You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How much boost can a 6L LS truck short-block take?

- Thread starter Maniacmechanic1

- Start date

Maniacmechanic1

solid fixture here in the forum

Home

Super Chevy

How To

Engines & Drivetrain

How much boost can a 6L LS truck short-block take?

Breaking Point

Richard Holdener Nov 28, 2017

Share

View Full Gallery

View Full Gallery

If you are new to the LS scene or haven’t spent much time online, or at events, or near other LS owners, you might have missed the first or second “big bangs.” Originally, the big bang test was designed to find the absolute boost and/or power limit of the factory LS short-block. With drag racers out there laying down some pretty impressive numbers using stock short-blocks, we wanted to find the absolute power limit of the LS platform. Armed with a 4.8L back in 2011 for Hot Rod, we subjected it to some minor top-end mods and a pair of turbos to the tune of over 1,200 hp. We followed that exercise up with the same program on the larger (and more popular) 5.3L for Truckin magazine. The combination of lessons learned and increased displacement allowed us to push the 5.3L over 1,300 hp before things went south. Having run both the 4.8L and 5.3L, this left only the iron 6.0L yet to be tested. Well my friends, that day has come and we finally got the chance to give a Gen III 6.0L LQ4 the old big bang treatment.

Before we get to the test, know that the larger 6.0L had a great many strikes against it, at least according to the Internet. The 5.3L was by far the favorite among turbo LS owners, due no doubt to the combination of reduced cost and tremendous availability. GM produced millions of 5.3L LM7s (and its variants), but the larger 6.0Ls were (relatively speaking) few and far between. One need only peruse eBay, local wrecking yards, or even Craigslist to see the difference in pricing and availability between the two. Pricing aside, according to online rumblings, the bigger bore used on the 6.0L (4.00 vs 3.78) also made it less desirable from a head gasket sealing standpoint. The theory was that the larger bores reduced both cylinder wall thickness and the sealing surface between cylinders—both bad for high-boost, turbo applications. Never mind all the other engine combinations that run elevated boost and power levels with considerably less sealing surface between cylinders, this folklore eventually became the law of the land. As such, prospective turbo LS owners tended to steer clear of the 6.0L for fear of head gasket or cylinder wall issues.

We decided to test the strength of the iron 6.0L for ourselves. After all, we were also told the stock powdered metal rods on the 4.8L and 5.3L wouldn’t last past 8 psi of boost and the stock pistons were going to break on the first hit. We know the stock, cast components (used in the truck engines) were never designed by GM to withstand the rigors of even minor boost, let alone the levels we had planned. That said, so far, the GM guys have been able to hold their heads pretty high, as 1,200 hp from the 4.8L and 1,300 hp from the 5.3L, are certainly nothing to scoff at. It was with these results in hand that we subjected our 6.0L to the big bang treatment. The procedure was a simple one. Locate a suitable, used, high-mileage (running) engine, increase the ring gap, and then throw in a ball hone and a deck surface. After this minor amount of prep, we’d toss in a good cam, ported heads, and the right intake. Then, sprinkle with the right amount of boost from a pair of sizable turbos. Using race gas and the proper tune, just crank up the boost until something pops. Easy-peasy, right?

The 6.0L used for this adventure came from a 2000 Suburban that had 247,000 miles on the clock. This early Gen III engine was sporting iron heads of all things. The engine was a runner (we ran it on the dyno prior to disassembly), but was taken apart and given a onceover, which consisted of a thorough cleaning, ball hone, and surface deck to ensure sealing under boost (remember those pesky head-gasket problems). Every part of the original short-block was reused, including the original pistons rings, which were given increased ring gap, from 0.022-0.032 inch. The stock 6.0L short-block was then treated to a new cam from Brian Tooley Racing, a set of CNC-ported 317 heads (factory aluminum 6.0L truck heads), and a Holley Hi-Ram intake. Also present was a set of factory LS9 (MLS) head gaskets, ARP head studs, and a Holley 105mm throttle body. The 120-pound injectors used on the Hi-Ram were controlled by a Holley HP management system. The engine was first run in naturally aspirated trim. So equipped, the Big-Bang 6.0L produced 529 hp at 6,800 rpm and 457 lb-ft of torque at 5,100 rpm. Now it was time for boost.

For those wondering why we chose to modify any components on what was essentially a strength test of the internal components, the answer is a simple one. Boost applied to an engine is simply a multiplier. The power output of any turbocharged engine is a function of the power output of the naturally aspirated engine multiplied by the boost pressure (pressure ratio). Your naturally aspirated engine is actually running at an atmospheric pressure of 14.5 psi. If you double this atmospheric pressure (by supplying boost from a turbo or blower), you can theoretically double the power output. On our 529hp 6.0L, this meant we could generate as much as 1,058 hp at 14.5 psi of boost, if everything went according to the formula (and the engine survived). This formula works regardless of the original power output. If we were to run the 6.0L in stock trim, the resulting power output would be around 400 hp (on this dyno the way we test). If we apply 14.5 psi from our turbos to the stock 400hp engine, we might get 800 hp. Having a more powerful naturally aspirated engine allowed us to produce more power with the turbos at any given boost level. More than just the boost limit of the Big-Bang engine, we wanted a big power number to go along with it. Big power is exactly what we got.

Recommended videos

Powered by AnyClip

Recommended videos

Powered by AnyClip

Now Playing

Air Intake Systems

eBay Motors - Connected Car

eBay Motors Tire Installation

Ebay Motors Brakes

FAST for Week To Wicked C10

Hot Rod Week to Wicked Day 2 Recap

With the Big-Bang 6.0L primed and ready for action, it was time we added some boost. Rather than go with the same turbos from CXRacing used on the previous two Big-Bang adventures, we stepped up to some serious hardware. John Bewley over at Lil John’s Motorsport Solutions hooked us up with a pair of BorgWarner S475 turbos. Capable of supporting nearly 1,000 hp each, the T4 turbos featured 83mm turbines and 1.0 A/Rs. For this application we were less interested in boost response and more in efficiency. As it turned out, the backpressure registered during testing was always less than boost pressure by 5-7 psi, a sure sign of an efficient system. The turbos were fed by a pair of stainless turbo manifolds from DNA and custom 90-degree bends that included both the T4 turbo and 45mm wastegate flanges. To control the boost, we installed a pair of Turbosmart Hyper-Gate45 wastegates along with one of their manual wastegate controllers and a variety of springs. The turbo system also featured a dual-core, air-to-water intercooler from CXRacing (used on the two previous Big-Bang tests). For the higher boost levels, we plumbed the system for ice water using a Meziere electric water pump. Fuel was supplied to the 120-pound injectors from an Aeromotive Eliminator pump augmented by a 17V Kenne Bell Boost-a-Pump. Using this system and a boost-referenced fuel-pressure regulator (from Aeromotive), the fuel pressure was rock steady and increased in relation to boost. All testing was run on 118-octane Rockett Brand race fuel.

2/23

2/23

The Big Bang 6.0L started out life as a Gen III iron block from a 2000 Chevy Suburban. The block was surfaced to ensure proper head gasket sealing and given a light ball hone.

3/23

3/23

The stock Gen III rods and LQ4 dished pistons were reused. After all, with only 247,000 miles logged, they were still mint.

4/23

4/23

The one change we did make was to substantially increase the ring gap on the factory rings (yes, we reused the 247,000-mile rings) from 0.022 to 0.032 inch. We gapped the rings using this trick ring-gap tool from Total Seal Rings.

5/23

5/23

Looking to make a big number along with the big boost, we installed a Stage 3 Turbo camshaft from Brian Tooley Racing. The dedicated turbo cam featured a 0.609/0.610-inch lift split, a 230/235-degree duration split, and 114+4-degree LSA. The right cam can yield huge power gains, especially once you crank the boost up.

6/23

6/23

Once cammed up with extra ring gap, the short-block was prepped with a set of LS9 head gaskets and ARP head studs.

7/23

7/23

Topping the 6.0L short-block was a set of Stage 2, CNC-ported heads from Total Engine Airflow (TEA). The CNC program was applied to the intake and exhaust ports (shown), as well as the all-important bowl area.

8/23

8/23

Only minor work was performed to the combustion chambers, but the already sizable chambers helped keep the static compression ratio in the safety zone.

9/23

9/23

The TEA heads were assembled with a dual valvespring package that provided both adequate coil-bind clearance and plenty of pressure for the combination of rpm and boost we planned to run.

10/23

10/23

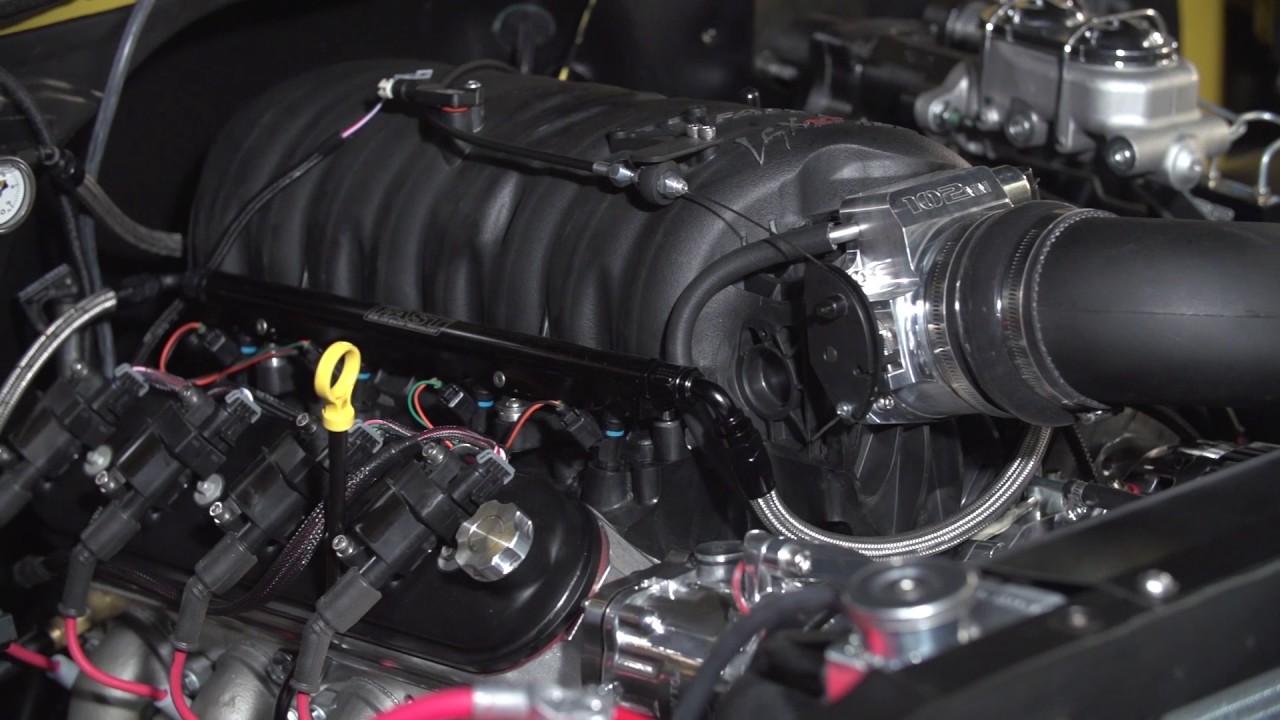

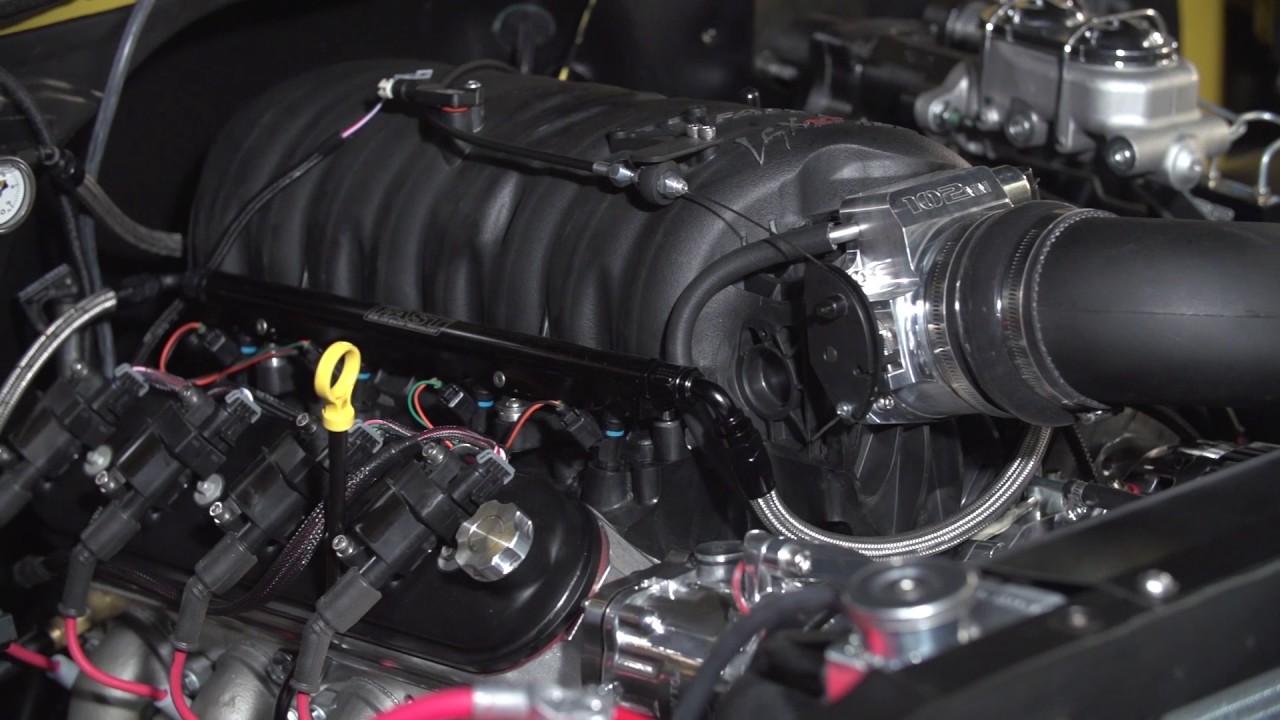

To optimize power production higher in the rev range we enlisted the aid of a Holley Hi-Ram intake manifold combined with a 105mm Holley throttle body.

11/23

11/23

To ensure adequate fuel delivery, we installed a set of 120-pound Holley injectors fed by an Aeromotive fuel pump. The pump was augmented by a 17-volt Kenne Bell Boost-a-Pump.

12/23

12/23

Since the proper air/fuel ratio and timing values were critical on a twin-turbo combination, we relied on a Holley HP management system.

13/23

13/23

Before adding boost, we ran the modified 6.0L LQ4 engine on the dyno in naturally aspirated trim. The 6.0L produced 529 hp at 6,800 rpm and 457 lb-ft of torque at 5,100 rpm.

14/23

14/23

After the initial dyno test, we replaced the long-tube headers with the turbo components. The stainless turbo headers were used to feed a pair of 90-degree bends that included the T4 turbo and wastegate flanges. We relied on 4-inch sections of tubing to allow exhaust to escape. Note the oxygen sensor and stainless steel fitting with coiled aluminum tubing used to measure backpressure before the turbo.

15/23

15/23

Boost was supplied by a pair of BorgWarner S475 turbos from John Bewley at Lil John’s Motorsport Solutions. Capable of supporting nearly 1,000 hp each, the turbos were plenty capable of putting the big bang on our 6.0L.

16/23

16/23

Though available with a larger T6 housing, we elected to run a pair of smaller T4 housings (1.0 A/R) in conjunction with our 83mm turbine wheels.

17/23

17/23

Boost is useless without control, especially when you have the ability to easily overwhelm the combination. Keeping the boost in check was a pair of 45mm Turbosmart Hyper-Gate45 wastegates. We also relied on one of their manual wastegate controllers and additional wastegate springs to dial up the boost pressure.

18/23

18/23

Since elevated boost was in the cards, we installed an air-to-water intercooler in the mix. At the higher boost levels, we ran ice water through the system using a 10-gallon cell and Meziere electric water pump.

19/23

19/23

Since elevated boost was in the cards, we installed an air-to-water intercooler in the mix. At the higher boost levels, we ran ice water through the system using a 10-gallon cell and Meziere electric water pump.

20/23

20/23

After the turbo system was up and running, we snuck up on the terminal boost pressure. The twin-turbo 6.0L made multiple passes near the 1,000hp mark, but we eventually started cranking up the boost. At 14.6 psi it produced 1,054 hp, while 20 psi pushed things up to 1,277 hp. At 25.3 psi it was up to 1,435 hp, but the big bang came at 28.5 psi and 1,482.7 hp. The engine was on track to easily exceed 1,500 hp, but one of the sissy Gen III connecting rods called it quits.

21/23

21/23

The cracked oil pan and blown-out windage tray only hinted at the carnage within the dearly departed 6.0L block. Still, making 1,483 hp at 28.5 psi is pretty damn impressive. Now we’re curious how far we could take a set of Gen IV LS rods.

22/23

22/23

Before we cranked up the boost to a big bang level, we made pulls at lower boost levels. Equipped with the TEA Stage 2 317 heads, BTR Stage 3 turbo cam, and Holley Hi-Ram intake, the naturally aspirated 6.0L produced 529 hp and 457 lb-ft of torque. After the application of boost from the twin BorgWarner S475s, the power jumped to 914 hp at 10.8 psi, 974 hp at 12.9 psi, and 1,054 hp at 14.6 psi. Making these numbers all the more impressive was the fact that they came without the use of ice water in the intercooler.

23/23

23/23

Things got serious once we plumbed the system for ice water. Cranking up the boost to an even 20 psi brought 1,277 hp, while 22 psi brought 1,343 hp. After dialing in another 3.3 psi for a total of 25.3 psi, the twin-turbo 6.0L produced 1,435 hp and 1,240 lb-ft of torque. The final step up to 28.5 psi brought 1,482.7 hp, 1,330 lb-ft, and the end of the Big-Bang 6.0L. In the end, it was a Gen III connecting rod that let go, which begs the question, shouldn’t we now run the same test on a Gen IV 6.0L with the stronger rods?

Photos by Richard Holdener

Sources

Comp Cams

Memphis, TN 38118

901-795-2400

http://www.compcams.com

Turbosmart

Rancho Cucamonga, CA 91730

909-476-2570

www.turbosmartusa.com

FAST

Memphis, TN 38118

877-334-8355

http://www.fuelairspark.com

Brian Tooley Racing

888-959-8335

www.briantooleyracing.com

Total Seal

Phoenix, AZ

(800) 874-2753

totalseal.com

Kenne Bell Enterprises

Rancho Cucamonga, CA 91730

909-941-0985

www.kennebell.net

ARP

Ventura, CA 93003

800-826-3045

arpdiesel.com

CXRacing

626-575-3288

http://www.CXRacing.com

DNA Motoring

626-965-8898

www.dnamotoring.com

Lil John’s Motorsport Solutions

888-583-4408

liljohnsmotorsports.com

Holley/Hooker

270-781-9741

www.holley.com

MORE PHOTOS

VIEW FULL GALLERY

Sponsored Content

LINCOLN NAUTILUS: LUXURY & ELEGANCE UNDERPINNED WITH TECH

By Lincoln

In a luxury mid-size crossover segment awash with alphanumeric nomenclature, the wonderfully...

Sponsored Content

Sponsored Content

Connect With Us

Get Latest News and Articles. Newsletter Sign Up

recent how to articles

Fixing Anti-Lock Brake Electrical System on 2001-2004 Corvettes

New Products to Keep Your Chevy Running and Looking Great

How to Rebuild a Holley 4150 780-cfm Carburetor

QA1 and Eaton Detroit Spring First-Gen Camaro Suspension Upgrade

Chevy High Performance 2018 Holiday Gift Guide

sponsored links

Sponsored Content

subscribe to the magazine

Subscribe and Save 74% off the Cover Price!

get digital get print

Super Chevy

How To

Engines & Drivetrain

How much boost can a 6L LS truck short-block take?

Breaking Point

Richard Holdener Nov 28, 2017

Share

View Full Gallery

View Full GalleryIf you are new to the LS scene or haven’t spent much time online, or at events, or near other LS owners, you might have missed the first or second “big bangs.” Originally, the big bang test was designed to find the absolute boost and/or power limit of the factory LS short-block. With drag racers out there laying down some pretty impressive numbers using stock short-blocks, we wanted to find the absolute power limit of the LS platform. Armed with a 4.8L back in 2011 for Hot Rod, we subjected it to some minor top-end mods and a pair of turbos to the tune of over 1,200 hp. We followed that exercise up with the same program on the larger (and more popular) 5.3L for Truckin magazine. The combination of lessons learned and increased displacement allowed us to push the 5.3L over 1,300 hp before things went south. Having run both the 4.8L and 5.3L, this left only the iron 6.0L yet to be tested. Well my friends, that day has come and we finally got the chance to give a Gen III 6.0L LQ4 the old big bang treatment.

Before we get to the test, know that the larger 6.0L had a great many strikes against it, at least according to the Internet. The 5.3L was by far the favorite among turbo LS owners, due no doubt to the combination of reduced cost and tremendous availability. GM produced millions of 5.3L LM7s (and its variants), but the larger 6.0Ls were (relatively speaking) few and far between. One need only peruse eBay, local wrecking yards, or even Craigslist to see the difference in pricing and availability between the two. Pricing aside, according to online rumblings, the bigger bore used on the 6.0L (4.00 vs 3.78) also made it less desirable from a head gasket sealing standpoint. The theory was that the larger bores reduced both cylinder wall thickness and the sealing surface between cylinders—both bad for high-boost, turbo applications. Never mind all the other engine combinations that run elevated boost and power levels with considerably less sealing surface between cylinders, this folklore eventually became the law of the land. As such, prospective turbo LS owners tended to steer clear of the 6.0L for fear of head gasket or cylinder wall issues.

We decided to test the strength of the iron 6.0L for ourselves. After all, we were also told the stock powdered metal rods on the 4.8L and 5.3L wouldn’t last past 8 psi of boost and the stock pistons were going to break on the first hit. We know the stock, cast components (used in the truck engines) were never designed by GM to withstand the rigors of even minor boost, let alone the levels we had planned. That said, so far, the GM guys have been able to hold their heads pretty high, as 1,200 hp from the 4.8L and 1,300 hp from the 5.3L, are certainly nothing to scoff at. It was with these results in hand that we subjected our 6.0L to the big bang treatment. The procedure was a simple one. Locate a suitable, used, high-mileage (running) engine, increase the ring gap, and then throw in a ball hone and a deck surface. After this minor amount of prep, we’d toss in a good cam, ported heads, and the right intake. Then, sprinkle with the right amount of boost from a pair of sizable turbos. Using race gas and the proper tune, just crank up the boost until something pops. Easy-peasy, right?

The 6.0L used for this adventure came from a 2000 Suburban that had 247,000 miles on the clock. This early Gen III engine was sporting iron heads of all things. The engine was a runner (we ran it on the dyno prior to disassembly), but was taken apart and given a onceover, which consisted of a thorough cleaning, ball hone, and surface deck to ensure sealing under boost (remember those pesky head-gasket problems). Every part of the original short-block was reused, including the original pistons rings, which were given increased ring gap, from 0.022-0.032 inch. The stock 6.0L short-block was then treated to a new cam from Brian Tooley Racing, a set of CNC-ported 317 heads (factory aluminum 6.0L truck heads), and a Holley Hi-Ram intake. Also present was a set of factory LS9 (MLS) head gaskets, ARP head studs, and a Holley 105mm throttle body. The 120-pound injectors used on the Hi-Ram were controlled by a Holley HP management system. The engine was first run in naturally aspirated trim. So equipped, the Big-Bang 6.0L produced 529 hp at 6,800 rpm and 457 lb-ft of torque at 5,100 rpm. Now it was time for boost.

For those wondering why we chose to modify any components on what was essentially a strength test of the internal components, the answer is a simple one. Boost applied to an engine is simply a multiplier. The power output of any turbocharged engine is a function of the power output of the naturally aspirated engine multiplied by the boost pressure (pressure ratio). Your naturally aspirated engine is actually running at an atmospheric pressure of 14.5 psi. If you double this atmospheric pressure (by supplying boost from a turbo or blower), you can theoretically double the power output. On our 529hp 6.0L, this meant we could generate as much as 1,058 hp at 14.5 psi of boost, if everything went according to the formula (and the engine survived). This formula works regardless of the original power output. If we were to run the 6.0L in stock trim, the resulting power output would be around 400 hp (on this dyno the way we test). If we apply 14.5 psi from our turbos to the stock 400hp engine, we might get 800 hp. Having a more powerful naturally aspirated engine allowed us to produce more power with the turbos at any given boost level. More than just the boost limit of the Big-Bang engine, we wanted a big power number to go along with it. Big power is exactly what we got.

