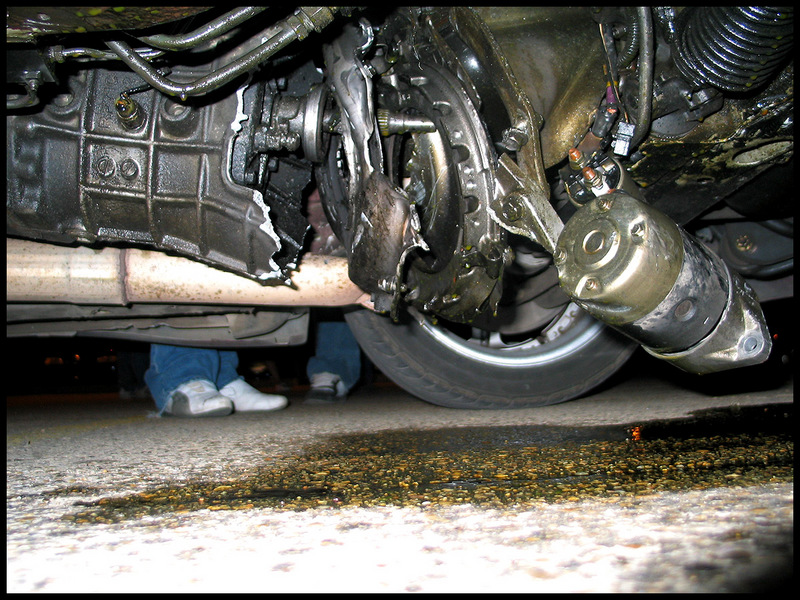

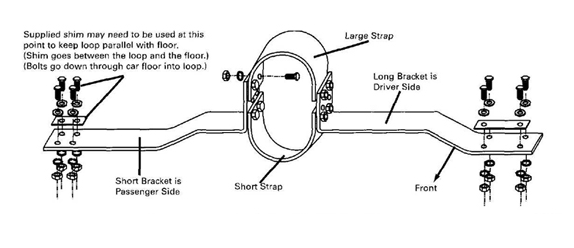

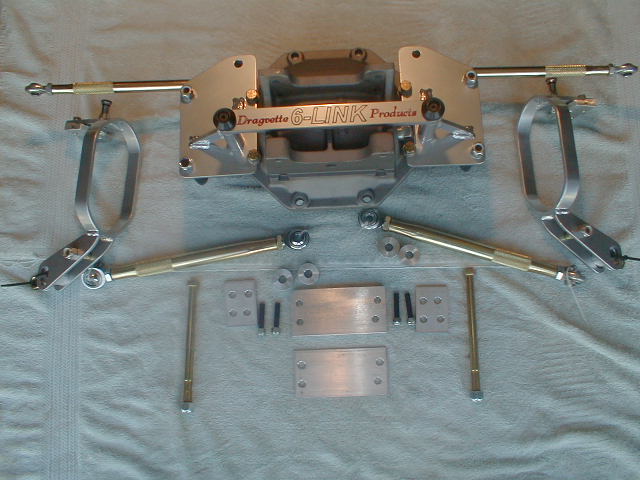

they come in a hundered designs but its important, to keep the drive shaft from dropping under the car if a u-joint fails

EXAMPLES

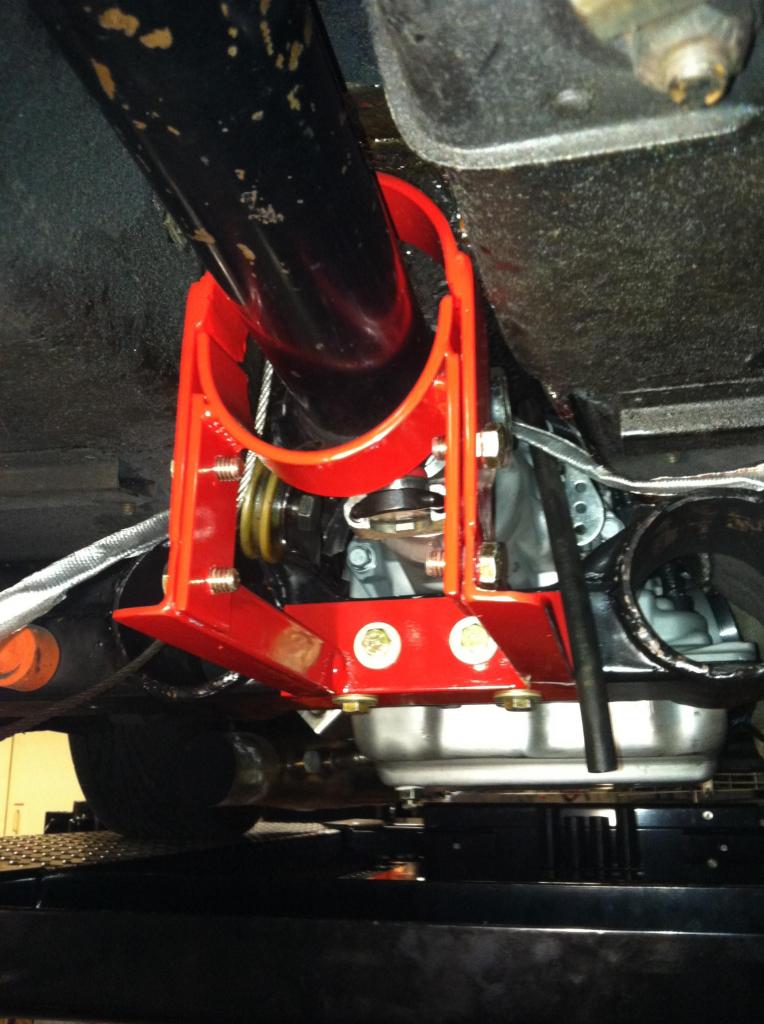

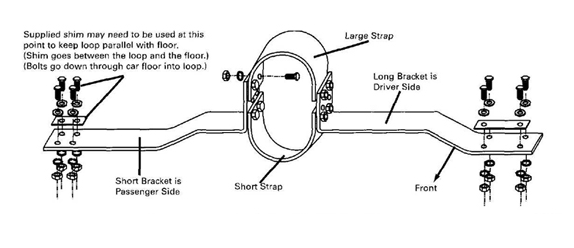

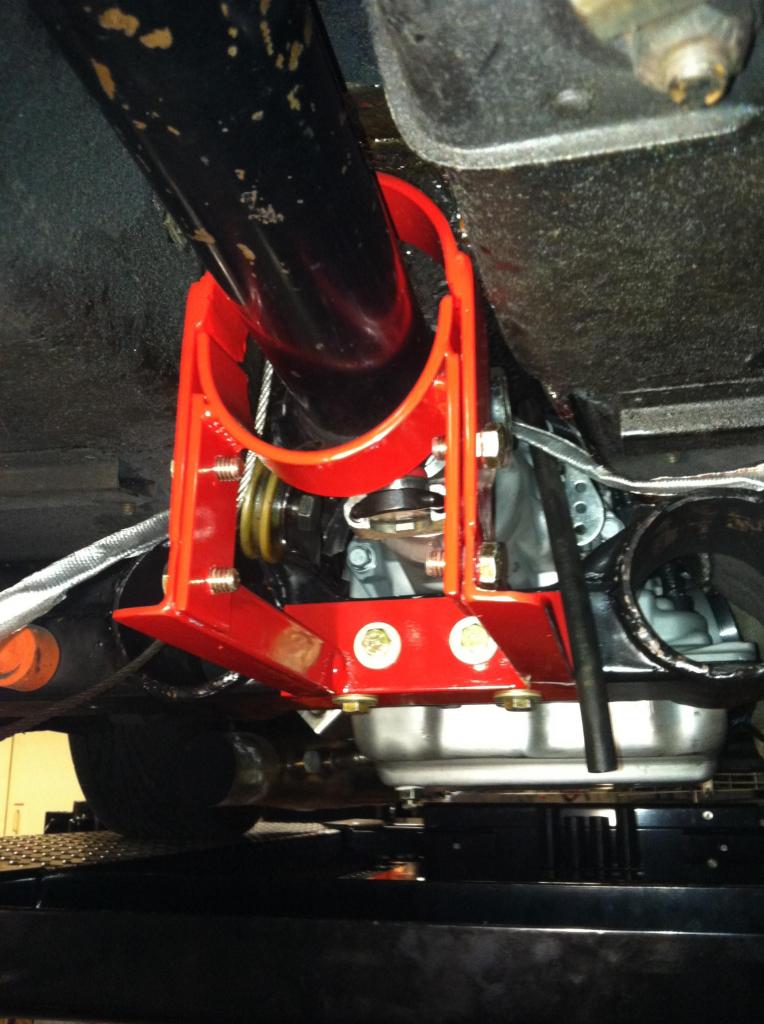

Most tracks require driveshaft safety loops for ET's quicker than 12.99 or 13.99 in the quarter. BMR's NHRA legal safety loop for the 2004-06 GTO welds onto the factory floorpan reinforcement and has locating holes for proper positioning. Two piece design allows installation without removing driveshaft and will fit driveshaft diameters up to 3.5". Available in Black Hammertone or red powdercoat

http://www.fordmuscle.com/forums/tech-e ... ation.html

http://www.thrashdriveshaft.com/

http://www.afterthoughtsauto.com/gto-loop.html

http://home.fuse.net/fastmonte/DSSL4Gbodies.htm

http://www.dragvette.com/

http://www.dragvette.com/irs_build_up.htm

http://www.eastcoastsupercharging.com/h ... haft_loops

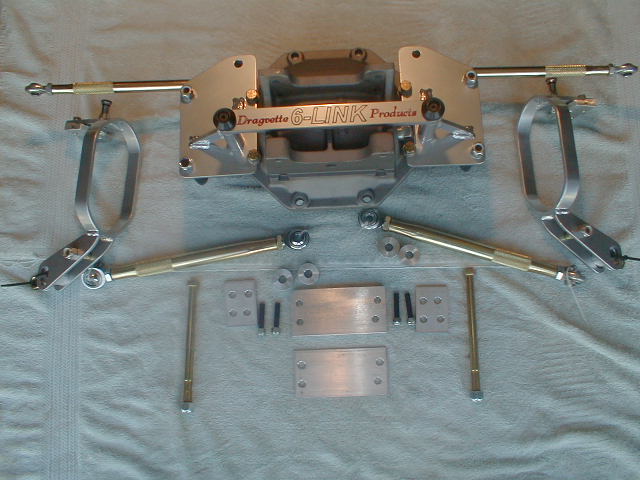

OBVIOUSLY youll want different designs for various applications, and having access to a welder, and a drill press or mill, and minimal fabrication skill can save you time and money

EXAMPLES

Most tracks require driveshaft safety loops for ET's quicker than 12.99 or 13.99 in the quarter. BMR's NHRA legal safety loop for the 2004-06 GTO welds onto the factory floorpan reinforcement and has locating holes for proper positioning. Two piece design allows installation without removing driveshaft and will fit driveshaft diameters up to 3.5". Available in Black Hammertone or red powdercoat

http://www.fordmuscle.com/forums/tech-e ... ation.html

http://www.thrashdriveshaft.com/

http://www.afterthoughtsauto.com/gto-loop.html

http://home.fuse.net/fastmonte/DSSL4Gbodies.htm

http://www.dragvette.com/

http://www.dragvette.com/irs_build_up.htm

http://www.eastcoastsupercharging.com/h ... haft_loops

OBVIOUSLY youll want different designs for various applications, and having access to a welder, and a drill press or mill, and minimal fabrication skill can save you time and money

Last edited by a moderator: