from everything I've read recently from people posting about the spiral gear oil pumps they bought,

and installed, they are NOT quieter, but more noisy oil pumps ,

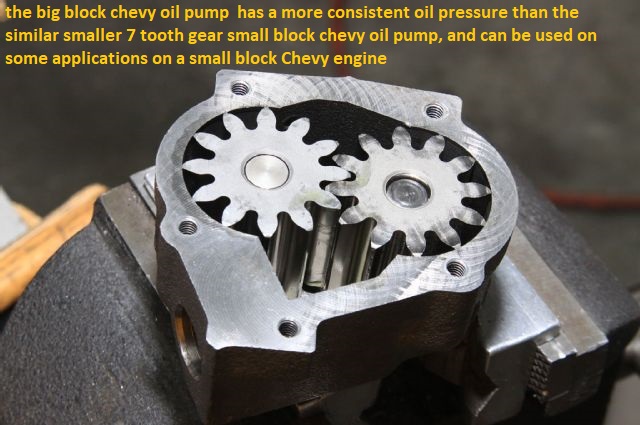

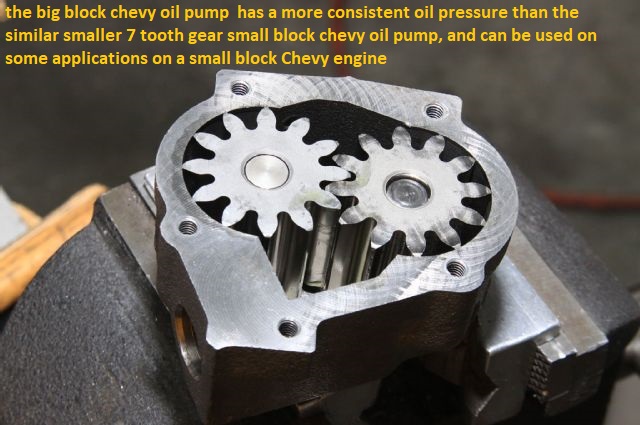

Ive generally found the 12 gear tooth BBC oil pumps to work very well, on both the SBC,

if you need significantly more oil flow than the stock z28 style pump provides,

(unlikely on a nearly stock SBC)

https://www.jegs.com/i/Melling/689/...MIwuTqqJn13wIVnbrACh0s8wdqEAQYASABEgJID_D_BwE

and the LS7 BBC works well on the BBC engines.

a great many problems seemingly related to oil pumps,

are really the result of improper clearances on the oil pump pick-up to oil pan floor.

or use of the wrong oil pump drive shaft length or type.

https://www.champpans.com/products/p/m99hvs/

https://www.champpans.com/products/p/m10770/

https://www.summitracing.com/search/brand/moroso/part-type/oil-pumps

https://www.amazon.com/Moroso-22175...ocphy=9012039&hvtargid=pla-608671094115&psc=1

https://pitstopusa.com/i-5073333-mo...MIrdu_6pv13wIVDY3ICh0IoASSEAQYBCABEgL0y_D_BwE

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

http://garage.grumpysperformance.co...chevy-oil-pump-style-guidelines-advice.13205/

you have several potential major sources for traditional wet sump SBC and BBC oil pumps

obviously youll want to shop carefully to correctly match the pump and pick-up combo ,

to the engines requirements and oil pan clearances

TRW

https://www.ebay.com/b/TRW-Car-Truck-Oil-Pumps-for-Chevrolet/6778/bn_21017532

MELLING

https://www.summitracing.com/search/make/chevrolet?keyword=melling oil pumps&ar=1&kr=melling chevy oil pumps

MOROSO

https://www.summitracing.com/search/brand/moroso/part-type/oil-pumps

and installed, they are NOT quieter, but more noisy oil pumps ,

Ive generally found the 12 gear tooth BBC oil pumps to work very well, on both the SBC,

if you need significantly more oil flow than the stock z28 style pump provides,

(unlikely on a nearly stock SBC)

https://www.jegs.com/i/Melling/689/...MIwuTqqJn13wIVnbrACh0s8wdqEAQYASABEgJID_D_BwE

and the LS7 BBC works well on the BBC engines.

a great many problems seemingly related to oil pumps,

are really the result of improper clearances on the oil pump pick-up to oil pan floor.

or use of the wrong oil pump drive shaft length or type.

https://www.champpans.com/products/p/m99hvs/

https://www.champpans.com/products/p/m10770/

https://www.summitracing.com/search/brand/moroso/part-type/oil-pumps

https://www.amazon.com/Moroso-22175...ocphy=9012039&hvtargid=pla-608671094115&psc=1

https://pitstopusa.com/i-5073333-mo...MIrdu_6pv13wIVDY3ICh0IoASSEAQYBCABEgL0y_D_BwE

http://garage.grumpysperformance.com/index.php?threads/installing-an-oil-pump-pick-up-tube.1800/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

http://garage.grumpysperformance.co...chevy-oil-pump-style-guidelines-advice.13205/

you have several potential major sources for traditional wet sump SBC and BBC oil pumps

obviously youll want to shop carefully to correctly match the pump and pick-up combo ,

to the engines requirements and oil pan clearances

TRW

https://www.ebay.com/b/TRW-Car-Truck-Oil-Pumps-for-Chevrolet/6778/bn_21017532

MELLING

https://www.summitracing.com/search/make/chevrolet?keyword=melling oil pumps&ar=1&kr=melling chevy oil pumps

MOROSO

https://www.summitracing.com/search/brand/moroso/part-type/oil-pumps

Last edited: