Long story short, on an error code 33, check the Instrument panel fuse first.

typical symtoms

car starts and does not idle consistently (so you might think TPS (set at .54 volts)

or the IAC is gummed up, (clean and test if required) look for vacuum leaks.

it also helps to throw a can or two of fuel injector cleaner in the fuel tank and get out the multi meter and verify the OHMS resistance in the ignition wires,

and changing to new spark plugs won,t hurt either,

changing the fuel filter can,t hurt.

http://garage.grumpysperformance.com/index.php?threads/maf-burn-off-relay-info.661/#post-908

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-3325

http://garage.grumpysperformance.com/index.php?threads/adjusting-your-tps-and-iac.168/#post-82331

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/#post-70653

http://garage.grumpysperformance.co...vette-fuel-pump-replacement.15269/#post-88619

http://garage.grumpysperformance.co...-won-t-start-intermittently.14212/#post-72158

http://garage.grumpysperformance.co...asic-trouble-shooting-on-the-c4.302/#post-367

http://garage.grumpysperformance.com/index.php?threads/tpi-fuel-pressure-issue.10385/#post-42943

http://garage.grumpysperformance.co...-runs-rough-idles-and-sometimes-stalls.10688/

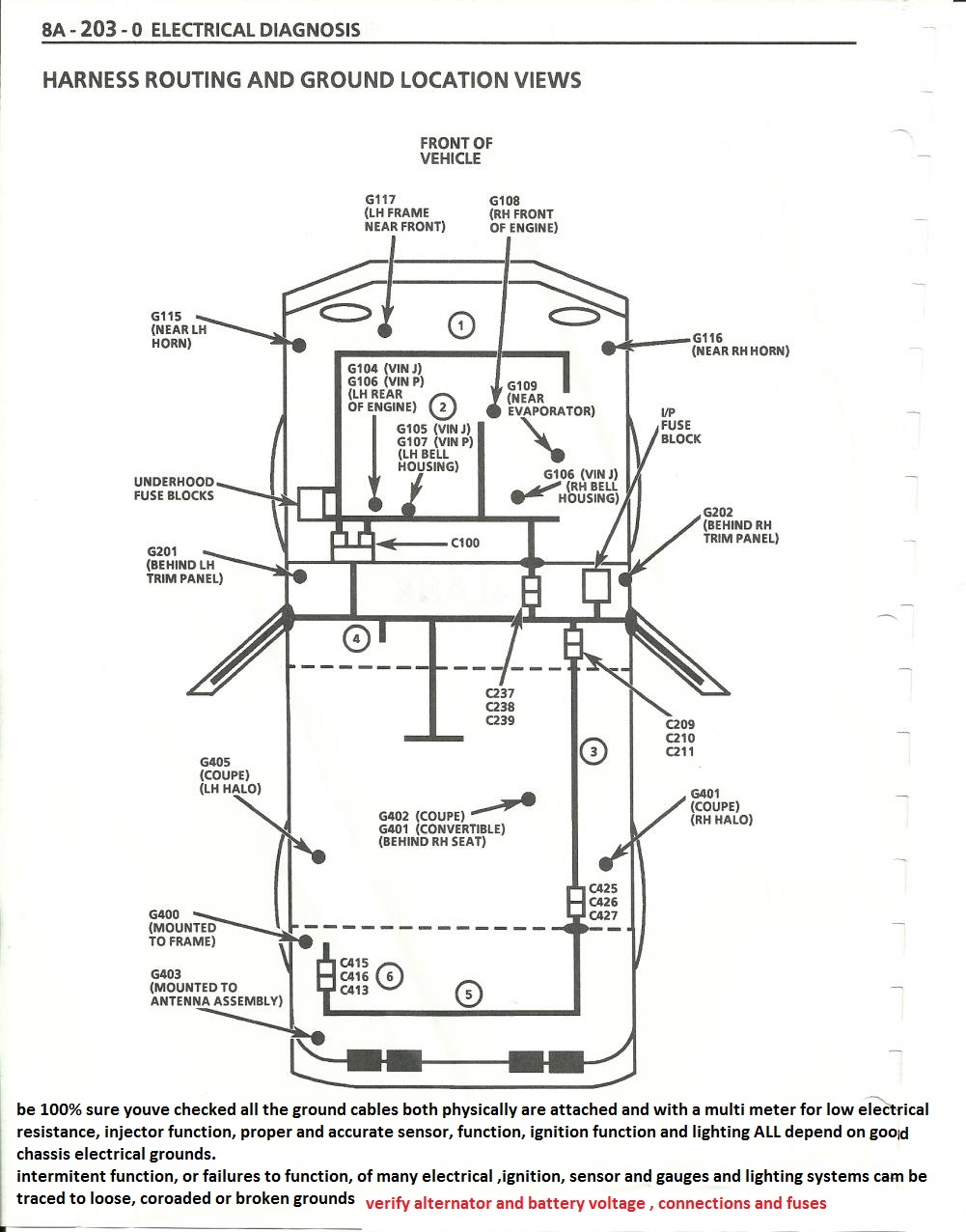

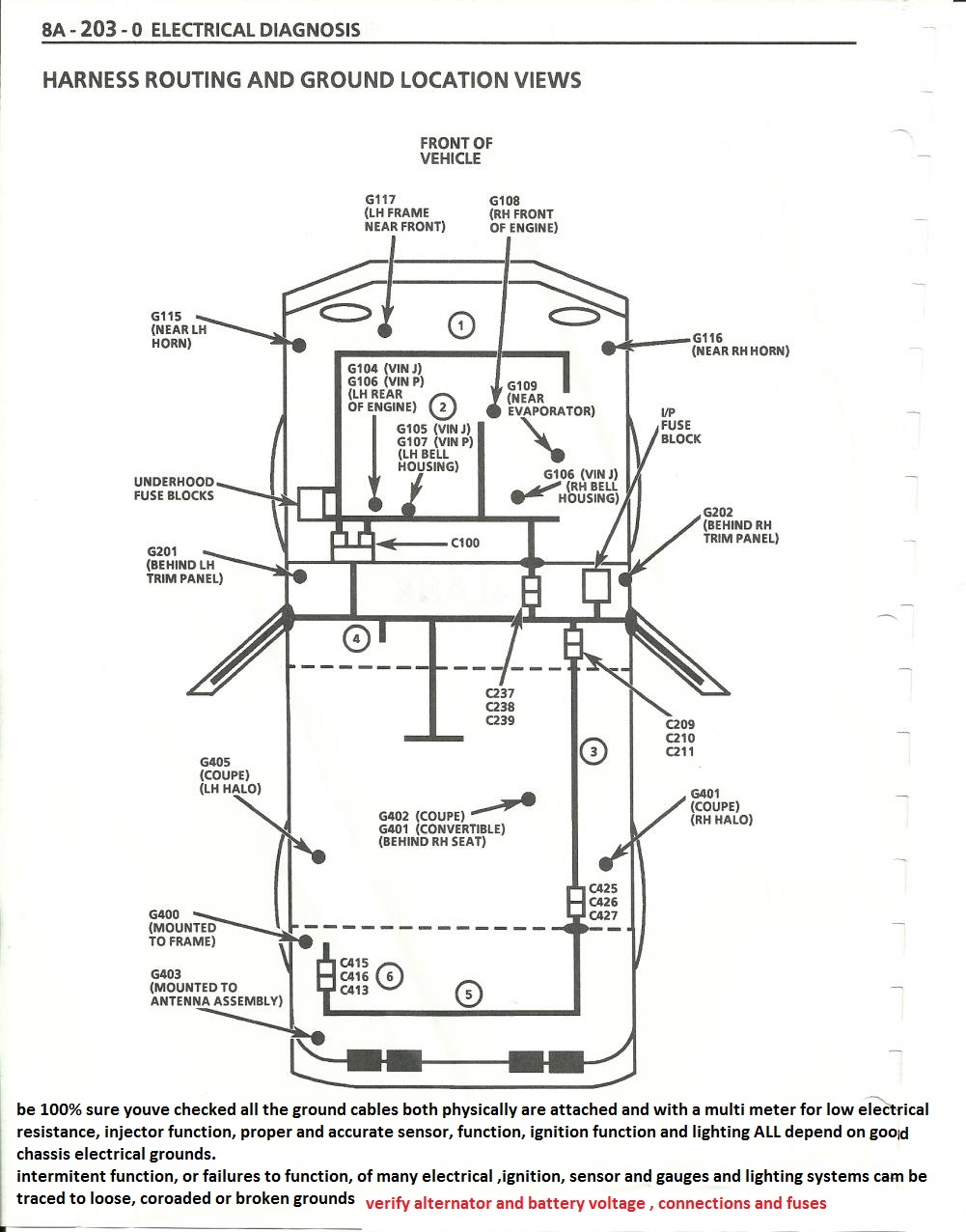

be aware the electrical grounds 104-105,106,107 must be checked and firmly connected to the engine

here i copied this :Just some additional info for the codes for the 85-91 tpi OBDI .

http://www.corvettedoctor.com/1985_91_DTC_Codes.html

http://garage.grumpysperformance.co...rouble-shooting-flow-chart-info.596/#post-793

Code #12: Normal No Codes.

Code #13: Open Oxygen Sensor Circuit.

Code #14: Coolant Sensor Circuit Low.

Code #15: Coolant Sensor Circuit High.

Code #21: Throttle Position Sensor High.

Code #22: Throttle Position Sensor Low.

Code #23: Manifold Air Temperature Circuit High.

Code #24: Vehicle Speed Sensor.

Code #25: Manifold Air Temperature Circuit Low.

Code #32: EGR System Failure.

Code #33: Mass Air Flow Sensor High.

Code #34: Mass Air Flow Sensor Low.

Code #36: Mas Air Flow Sensor Burn-Off Function Fault.

Code #41: Cylinder Select Error.

Code #42: Electronic Spark Timing.

Code #43: Electronic Spark Control.

Code #44: Lean Exhaust indication.

Code #45: Rich Exhaust Indication.

Code #46: Vehicle Anti Theft Fault.

Code #51: Faulty Mem-Cal.

Code #52: Fuel Calpak Missing.

Code #52: (1990-91 Corvette Only): Engine Oil Temperature Sensor Low.

Code #53: System Over Voltage.

Code #54: Fuel Pump Circuit Low Voltage.

Code #55: Defective ECM.

Code #62: Engine Oil Temperature Sensor Circuit High.

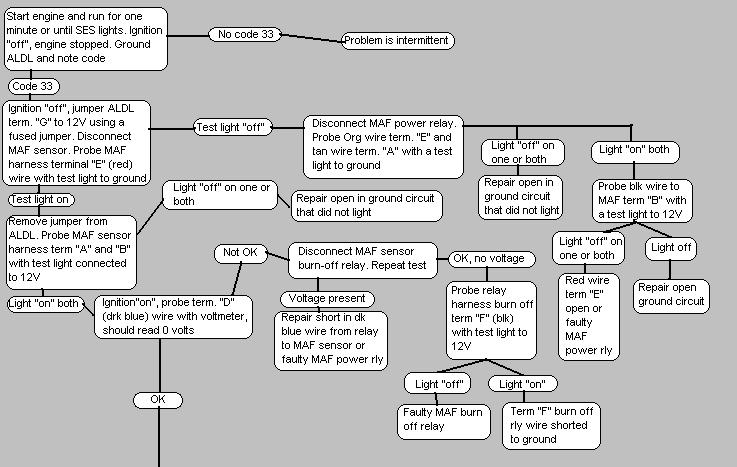

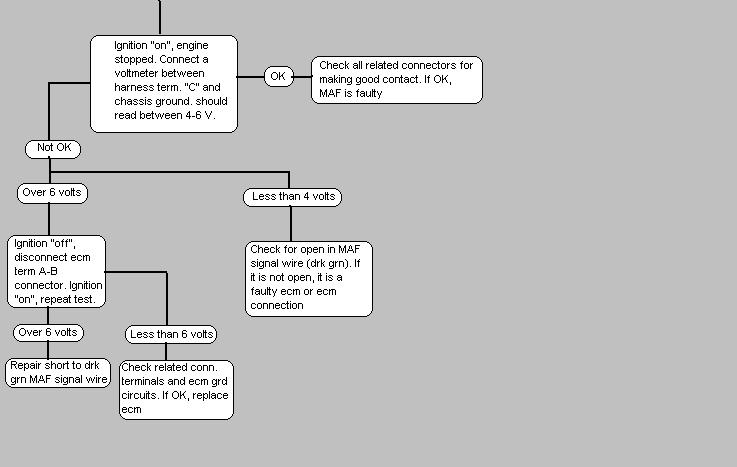

CODE 33

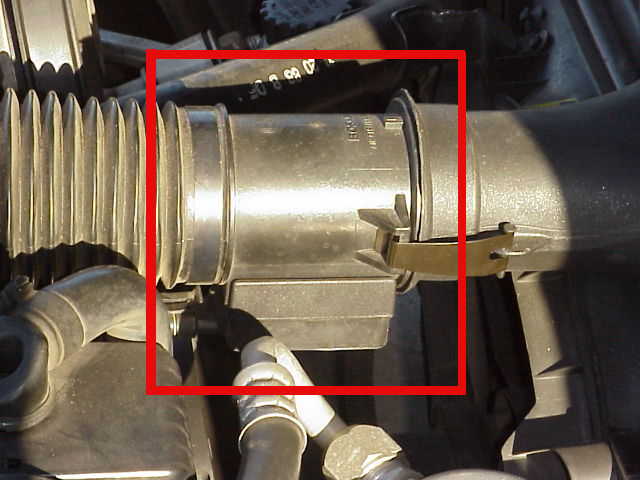

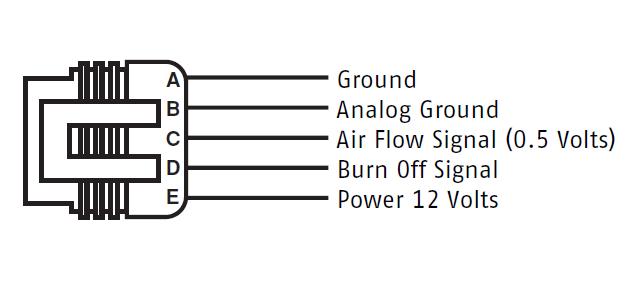

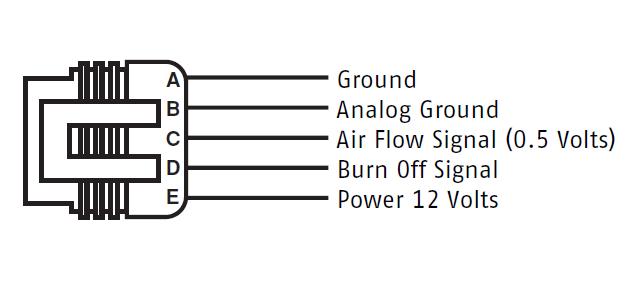

Trouble Code 33 indicates that the Mass Air Flow (MAF) sensor is reporting more air is entering the engine than makes sense based on RPM and TPS. The MAF sensor produces a frequency output; around 30 Hz at idle to 150 Hz under acceleration. The frequency varies proportionally to airflow. The ECM monitors the frequency and thus determines airflow into the engine. Typical idle MAF is 5 to 7 grams per second.

The conditions for setting this code are:

no Code 21 or 22 (TPS Error) present, and

the air flow reported is > 40 grams per second, and

TPS indicates < 10% throttle position, and

the engine speed is 1400 RPM or less, and

the above conditions exist for over 5 seconds.

Typical causes for this code include:

1) Faulty MAF-to-ECM connection

2) Exceedingly noisy spark plug wires

3) Poor routing of MAF harness (i.e. near coil packs)

4) Maladjusted TPS sensor

5) Defective MAF sensor

6) Defective ECM

Re: MAF & code 34

the threads linked below may help, but its more than likely a bad temp sensor or the TPS OR IAC is out of adjustment. so the first thing Id suggest is to adjust the TPS and IAC per the linked info and check for loose connections and vacuum leaks, and loose plenum and intake runner gaskets

34 Mass Air Flow Circuit (1985-1990) Clean the throttle body. Check MAF connections. Replace MAF relay. Replace MAF Sensor. Possible ECM failure.

34 Manifold Absolute Pressure Low (1984) Check Vacuum hoses associated with MAP sensor. Check wiring and connections, particularly at ECM. Replace the sensor. Possible ECM failure.

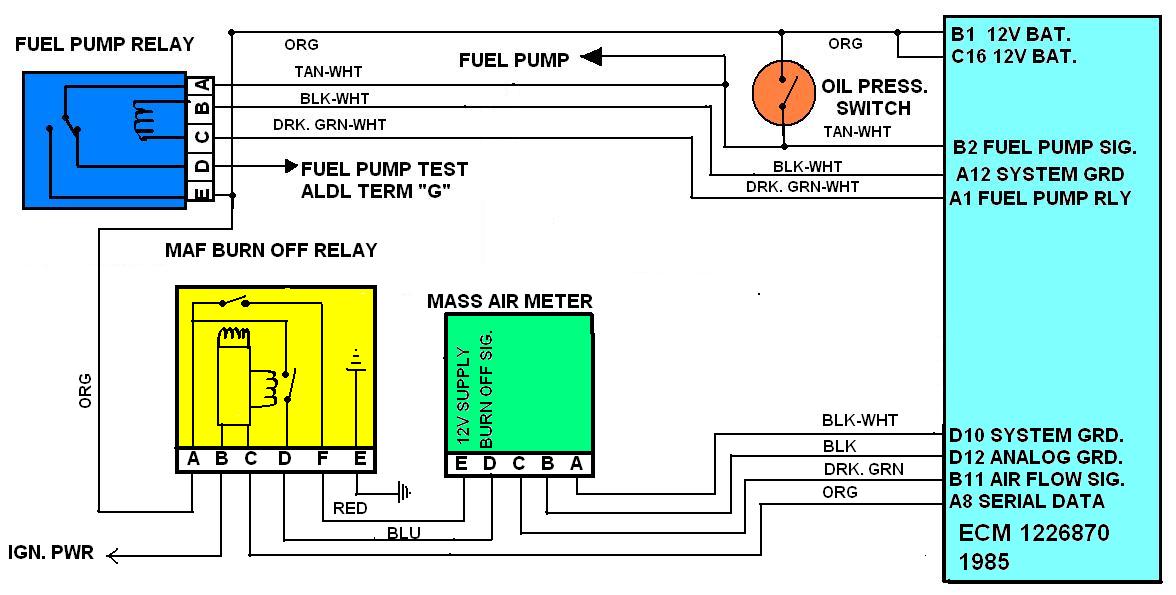

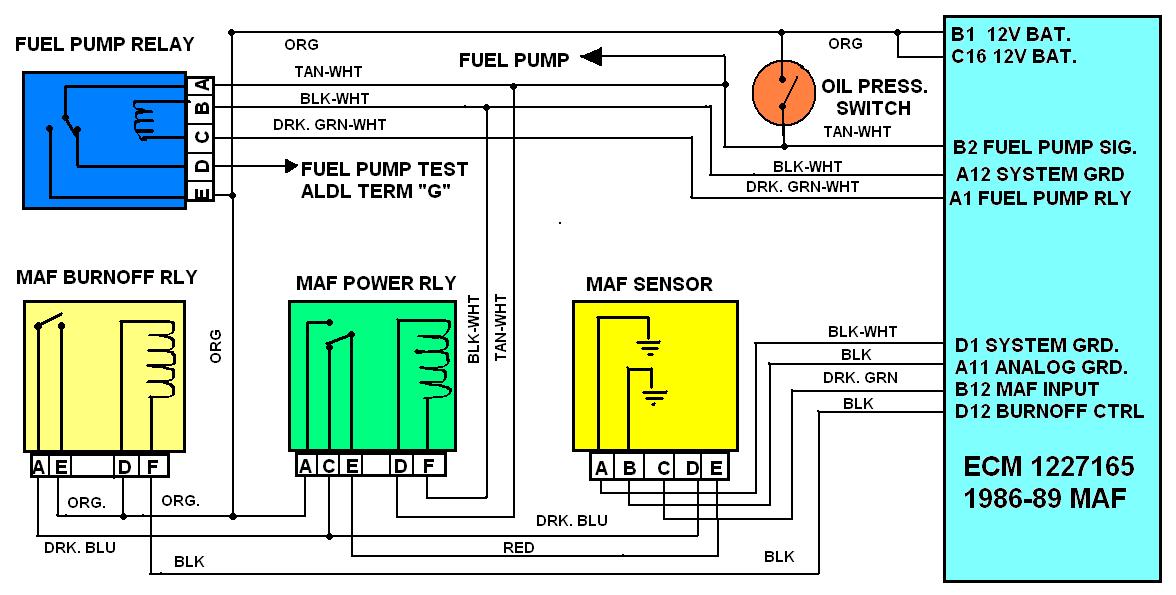

MAF SENSORS AND RELAYS ARE FREQUENT SOURCE OF INTERMEDIATE OR HARD TO ISOLATE RUN ISSUES ON EARLIER TPI CORVETTES SO CHECK THEIR FUNCTION

a factory shop manual and a v.o.m. meter come in handy for testing!

http://www.chevythunder.com/Flow chart index.htm

http://www.mamotorworks.com/corvette-c4 ... 6-893.html

https://www.zip-corvette.com/85-89-high-performance-adjustable-maf-sensor.html

85-89 High Performance Adjustable MAF Sensor

https://www.rockauto.com/en/catalog...,exhaust+&+emission,mass+air+flow+sensor,5128

--------------------------------------------------------------------------------

CODE 34

Trouble Code 34 indicates that the Mass Air Flow (MAF) sensor is reporting less air is entering the engine than makes sense based on RPM and TPS. The MAF sensor produces a frequency output; around 30 Hz at idle to 150 Hz under acceleration. The frequency varies proportionally to airflow. The ECM monitors the frequency and thus determines airflow into the engine. Typical idle MAF is 5 to 7 grams per second.

The conditions for setting this code are:

no Code 21 or 22 (TPS Error) present, and

the air flow reported is < 4 grams per second, and

TPS indicates 10% or more throttle position, and

the engine speed is 1800 RPM or higher, and

the above conditions exist for over 5 seconds.

Typical causes for this code include:

1) Faulty air ducting to or from MAF sensor

2) Faulty ECM-to-MAF connections

3) Poor routing of MAF harness (i.e. near coil packs)

4) Maladjusted TPS sensor

5) Defective MAF sensor

6) Defective ECM

1989 corvette shows a trouble code #33

1989 corvette shows a trouble code #33

related info links

http://garage.grumpysperformance.co...your-c4-corvette-runs-badly.15212/#post-87228

http://garage.grumpysperformance.com/index.php?threads/adjusting-your-tps-and-iac.168/#post-82331

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-72181

http://garage.grumpysperformance.co...le-shooting-flow-chart-info.11536/#post-71845

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/#post-70653

http://garage.grumpysperformance.co...s-air-flow-vs-speed-density.11952/#post-56852

http://garage.grumpysperformance.co...urrent-flow-grounds-and-more.3504/#post-54624

http://garage.grumpysperformance.com/index.php?threads/diagnoseing-tpi-lt1-problems.1241/#post-3037

http://garage.grumpysperformance.co...g-tpi-crossfire-or-lt1-vette.1401/#post-27000

http://garage.grumpysperformance.co...-idles-and-sometimes-stalls.10688/#post-46303

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

typical symtoms

car starts and does not idle consistently (so you might think TPS (set at .54 volts)

or the IAC is gummed up, (clean and test if required) look for vacuum leaks.

it also helps to throw a can or two of fuel injector cleaner in the fuel tank and get out the multi meter and verify the OHMS resistance in the ignition wires,

and changing to new spark plugs won,t hurt either,

changing the fuel filter can,t hurt.

http://garage.grumpysperformance.com/index.php?threads/maf-burn-off-relay-info.661/#post-908

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-3325

http://garage.grumpysperformance.com/index.php?threads/adjusting-your-tps-and-iac.168/#post-82331

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/#post-70653

http://garage.grumpysperformance.co...vette-fuel-pump-replacement.15269/#post-88619

http://garage.grumpysperformance.co...-won-t-start-intermittently.14212/#post-72158

http://garage.grumpysperformance.co...asic-trouble-shooting-on-the-c4.302/#post-367

http://garage.grumpysperformance.com/index.php?threads/tpi-fuel-pressure-issue.10385/#post-42943

http://garage.grumpysperformance.co...-runs-rough-idles-and-sometimes-stalls.10688/

be aware the electrical grounds 104-105,106,107 must be checked and firmly connected to the engine

here i copied this :Just some additional info for the codes for the 85-91 tpi OBDI .

http://www.corvettedoctor.com/1985_91_DTC_Codes.html

http://garage.grumpysperformance.co...rouble-shooting-flow-chart-info.596/#post-793

Code #12: Normal No Codes.

Code #13: Open Oxygen Sensor Circuit.

Code #14: Coolant Sensor Circuit Low.

Code #15: Coolant Sensor Circuit High.

Code #21: Throttle Position Sensor High.

Code #22: Throttle Position Sensor Low.

Code #23: Manifold Air Temperature Circuit High.

Code #24: Vehicle Speed Sensor.

Code #25: Manifold Air Temperature Circuit Low.

Code #32: EGR System Failure.

Code #33: Mass Air Flow Sensor High.

Code #34: Mass Air Flow Sensor Low.

Code #36: Mas Air Flow Sensor Burn-Off Function Fault.

Code #41: Cylinder Select Error.

Code #42: Electronic Spark Timing.

Code #43: Electronic Spark Control.

Code #44: Lean Exhaust indication.

Code #45: Rich Exhaust Indication.

Code #46: Vehicle Anti Theft Fault.

Code #51: Faulty Mem-Cal.

Code #52: Fuel Calpak Missing.

Code #52: (1990-91 Corvette Only): Engine Oil Temperature Sensor Low.

Code #53: System Over Voltage.

Code #54: Fuel Pump Circuit Low Voltage.

Code #55: Defective ECM.

Code #62: Engine Oil Temperature Sensor Circuit High.

CODE 33

Trouble Code 33 indicates that the Mass Air Flow (MAF) sensor is reporting more air is entering the engine than makes sense based on RPM and TPS. The MAF sensor produces a frequency output; around 30 Hz at idle to 150 Hz under acceleration. The frequency varies proportionally to airflow. The ECM monitors the frequency and thus determines airflow into the engine. Typical idle MAF is 5 to 7 grams per second.

The conditions for setting this code are:

no Code 21 or 22 (TPS Error) present, and

the air flow reported is > 40 grams per second, and

TPS indicates < 10% throttle position, and

the engine speed is 1400 RPM or less, and

the above conditions exist for over 5 seconds.

Typical causes for this code include:

1) Faulty MAF-to-ECM connection

2) Exceedingly noisy spark plug wires

3) Poor routing of MAF harness (i.e. near coil packs)

4) Maladjusted TPS sensor

5) Defective MAF sensor

6) Defective ECM

Re: MAF & code 34

the threads linked below may help, but its more than likely a bad temp sensor or the TPS OR IAC is out of adjustment. so the first thing Id suggest is to adjust the TPS and IAC per the linked info and check for loose connections and vacuum leaks, and loose plenum and intake runner gaskets

34 Mass Air Flow Circuit (1985-1990) Clean the throttle body. Check MAF connections. Replace MAF relay. Replace MAF Sensor. Possible ECM failure.

34 Manifold Absolute Pressure Low (1984) Check Vacuum hoses associated with MAP sensor. Check wiring and connections, particularly at ECM. Replace the sensor. Possible ECM failure.

MAF SENSORS AND RELAYS ARE FREQUENT SOURCE OF INTERMEDIATE OR HARD TO ISOLATE RUN ISSUES ON EARLIER TPI CORVETTES SO CHECK THEIR FUNCTION

a factory shop manual and a v.o.m. meter come in handy for testing!

http://www.chevythunder.com/Flow chart index.htm

http://www.mamotorworks.com/corvette-c4 ... 6-893.html

https://www.zip-corvette.com/85-89-high-performance-adjustable-maf-sensor.html

85-89 High Performance Adjustable MAF Sensor

https://www.rockauto.com/en/catalog...,exhaust+&+emission,mass+air+flow+sensor,5128

--------------------------------------------------------------------------------

CODE 34

Trouble Code 34 indicates that the Mass Air Flow (MAF) sensor is reporting less air is entering the engine than makes sense based on RPM and TPS. The MAF sensor produces a frequency output; around 30 Hz at idle to 150 Hz under acceleration. The frequency varies proportionally to airflow. The ECM monitors the frequency and thus determines airflow into the engine. Typical idle MAF is 5 to 7 grams per second.

The conditions for setting this code are:

no Code 21 or 22 (TPS Error) present, and

the air flow reported is < 4 grams per second, and

TPS indicates 10% or more throttle position, and

the engine speed is 1800 RPM or higher, and

the above conditions exist for over 5 seconds.

Typical causes for this code include:

1) Faulty air ducting to or from MAF sensor

2) Faulty ECM-to-MAF connections

3) Poor routing of MAF harness (i.e. near coil packs)

4) Maladjusted TPS sensor

5) Defective MAF sensor

6) Defective ECM

1989 corvette shows a trouble code #33

1989 corvette shows a trouble code #33related info links

http://garage.grumpysperformance.co...your-c4-corvette-runs-badly.15212/#post-87228

http://garage.grumpysperformance.com/index.php?threads/adjusting-your-tps-and-iac.168/#post-82331

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-72181

http://garage.grumpysperformance.co...le-shooting-flow-chart-info.11536/#post-71845

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/#post-70653

http://garage.grumpysperformance.co...s-air-flow-vs-speed-density.11952/#post-56852

http://garage.grumpysperformance.co...urrent-flow-grounds-and-more.3504/#post-54624

http://garage.grumpysperformance.com/index.php?threads/diagnoseing-tpi-lt1-problems.1241/#post-3037

http://garage.grumpysperformance.co...g-tpi-crossfire-or-lt1-vette.1401/#post-27000

http://garage.grumpysperformance.co...-idles-and-sometimes-stalls.10688/#post-46303

http://garage.grumpysperformance.com/index.php?threads/testing-1985-89-m-a-f-sensor.1475/#post-43635

Last edited: