Speedlink1973

Well-Known Member

Hi everyone,

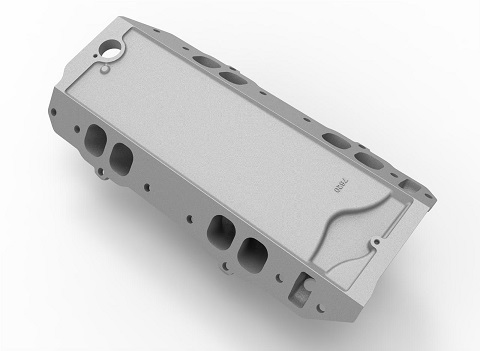

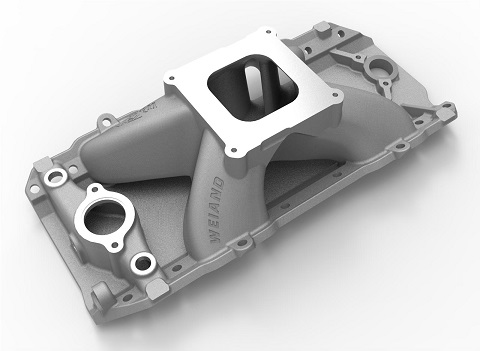

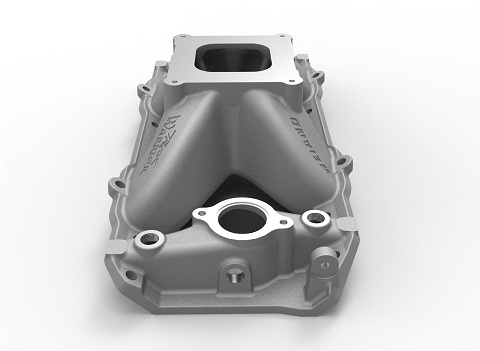

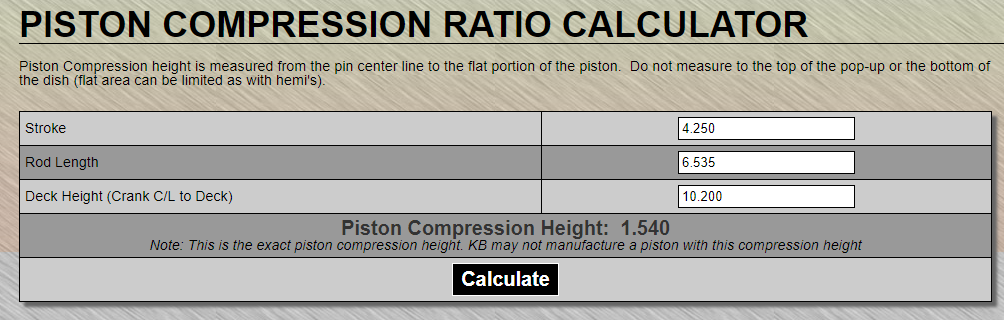

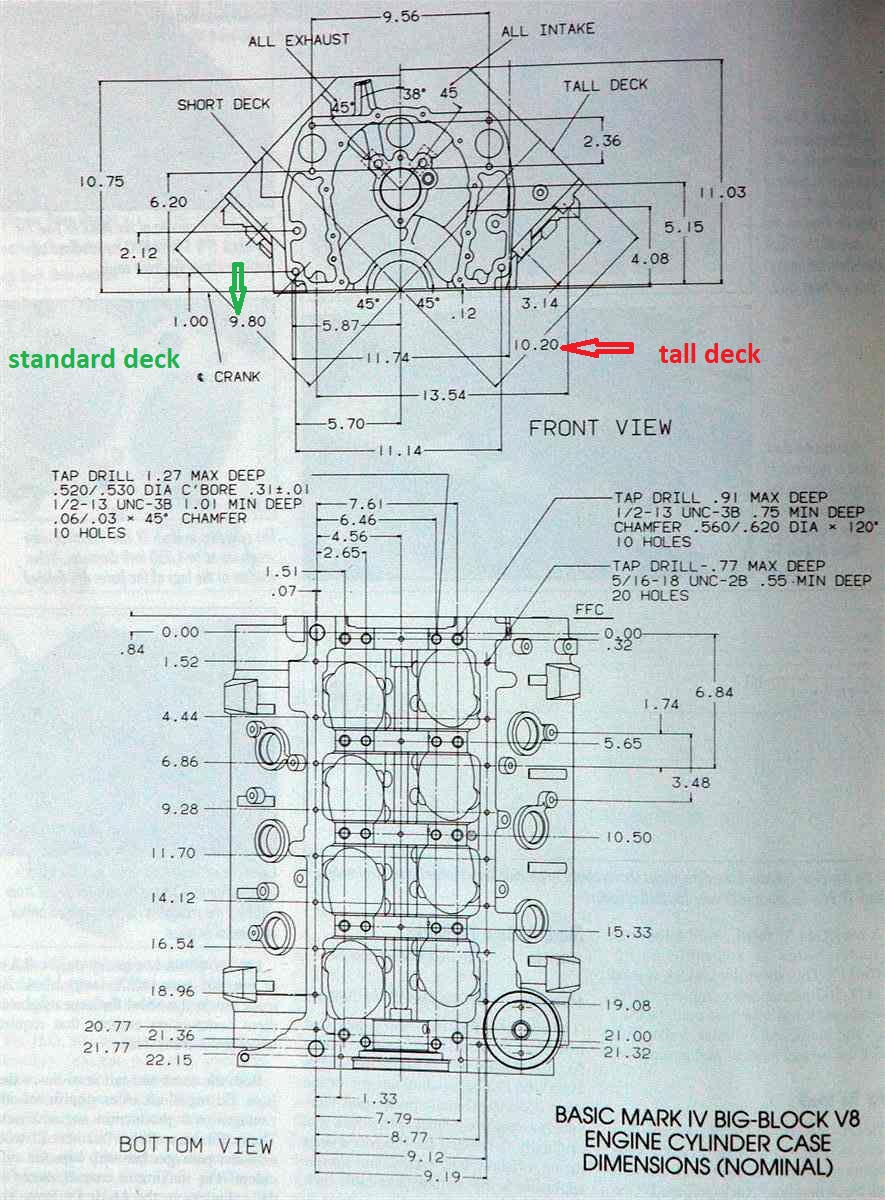

Some have seen a few of my posts on a revamped 496ci I'm working on

I have everything finely to do the assembly.

Want to say thanks to all who has made me think outside the box on this build.

Some pictures I've already posted here and their so I will post pictures as I go on this thread so I don't clog up other threads.

Some have seen a few of my posts on a revamped 496ci I'm working on

I have everything finely to do the assembly.

Want to say thanks to all who has made me think outside the box on this build.

Some pictures I've already posted here and their so I will post pictures as I go on this thread so I don't clog up other threads.

Attachments

Last edited: