elisalvador

Member

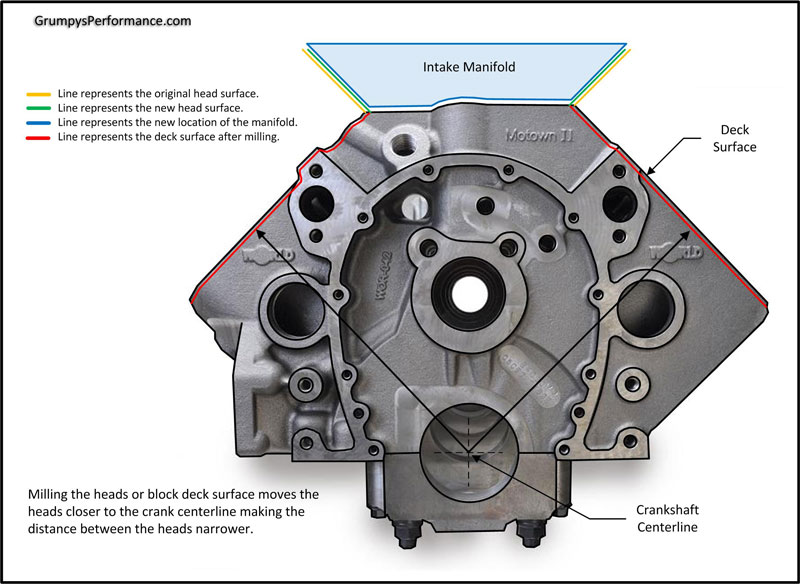

hi , i have a 350 that im stroking to 383

i had the machine shop deck the block , so the piton sits .015 in the whole,

i installed the heads , and im using .040 thick mls gaskets. the problem im having is that im ready to instal the intake manifold, but were the intake meets the block, is very tight,

were talkin .006 of gap between intake and actual block surface and the intake sits a little funny , the bolt wholes kinda sorta lign up , i got the the manifold to bolt. but i noticed

the mating from intake to heads was not tight it was tight on the top portion of the manifold

but the closer it got to the block the mating gap had increased, im confused on whats going on here, does the block need to be resurfaced were the intake meets, or does the intake manifold

need machining .. thanks :?

i had the machine shop deck the block , so the piton sits .015 in the whole,

i installed the heads , and im using .040 thick mls gaskets. the problem im having is that im ready to instal the intake manifold, but were the intake meets the block, is very tight,

were talkin .006 of gap between intake and actual block surface and the intake sits a little funny , the bolt wholes kinda sorta lign up , i got the the manifold to bolt. but i noticed

the mating from intake to heads was not tight it was tight on the top portion of the manifold

but the closer it got to the block the mating gap had increased, im confused on whats going on here, does the block need to be resurfaced were the intake meets, or does the intake manifold

need machining .. thanks :?