the 10mm is rather unique in that its one of the few auto pistol calibers designed to exceed the 357 mag revolver power level.

and once you can exceed the 357 mag, you at least in theory can use the pistol as a decent hunting caliber option.

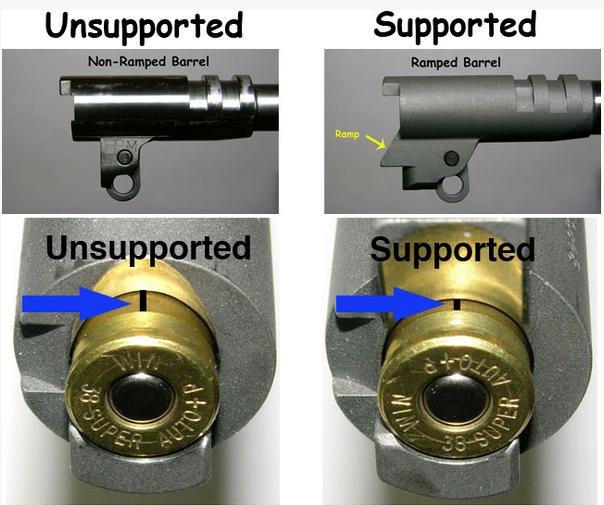

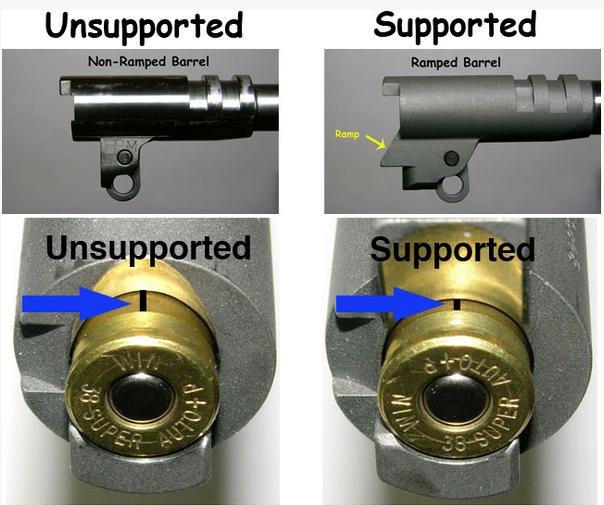

theres dozens of aftermarket barrel suppliers and designs differ in the areas they support the brass case,s thus the strength limitations on the designs vary

Un fortunately, theres a tendency to try to overload the 10mm,

to allow it to reach true 41 mag power levels,

the best advice is to keep load levels reasonable the 10mm if fine for deer, hogs and smaller bear,

I know from experience it does a fine job on deer and hogs at ranges under 50 yards ,

with good hand loads and exceeding 650ft lbs of energy is not difficult with a longer 6" barrel.

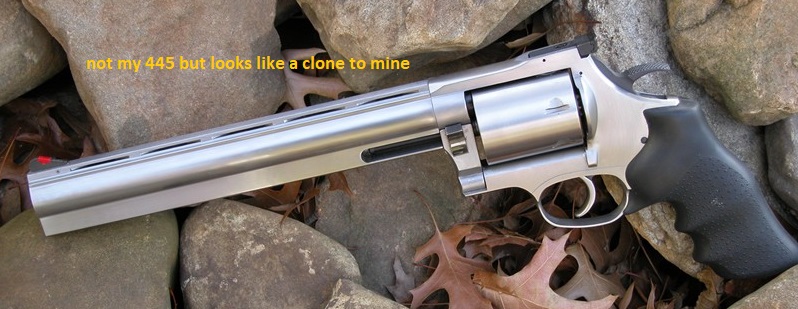

but , in my opinion youll be better armed with a 44 mag--454, 445, 460, or 500 mag on much larger game.

from a realistic view point , your very unlikely to need to defend yourself with any handgun.

https://www.luckygunner.com/labs/10mm-auto-self-defense-ammo-ballistic-gel-tests/

people with little field experience always think ,

its a total no-brainer, more shots is the way to go.

glock 10mm holds 15 shots,

with maybe 650 ft lbs of energy per cartridge,

and maybe 200-210 grain bullets

a 500 S&W only 5 shots, with an easy 2200 plus ft lbs of energy,

per cartridge

and maybe 400-500 grain bullets

a 44 mag

S&W only 6 shots, with an easy 1250 plus ft lbs of energy,

per cartridge

and maybe 240-310 grain bullets

the problem is time, and distance,

your almost always limited, if your attacked and while you may have the time to get off,

two or three shots on a charging bear, that's about the best case.

yes you might get off an additional shot or two with a 10 mill,

but only hits that reach the vitals count!

make your choice both potentially work,

its the skill and nerve of the operator thats critical,

but Id prefer more power and deeper penetration and 2-3 times the impact energy in a double action mag revolver.

From decades of experience ,hunting, I can assure you,

the mag revolvers with hard cast bullets punch considerably deeper.

thats not suggesting the 10mm lacks lethality in skilled hands

its just physics, remember you might only get one or two shots off, your potentially compromising making either choice

http://www.handloads.com/loaddata/defau ... pe=Handgun

http://www.loaddata.com/members/search_ ... ing%20Data

http://www.lonewolfdist.com/Detail.aspx ... 27&CAT=237

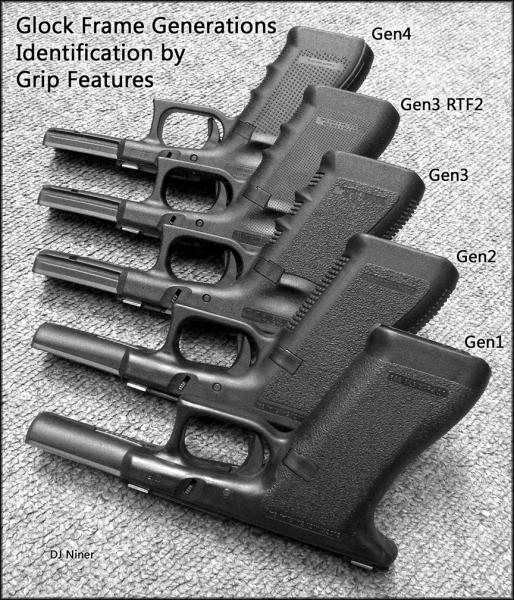

GLOCK SUGGEST YOU REPLACE SOME COMPONENTS EVERY 15K ROUNDS and OBVIOUSLY keep the pistol clean and regularly lubricated

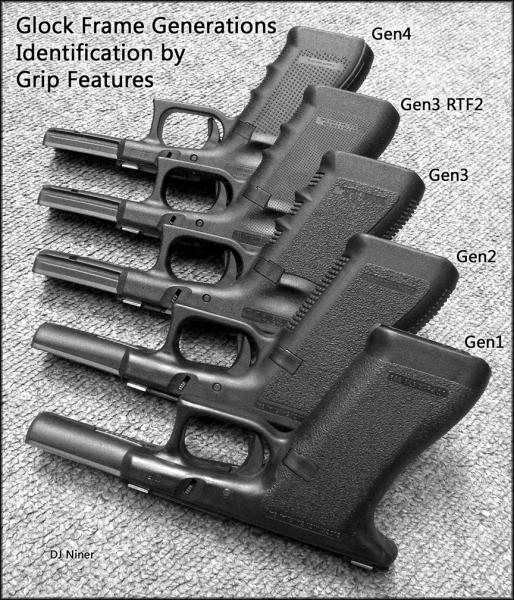

1. Recoil Spring Assembly: 3,000-4,000 rounds (Gen 1-3). 5,000-7,500 rounds (Glock Gen 4)

2. Firing Pin Spring (striker): 15,000 rounds

3. Firing Pin Safety Spring: 15,000 rounds

4. Extractor Depressor Plunger Spring: 15,000 rounds

5. Magazine Catch Spring: 15,000 rounds

6. Standard Trigger Spring: 15,000 rounds

7. Slide Lock Spring: 15,000 rounds

8. Slide Stop Lever Spring (attached to slide stop lever): 15,000 rounds

In keeping up with this maintenance schedule you can generally expect from proven data that this firearm has a good chance of reaching 100K without catastrophic failure.

heres some stuff I cut/pasted here!

"Seems like we need a good thread on why you might want one brand of aftermarket barrel over another.

Yesterday I ordered a Storm Lake barrel for my G20. I won't find out till Monday if they've got one in stock or if mine will be added to the production lineup to build. Either way it is paid for and will be on it's way to me in the very near future. The one I ordered is a nonported, nonthreaded, nonblack finished (Isonite QPQ), 6.02" barrel for $175.00. And for the record I'm very excited about it!

Now to the juicy details, outside of options and what length barrels are offered, that are the same for all barrels by each manufacturer:

Bar-Sto (out of Sturgis, SD) http://www.barsto.com

Steel = other than that it's a stainless steel, it's a secret I guess

Hardness = 39 - 43 RC

Rifling = broach cut

Fit = semi drop-in (they claim 7 out of 10 times it should "drop in" without fitting), or, match target (100% of the time requires machining to fit)

Claimed Accuracy = 1.25" @ 25 yards or better

Cost of a bare bones G20 4.6" barrel = $215.00

What else do they claim? - 14 to 16 week wait time for barrels not in stock...very best and most consistent product on the market...best service humanly possible...family run and owned since 1967 (started making their first auto pistol barrels in 1971)...full case support...and have been used to win every major pistol tournament worldwide.

Storm Lake (out of Lenoir City,TN) http://www.storm-lake.com

Steel = 416R stainless steel

Hardness = 40 - 42 RC

Rifling = broach cut

Fit = usually drop-in, but occasionally require fitting

Claimed Accuracy = N/A

Cost of a bare bones G20 4.6" barrel = $160.00

What else do they claim? - 6.5 weeks or less wait time for barrels not in stock...dedicated to excellence in accuracy, excellence in quality, and excellence in value...company has existed since 1983...full case support...proudly made in the USA.

KKM Precision (out of Carson City, NV) http://www.kkmprecision.com/custom_pist ... s/home.php

Steel = 416 stainless steel

Hardness = 42 - 45 RC

Rifling = button

Fit = drop-in

Claimed Accuracy = N/A

Cost of a bare bones G20 4.6" barrel = $165.00

What else do they claim? - leader in custom pistol barrel manufacturing for the last decade...one of the most accurate aftermarket barrels available today and our secret is our unique Button Rifling process...Glock barrels come with fully supported match chambers.

EFK Fire Dragon (out of Mesa, AZ) http://www.efkfiredragon.com

Steel = 416 stainless steel

Hardness = 40 - 43 HC

Rifling = Electrostatic Discharge Machine process

Fit = drop-in

Claimed Accuracy = N/A

Cost of a bare bones G20 4.6" barrel = $150.99

What else do they claim? - made in the USA...highest close tolerance of any barrel available today...products are proudly made and manufactured entirely within the United States...totally commited to customers satisfaction...EDM process produces an accuracy of +/- 50 millionths of an inch and a superior finish of 16 RMS or better.

Lone Wolf Distributors (out of Oldtown, ID) http://www.lonewolfdist.com

Steel = 416R stainless steel

Hardness = N/A

Rifling = broach cut

Fit = drop-in

Claimed Accuracy = N/A

Cost of a bare bones G20 4.6" barrel = $109.95

What else do they claim? - Polished feed ramp and bore...diamond turned exterior...maximum chamber support...improved feed ramp design...target crown.

Lastly, some tidbits you may or may not care about -

Hardness is measured by the Rockwell C scale. The higher the RC number the more brittle the steel is. A higher RC number does not equal greatest overall strength. It is simply a measurement of one aspect of the steel.

Rifling: Button rifling stresses steel but leaves behind a highly polished finish. Broach cut rifling doesn't stress steel but doesn't leave as polished of a finish except that the barrel may still be polished afterward. The Electrostatic Discharge Machine process doesn't stress steel and leaves a highly polished finish.

They all say they warranty defects in material and workmanship.

All 416 SS is not created equal. 416 SS is basically a recipe for steel that allows some variance. 416 SS is by far the most commonly used steel for pistol and rifle barrels. 416 with an "R" after it is unclear to me but I've seen it said that if the "R" is designated it means rifle barrel quality. Though actual rifle barrels are not hardened to anywhere near the hardness of these pistol barrels (generally more like 30 - 32 RC). Sometimes the steel manufacturer heat treats the steel to the buyers specifications which would be optimal. 416 SS was developed for good gun barrel qualities while still being easy to machine as far as stainless steels go because of its sulphur content in the recipe.

Hope this helps in the decision making process. Good Luck!"

and once you can exceed the 357 mag, you at least in theory can use the pistol as a decent hunting caliber option.

theres dozens of aftermarket barrel suppliers and designs differ in the areas they support the brass case,s thus the strength limitations on the designs vary

Un fortunately, theres a tendency to try to overload the 10mm,

to allow it to reach true 41 mag power levels,

the best advice is to keep load levels reasonable the 10mm if fine for deer, hogs and smaller bear,

I know from experience it does a fine job on deer and hogs at ranges under 50 yards ,

with good hand loads and exceeding 650ft lbs of energy is not difficult with a longer 6" barrel.

but , in my opinion youll be better armed with a 44 mag--454, 445, 460, or 500 mag on much larger game.

from a realistic view point , your very unlikely to need to defend yourself with any handgun.

people with little field experience always think ,

its a total no-brainer, more shots is the way to go.

glock 10mm holds 15 shots,

with maybe 650 ft lbs of energy per cartridge,

and maybe 200-210 grain bullets

a 500 S&W only 5 shots, with an easy 2200 plus ft lbs of energy,

per cartridge

and maybe 400-500 grain bullets

a 44 mag

S&W only 6 shots, with an easy 1250 plus ft lbs of energy,

per cartridge

and maybe 240-310 grain bullets

the problem is time, and distance,

your almost always limited, if your attacked and while you may have the time to get off,

two or three shots on a charging bear, that's about the best case.

yes you might get off an additional shot or two with a 10 mill,

but only hits that reach the vitals count!

make your choice both potentially work,

its the skill and nerve of the operator thats critical,

but Id prefer more power and deeper penetration and 2-3 times the impact energy in a double action mag revolver.

From decades of experience ,hunting, I can assure you,

the mag revolvers with hard cast bullets punch considerably deeper.

thats not suggesting the 10mm lacks lethality in skilled hands

its just physics, remember you might only get one or two shots off, your potentially compromising making either choice

http://www.handloads.com/loaddata/defau ... pe=Handgun

http://www.loaddata.com/members/search_ ... ing%20Data

http://www.lonewolfdist.com/Detail.aspx ... 27&CAT=237

GLOCK SUGGEST YOU REPLACE SOME COMPONENTS EVERY 15K ROUNDS and OBVIOUSLY keep the pistol clean and regularly lubricated

1. Recoil Spring Assembly: 3,000-4,000 rounds (Gen 1-3). 5,000-7,500 rounds (Glock Gen 4)

2. Firing Pin Spring (striker): 15,000 rounds

3. Firing Pin Safety Spring: 15,000 rounds

4. Extractor Depressor Plunger Spring: 15,000 rounds

5. Magazine Catch Spring: 15,000 rounds

6. Standard Trigger Spring: 15,000 rounds

7. Slide Lock Spring: 15,000 rounds

8. Slide Stop Lever Spring (attached to slide stop lever): 15,000 rounds

In keeping up with this maintenance schedule you can generally expect from proven data that this firearm has a good chance of reaching 100K without catastrophic failure.

heres some stuff I cut/pasted here!

"Seems like we need a good thread on why you might want one brand of aftermarket barrel over another.

Yesterday I ordered a Storm Lake barrel for my G20. I won't find out till Monday if they've got one in stock or if mine will be added to the production lineup to build. Either way it is paid for and will be on it's way to me in the very near future. The one I ordered is a nonported, nonthreaded, nonblack finished (Isonite QPQ), 6.02" barrel for $175.00. And for the record I'm very excited about it!

Now to the juicy details, outside of options and what length barrels are offered, that are the same for all barrels by each manufacturer:

Bar-Sto (out of Sturgis, SD) http://www.barsto.com

Steel = other than that it's a stainless steel, it's a secret I guess

Hardness = 39 - 43 RC

Rifling = broach cut

Fit = semi drop-in (they claim 7 out of 10 times it should "drop in" without fitting), or, match target (100% of the time requires machining to fit)

Claimed Accuracy = 1.25" @ 25 yards or better

Cost of a bare bones G20 4.6" barrel = $215.00

What else do they claim? - 14 to 16 week wait time for barrels not in stock...very best and most consistent product on the market...best service humanly possible...family run and owned since 1967 (started making their first auto pistol barrels in 1971)...full case support...and have been used to win every major pistol tournament worldwide.

Storm Lake (out of Lenoir City,TN) http://www.storm-lake.com

Steel = 416R stainless steel

Hardness = 40 - 42 RC

Rifling = broach cut

Fit = usually drop-in, but occasionally require fitting

Claimed Accuracy = N/A

Cost of a bare bones G20 4.6" barrel = $160.00

What else do they claim? - 6.5 weeks or less wait time for barrels not in stock...dedicated to excellence in accuracy, excellence in quality, and excellence in value...company has existed since 1983...full case support...proudly made in the USA.

KKM Precision (out of Carson City, NV) http://www.kkmprecision.com/custom_pist ... s/home.php

Steel = 416 stainless steel

Hardness = 42 - 45 RC

Rifling = button

Fit = drop-in

Claimed Accuracy = N/A

Cost of a bare bones G20 4.6" barrel = $165.00

What else do they claim? - leader in custom pistol barrel manufacturing for the last decade...one of the most accurate aftermarket barrels available today and our secret is our unique Button Rifling process...Glock barrels come with fully supported match chambers.

EFK Fire Dragon (out of Mesa, AZ) http://www.efkfiredragon.com

Steel = 416 stainless steel

Hardness = 40 - 43 HC

Rifling = Electrostatic Discharge Machine process

Fit = drop-in

Claimed Accuracy = N/A

Cost of a bare bones G20 4.6" barrel = $150.99

What else do they claim? - made in the USA...highest close tolerance of any barrel available today...products are proudly made and manufactured entirely within the United States...totally commited to customers satisfaction...EDM process produces an accuracy of +/- 50 millionths of an inch and a superior finish of 16 RMS or better.

Lone Wolf Distributors (out of Oldtown, ID) http://www.lonewolfdist.com

Steel = 416R stainless steel

Hardness = N/A

Rifling = broach cut

Fit = drop-in

Claimed Accuracy = N/A

Cost of a bare bones G20 4.6" barrel = $109.95

What else do they claim? - Polished feed ramp and bore...diamond turned exterior...maximum chamber support...improved feed ramp design...target crown.

Lastly, some tidbits you may or may not care about -

Hardness is measured by the Rockwell C scale. The higher the RC number the more brittle the steel is. A higher RC number does not equal greatest overall strength. It is simply a measurement of one aspect of the steel.

Rifling: Button rifling stresses steel but leaves behind a highly polished finish. Broach cut rifling doesn't stress steel but doesn't leave as polished of a finish except that the barrel may still be polished afterward. The Electrostatic Discharge Machine process doesn't stress steel and leaves a highly polished finish.

They all say they warranty defects in material and workmanship.

All 416 SS is not created equal. 416 SS is basically a recipe for steel that allows some variance. 416 SS is by far the most commonly used steel for pistol and rifle barrels. 416 with an "R" after it is unclear to me but I've seen it said that if the "R" is designated it means rifle barrel quality. Though actual rifle barrels are not hardened to anywhere near the hardness of these pistol barrels (generally more like 30 - 32 RC). Sometimes the steel manufacturer heat treats the steel to the buyers specifications which would be optimal. 416 SS was developed for good gun barrel qualities while still being easy to machine as far as stainless steels go because of its sulphur content in the recipe.

Hope this helps in the decision making process. Good Luck!"

Last edited by a moderator: