1987 Corvette 43 Overdrive Specs

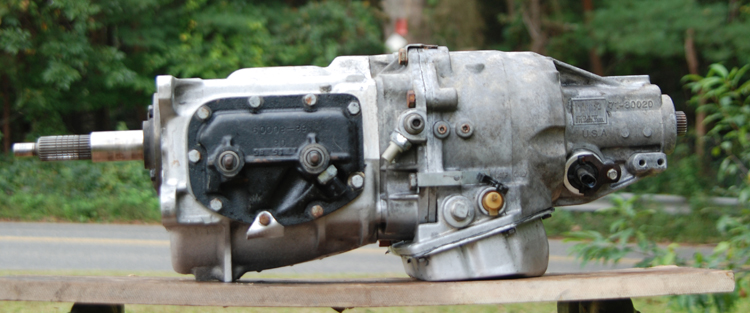

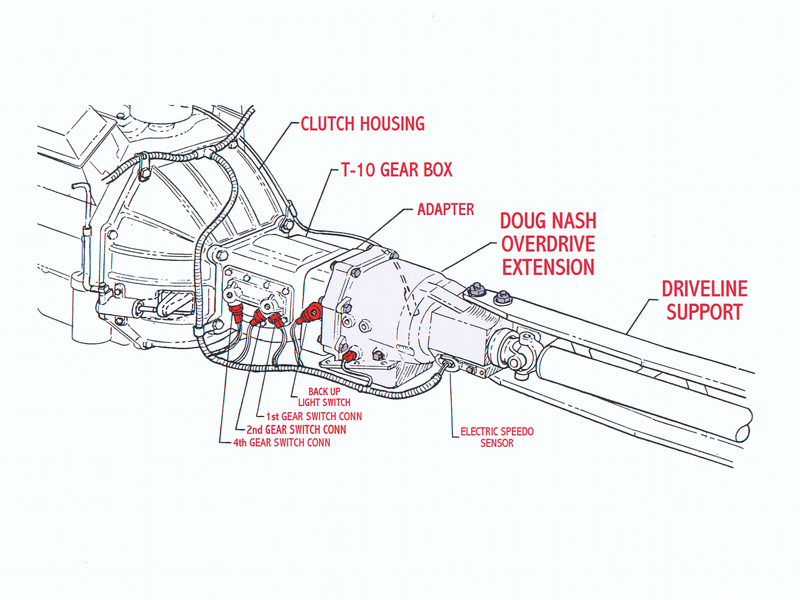

The fourth-generation Corvette, referred to amongst enthusiasts as the C4, debuted as a 1984 model. From 1984 through 1988 the manual transmission on the C4 Corvette was a Doug Nash 4+3 Overdrive unit. This featured a unique setup in that it was a four-speed manual, but the second through fourth gears featured a push-button overdrive feature for added fuel efficiency. Despite its reliable gearbox, the car's overdrive function was prone to failure.

The C4 Corvette had a General Motors' L98 engine. This V-8 engine has 5.7 liters of displacement. It is a cast-iron block with aluminum cylinder heads. The L98 is an overhead valve engine with a four-inch bore, three-inch stroke and a compression ratio of 9.5-to-1. This motor uses tuned port induction to deliver fuel to the engine block and produces 240 hp at 4,000 rpm and 345 foot-pounds of torque at 3,200 rpm.

Doug Nash 4+3 Overdrive Transmission

In addition to the four-speed automatic transmission, Chevrolet offered a four-speed manual gearbox in the 1987 Corvette. This floor-mounted stick shift was on the center console and featured an overdrive option that would engage on the top three gears for fuel efficiency. The first gear has a 2.88 ratio, while second through fourth had 1.91, 1.33 and 1.00 ratios, respectively. The overdrive gear featured a .67-to-1 ratio, while reverse was 2.78-to-1. The final drive ratio of this gearbox was 3.07-to-1.

Dimensions

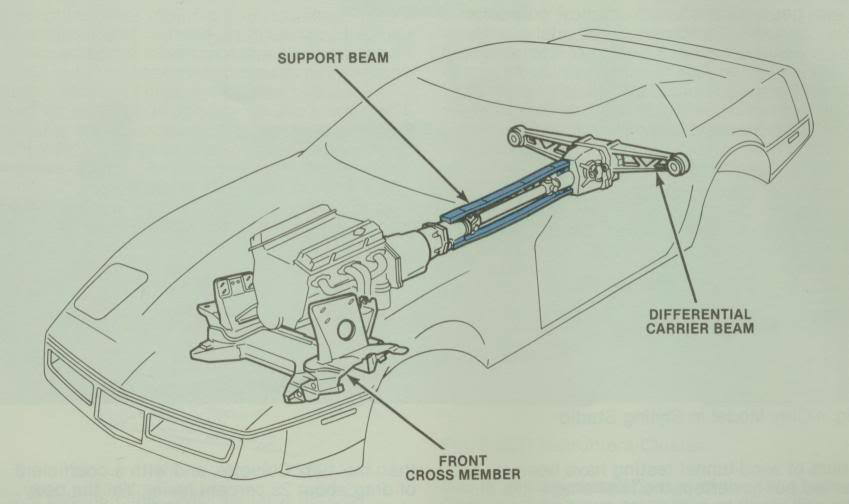

The 1987 Chevrolet Corvette sits on a 96.2-inch wheelbase with a front track of 59.6 inches and a rear track of 60.4 inches. The body of this two-door sports car has an overall length of 176.5 inches, width of 71 inches and height of 46.4 inches. This sports car has 16-by-8.5-inch rims with either P245/50VR16 tires or the slightly wider P255/50VR16 tires

Originally Posted by c4cruiser

Changing the ATF fluid in the OD unit is not hard at all and it's just like you have found out. It would help to get the car as high as possible so you can access the pan bolts. There's not a lot of fluid in the pan (roughly 2 quarts) so a small drain pan is all you need to catch the old fluid.

Start by removing the fill plug! If you can't do that, there will be no easy way to refill the OD. Remove the bolts but leave two corner bolts loose. Once you start to pull the pan off the housing, the fluid will start to drain out. Once that finishes, pull the last of the bolts to remove the pan. Pull the filter straight down; it's held in place by a rubber grommet. Save the grommet!

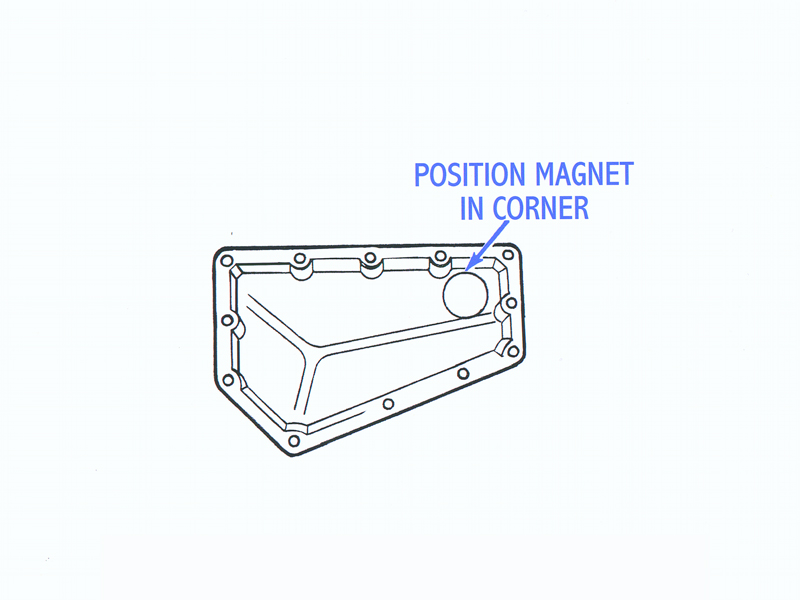

Clean all of the gasket material from both the pan rail and the rail on the OD housing. Clean the pan using a solvent or even brake parts cleaner. Remove the magnet and clean it too. Replace in the same spot in the pan. Make sure the pan rails are straight and the edges around the bolt holes are level with the rail.

Here's some part numbers for a new filter. The filter is the same one used in some Ford FMX transmissions found in early 70's Mustangs, Torino's and even a few F-150's:

Carquest 85926 (now Advanced Auto Parts and the p/n may be different

AC Delco TF 184

Fram FT 1024

NAPA ATP14717

Ford D0AZ-7A098-A

These should run about $8 to $10. The do not come with a grommet so save the old one.

Use a good black RTV sealant on the pan rails making sure you go around the bolt holes. The bolts don't need to be very tight but they should be tightened equally.

Use non-synthetic ATF such as Dexron III. You should be able to find that at any parts store. You will need a pump to get the fluid in. Use one that screws onto the bottle and will allow for attaching a short piece of tubing.

http://content.mamotorworks.com/pdf/603817.pdf

http://www.mamotorworks.com/corvett...uild-kits+1984+1988+4+3-manual-1-327-735.html

http://members.cisdi.com/~anesthes/f-car-t5/

http://www.ecklerscorvette.com/corvette-transmission-rebuild-kit-doug-nash-4-3-1985late-1988.html

http://www.5speeds.com/dne.htm

http://www.5speeds.com/43table.htm

http://www.ecklerscorvette.com/corv...rive-rebuild-kit-doug-nash-4-3-1984-1988.html

http://forums.corvetteforum.com/c4-gene ... pdate.html

http://www.ecklerscorvette.com/corvette ... -1988.html

http://tech.corvettecentral.com/2007/01 ... nsmission/

http://www.ecklerscorvette.com/corvette ... uct_Viewed

http://forums.corvetteforum.com/c4-tech ... ide-2.html

http://www.vetteweb.com/tech/vemp_0511_ ... ewall.html

http://www.mamotorworks.com/corvette-c4 ... 7-735.html

4+3 filter LISTED ON A DIFFERENT SITE

Carquest # 85926

AC-Delco #: TF184 ($4.50 at Rockauto.com)

Fram #: FT1024 ($9 at Kragen)

Napa #: ATP14717 ($8.50)

Ford #: D0AZ-7A098-A

General Motors #: 12339143

Last edited by a moderator: