http://www.superchevy.com/how-to/en...e=cxrecs&cx_navSource=related-bottom#cxrecs_s

http://airflowresearch.com/articles/article031/A-P1.htm

It’s been said that “Horsepower sells engines, but torque wins races.” There’s no question that a broad torque band makes for good street performance and driveability. An engine with more cubic inches has greater torque potential than a smaller-displacement engine, and assuming similar overall displacement, a longer-stroke engine generally develops more torque than a short-stroke mill. That’s why for many years Chevy’s 400ci small-block—with its 4.125-inch bore and 3.75-inch stroke—was the choice for car crafters looking to maximize torque in a relatively compact, lightweight package. Unfortunately, used 400 cores are getting scarce. While the as-delivered 4-inch bore on GM Performance Parts’ Bow Tie block can be overbored to 4.125-inches, the General charges premium prices for these premium blocks. What’s a torque-hungry small-block lover to do?

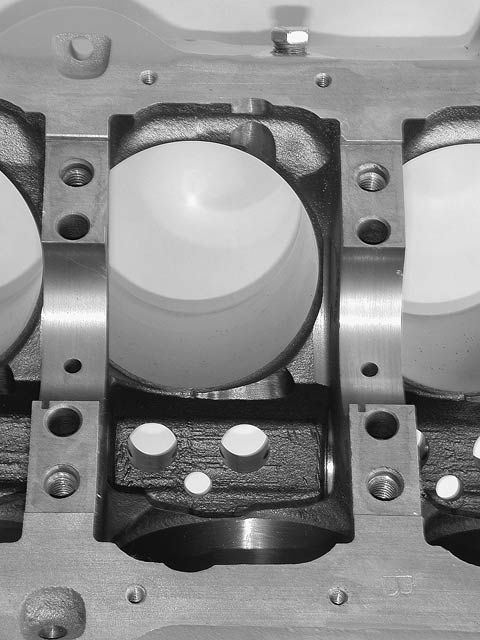

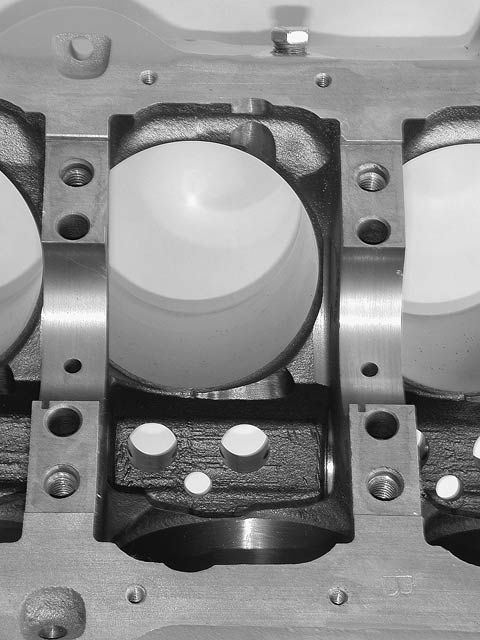

Enter American Speed Enterprises (ASE), specialists in building powerful but cost-effective Chevrolet engines for the masses. With the advent of affordable 3.875-inch forged stroker cranks and 6.0-inch rods, ASE owner Gail Trent has developed a 401ci small-block Chevy package built around a Mr. Goodwrench service replacement block (PN 10066034). Trent says these blocks have thicker cylinder walls than standard production blocks built in the last 25 years, so they readily accept a 0.060-inch overbore. Even though a long stroke is good for torque production, traditionalists argue that a long-arm crank makes for a lazy engine upstairs. ASE fixes this with lightweight reciprocating components. Typical Chevy 350 bob-weights are in the 1,910-1,930–gram range, but on its 401, ASE holds bob-weights down to only 1,577 grams. The engine makes power past 6,000, and is internally balanced without Mallory metal.

Arguably the best all-around 23-degree valve-angle, conventional port location, small-block Chevy cylinder head, Air Flow Research’s 195cc Race-Port aluminum casting comes CNC-ported on both intakes and exhausts. The result is a more consistent casting that doesn’t require hand-finishing. The exhaust ports

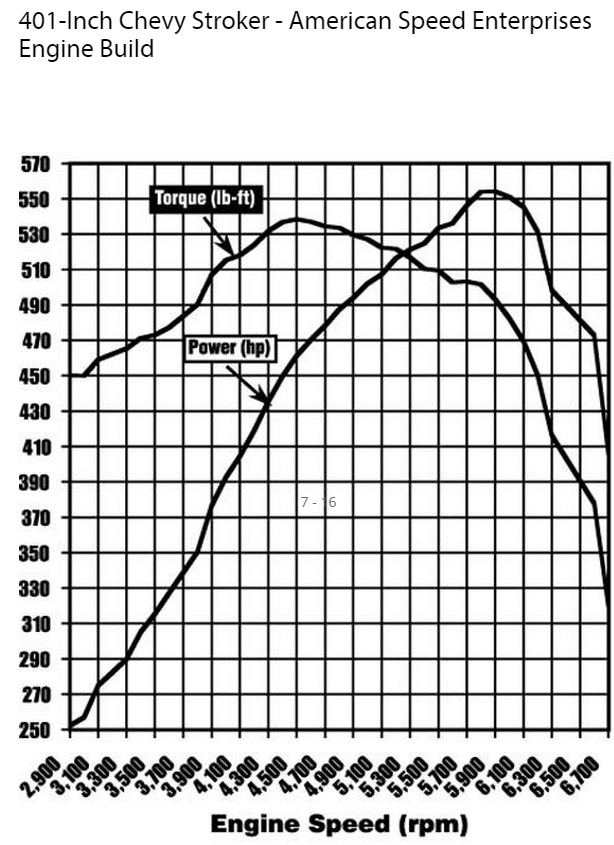

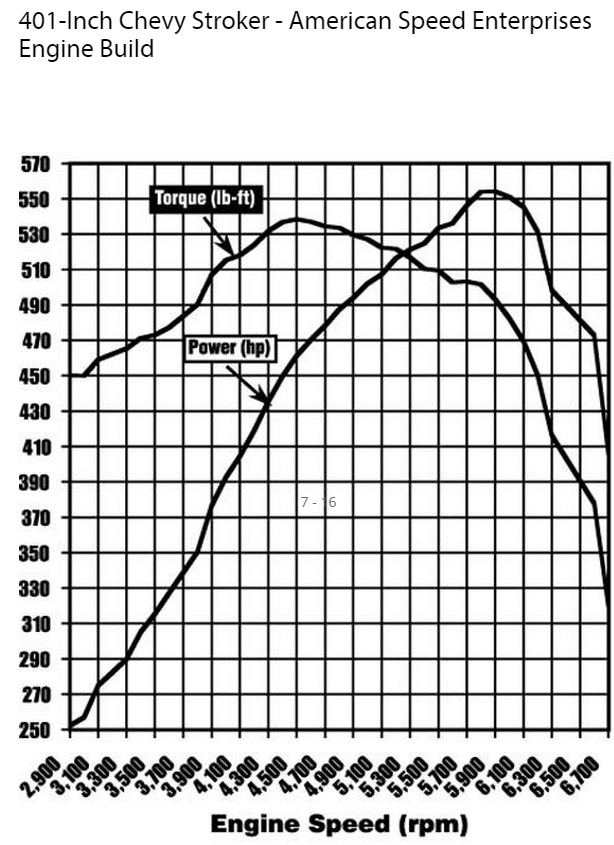

how a drag-race engine is loaded in the real world when you dump the clutch or load it up against the torque converter. Under these conditions, using 93-octane gas with 36-degrees of ignition lead, the engine churned out a whopping 538.5 lb-ft of torque at 4,500 rpm, and it developed a stout 554.2 hp at 5,900. The animal made over 500 lb-ft from 3,900 to 5,800 rpm, and it exceeded the 400 lb-ft mark through 6,300…definitely as advertised—and competitive with many a big-block! If you want to be the torque of the town, ASE’s complete 401 crate engine, assembled using all-new parts and carrying a 90-day warranty, goes out the door for $7,500 complete, less headers and a water pump

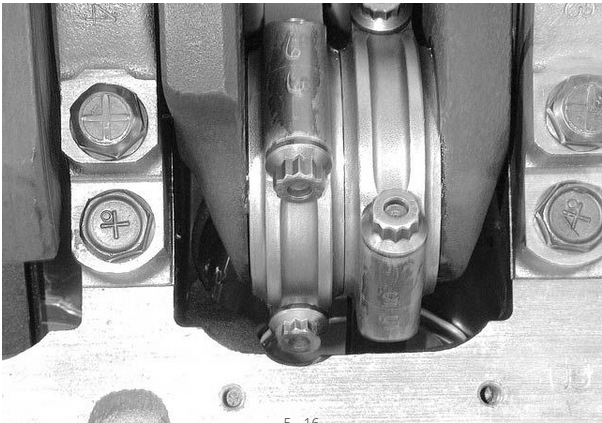

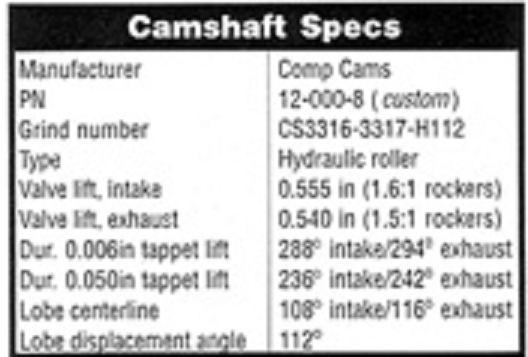

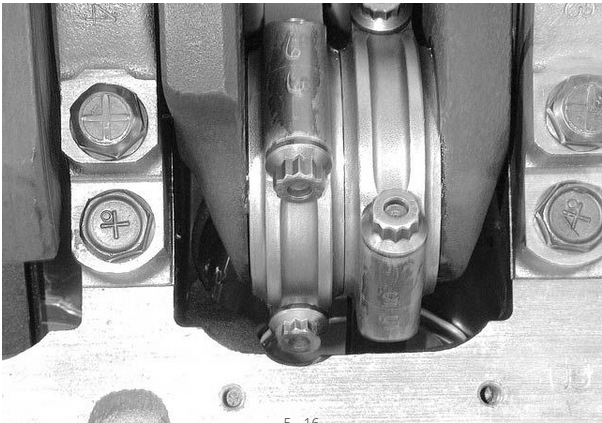

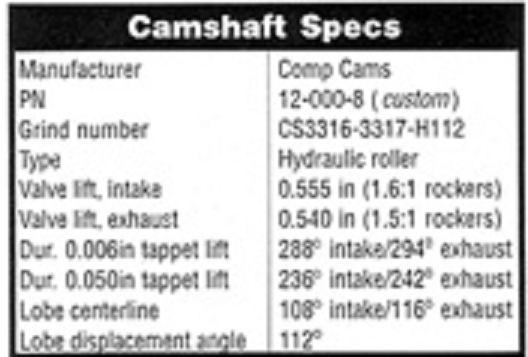

flowed so well that—with ASE’s dual-pattern cam—the best overall power and torque curve was obtained by installing 1.5:1 rockers on the exhaust side to complement the 1.6:1 rockers used to open the intake valves.

The heads are fed by a Holley 750-cfm double-pumper carb atop an Edelbrock RPM Air-Gap intake, while an MSD distributor and Champion RC12YC plugs (gapped at 0.035-inch) ignite the spark. You’re on your own for headers, but ASE recommends 13¼4-inch primaries with 3-inch collectors, which is what it used to dyno-test the prototype assembly.

notice the similarity to the crower 00471 hydraulic roller which in my experience has always produce a bit better power

http://airflowresearch.com/articles/article031/A-P1.htm

It’s been said that “Horsepower sells engines, but torque wins races.” There’s no question that a broad torque band makes for good street performance and driveability. An engine with more cubic inches has greater torque potential than a smaller-displacement engine, and assuming similar overall displacement, a longer-stroke engine generally develops more torque than a short-stroke mill. That’s why for many years Chevy’s 400ci small-block—with its 4.125-inch bore and 3.75-inch stroke—was the choice for car crafters looking to maximize torque in a relatively compact, lightweight package. Unfortunately, used 400 cores are getting scarce. While the as-delivered 4-inch bore on GM Performance Parts’ Bow Tie block can be overbored to 4.125-inches, the General charges premium prices for these premium blocks. What’s a torque-hungry small-block lover to do?

Enter American Speed Enterprises (ASE), specialists in building powerful but cost-effective Chevrolet engines for the masses. With the advent of affordable 3.875-inch forged stroker cranks and 6.0-inch rods, ASE owner Gail Trent has developed a 401ci small-block Chevy package built around a Mr. Goodwrench service replacement block (PN 10066034). Trent says these blocks have thicker cylinder walls than standard production blocks built in the last 25 years, so they readily accept a 0.060-inch overbore. Even though a long stroke is good for torque production, traditionalists argue that a long-arm crank makes for a lazy engine upstairs. ASE fixes this with lightweight reciprocating components. Typical Chevy 350 bob-weights are in the 1,910-1,930–gram range, but on its 401, ASE holds bob-weights down to only 1,577 grams. The engine makes power past 6,000, and is internally balanced without Mallory metal.

Arguably the best all-around 23-degree valve-angle, conventional port location, small-block Chevy cylinder head, Air Flow Research’s 195cc Race-Port aluminum casting comes CNC-ported on both intakes and exhausts. The result is a more consistent casting that doesn’t require hand-finishing. The exhaust ports

how a drag-race engine is loaded in the real world when you dump the clutch or load it up against the torque converter. Under these conditions, using 93-octane gas with 36-degrees of ignition lead, the engine churned out a whopping 538.5 lb-ft of torque at 4,500 rpm, and it developed a stout 554.2 hp at 5,900. The animal made over 500 lb-ft from 3,900 to 5,800 rpm, and it exceeded the 400 lb-ft mark through 6,300…definitely as advertised—and competitive with many a big-block! If you want to be the torque of the town, ASE’s complete 401 crate engine, assembled using all-new parts and carrying a 90-day warranty, goes out the door for $7,500 complete, less headers and a water pump

flowed so well that—with ASE’s dual-pattern cam—the best overall power and torque curve was obtained by installing 1.5:1 rockers on the exhaust side to complement the 1.6:1 rockers used to open the intake valves.

The heads are fed by a Holley 750-cfm double-pumper carb atop an Edelbrock RPM Air-Gap intake, while an MSD distributor and Champion RC12YC plugs (gapped at 0.035-inch) ignite the spark. You’re on your own for headers, but ASE recommends 13¼4-inch primaries with 3-inch collectors, which is what it used to dyno-test the prototype assembly.

notice the similarity to the crower 00471 hydraulic roller which in my experience has always produce a bit better power

Last edited: