I'd suggest you don,t mill the heads as its potentially going to add far more problems that it cures.

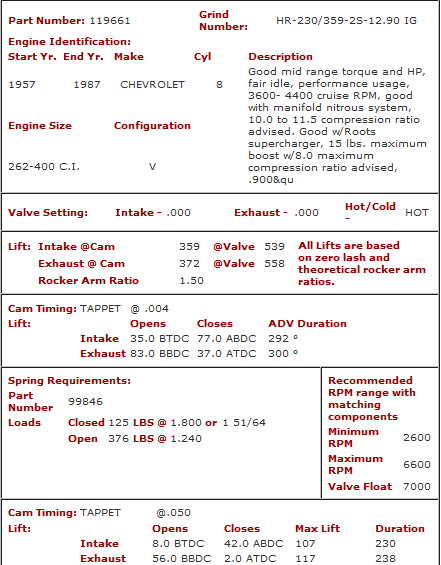

ideally youll want a fairly tight LSA of close to 106 in a cam for a 383, but the difference between a 106-to a- 110 LSA,is not going to make or brake the combo, it simply changes the volumetric efficiency

slightly and its only ONE of dozens of factors that will effect your results.

going with a slightly wider LSA tends to broaden the power band and smooth out the idle SLIGHTLY but the difference is not huge on cams with the same lift and duration.

yes the more factors that you calculate and take the time to maximize the better, but don,t think that one change will destroy the engines power curve.

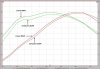

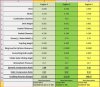

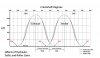

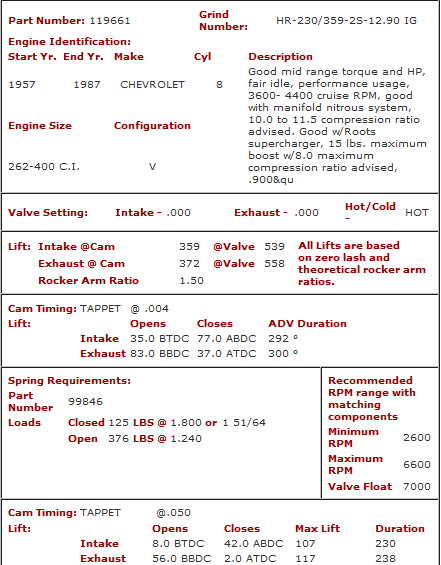

I tried the CROWER 00471 in my cars 383 and then settled on the CRANE 119661, there was no question the crower 00471 made better

peak power, than the crane 119661 , but being a bit older and less impressed with "POWER" than over all day to day drive-ability, and

having installed a 200 hp wet nitrous system on that car that provided more than enough EXTRA kick when I needed it I felt I could compromise and loose a few PEAK N/A hp with ZERO NET LOSS

every choice you make is a compromise in some area!, ID strongly suggest you talk to at least 5 cam manufacturers and get their opinions on what cam to use, in YOUR application, then take that info, average the results in LSA,LIFT AND DURATION, and BUY the cam that best matches that AVERAGE and NEVER discuss with any cam manufacturer what a different supplier might have recommended, simply, give them all the factors in the engine and drive train and let them make a choice, if you relate what others have said your skuew the results, and in most cases guys seem to want larger cam duration that the engines ideal cam might have, remember insisting on bigger,or longer spec, in a cam duration, is rarely going to result in a better, running engine ,in a street car cam selection, once you get into the correct ball park in lift and duration.

