your obviously correct that if the cars tires can,t get decent traction the tires spin, and much of the potential shock and torque loads on the transmission are negated, but not necessarily the heat generated, obviously the heavier the car and the more traction the harder it is to rapidly accelerate and the more heat and stress is induced in the drive train.

or put a different way , Ive never snapped a half shaft or u-joint, or destroyed a transmission, with street tires , but once you install slicks the shock loads on the drive train skyrocket.

stress is cumulative, while the trans may be rated at 400-500 ft lbs if you subject it to a constant hammering at lets say 370 ft lbs and 6000rpm, and if you don,t use an effective trans cooler its just a matter of time before it fails,prematurely, because of parts wear and metal fatigue, the time it takes will vary , due to temps, lubrication, fluid quality and the type of shock loads and how frequently they occur but it will eventually fail

while thats good info and theres no doubt that the stock 700r4 can be improved with aftermarket components, if your building a 500hp sbc based engine beefing up the stock trans makes a great deal of sense.but your basically beating a dead horse if your using a 700r4 with an engine that exceeds about 600 ft lbs of torque,at 500 plus hp,its torque loads and heat, not horse power that kills a transmission, youll be far ahead swapping to a 4L80E or a manual shift version if you build a serious engine

read this also

if its a 700r4 it has either 27 or 30 splines

in an 1986 its more likely but not sure to be 27 splines, in theory 1987 and newer are 30 spline

http://www.hotrod.com/techarticles/113_ ... nsmission/

http://www.novak-adapt.com/knowledge/th700r4.htm

http://texasz.net/allan_and_rosanne/Z-C ... 204L60.htm

http://purplesagetradingpost.com/sumner ... 0R4p1.html

http://www.transmissioncenter.org/GM_Sp ... _Gears.htm

viewtopic.php?f=87&t=5121

viewtopic.php?f=32&t=430

viewtopic.php?f=50&t=422&p=518&hilit=horse+power+torque+calculate#p518

http://www.classicchevychevelleparts.co ... ification/

Best to talk to a trans guru

Dana at Probuilt Autos has a good reputation around the forums for honest no BS answers and matching parts to individual requirements

http://www.700r4l60e.com/

He even has his own Forum for Q & A

http://www.700r4l60e.com/forum/viewforum.php?f=7

He does modified Transgo kits

https://www.700r4l60e.com/store/home.php?cat=65

How big is your wallet?

T700 parts

https://www.700r4l60e.com/store/home.php?cat=52

T700 upgrades

https://www.700r4l60e.com/store/home.php?cat=84

https://www.hemmings.com/blog/article/gm-th200-4r-transmission-conversions/

HEMMINGS MUSCLE MACHINES

GM TH200-4R Transmission Conversions

By Jim O'Clair from the January 2006 issue of Hemmings Muscle Machines

SHARE

GM TH200-4R has an economy 0.067:1 fourth gear

With gasoline prices reaching all-time highs, some of you may have considered converting your two-speed Powerglide or even your Turbo Hydra-Matic 350 or 400 to a more miserly overdrive transmission. Many enthusiasts recommend installing a TH700R-4, however another alternative for an overdrive on the cheap is the TH200-4R. Because the TH200-4R uses less engine horsepower to operate than any of the two- or three-speed transmissions, not only will you save some money on fuel, but this transmission will allow your engine to operate at a lower rpm, saving you wear and tear on the engine as well. Converting to an overdrive transmission also allows you to add taller rear differential gears without sacrificing fuel mileage.

These transmissions, when properly adjusted and maintained, can be as reliable a unit as any other GM automatic. TH200-4Rs are also readily available from your local pick-a-part because they were used in many different GM body styles, from A and G-Bodies right up to full-size cars. That means when you do find one, most of them can be pretty inexpensive as well.

The TH200-4R was used in all GM nameplates, including Cadillac. Production of this transmission began in 1981 and they were used continually up into the early 1990s. The TH200-4R is an adaptation of the TH200 with the addition of an overdrive drum that adds an overdrive gear.

The TH200-4R can be identified by its odd-shaped 16-bolt pan, which roughly resembles the state of Nevada (check your maps), and the transmission pan bolts have 13mm heads. The TH200-4R was used in GM rear-wheel-drive cars equipped with the 231 Buick, 301 Pontiac, the Oldsmobile 307, as well as the 350 gas and 350 diesel engines from 1981-’90. Many Chevrolet 267 and 305 engines also used the TH200-4R with a multi-fit bellhousing. You can look for one in any of these vehicles with those engine sizes:

1981-’88 Buick LeSabre and Electra RWD

1981 Century

1981-’87 Regal

1981-’90 Cadillac Fleetwood, Deville and Brougham

1982-’90 Chevrolet Impala and Caprice

1981-’88 Chevelle, Monte Carlo, Malibu and El Camino

1984-’87 GMC Caballero

1982-’90 Olds Delta 88, 98 and Custom Cruiser

1983-’88 Olds Cutlass 4-4-2 and Supreme

1983-’89 Pontiac Bonneville, Parisienne and Safari Wagon

1981 Pontiac Firebird with 301

1984-’87 Pontiac Grand Prix

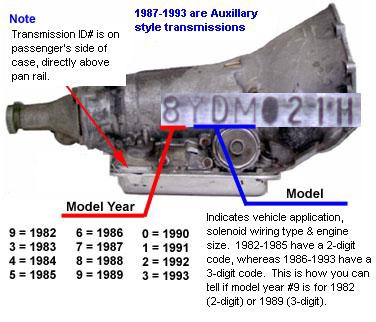

The transmission identification is on a plate on the right side of the case towards the tailshaft. This ID tag is usually held on by one rivet. The plate will have a two- or three-letter transmission code in large letters, and then a 13- or 14-digit identification number along the bottom:

1st digit: month of production (A through M, skipping the letter “I”)

2nd-3rd: production day of the month

4th: shift transmission was produced (1st-3rd shift)

5th: assembly plant (T: Three Rivers, MI; J: Windsor, Canada; W: Warren, MI)

6th-7th: decade and year

8th-9th: or 8th-10th: transmission ID code

10th-13th: or 11th-14th: transmission serial number

The TH200-4R, like the TH350, uses a 27-spline input shaft. It is also similar in length to the TH350 and the TH200, making it a natural for conversions where an overdrive transmission is desired. The TH200-4R is also similar in length to the Powerglide as well, which makes it a natural for converting from a two-speed to a four-speed automatic. Overall dimensions for the TH200-4R will be added to our online database, located in the parts locator section of our website:

www.hemmings.com/parts-locator.

Shift ratios for this transmission: 1st 2.74:1; 2nd 1.57:1; 3rd 1.00:1; 4th 0.67:1.

As a rule of thumb, the taller the rear-end gearing you have in the car, the more gas savings you will realize. Generally, installing a TH200-4R in a passenger car with a gear ratio of 2.73:1 or less will not give you much in the way of fuel economy. This is because when the 0.067:1 overdrive gear is applied to the 2.73:1 differential ratio, this will reduce your final drive ratio to 1.82:1. Final drive numbers that low can actually work out to be worse for your gas mileage than sticking with your stock transmission. So rear-end gearing is something you should check into before considering this conversion.

The most desirable TH200-4R for speed enthusiasts are the units manufactured for Buick Grand National, Olds 4-4-2 and Chevy Monte Carlo SS in 1986-’87. These units used a special valve body. They also had a larger reverse boost valve and 2nd to 3rd intermediate servo and a specially designed governor assembly. Buick units are identified by the BQ or BRF transmission codes. Monte Carlos used the CZF code. The Hurst Olds/4-4-2 units had a KZF or an OZ code. Many aftermarket suppliers offer an upgraded replacement valve body to retrofit into all TH200-4R transmissions. It duplicates the design used in these G-body transmission codes. The governor on a standard TH200-4R is designed to shift at about 3,000 rpm leading to a quick upshift through all four gears using a minimum amount of power. The specially designed governors used in the aforementioned performance transmissions are designed to shift at over 4,500 rpm making more efficient use of your engine’s power band. Performance governors with this higher shift rating and the larger boost valves are available from the performance transmission parts suppliers as well.

When purchasing any used transmissions, we always recommend that you go through the transmission thoroughly before installation. Check the condition of the steel and friction clutches and the passages in the valve body carefully. You should always change the fluid, fluid filter and oil pan gasket, and you might want to consider installing a shift kit while you have it apart. It is much easier to do it now while it is on the kitchen table instead of later while you’re on your back on the cold ground.

This transmission is a great candidate for swapping into cars with a TH350 or a Powerglide, because the overall length and the bellhousing bolt pattern of the TH200-4R are the same, and your original driveshaft does not have to be shortened. Moving the crossmember will be necessary though, because the TH200-4R crossmember is mounted on the extreme end of the tailshaft. Using an aftermarket crossmember in vehicles where the crossmember must be moved back makes this relocation much easier. It will save you the trouble of re-drilling mounting holes and shortening the crossmember in some cases.

On a TH200-4R, the length and adjustment of the detent cable is critical. One of the biggest complaints about the reliability of the TH200-4R can be traced back to a poorly adjusted detent cable. When installing in an earlier vehicle that used no detent, you will need the proper cable for the transmission you are installing as well as a bracket kit to connect the carburetor end to the throttle linkage. There are some really trick steel-braided aftermarket detent cables available too.

When exchanging the TH350 with the TH200-4R, the existing TH350 detent can be used, but it is best to make sure the cable length is the same as what you need for your particular engine size. The engine computer activates the torque converter lockup; however, an aftermarket universal lockup adapter can be purchased for non-computerized cars and trucks. We have seen some toggle-switch-designed lock-up creations that have been made to replace the lock-up adapter too, but we recommend the pre-packaged lockup adapter to make the exchange look a lot more professional. Some of the aftermarket lockup adapters contain a manual override setup, if you need that option for a racing application. Whatever method you choose, the lock-up should be used or the torque converter will slip too much and cause a lot of extra heat in the transmission. This will lead to early transmission failure.

GM also sells many replacement speedometer gears available to correct for inaccuracies in the speedometer, after this installation is complete. If your speedometer is reading low, you add driven-gear teeth. If your speedometer is reading too high, you subtract driven-gear teeth. Each tooth up or down will change your reading by about 5 percent. A listing of GM part numbers is also included on our

www.hemmings.com/parts-locator web site in the same parts locator section where the transmission dimensions are displayed. The easiest way to calibrate how far off your speedometer is reading is to take the car to an area where you can do 60 mph and that has mile markers. Measure the amount of time it takes for you to travel mile marker to mile marker holding your speed at 60 mph as indicated on the speedometer. Your actual miles per hour will be 3,600 divided by the time taken to travel that distance:

Actual MPH = 3,600 ÷ Elapsed time in seconds to complete 1 mile

For example, a time of 65 seconds indicates a speed of 55.3 mph, an error of 4.7 mph (or 8 percent) lower than actual speed. In this particular example, you would add two teeth (10 percent) to correct this reading.

The TH200-4R can be a great transplant unit for AMC, Ford and Mopar as well. Adapters are available to mate the multi-fit bellhousing to many different makes. In fact, just about anywhere that you can transplant a TH350, you can substitute the TH200-4R.

As we mentioned in this column in the November 2005 issue, many collector cars can benefit from this conversion as well. This includes Hudson, International trucks and Studebakers, in addition to early Buick, Chrysler, Lincoln, Cadillac, Ford and Edsel engines.

If you were scouring through a salvage yard looking for a unit with a multi-fit bellhousing, it would probably be a little easier to check out the full-size Cadillacs first. Most of the used multi-fit units you are going to find these days seem to be turning up on Cadillacs, because most of the Chevrolets may have already been picked through. If you have to remove the used unit yourself, or you are calling ahead to have the unit removed, make sure to grab the detent cable, ECM lockup harness, and the 27-spline slip yoke from the driveshaft. If the transmission was already removed and the yoke is not included, Spicer makes a new replacement slip yoke that fits the TH200-4R as well as the TH350, and mates to the 1310 series driveshaft used on GM cars and trucks (Spicer part number 2-3-4911X).

Checking into finding a TH200-4R at a reasonable price, we discovered used transmission pricing for a TH200-4R with the B-O-P bellhousing runs between $350 and $450. If you happen to find a BRF code unit, they run about $800 used. (We did actually manage to find one BRF code in Florida for that price.) Rebuilt units with the B-O-P bolt pattern are available for around $1,050; however, that pricing reflects having a trade-in unit to return.

Multi-fit units with the bellhousing for Chevrolet and everything else run anywhere from $375 to $600 for a good used one. We could not locate a multi-fit CZF-coded unit used at any price. This is probably one instance where finding a decent used unit and building it up to simulate a CZF-coded transmission is your best course of action.

Opting to convert to a four-speed automatic will pay for itself in the long run. Although many are of the opinion that the TH700R-4 is the way to go, a TH200-4R uses much less engine horsepower to operate, and with proper modification can handle engines producing up to 350hp.