first let me say, congratulations on having a big block built under conditions that Im sure are far from ideal or cheap,Im sure you will enjoy the results.

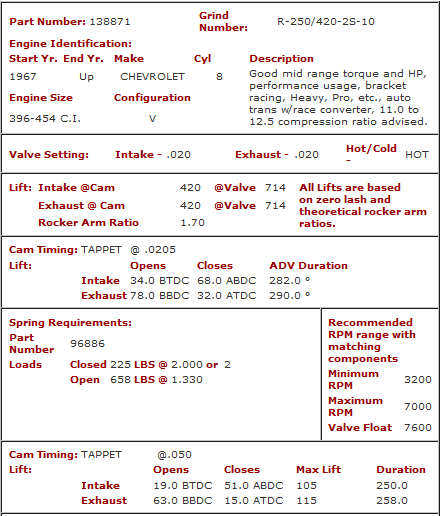

its true that each engine combo will need to be tuned to what it likes best and thats usually found on a dyno or the track, mostly by trial and error but obviously experience has a great deal to do with what you will find works best.

Ive built at least two dozen 489-496 big blocks and its not hard to build a 550hp-600hp combo.

viewtopic.php?f=69&t=5123

viewtopic.php?f=69&t=6125

viewtopic.php?f=69&t=3153

viewtopic.php?f=69&t=189

http://www.dragzine.com/tech-stories/engine/ultimate-guide-to-budget-bbc-cylinder-heads-under-2000/

yes its possible that that engine runs best on a leaner fuel air ratio, but I rarely see engines run best on ratios leaner than about 13.7:1.

now on a fairly high compression engine its been my experience that a fuel/air ratio in the 12.5:1-13.3:1 range usually produces the best results , but factors like quench distance, cylinder head temperatures and ignition advance curve obviously need to match the fuel air ratio used.

your running a fairly low static compression ratio, which tends to run better with a slightly leaner fuel air ration and a slightly slower ignition advance.

now Im not saying that thats the absolute only useable correct fuel/air ratio, because changes in the ignition advance and other factors can easily effect the results.

If it was my engine Id try to richen the fuel/air mix up to keep it consistently richer than 13.7:1 as I seldom see leaner mixture ratio than that produce best torque

Btw heres a tip learned through experience , if your 496 -540 displacement BBC combo includes an engine with at least 10:1 compression and a cam with at least 240 duration at .050 lift, and oval port heads, youll almost always find a single plane intake has some advantages over a dual plane intake.