Recommended videos

Powered by AnyClip

Recommended videos

Powered by AnyClip

Now Playing

Air Intake Systems

eBay Motors - Connected Car

eBay Motors Tire Installation

Ebay Motors Brakes

FAST for Week To Wicked C10

Hot Rod Week to Wicked Day 2 Recap

With the Big-Bang 6.0L primed and ready for action, it was time we added some boost. Rather than go with the same turbos from CXRacing used on the previous two Big-Bang adventures, we stepped up to some serious hardware. John Bewley over at Lil John’s Motorsport Solutions hooked us up with a pair of BorgWarner S475 turbos. Capable of supporting nearly 1,000 hp each, the T4 turbos featured 83mm turbines and 1.0 A/Rs. For this application we were less interested in boost response and more in efficiency. As it turned out, the backpressure registered during testing was always less than boost pressure by 5-7 psi, a sure sign of an efficient system. The turbos were fed by a pair of stainless turbo manifolds from DNA and custom 90-degree bends that included both the T4 turbo and 45mm wastegate flanges. To control the boost, we installed a pair of Turbosmart Hyper-Gate45 wastegates along with one of their manual wastegate controllers and a variety of springs. The turbo system also featured a dual-core, air-to-water intercooler from CXRacing (used on the two previous Big-Bang tests). For the higher boost levels, we plumbed the system for ice water using a Meziere electric water pump. Fuel was supplied to the 120-pound injectors from an Aeromotive Eliminator pump augmented by a 17V Kenne Bell Boost-a-Pump. Using this system and a boost-referenced fuel-pressure regulator (from Aeromotive), the fuel pressure was rock steady and increased in relation to boost. All testing was run on 118-octane Rockett Brand race fuel.

The Big Bang 6.0L started out life as a Gen III iron block from a 2000 Chevy Suburban. The block was surfaced to ensure proper head gasket sealing and given a light ball hone.

The stock Gen III rods and LQ4 dished pistons were reused. After all, with only 247,000 miles logged, they were still mint.

The one change we did make was to substantially increase the ring gap on the factory rings (yes, we reused the 247,000-mile rings) from 0.022 to 0.032 inch. We gapped the rings using this trick ring-gap tool from Total Seal Rings.

Looking to make a big number along with the big boost, we installed a Stage 3 Turbo camshaft from Brian Tooley Racing. The dedicated turbo cam featured a 0.609/0.610-inch lift split, a 230/235-degree duration split, and 114+4-degree LSA. The right cam can yield huge power gains, especially once you crank the boost up.

Once cammed up with extra ring gap, the short-block was prepped with a set of LS9 head gaskets and ARP head studs.

Topping the 6.0L short-block was a set of Stage 2, CNC-ported heads from Total Engine Airflow (TEA). The CNC program was applied to the intake and exhaust ports (shown), as well as the all-important bowl area.

Only minor work was performed to the combustion chambers, but the already sizable chambers helped keep the static compression ratio in the safety zone.

The TEA heads were assembled with a dual valvespring package that provided both adequate coil-bind clearance and plenty of pressure for the combination of rpm and boost we planned to run.

To optimize power production higher in the rev range we enlisted the aid of a Holley Hi-Ram intake manifold combined with a 105mm Holley throttle body.

To ensure adequate fuel delivery, we installed a set of 120-pound Holley injectors fed by an Aeromotive fuel pump. The pump was augmented by a 17-volt Kenne Bell Boost-a-Pump.

Since the proper air/fuel ratio and timing values were critical on a twin-turbo combination, we relied on a Holley HP management system.

Before adding boost, we ran the modified 6.0L LQ4 engine on the dyno in naturally aspirated trim. The 6.0L produced 529 hp at 6,800 rpm and 457 lb-ft of torque at 5,100 rpm.

After the initial dyno test, we replaced the long-tube headers with the turbo components. The stainless turbo headers were used to feed a pair of 90-degree bends that included the T4 turbo and wastegate flanges. We relied on 4-inch sections of tubing to allow exhaust to escape. Note the oxygen sensor and stainless steel fitting with coiled aluminum tubing used to measure backpressure before the turbo.

Boost was supplied by a pair of BorgWarner S475 turbos from John Bewley at Lil John’s Motorsport Solutions. Capable of supporting nearly 1,000 hp each, the turbos were plenty capable of putting the big bang on our 6.0L.

Though available with a larger T6 housing, we elected to run a pair of smaller T4 housings (1.0 A/R) in conjunction with our 83mm turbine wheels.

Boost is useless without control, especially when you have the ability to easily overwhelm the combination. Keeping the boost in check was a pair of 45mm Turbosmart Hyper-Gate45 wastegates. We also relied on one of their manual wastegate controllers and additional wastegate springs to dial up the boost pressure.

Since elevated boost was in the cards, we installed an air-to-water intercooler in the mix. At the higher boost levels, we ran ice water through the system using a 10-gallon cell and Meziere electric water pump.

Since elevated boost was in the cards, we installed an air-to-water intercooler in the mix. At the higher boost levels, we ran ice water through the system using a 10-gallon cell and Meziere electric water pump.

After the turbo system was up and running, we snuck up on the terminal boost pressure. The twin-turbo 6.0L made multiple passes near the 1,000hp mark, but we eventually started cranking up the boost. At 14.6 psi it produced 1,054 hp, while 20 psi pushed things up to 1,277 hp. At 25.3 psi it was up to 1,435 hp, but the big bang came at 28.5 psi and 1,482.7 hp. The engine was on track to easily exceed 1,500 hp, but one of the sissy Gen III connecting rods called it quits.

The cracked oil pan and blown-out windage tray only hinted at the carnage within the dearly departed 6.0L block. Still, making 1,483 hp at 28.5 psi is pretty damn impressive. Now we’re curious how far we could take a set of Gen IV LS rods.

Before we cranked up the boost to a big bang level, we made pulls at lower boost levels. Equipped with the TEA Stage 2 317 heads, BTR Stage 3 turbo cam, and Holley Hi-Ram intake, the naturally aspirated 6.0L produced 529 hp and 457 lb-ft of torque. After the application of boost from the twin BorgWarner S475s, the power jumped to 914 hp at 10.8 psi, 974 hp at 12.9 psi, and 1,054 hp at 14.6 psi. Making these numbers all the more impressive was the fact that they came without the use of ice water in the intercooler.

Things got serious once we plumbed the system for ice water. Cranking up the boost to an even 20 psi brought 1,277 hp, while 22 psi brought 1,343 hp. After dialing in another 3.3 psi for a total of 25.3 psi, the twin-turbo 6.0L produced 1,435 hp and 1,240 lb-ft of torque. The final step up to 28.5 psi brought 1,482.7 hp, 1,330 lb-ft, and the end of the Big-Bang 6.0L. In the end, it was a Gen III connecting rod that let go, which begs the question, shouldn’t we now run the same test on a Gen IV 6.0L with the stronger rods?

Photos by Richard Holdener

Sources

Comp Cams

Memphis, TN 38118

901-795-2400

http://www.compcams.com

Turbosmart

Rancho Cucamonga, CA 91730

909-476-2570

www.turbosmartusa.com

FAST

Memphis, TN 38118

877-334-8355

http://www.fuelairspark.com

Brian Tooley Racing

888-959-8335

www.briantooleyracing.com

Total Seal

Phoenix, AZ

(800) 874-2753

totalseal.com

Kenne Bell Enterprises

Rancho Cucamonga, CA 91730

909-941-0985

www.kennebell.net

ARP

Ventura, CA 93003

800-826-3045

arpdiesel.com

CXRacing

626-575-3288

http://www.CXRacing.com

DNA Motoring

626-965-8898

www.dnamotoring.com

Lil John’s Motorsport Solutions

888-583-4408

liljohnsmotorsports.com

Holley/Hooker

270-781-9741

www.holley.com

MORE PHOTOS

VIEW FULL GALLERY

Sponsored Content

LINCOLN NAUTILUS: LUXURY & ELEGANCE UNDERPINNED WITH TECH

By Lincoln

In a luxury mid-size crossover segment awash with alphanumeric nomenclature, the wonderfully...

Sponsored Content

-

46-year-old bets $44.2 Billion on One Stock for Next Gen The Motley Fool

46-year-old bets $44.2 Billion on One Stock for Next Gen The Motley Fool -

Ford or Chevy? 94% of People Get It Wrong [Quiz] HowStuffWorks

Ford or Chevy? 94% of People Get It Wrong [Quiz] HowStuffWorks - Home Office: Managing Your Risk Amica

-

The 25 Fastest Cars From Around The World DriveZing

The 25 Fastest Cars From Around The World DriveZing

Sponsored Content

- Online Degrees - Search for Affordable MBA Options Here (Online MBA Programs | Sponsored Listings)

- 7 Common Situations When You Need a Financial Advisor Most (SmartAsset)

- How Vitamin D Affects Rheumatoid Arthritis (HealthCentral)

- This 2015 Chevy HHR Comp Eliminator Drag Car is One of a Kind

- SSRE's 700hp Pump-Gas Big Dawg 434 Small-Block is Wicked

- 355ci Small Block - The Spruced Goose

Connect With Us

Get Latest News and Articles. Newsletter Sign Up

recent how to articles

Fixing Anti-Lock Brake Electrical System on 2001-2004 Corvettes

New Products to Keep Your Chevy Running and Looking Great

How to Rebuild a Holley 4150 780-cfm Carburetor

QA1 and Eaton Detroit Spring First-Gen Camaro Suspension Upgrade

Chevy High Performance 2018 Holiday Gift Guide

sponsored links

Sponsored Content

-

General Motors purges factories, staff, vehicle lineup to fund future tech Digital Trends

General Motors purges factories, staff, vehicle lineup to fund future tech Digital Trends -

We Ranked This Year's Best Luxury Vehicles for Seniors! The Winners… Faqeo

We Ranked This Year's Best Luxury Vehicles for Seniors! The Winners… Faqeo -

20 Hidden Gems You Can Only Find At Costco PostFun

20 Hidden Gems You Can Only Find At Costco PostFun - One Thing All Liars Have in Common, Brace Yourself TruthFinder

-

Every White House Rule You're Not Technically Allowed to Know Ranker

Every White House Rule You're Not Technically Allowed to Know Ranker

subscribe to the magazine

Subscribe and Save 74% off the Cover Price!

get digital get print

Maniacmechanic1

solid fixture here in the forum

It is similar to the Race shop I worked in last year.

I was building Ford Winsdor, Mitsubishi EVO 4-bangers, & LS Engines.

The young do not know how to build no longer so the old timer myself was hired to do it.

Breaking every single rule here on Grumpys.

I can not agree either but it works for a short time HERO POWER.

The shortblock is disposable.

Thinking there is $7000 in hardware still.

I Like the Borg Warner S475 Turbos.

If Pontiac V8 was not so valuable to me.....what the Hell...!

Can not help questioning spending $1000- 1200 on Diamond pistons come after the holidays.

January 2019.

Look what they did with cast Hyperuentic pistons in the LS engine.

Pistons held up.

The reports of Keith Black Hyperuentic pistons holding up in a Pontiac 455 at 800 Hp with a a Nitrous Hit I think is True.

I have a set of them for my Crower Forged Pontiac V8 Connecting Rods.

I was building Ford Winsdor, Mitsubishi EVO 4-bangers, & LS Engines.

The young do not know how to build no longer so the old timer myself was hired to do it.

Breaking every single rule here on Grumpys.

I can not agree either but it works for a short time HERO POWER.

The shortblock is disposable.

Thinking there is $7000 in hardware still.

I Like the Borg Warner S475 Turbos.

If Pontiac V8 was not so valuable to me.....what the Hell...!

Can not help questioning spending $1000- 1200 on Diamond pistons come after the holidays.

January 2019.

Look what they did with cast Hyperuentic pistons in the LS engine.

Pistons held up.

The reports of Keith Black Hyperuentic pistons holding up in a Pontiac 455 at 800 Hp with a a Nitrous Hit I think is True.

I have a set of them for my Crower Forged Pontiac V8 Connecting Rods.

Maniacmechanic1

solid fixture here in the forum

1400 HP & the 6.0 stayed together.

Almost 1500 Hp it blew. Bone stock 6.0 shortblock.

Almost 1500 Hp it blew. Bone stock 6.0 shortblock.

Maniacmechanic1

solid fixture here in the forum

529 HP Normal aspirated.

They added 953 Horsepower with Twin Turbo Boost for 1482 Hp when a stock powder metal connecting rod let go.

They added 953 Horsepower with Twin Turbo Boost for 1482 Hp when a stock powder metal connecting rod let go.

yes interesting post, but, reading carefully,

it sure points out the need to swap

to some much stronger aftermarket rods and probably pistons

Id also point out that they stated they used 118 octane gas...

something that if over looked or ignored would have been a source of a huge problem,

if the same engine was run on more common and far cheaper, pump high test gas.

(it would never last to those power levels.)

and at anywhere near that power level, swapping to a forged crank and new bearings would be a smart move to increase durability.

remember the test was only designed to push the engine past its failure point,

they were never concerned in the least with its longer term durability,

so knowing that, they ignored factors any reasonable engine builder,

would have spent time correcting.

Id also point out that if you were starting with a BBC properly set up, there are far larger gains to potentially be had.

http://garage.grumpysperformance.com/index.php?threads/new-2000-hp-plus-garret-turbo-design.13612/

http://garage.grumpysperformance.com/index.php?threads/turbo-maps-and-related-turbo-info.1215/

http://garage.grumpysperformance.co...ors-size-for-boosted-combo-related-info.2792/

http://garage.grumpysperformance.com/index.php?threads/turbo-big-block.6835/

it sure points out the need to swap

to some much stronger aftermarket rods and probably pistons

Id also point out that they stated they used 118 octane gas...

something that if over looked or ignored would have been a source of a huge problem,

if the same engine was run on more common and far cheaper, pump high test gas.

(it would never last to those power levels.)

and at anywhere near that power level, swapping to a forged crank and new bearings would be a smart move to increase durability.

remember the test was only designed to push the engine past its failure point,

they were never concerned in the least with its longer term durability,

so knowing that, they ignored factors any reasonable engine builder,

would have spent time correcting.

Id also point out that if you were starting with a BBC properly set up, there are far larger gains to potentially be had.

http://garage.grumpysperformance.com/index.php?threads/new-2000-hp-plus-garret-turbo-design.13612/

http://garage.grumpysperformance.com/index.php?threads/turbo-maps-and-related-turbo-info.1215/

http://garage.grumpysperformance.co...ors-size-for-boosted-combo-related-info.2792/

http://garage.grumpysperformance.com/index.php?threads/turbo-big-block.6835/

Last edited:

Maniacmechanic1

solid fixture here in the forum

yes interesting post, but, reading carefully,

it sure points out the need to swap

to some much stronger aftermarket rods and probably pistons

Id also point out that they stated they used 118 octane gas...

something that if over looked or ignored would have been a source of a huge problem,

if the same engine was run on more common and far cheaper, pump high test gas.

(it would never last to those power levels.)

and at anywhere near that power level, swapping to a forged crank and new bearings would be a smart move to increase durability.

remember the test was only designed to push the engine past its failure point,

they were never concerned in the least with its longer term durability,

so knowing that, they ignored factors any reasonable engine builder,

would have spent time correcting.

Id also point out that if you were starting with a BBC properly set up, there are far larger gains to potentially be had.

http://garage.grumpysperformance.com/index.php?threads/new-2000-hp-plus-garret-turbo-design.13612/

http://garage.grumpysperformance.com/index.php?threads/turbo-maps-and-related-turbo-info.1215/

http://garage.grumpysperformance.co...ors-size-for-boosted-combo-related-info.2792/

http://garage.grumpysperformance.com/index.php?threads/turbo-big-block.6835/

I am not going there personally right now Grumpy.

At least it was not a Big Block Chevy that blew up or a Pontiac V8.

Bought those 389 early Pontiac V8 engines for a reason.

Ultra thick wall blocks.

Only production GM engines known to survive Nitro.

Actually going to build an all out Road race style engine and use it for Street Race Drag & Strip.

My Motto is you can not win finish the Street race if it blows up.

Screwed also...Cops 5.0 will get you.

Sitting there with a Blown up engine.

NO GOOD.