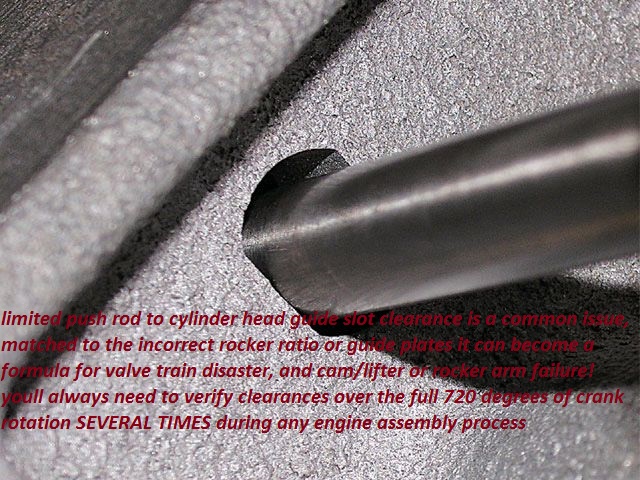

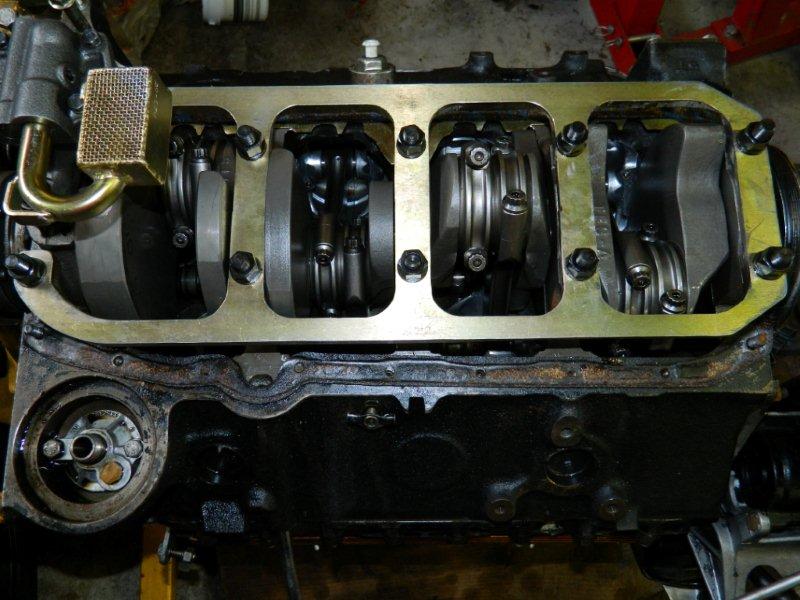

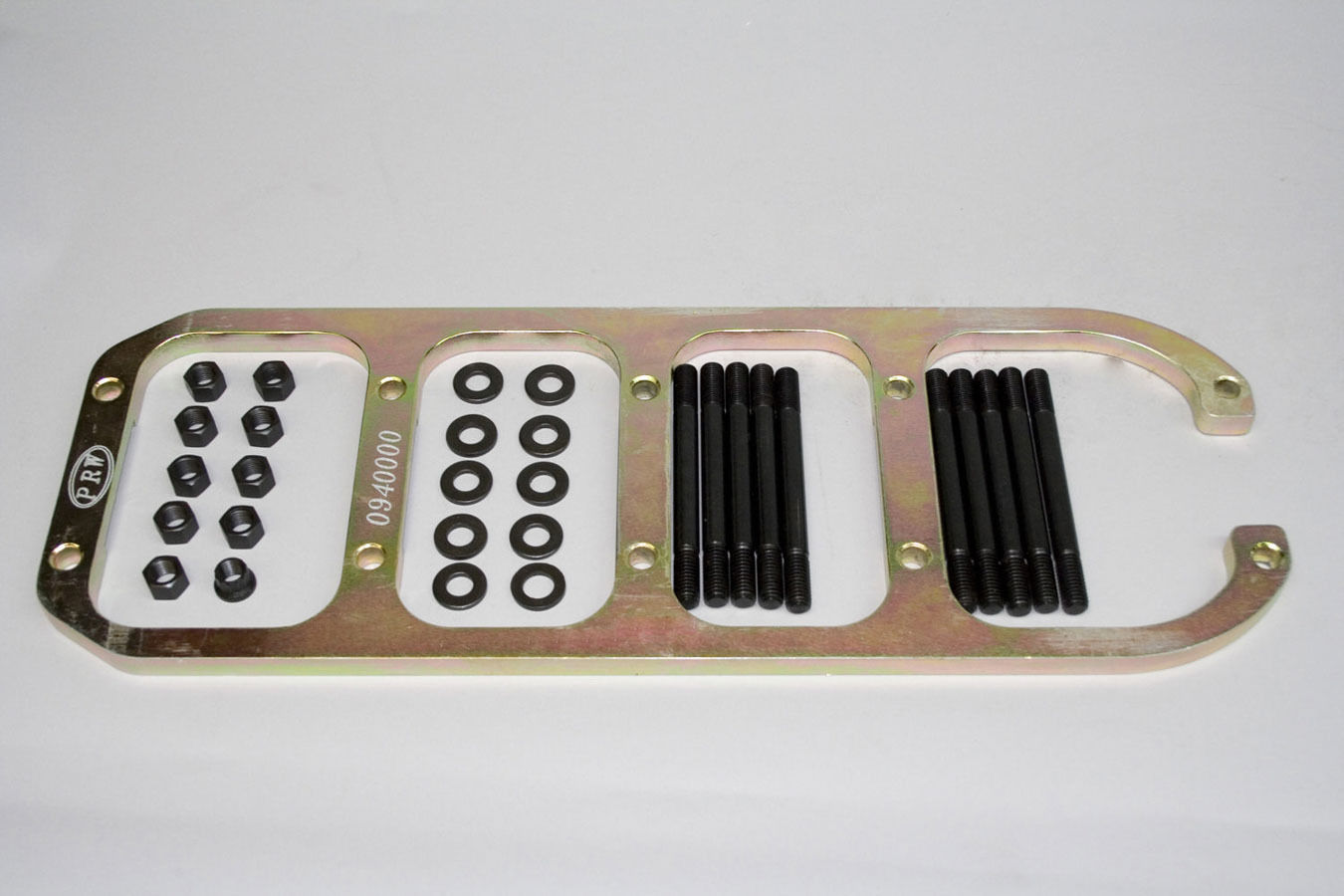

Verifying your engines clearances, and rocker geometry, and use of A rocker stud girdle and high quality roller rockers go a long way towards maintaining valve train durability

first CHEVK CLEARANCES AND GEOMETRY

the higher rocker ratio increases the effective acceleration rate of the cams lobe ramp, being transmitted to the valve so the higher ratio tends to cause valve control issues at a lower rpm level UNLESS the valve spring load rates increased to compensate. this allows a greater area of lift or open port area so the engine will tend to run better in the mid rpm range, generally making it well worth while as the mile duration cam can use the extra lift and duration at the valve.

btw, if you've ever had to stop a project because you could not locate the required matching bolt, or fastener, to install a bracket or accessory or engine component ,

you know how frustrating it will be to have to stop and locate the required fastener or go to a local hardware store and hope they have the required bolt.

and yes theres a great many sizes and types that are rather unique to automotive use and some specific to brands, and models.

now obviously you can spend a small fortune buying a vast assortment for your shops use.

or you can grab a 5 gallon bucket and a small assortment of ratchets wrenches and sockets ,

and visit your local salvage yard and grab some accessory or component you need and in the process,

you can remove and save, and throw several hands full of assorted fasteners in the bucket , on every trip to the salvage yard when your purchasing used re-buildable major components

to re-stock your shops bolt box.

most salvage yards don,t mind this approach

IF YOUR BUYING SEVERAL COMPONENTS in the process,

like all the parts and brackets off an engine , a set of cylinder heads, a power steering pump, or intake manifold for example or the disc brakes

most will NOT allow you to simply start pulling a large selection of fasteners , without a significant component purchase, or two too cover the cost of those fasteners.

http://garage.grumpysperformance.com/index.php?threads/fastener-storage-idea.3898/#post-10324

http://garage.grumpysperformance.co...spare-bolts-and-assorted-spare-parts-in.3557/

RELATED INFO

viewtopic.php?f=52&t=727

viewtopic.php?f=52&t=1070

viewtopic.php?f=32&t=430.