Daan, those heads almost certainly came with exhaust valve rotators from the factory.

For performance use rotators are not used - only retainers like the ones on the intake valves.

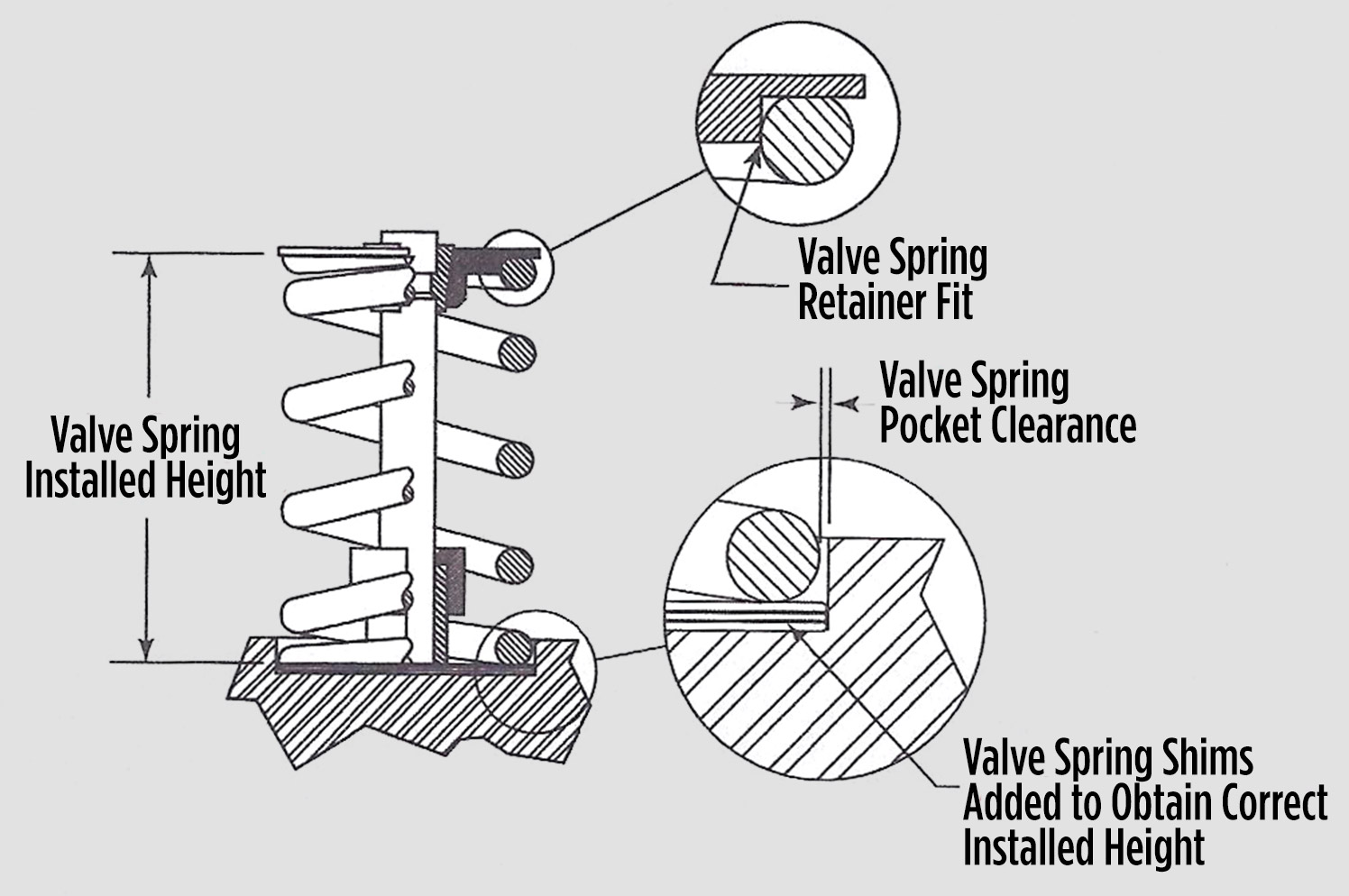

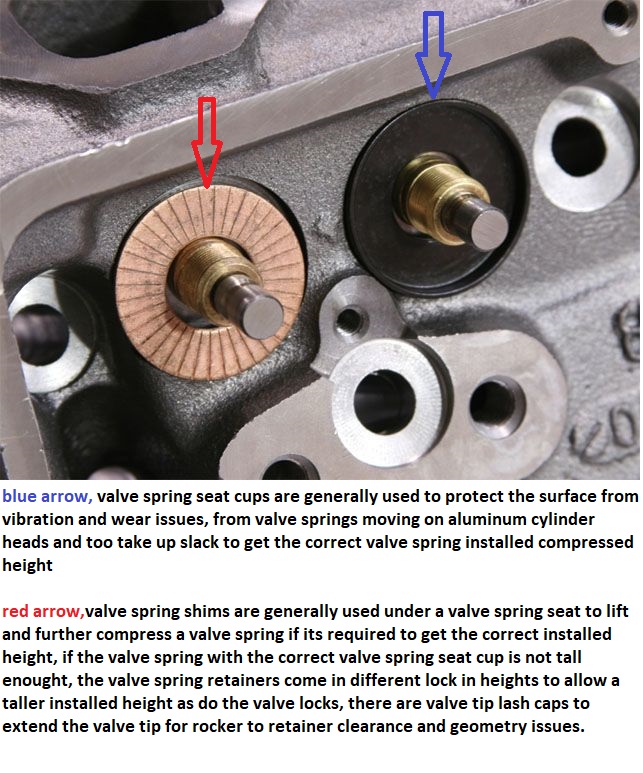

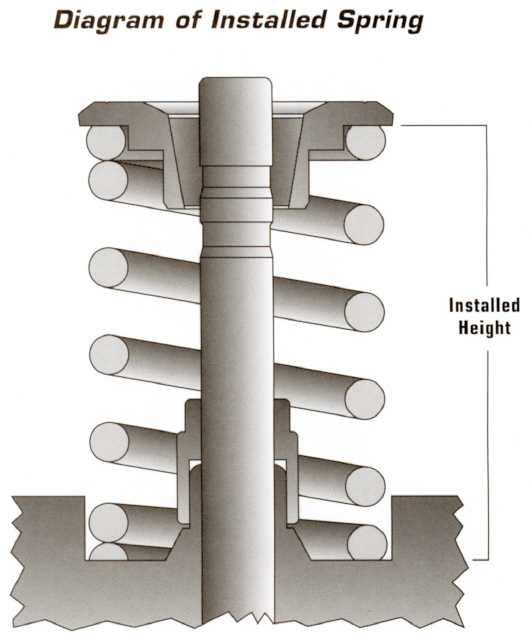

That shim makes up the difference in the thickness between the two in order to get the proper spring installed height.

You might find that the exhaust spring seats are machined deeper in those heads to compensate for the difference in thickness if rotators were in fact used.

I see that you did not use the spring shields. Good for you. Back in the day, all that was used for valve seals was a combination of an o-ring that went in that extra lower groove in the valve stem (the groove under where the locks grab) and those metal shields for oil control. We have much better valve seals now. I see your valve guides have already been machined for them.

To use those metal shields today is a complete waste. It's just unnecessary added weight to the valvetrain that can serve no other purpose but to lower your rpm potential.

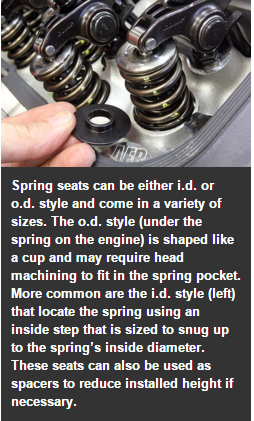

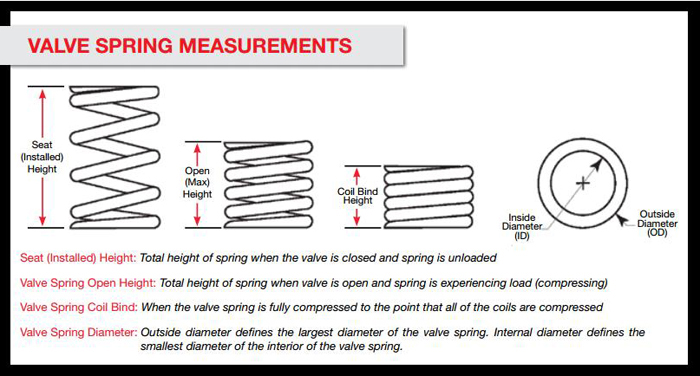

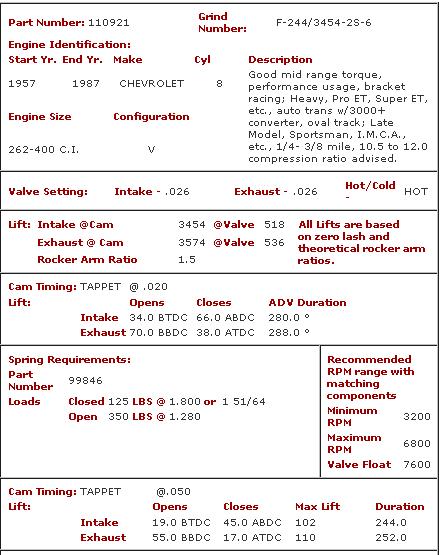

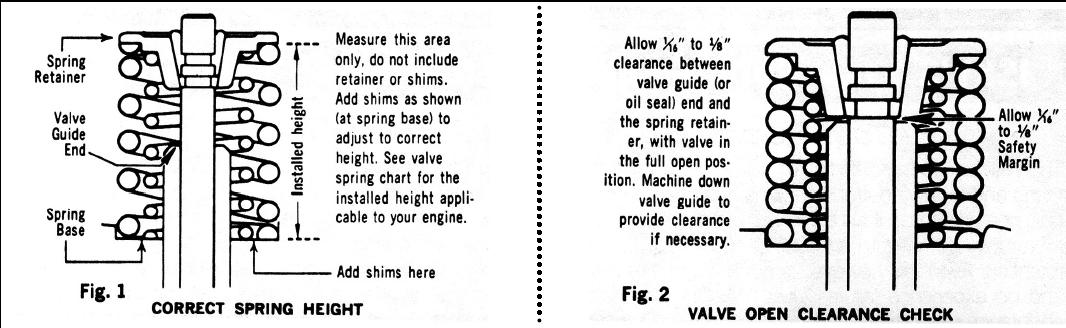

Ultimately whether you use shims, cups, or locators, plus or minus retainers, or plus or minus locks, you need to find the best combination to get the correct spring installed height without having coil bind occur, or the bottom of the retainer contacting the top of the valve seal at full lift. There must also be clearance between the rocker arm and spring retainer and clearance between the rocker arm slot and its stud through the entire lift cycle.

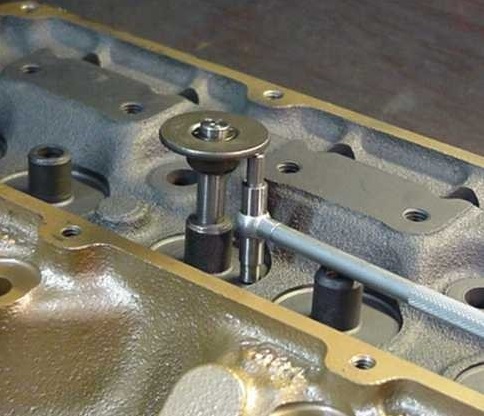

After you get all of that correct, then you have to determine the correct pushrod length to achieve proper valvetrain geometry.

Read through Grumpy's links for more detailed explanations.