https://www.holley.com/products/intakes/single_plane_manifolds/parts/7620

viewtopic.php?f=55&t=109

viewtopic.php?f=70&t=4683

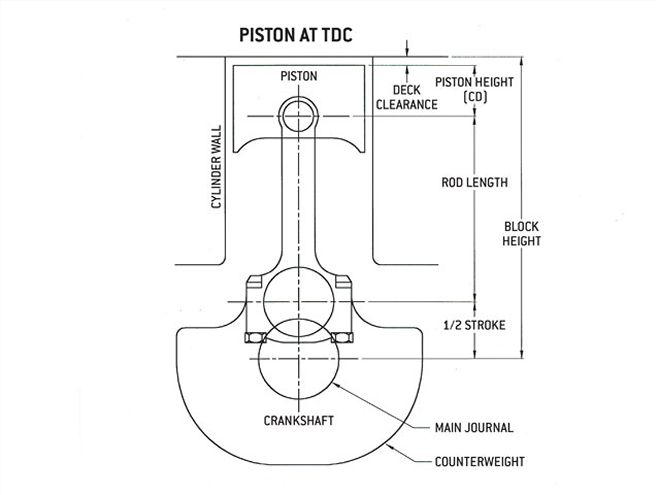

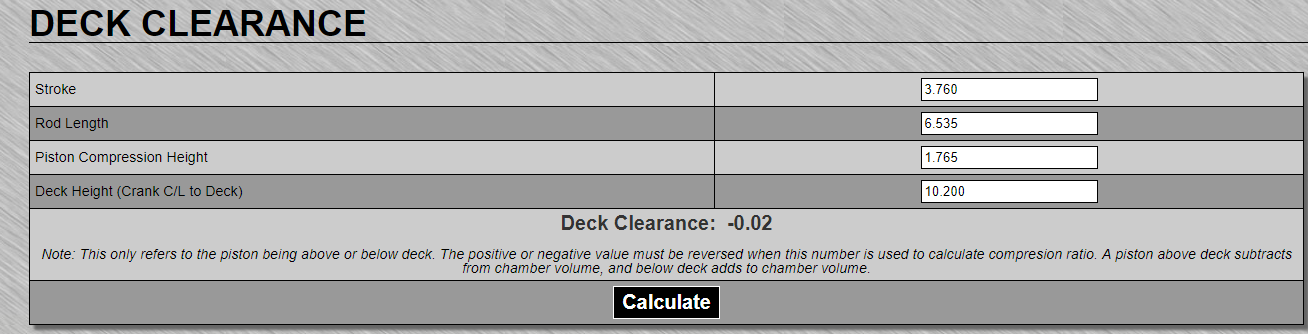

the best solution from a performance perspective is to do the required calculations to select the longest length connecting rod and the lowest weight piston,

of a decent design that will reduce the reciprocating mass significantly more.

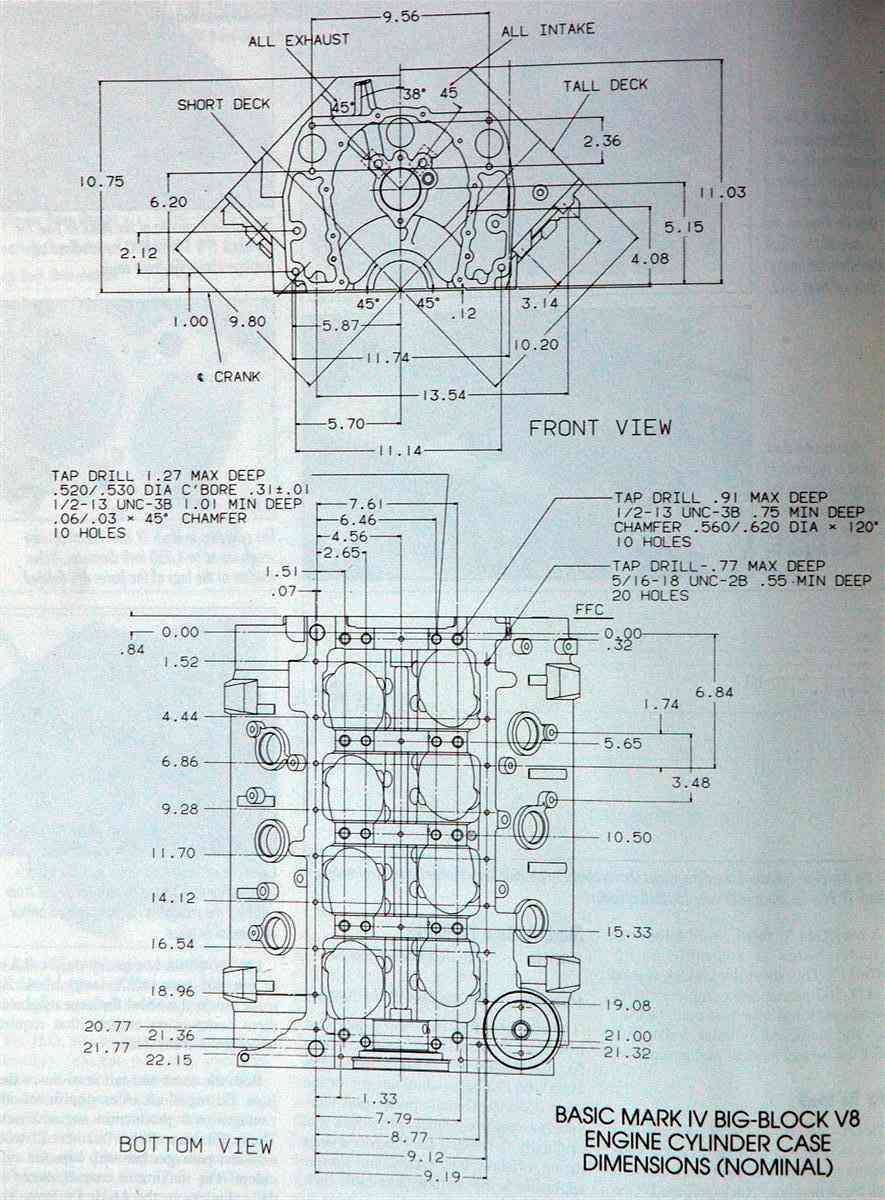

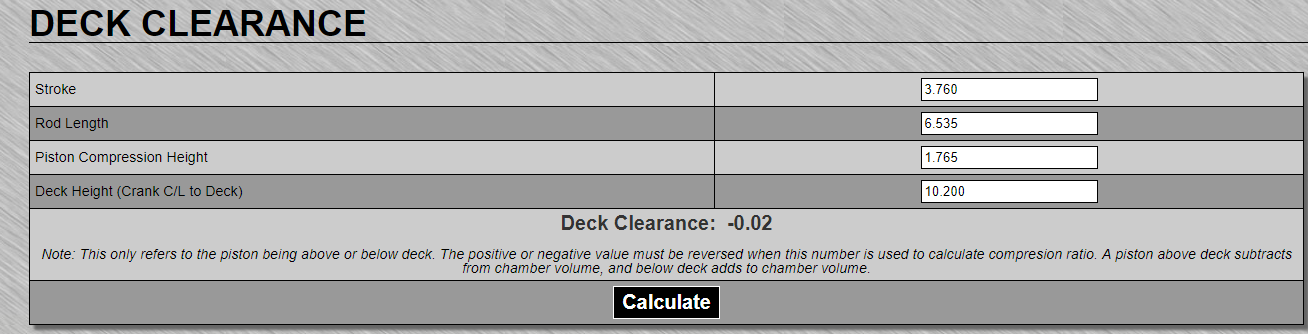

the tall deck has a 10.2" deck height, a good dual plane aluminum high rise intake manifold will tend to provide the best compromise if you use a low compression and mild cam duration,

while it might seem like a waste of time, now, reading the links and sub-links will provide a good base to work from, later and save you a great deal of wasted time and money

you have a choice, you can slap the components you own together, now and live with what you have built regardless of the results , or you can put some real thought into making the result perform and carefully select parts and significantly boost power... yes that routes more expensive up front, but in the long term it tends to get better results and cost LESS.

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

notice the pin height in the pistons pictured above allow a longer or shorter connecting rod length

heres a selection of commonly available big block chevy connecting rod lengths

https://www.uempistons.com/index.ph...e=deck&zenid=823ce2c9e2ffa691864d832c10107df0

https://www.uempistons.com/index.php?main_page=calculators&zenid=823ce2c9e2ffa691864d832c10107df0

1.765 compression height, pistons in standard 9.8" deck block, a 10.2" tall deck requires a longer connecting rod

most likely a 6.535" aftermarket connecting rod

threads you should read through carefully,and the sub links in them are below,

the tall deck block is put to much better use building a 496 with a 4.25" stroke and a .060 over bore and 6.385" connecting rods

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/

http://garage.grumpysperformance.co...g-block-head-comparison.319/page-2#post-61658

http://www.maliburacing.com/patrick_budd_article.htm

http://garage.grumpysperformance.com/index.php?threads/427-tall-deck-bbc.14451/

http://garage.grumpysperformance.com/index.php?threads/big-block-chevy-info.710/#post-60299

http://garage.grumpysperformance.co...-displacement-street-engine.10961/#post-50668

![7620_2[583x].jpg](/proxy.php?image=http%3A%2F%2Fwww.grumpysperformance.com%2Fjuly2017%2F7620_2%5B583x%5D.jpg&hash=5931892943d24f9505466692c10aa541)