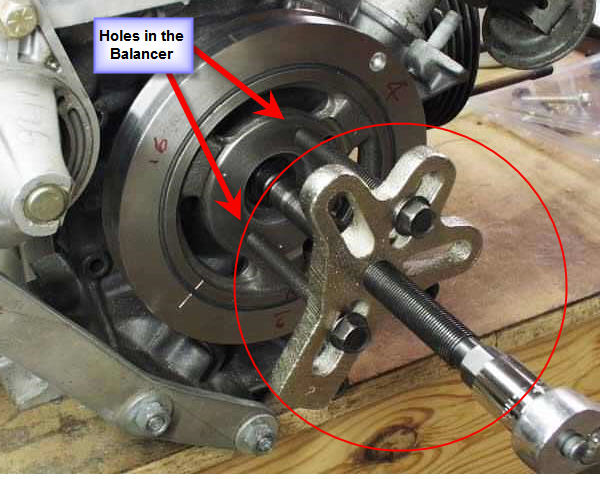

there's a TOOL designed expressly for removing the damper and its NOT a conventional swing jaw type gear puller LIKE THESE

they tend to bind and distort the damper, frequently damaging it

youll need something like this (you can get a cheap version at most auto parts stores for under $40 but the one from summit better quality

http://store.summitracing.com/partdetail.asp?part=PRO-66514&autoview=sku

http://store.summitracing.com/partdetail.asp?part=ATI-918999&autoview=sku

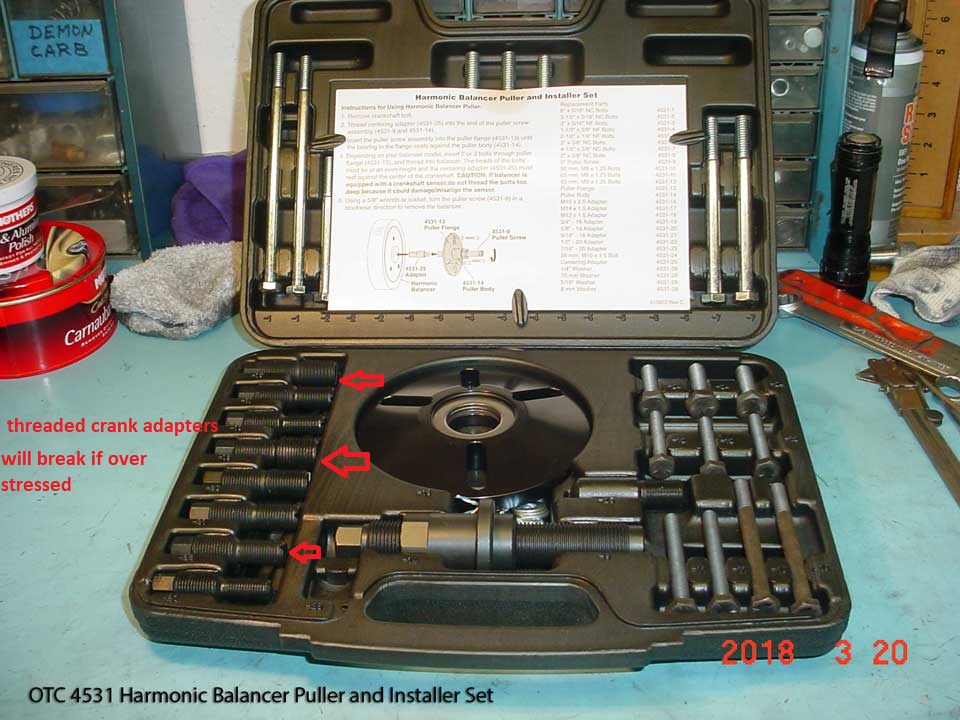

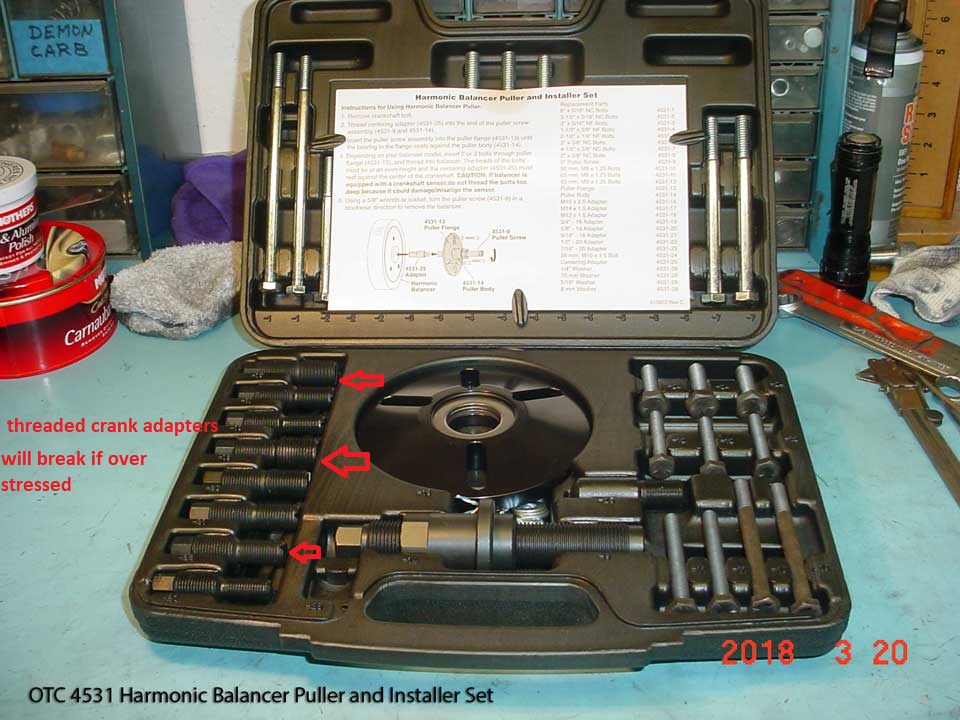

https://www.amazon.com/gp/product/B000F5LIW4/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

link to order replacement parts you may loose or break on that damper tool

https://www.summitracing.com/parts/otc-4531/replacementparts

https://www.amazon.com/gp/product/B000F5LIW4/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

https://www.otctools.com/products/harmonic-balancer-pullerinstaller-set

damn the gal in that video, makes that process, look a whole lot more difficult in the video that it generally is,

and yes its very easily possible to over tighten the interchangeable central adapter screw,parts

if your not careful, and yes they do sell replacement adapter screws

(never lend tools to your friends, or you'll be buying , and replacing those replacement threaded, adapter components)

