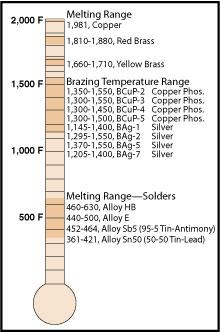

lead/tin solders and lead alloys melt hundreds of degrees LOWER in temp than

BRAZING alloys (typically in the 300-F 680-F temp range)

its physically impossible to braze over a solder alloy,

you might succeed in brazing through to the base metal surface,with a silver or copper braze rod,(used in the typically 850-F 1300-F temp range)

but it would almost always result in a less structural sound brazed surface.

https://www.thefabricator.com/article/arcwelding/brazing-copper-and-copper-alloys

From:

http://mwsco.com/kb/kb_Tree.asp

Soldering is defined as a group of joining processes that produce coalescence of materials by heating them to the soldering temperature and by using a filler metal (solder) having a liquidus not exceeding 840F (450C) and below the solidus of the base metals. The solder is distributed between closely fitted faying surfaces of the joint by capillary action.

Brazing joins materials by heating them in the presence of a filler metal having a liquidus above 840F (450C) but below the solidus of the base metals. Heating may be provided by a variety of processes. The filler metal distributes itself between the closely fitted surfaces of the joint by capillary action. Brazing differs from soldering, in that soldering filler metals have a liquidus below 840F (450C).

Brazing with silver alloy filler metals is

sometimes called silver soldering, a nonpreferred term. Silver brazing filler metals are not solders; they have liquidus temperatures above 840F (450C).

Brazing does not include the process known as braze welding. Braze welding is a method of welding with a brazing filler metal. In braze welding, the filler metal is melted and deposited in grooves and fillets exactly at the points where it is to be used. Capillary action is not a factor in distribution of the brazing filler metal. Indeed, limited base metal fusion may occur in braze welding.

Brazing must meet each of three criteria:

(1) The parts must be joined without melting the base metals.

(2) The filler metal must have a liquidus temperature above 840F (450C).

(3) The filler metal must wet the base metal surfaces and be drawn into or held in the joint by capillary action.

To achieve a good joint, the parts must be properly cleaned and must be protected by either flux or atmosphere during the heating process to prevent excessive oxidation. The parts must be designed to afford a capillary for the filler metal when properly aligned, and a heating process must be selected that will provide the proper brazing temperature and heat distribution.