Hello. I have a 383(385) stroker that I got a good deal on, and which I plan to look over and put together again during the winter, before I install it in my 70 corvette.

I have the following parts:

•GM 350 four bolt block modified for stroker crank. Newly machined 4.040

•Scat cast steel crank 9-350-3750-6000-

•Scat 6" I beam rods,

•Icon forget flat top piston +3,7cc,

•AFR 195 eliminator street heads 75cc part no.1038,

•ptp stainless steel roller rockers 1.6

•Comp cam XE294H hydraulic flat tappet cam,

•pro comp single plane high rise intake PC 22030

•AED 750HO double pumper carb.

•Compression around 9.5

I have never seen this engine running, but the guy I bought it from claim that it was tested in dyno to 520hp, but he did not have any print out of this.

My idea is to put this together to be a decent preforming street engine, possible with some tests at the strip.

I am wondering if you could give me a indication if these parts will be suitable for street engine as is, or if the cam I have is too radical for a street engine?. I would look into swapping for a milder cam and possible a dual plane intake, if this will give me a more street useable engine. I am hoping for 450-500hp if possible, while still having acceptable street manners

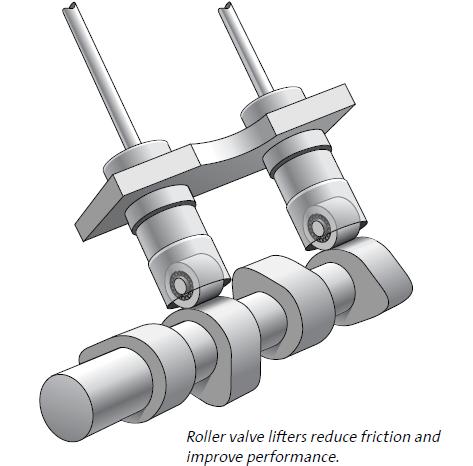

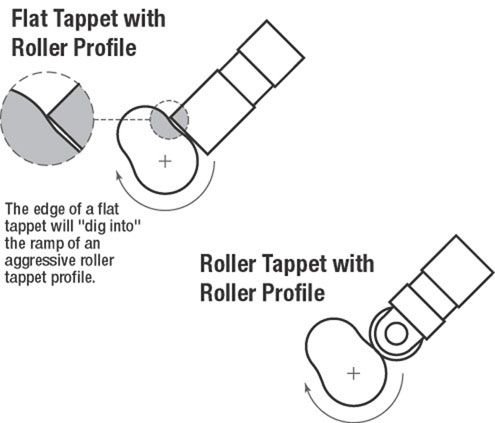

Alternatively I would also consider a switch to a hydraulic roller cam, but understand that this will also require change of quite a few other parts, and a higher cost.

I have a MSD ignition and Hooker Headers side pipe exhaust 2224-1 with 1.875" primary tubes and a 2,5" cambered pipe muffler.

At present I have M22 four speed transmission and a 3.73 rear ratio in the car. I may look into changing to a 5 speed Tremec transmission also during the winter for more comforting high way driving.

As this is the first engine I put together, I am hoping for some good advice specially related to the cam and intake selection, and any other stuff that stick out as mismatching for a street engine.

Thank you in advance for any advice.

Pal

I have the following parts:

•GM 350 four bolt block modified for stroker crank. Newly machined 4.040

•Scat cast steel crank 9-350-3750-6000-

•Scat 6" I beam rods,

•Icon forget flat top piston +3,7cc,

•AFR 195 eliminator street heads 75cc part no.1038,

•ptp stainless steel roller rockers 1.6

•Comp cam XE294H hydraulic flat tappet cam,

•pro comp single plane high rise intake PC 22030

•AED 750HO double pumper carb.

•Compression around 9.5

I have never seen this engine running, but the guy I bought it from claim that it was tested in dyno to 520hp, but he did not have any print out of this.

My idea is to put this together to be a decent preforming street engine, possible with some tests at the strip.

I am wondering if you could give me a indication if these parts will be suitable for street engine as is, or if the cam I have is too radical for a street engine?. I would look into swapping for a milder cam and possible a dual plane intake, if this will give me a more street useable engine. I am hoping for 450-500hp if possible, while still having acceptable street manners

Alternatively I would also consider a switch to a hydraulic roller cam, but understand that this will also require change of quite a few other parts, and a higher cost.

I have a MSD ignition and Hooker Headers side pipe exhaust 2224-1 with 1.875" primary tubes and a 2,5" cambered pipe muffler.

At present I have M22 four speed transmission and a 3.73 rear ratio in the car. I may look into changing to a 5 speed Tremec transmission also during the winter for more comforting high way driving.

As this is the first engine I put together, I am hoping for some good advice specially related to the cam and intake selection, and any other stuff that stick out as mismatching for a street engine.

Thank you in advance for any advice.

Pal