Yep, I was looking at that Eastwood product.

I purchased a sand blaster from HF.

https://www.harborfreight.com/portable-abrasive-blaster-kit-37025.html

My plans are to use walnut shells to blast the inside of the roof and the rest of the interior structure ( then hope there is something left )

I will use a slag media to blast all the weld joints on the rest of the car.

I'm not worried about the panels warping cause they are all getting replaced.

I am concerned about the roof skin though. I may end up just replacing it for piece of mind because

I have found that the drip rail support is completely rotted away. I have also found two pin holes in the roof skin which leads me

to believe there is alot more than what I am seeing so far. By removing the roof skin...I also have access to the upper side of the roof supports

and can blast and encapsulate them also. This car looks like it has spent 20 years in a swamp! Is this what you guys near the ocean deal with?

In Michigan... we deal with ALOT of rust and holes...but I have never seen rust on the interior side like this car.

All in All though...it will just take me a little longer for the project.

I just need to put my BIG BOY pants on and go for it.

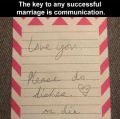

I told the wife that she will need to buy a few more pairs for me cause I'm definitely

going to need a few pair on this project!