http://www.dennysdriveshaft.com/how_to_measure.html

http://www.dennysdriveshaft.com/how_to_measure.html

http://www.arizonadrivelines.com/how_to ... _shaft.htm

http://www.arizonadrivelines.com/how_to ... _shaft.htm

http://www.actionmachineinc.com/onepiec ... guide.aspx

http://www.dennysdriveshaft.com/p461_3r_series_u

http://www.dennysdriveshaft.com/c130_un ... oints.html

http://www.dennysdriveshaft.com/p766_st ... shaft.html

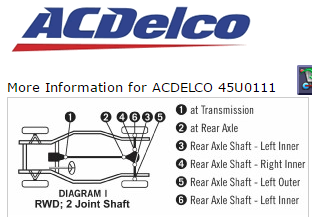

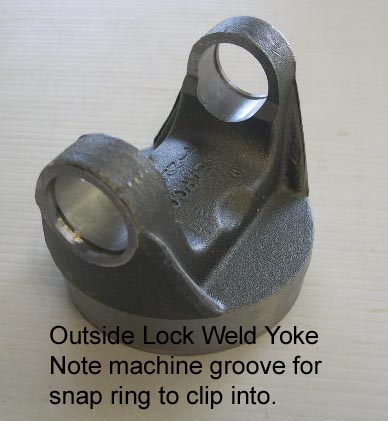

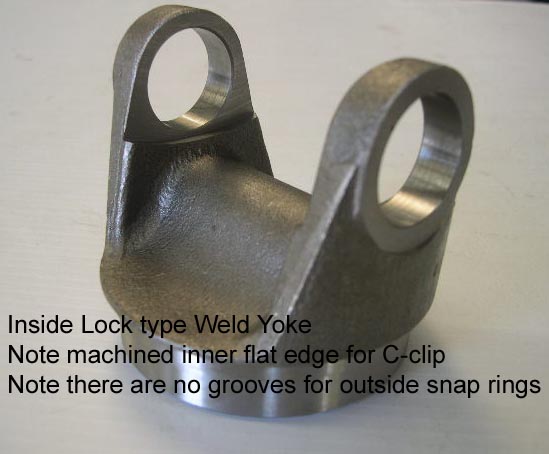

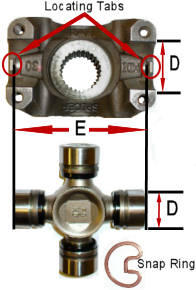

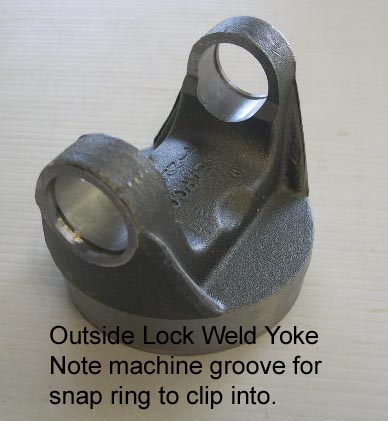

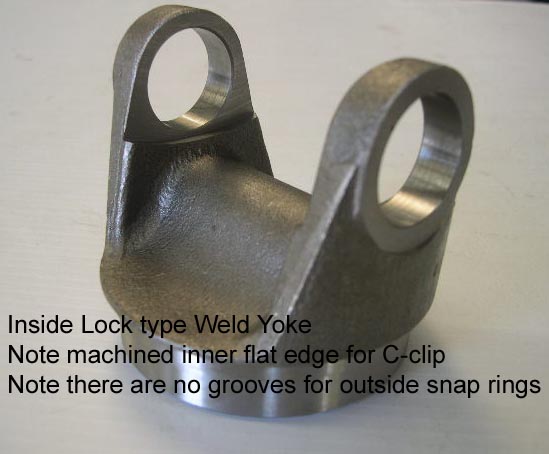

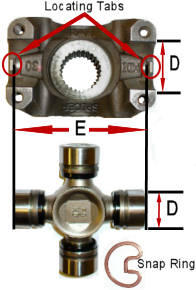

be aware there are different spline counts, and adapter u-joints so talk to the guys fabricating your new drive shaft and give them all the info they need.

your car might require new yokes and u-joints, made from far stronger steel alloys, so ask if theres upgrades or larger sizes available, theres no sense having a drive shaft custom built and balanced that might need to be replaced or upgraded, get the cost of the original to cover the process, so you don,t need to do it twice

http://www.dennysdriveshaft.com/how_to_measure.html

http://www.arizonadrivelines.com/how_to ... _shaft.htm

http://www.arizonadrivelines.com/how_to ... _shaft.htm

http://www.actionmachineinc.com/onepiec ... guide.aspx

http://www.dennysdriveshaft.com/p461_3r_series_u

http://www.dennysdriveshaft.com/c130_un ... oints.html

http://www.dennysdriveshaft.com/p766_st ... shaft.html

be aware there are different spline counts, and adapter u-joints so talk to the guys fabricating your new drive shaft and give them all the info they need.

your car might require new yokes and u-joints, made from far stronger steel alloys, so ask if theres upgrades or larger sizes available, theres no sense having a drive shaft custom built and balanced that might need to be replaced or upgraded, get the cost of the original to cover the process, so you don,t need to do it twice

Last edited by a moderator: