http://www.superchevy.com/how-to/engines-drivetrain/sucp-0711-big-block-chevy-supercharger/

http://www.superchevy.com/how-to/engines-drivetrain/camp-1302-weiland-blowers-on-built-454/

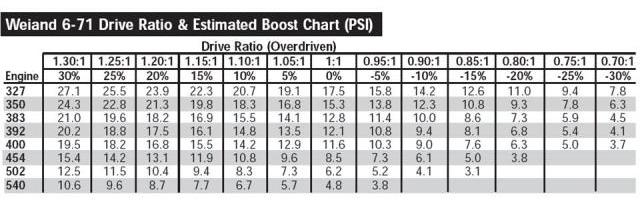

OK, LS engines are arguably one of the best, if not the best, engines ever fielded by GM, or anyone for that matter. But sometimes they just feel a bit sterile and “soulless.” Maybe what you need is something a bit more retro, and nothing says, “old-school performance,” like a supercharged big-block. We’re not talking one of those fancy centrifugal blowers either, but a good old roots-style huffer. Knowing you want a big-block with a blower sitting majestically on top is only half the battle. You also need to make sure you properly size the supercharger to your mill. This is where hot rodders often make mistakes. Most people think in terms of boost and don’t consider how much atmosphere the unit is capable of moving. It also happens that when they see a blower that’s advertised as providing an X percent increase in power, they just assume it will translate to their engine. Maybe it will, maybe it won’t. Keep in mind that when a manufacturer states that a blower will give a certain power increase, the amount is based on a specific engine combination and doesn’t apply to a variety of engines. A small blower may give you that 40 percent boost in power on your nearly stock 396, but it just won’t move enough volume to give you the hoped-for results on a built 454 or 502. It’s akin to the law of diminishing returns. The bigger the engine, the smaller (percentage wise) the gain will be at a given boost level; at least until you step up to a bigger blower. At that point the cycle repeats. So the small 177 Weiand might be just the ticket for your 396, while that 454 or 502 might be better served by a 6-71, and even larger engines might require a monstrous 8-71 supercharger. Also, you might be better off running a larger blower and spinning it slower since this generates less heat. So, an underdriven 8-71 will most likely make more power than an overdriven 6-71. Try and follow this rule of thumb: A larger volume blower will typically make more power than a smaller volume unit at the same boost level.

To put this theory to the test we built up a Dart 454 big-block, grabbed a couple of Weiand blowers, and headed over to Westech Performance in Mira Loma, California, for some dyno time on their Superflow 902.

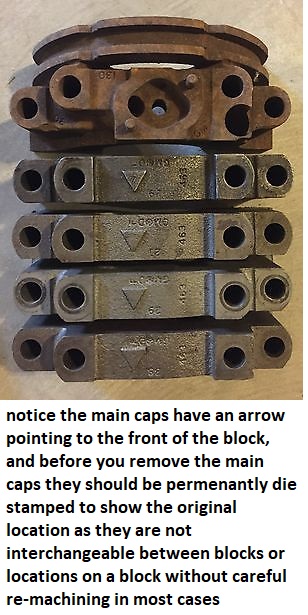

01 As shipped, Dart blocks (PN 31263644, $2,544) are pretty clean, but they do require some TLC. JR Twedt, owner of JR Competition Engines in Escondido, California, explained, “We deburred all the casting flash, which can eventually chip away, causing heat and stress risers.” Extra-thick siamesed cylinder walls resist cracking and have improved ring seal, scalloped outer water jacket walls help improve coolant flow, stronger steel caps incorporate splayed outer bolts, and improved lifter valley head bosses are just a few of the refinements. Other items, like true “priority main” oiling and a crank tunnel pre-clearanced for big strokes just make life easier.

3/23

02 The rotating assembly came as a kit, so our first step was to mate the Engine Pro H-beam forged rods (6.135-inch) with the KB pistons. With that done, JR custom-fitted the Hastings rings.

4/23

03 After wiping down the cylinder walls with a light coat of oil, JR went about stabbing the rod/piston assemblies into the Dart block. Since we will be running boost on this engine, our targeted compression ratio was 9.0:1.

5/23

04 We then installed and secured the Eagle 4340 forged crank. The Dart block came with high-grade main cap bolts, which saved us a few bucks.

6/23

05 Now, if all we cared about was wowing you with big dyno numbers, we could have tossed in an insanely rowdy camshaft that would be a true pain to live with on the street, but we live in the real world where idle characteristics are nearly as important as how much peak power an engine puts out. To that end, we selected a hydraulic roller camshaft from COMP that offers a good balance between power and street manners. Duration numbers (at 0.50) came in at 236/244 with lift of 0.646-inch on a 110 LSA (PN 11-000-8, $297).

7/23

06 A broken timing chain can wreak havoc on an engine’s valvetrain, so we bought this double-roller COMP chain and gear set (PN 7110, $104). It features billet steel sprockets and a nine-keyway crank sprocket for 2-degree incremental adjustability. It’s pre-stretched, heat-treated, and includes the Torrington roller thrust bearing. What’s not to love?

8/23

07 Billet front covers look great, but there’s more to them than just looks. Even with a thrust button, a stock stamped-steel front cover can flex under pressure, causing erratic ignition timing. This COMP two-piece billet aluminum cover (PN 212, $250) is super rigid and will hold our cam in place where it belongs. It also made endplay adjustment a snap due to its handy access hole. For racers, the two-piece design makes cam swaps that much easier. And just like that, our short block was done and lookin’ good in its Chevy Orange paint.

9/23

08 The fully assembled 308cc Dart Iron Eagle heads (PN 15100112, $890 each) feature big 2.250-inch intake and 1.880-inch exhaust valves along with thick port walls and enlarged water passages. JR did a mild amount of porting to the cross-section and short turn radius. The key was to do just enough to improve flow and cylinder fill, but not slow down the airspeed at low- to mid-lift point.

10/23

09 Adjusting a solid roller setup is a pain, which is why we went hydraulic. Key players in our valvetrain are these COMP High Energy hydraulic roller lifters (PN 854S-16, $531). They have a vertical bar and are perfect for dropping into blocks designed for flat tappets. JR also checked piston-to-valve clearance, and there was plenty. Again, reliability is in the details.

11/23

10 The heads were then secured using an ARP bolt kit (PN 135-3603, $108) and sealed with a Fel-Pro PermaTorque MLS gasket (PN 1071, $80 each).

12/23

11 Rounding out our roller valvetrain were these investment-cast 8650 chromoly 1.7 ratio Ultra Pro Magnum rockers from COMP (PN 1620-16, $335). The arched, web-like design delivers an almost 29 percent increase in strength of rigidity, while coming in with a lower moment of inertia. In English, this means they weigh less yet won’t distort at high rpm. They also feature oversized trunnions and needle bearings suited to high-load valvesprings.

13/23

12 A sketchy oiling system can quickly kill even the best built engine. To keep the juices flowing, we picked up this high-volume pump from Moroso (PN 22185, $112). This pump is designed for an 8-inch deep pan and the pickup is fully welded in place. The other big player in our rock-solid oiling system was a fully baffled 6-quart Moroso pan (PN 20403, $263). It featured a kicked-out sump for improved oil control and an integrated windage tray. We bolted it in place using a Fel-Pro gasket set (PN 1884R, $33) and stainless fasteners from our ARP accessory bolt kit (PN 535-9601, $146).

14/23

13 Just for giggles we wanted to see what the 454 would make with only a carb, so we grabbed a 950-cfm unit off the shelf along with a Weiand single-plane intake manifold. Given the low compression, we knew the power numbers wouldn’t be stellar, but we wanted some sort of baseline.

15/23

14 To be honest, these numbers were better than we expected. The 454 made tons of low-end torque and over 500 hp at 5,800 rpm. Better numbers than a ZZ502 GM crate engine.

16/23

15 OK, so the point here is to make some boosted power, but keep in mind that all blowers are not the same. For a budget-minded person, or one without hood clearance, one of the mini-blowers on the market might be just the ticket. This unit we are testing is a Weiand 177 Pro Street roots-style supercharger (PN 6530-1, $2,400).

17/23

16 Now, the 177 supercharger is advertised as giving 25 to 40 percent more power, but keep in mind that’s typically on a milder engine. The more built or bigger inch the engine, the less “bang for the buck” it’s going to yield. With a carb, our 454 put out 504 hp, so a 25 percent increase would be around 125 hp. Well, as you can see it only picked up 52 hp, which is around a 10 percent gain. The reason is that the small blower couldn’t move enough air to feed the built 454. Typically, these small-displacement blowers are better suited to milder 396 and 427 engines where they can deliver the stated gains. What’s the moral of the story? Buy a blower that’s properly sized to your engine and power goals.

18/23

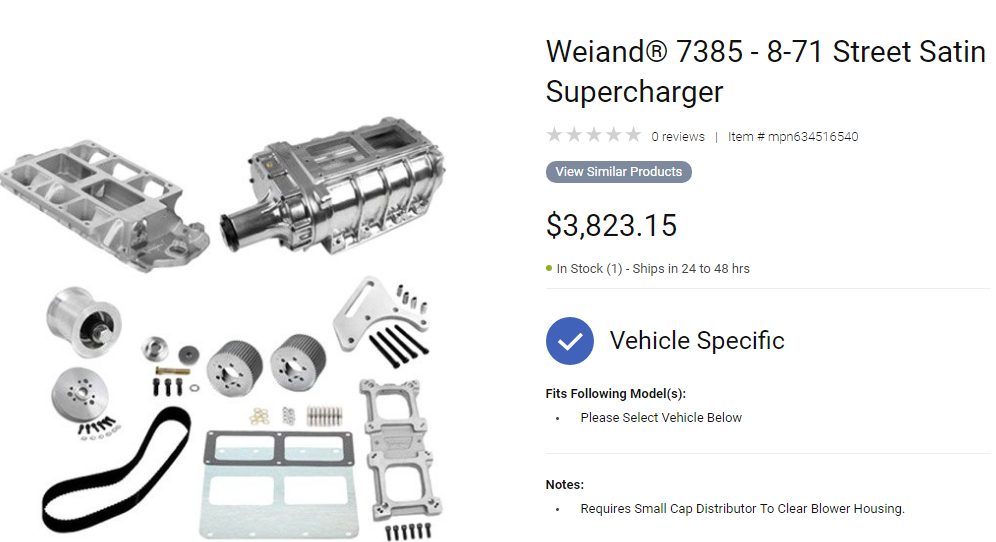

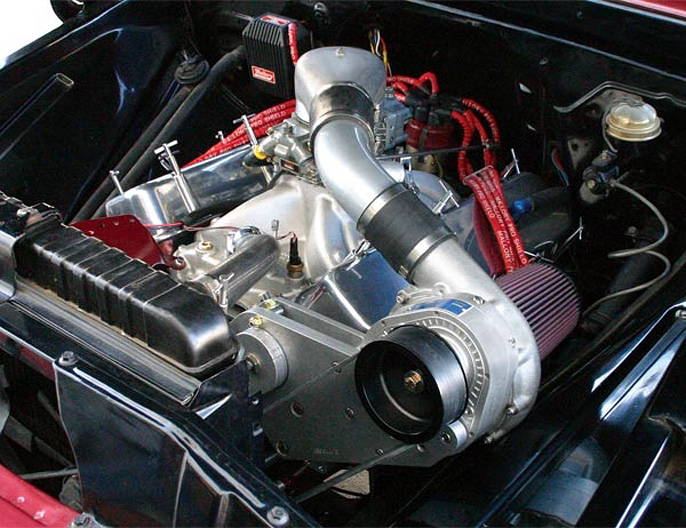

17 For a built engine you need to stuff in more air, and for this we went with a Weiand 6-71 series supercharger (PN 7483, $3,000). Now, the kit costs $600 more than the 177 blower, but it will be capable of stuffing enough atmosphere into our 454 to justify the cost. The other added expense is that it requires two supercharger-tuned Holley carbs (PN 0-80573S, $586 each) and a linkage kit (PN 7167, $200) to make it all work.

19/23

18 So what does that extra cash get you besides a killer looking blower poking through your hood? Well, at a very conservative boost level on 91-octane pump gas, the horsepower number rocketed up to 691 ponies. That’s 187 hp over what it made with the carb, and 125 more than our maxed-out 177 Weiand blower.

20/23

19 The other big advantage to this 6-71 Wieand is potential. Want more power? Simply toss on an overdrive pulley and get ready to rock. But keep in mind, a smaller pulley will only get you so far since the blower will eventually max out on its ability to move air. At that point you would need to move to a larger unit.

21/23

20 A few more pounds of overdriven boost and some 100-octane Rocket race gas netted us 782 hp at 6,500 rpm! That’s 278 more horsepower than the carbureted pull and 91 hp more than the 6-71, pump-gas pull. This flexibility is perfect for the guy who wants to cruise around town then swap some pulleys and hit the dragstrip on the weekend.

22/23

21 And here’s a good way to look at the four tests we did (carbureted, 177 blower, underdriven 6-71, and overdriven 6-71). As you can see, the properly sized blower brings a lot more fun to the table for not a ton more cash.

3/14

3/14 4/14

4/14 8/14

8/14 9/14

9/14 10/14

10/14 11/14

11/14 12/14

12/14 13/14

13/14 14/14

14/14