55C150

Well-Known Member

OK yesterday my girlfriend, my daughter and me did a 21 hours trip to the netherlands and back to pick up a 1961 Chevrolet Corvair 95 Rampside Truck.

The truck has a V8 middle engine conversion. It is a 300 cui Buick engine with an unknown auto trans. Rear end is a 55-64 with leaf springs, like my 55 150 chevy, but without the Posi Trac.

It is my girlfriends truck, she felt in love the first minute she saw the truck in the Internet.

It is a project truck. The body is in good condition, but the V8 conversion was build not so good.

The truck needs new suspension, electric, steering parts, side windows.

We want to get the truck 1 or 2" lower, I want the engine / trans hanging a bit lower.

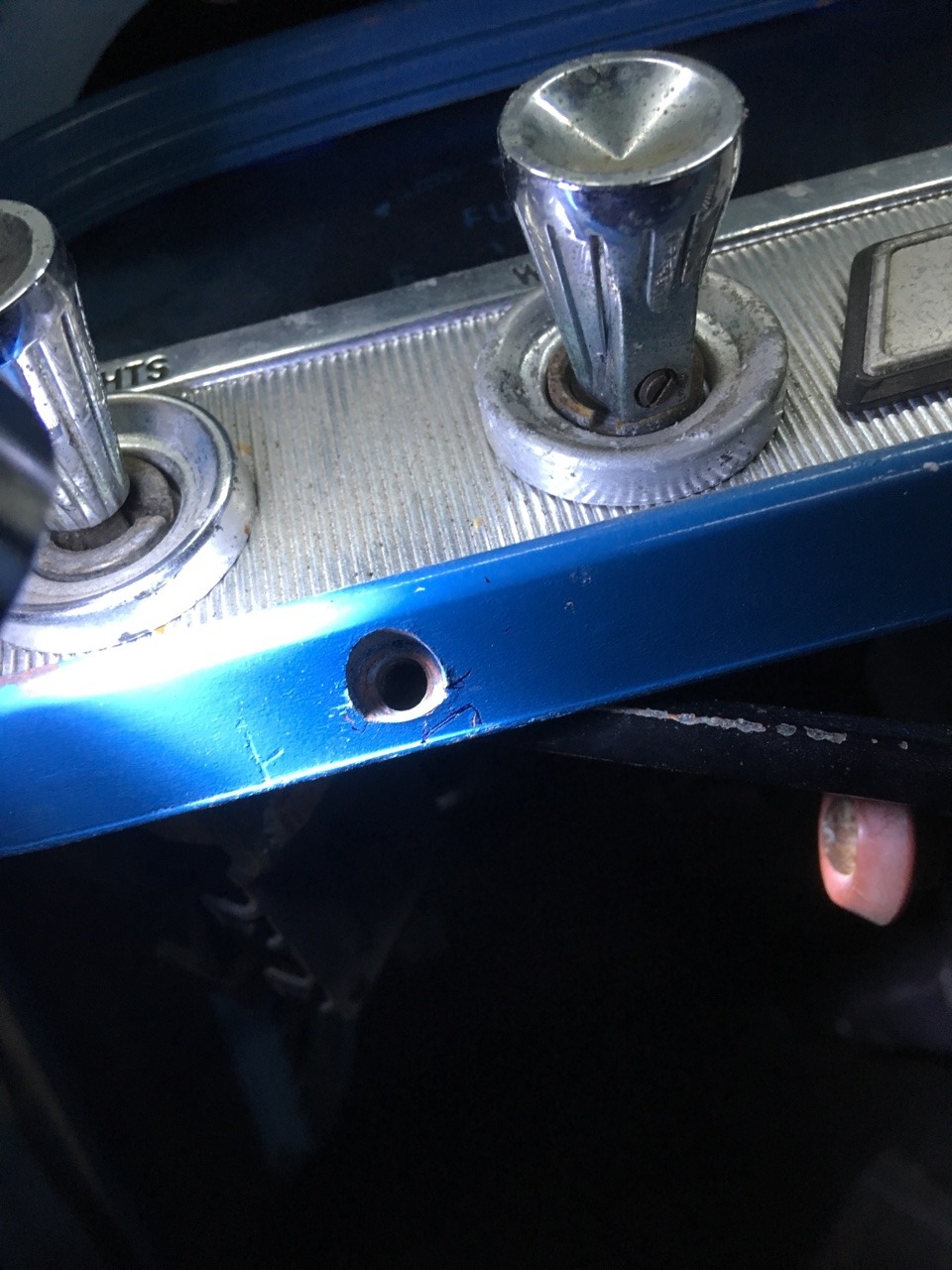

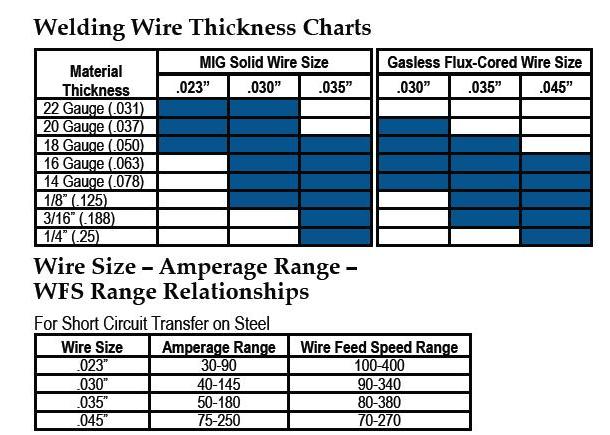

I have to rework the engine and trans mounts, emergency brake, brake lines, stiffen the chassis and welding some small holes.

Maybe I do a disc brake conversion in the front. For safety issues I will put a two circuit master cylinder in it.

My girlfriend dont want the monster shifter in it, she wants a shorter version.

The truck has a V8 middle engine conversion. It is a 300 cui Buick engine with an unknown auto trans. Rear end is a 55-64 with leaf springs, like my 55 150 chevy, but without the Posi Trac.

It is my girlfriends truck, she felt in love the first minute she saw the truck in the Internet.

It is a project truck. The body is in good condition, but the V8 conversion was build not so good.

The truck needs new suspension, electric, steering parts, side windows.

We want to get the truck 1 or 2" lower, I want the engine / trans hanging a bit lower.

I have to rework the engine and trans mounts, emergency brake, brake lines, stiffen the chassis and welding some small holes.

Maybe I do a disc brake conversion in the front. For safety issues I will put a two circuit master cylinder in it.

My girlfriend dont want the monster shifter in it, she wants a shorter version.