use moly grease on tool threads

BTW

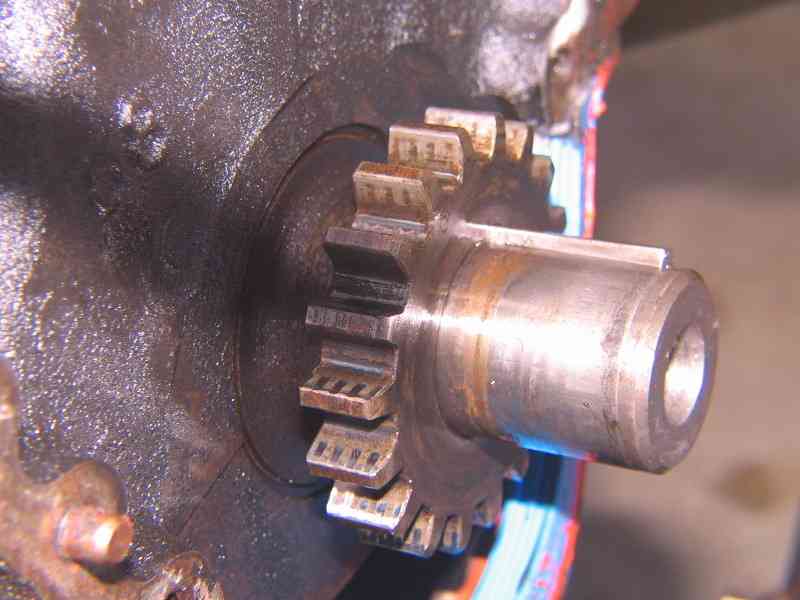

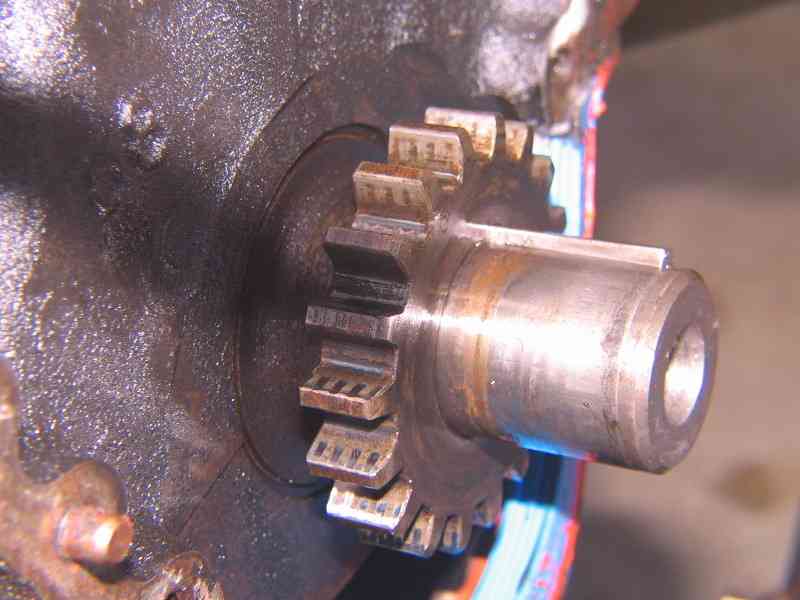

the crank gears requires a 3 or 4 jaw gear puller ,because the two jaw style tends to try and fold/bind the gear into the crank snout, a lighted propane torch applied briefly to heat the crank gear tends to expand & loosen its hold on the crank

http://www.ccohs.ca/oshanswers/safety_h ... llers.html

http://www.tooltopia.com/sunex-tools-39 ... lebase_18u

http://www.tooltopia.com/kd-tools-3624.aspx

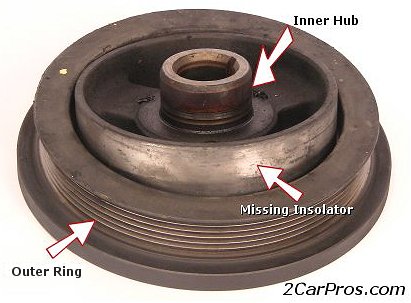

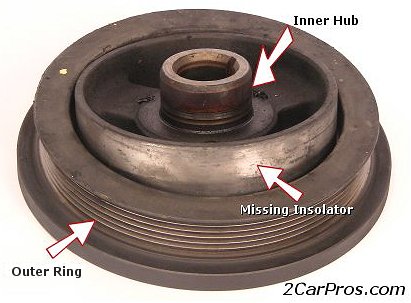

be aware that some damper designs do tend to fail over time!

beating a balancer onto a crank, pulling it with the wrong type of tool, or letting it get fuel or oil soaked can damage a damper, this can easily result in the outer damper ring with the TDC mark rotating to a random location

if your front crank seal leaks, over time it can dissolve the elastic, between the inner and outer damper hub weight, beating on a damper tends to hurt the flex ring seal alsos

first bit of advice, Id strongly suggest you NEVER waste money on crappy imported Chinese gear pullers they are a total waste of money

EXAMPLE

http://www.atiracing.com/products/dampe ... ctions.htm

I bought this set mostly just to see if there was any chance they were serviceable (but at $23 I really knew better, and I was correct the first puller I used broke withing minutes of force being applied)

http://www.harborfreight.com/three-jaw- ... 69105.html

after you replace a front timing cover seal and before you re-install the damper,

Id suggest installing the new seal, timing chain cover and spraying the contact area on the crank and damper,

where it contacts the crank snout and outer damper to timing chain cover seal surfaces with a decent spray lube, I've always used,

moly spray but there are lots of option's

CAST right into the arms is the word (FORGED STEEL) they are NOT, they are a cheap brittle casting that breaks the first time a significant loads applied, I broke all three the first time I used them on applications that my old SEARS gear pullers smoothly and effectively removed with little effort.

http://www.summitracing.com/parts/pro-66514

or

http://www.summitracing.com/parts/shc-947626

heres a reasonably CHEAP but serviceable sets

Id strongly suggest you buy three jaw style pullers the two arm tend to bend and fold some types of metal pulleys rather than remove them.

http://www.zoro.com/g/Mechanical%20Jaw% ... /00059706/

two arm pullers can ocasionally damage dampers and gears

Three arm pullers are a bit less likely too damage dampers and gears

be aware the tools center screw shaft must not be allowed to damage crank threads, leaving a counter sunk crank bolt in the crank snout threads,after removing the retention washer and damper helps prevent crank thread damage, when using a gear puller to remove the crank timing chain gear,

http://www.jegs.com/i/ARP/070/234-2502/10002/-1?parentProductId=744916

http://www.zoro.com/i/G5310295/?category=5268

http://www.zoro.com/i/G5307382/?category=5268

http://www.sears.com/shc/s/p_10153_1260 ... Cookie=Yes

http://www.northerntool.com/webapp/wcs/ ... 3315_13315

https://www.mscdirect.com/browse/tn...-Separators/Pullers-Separators?navid=12104215

decent cheap pullers

http://www.stanleyproto.com/default.asp ... alog=PROTO

http://www.mytoolstore.com/otc/1020.html

keep in mind you NEVER want to center the threaded screw center section , of the puller into the end of a cranks threaded hole or the gear puller shaft will destroy the threaded section, UNLESS youve used a hardened center support between them.

http://www.stanleyproto.com/default.asp ... ement+Part

BTW check out local PAWN SHOPS I see snap-on and MAC gear pullers occasionally and buy any that are reasonably priced

use the correct tool, beating the damper onto the crank frequently damages both the damper and the thrust bearing in the engine

http://www.tavia.com/cat12.html#1

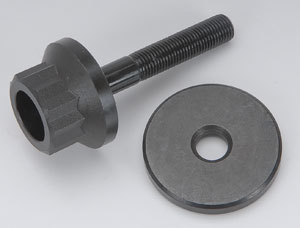

"You put the damper on the crankshaft after oiling the crank snout and inner damper as far as you can get it with a few soft taps of large plastic mallet.

You thread grump's tool into the crankshaft as far as possible.OIL THE THREADS...with the roller bearing against the damper, the washer next, between the nut and roller bearing, then the nut,outer most, you turn the nut forcing the damper on, but be aware the damper generally slides on and the tool makes it fairly easy, so carefully watch as over tightening the tool once the damper bottoms against the cranks shoulder will brake the tool..........the picture depicts the tool set up for a sbc, you'll need to use the larger end and reverse it for the bbc

You then turn the real big nut, and the balancer walks on to the crankshaft

RELATED INFO

viewtopic.php?f=52&t=90

they also make combo puller/installers Proform 66514 - Proform

http://www.jegs.com/webapp/wcs/stores/servlet/product_10001_10002_43866_-1

there's a TOOL designed expressly for removing the damper and its NOT a conventional swing jaw type gear puller LIKE THESE

they tend to bind and distort the damper, frequently damaging it

youll need something like this (you can get a cheap version at most auto parts stores for under $40 but the one from summit better quality

http://store.summitracing.com/partdetail.asp?part=PRO-66514&autoview=sku

http://store.summitracing.com/partdetail.asp?part=ATI-918999&autoview=sku

https://www.amazon.com/gp/product/B000F5LIW4/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

link to order replacement parts you may loose or break on that damper tool

https://www.summitracing.com/parts/otc-4531/replacementparts

https://www.amazon.com/gp/product/B000F5LIW4/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1

https://www.otctools.com/products/harmonic-balancer-pullerinstaller-set

damn the gal in that video, makes that process, look a whole lot more difficult in the video that it generally is,

and yes its very easily possible to over tighten the interchangeable central adapter screw,parts

if your not careful, and yes they do sell replacement adapter screws

(never lend tools to your friends, or you'll be buying , and replacing those replacement threaded, adapter components)

use moly grease on tool threads

BTW

the crank gears requires a 3 or 4 jaw gear puller ,because the two jaw style tends to try and fold/bind the gear into the crank snout, a lighted propane torch applied briefly to heat the crank gear tends to expand & loosen its hold on the crank

http://www.ccohs.ca/oshanswers/safety_h ... llers.html

http://www.tooltopia.com/sunex-tools-39 ... lebase_18u

http://www.tooltopia.com/kd-tools-3624.aspx

be aware that some damper designs do tend to fail over time!

beating a balancer onto a crank, pulling it with the wrong type of tool, or letting it get fuel or oil soaked can damage a damper, this can easily result in the outer damper ring with the TDC mark rotating to a random location

if your front crank seal leaks, over time it can dissolve the elastic, between the inner and outer damper hub weight, beating on a damper tends to hurt the flex ring seal alsos

Last edited by a moderator: