You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

496ci revamped

- Thread starter Speedlink1973

- Start date

So what you are wanting is the same as Sim 1, but with a dual plane intake?Hey Rick if you get some time

Just out of curiosity could you possibly

Run sim my cam and my 290cc heads

But with a dual plane intake.

If get time.

It would be greatly appreciated

Speedlink1973

Well-Known Member

Yes, that would be fantasticSo what you are wanting is the same as Sim 1, but with a dual plane intake?

Thanks again Rick

I'm Bob by the way aka Speedlink1973

Speedlink1973

Well-Known Member

See this stuff my be doneElectric controlled 4l80e needs only dual feet, right clearaces ,sonnax boost valve bigger feed holes and it can take lots of power

Internal mods are same as th400

Only pump is difrent ,it need only small hole drill to pump housing so converter gets constant oil feed

The place that built it says it needs very little vacuum to work.

He builds these things for 850hp

Big blocks and guy's are running them at 1000hp, a 1000hp big block I'm sure is not running some 221@50 looking for vacuum, but again just trying to verify

Before eating a transmission up.

But trying to verify

Bob, you can never go wrong with too much detail. Instead of saying MY cam, it would better to sayYes, that would be fantastic

Thanks again Rick

I'm Bob by the way aka Speedlink1973

my Howard cam with the single plane intake from the first simulation. You would not believe how

many things change and just when I think I know what's going on in a thread of many, I get it wrong .....

I hate making mistakes and it's most helpful to the person I'm trying to help, to help me stay on

track. You are not the first one, but anyone reading this thread it might help in the future. I have

thousands of photo and graphics to keep straight ........

Ok, so back to the technical details. As always it's in your best interest to make sure the info makes sense.

Hey Bob , I'm Rick in real life and I love helping people !!!

.

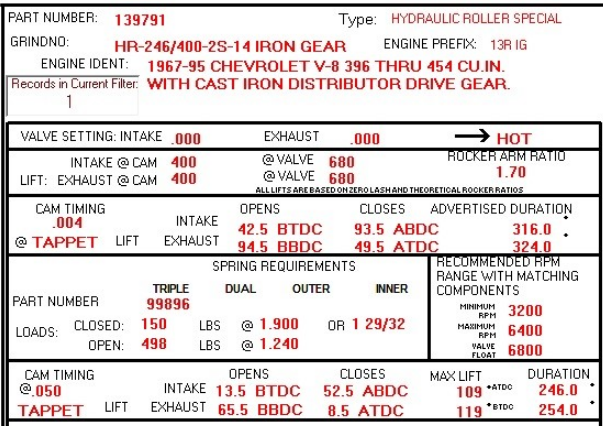

ok, RICK can you run a similar software dyno swapping three factors

now can you simply swap to the crane roller

jump to a 11:1 compression, and use a crane 139791 cam retarded 4 degrees

and the 315 cc heads

315cc BBC

https://www.airflowresearch.com/315cc-bbc-rectangle-port-cylinder-head/

.200 .300 .400 .500 .600 .700 .800

Int 169 249 312 353 380 386 387

Exh 146 184 238 271 296 310 315

now can you simply swap to the crane roller

jump to a 11:1 compression, and use a crane 139791 cam retarded 4 degrees

and the 315 cc heads

315cc BBC

https://www.airflowresearch.com/315cc-bbc-rectangle-port-cylinder-head/

.200 .300 .400 .500 .600 .700 .800

Int 169 249 312 353 380 386 387

Exh 146 184 238 271 296 310 315

Maniacmechanic1

solid fixture here in the forum

Dual plane intake is the Winner.Bob, you can never go wrong with too much detail. Instead of saying MY cam, it would better to say

my Howard cam with the single plane intake from the first simulation. You would not believe how

many things change and just when I think I know what's going on in a thread of many, I get it wrong .....

I hate making mistakes and it's most helpful to the person I'm trying to help, to help me stay on

track. You are not the first one, but anyone reading this thread it might help in the future. I have

thousands of photo and graphics to keep straight ........

Ok, so back to the technical details. As always it's in your best interest to make sure the info makes sense.

View attachment 10439

Hey Bob , I'm Rick in real life and I love helping people !!!

.

Picked up Torque and Hp.

Velocity air speed increased in the Intake Ports.

So 'VE Volumetric Efficiency improved.

Engine vacuum will be higher.

Run it.

Verify with a vacuum guage.

Cost is Nothing to use the 4L80e-3 Transgo as is.

At least $1,000 needed to convert to electronic shift.

Need the Stand Alone Trans controller computer.

Speedlink1973

Well-Known Member

I understand what you're saying,Bob, you can never go wrong with too much detail. Instead of saying MY cam, it would better to say

my Howard cam with the single plane intake from the first simulation. You would not believe how

many things change and just when I think I know what's going on in a thread of many, I get it wrong .....

I hate making mistakes and it's most helpful to the person I'm trying to help, to help me stay on

track. You are not the first one, but anyone reading this thread it might help in the future. I have

thousands of photo and graphics to keep straight ........

Ok, so back to the technical details. As always it's in your best interest to make sure the info makes sense.

View attachment 10439

Hey Bob , I'm Rick in real life and I love helping people !!!

.

I had a few instances on here where

Info was vague on the cam I was very interested in on the thread (another 496)

Question, does your dyno sim 5 account for spacers like 1" or 2" carburetor spacers.

Thanks again for helping me

Greatly appreciated

Speedlink1973

Well-Known Member

See I questioned this myself on air velocity, I noticed a few 496 builds on hereDual plane intake is the Winner.

Picked up Torque and Hp.

Velocity air speed increased in the Intake Ports.

So 'VE Volumetric Efficiency improved.

Engine vacuum will be higher.

Run it.

Verify with a vacuum guage.

Cost is Nothing to use the 4L80e-3 Transgo as is.

At least $1,000 needed to convert to electronic shift.

Need the Stand Alone Trans controller computer.

Running a AFR 265cc oval port heads

I'm assuming they're trying to pick up port air speed on lower end, is that what's going on?

AFR recommend 290cc for 496.

Maniacmechanic1

solid fixture here in the forum

The Camshaft profile you have I think is better suited for smaller CC Runner Volume Heads.See I questioned this myself on air velocity, I noticed a few 496 builds on here

Running a AFR 265cc oval port heads

I'm assuming they're trying to pick up port air speed on lower end, is that what's going on?

AFR recommend 290cc for 496.

Or The AFR 290 Heads work better with a Race Cam.

Different ways to look at it.

Pontiac in 1970 Built a Tunnel Port 400 engine.

Slated for production.

Made excellent Hp on top.

Enough to Topple whatever Chevrolet and Mopar had.

Huge intake ports with 5.5 square inches cross section.

Failed on the street. Lacked low speed torque. Only Responsive with 4.33 diff gears.

Made to Redine 7,000 Rpm.

A Dual Plane was made to speed up air port velocity and it helped.

Program cancelled. Just 69 made and sold over the counter at Pontiac Dealerships.

The Pontiac Ram Air IV 4 was a better street engine and drag race engine.

Perfect balance of port velocity and airflow.

Maniacmechanic1

solid fixture here in the forum

Buried deep on Grumpys site is an article by Rehr Morrison.

He found out 1st hand port velocity is more important on the Street that Big Airflow numbers.

Helps at the Dragstrip too.

Guys used to tell me I have 800 - 900 Hp.

I was Ok.

I have just 500-550 Hp.

Let's Street Race anyhow.

I cleaned their Clocks.

Marked off 1/4 mile too.

Guys always over estimate by 300-400 hp.

He found out 1st hand port velocity is more important on the Street that Big Airflow numbers.

Helps at the Dragstrip too.

Guys used to tell me I have 800 - 900 Hp.

I was Ok.

I have just 500-550 Hp.

Let's Street Race anyhow.

I cleaned their Clocks.

Marked off 1/4 mile too.

Guys always over estimate by 300-400 hp.

We did that back on page 6, except it was with a single plane intake. DynoSim5 does not know howok, RICK can you run a similar software dyno swapping three factors

now can you simply swap to the crane roller

jump to a 11:1 compression, and use a crane 139791 cam retarded 4 degrees

to handle the Crane 139791 cam with it's non-symmetrical lobes.

All simulations have a SCR of 11.22, so no significant change there.

No, I just have the option for several different flow rates (Standard, High and Max) for each style ofQuestion, does your dyno sim 5 account for spacers like 1" or 2" carburetor spacers.

manifold. I have done all your Sims with the Max or best manifold.

Last edited:

Speedlink1973

Well-Known Member

That's what's interesting about the latest curve Rick did ,Buried deep on Grumpys site is an article by Rehr Morrison.

He found out 1st hand port velocity is more important on the Street that Big Airflow numbers.

Helps at the Dragstrip too.

Guys used to tell me I have 800 - 900 Hp.

I was Ok.

I have just 500-550 Hp.

Let's Street Race anyhow.

I cleaned their Clocks.

Marked off 1/4 mile too.

Guys always over estimate by 300-400 hp.

And some people miss the peak power with single plane intake made a bit more at like 7k

But hp with dual plane intake made 10to

15 more across the whole curve.

Torque was even better than that.

A different cam and single plane intake would most likely be better.

But this is the cam I have.

So it appears for a street strip engine

This is a good combo.

As Grumpy mentioned before I do believe a 1" or 2" spacer will help on the dual plane intake.

Particularly because my throttle body injection only has one bore with mass air flow sensor and even with notch cutout in the center they can have problems with feedback, most guys run a 1/2" to 1" just to get better feedback on that style of injection. With dual plane intakes

Attachments

Last edited:

Speedlink1973

Well-Known Member

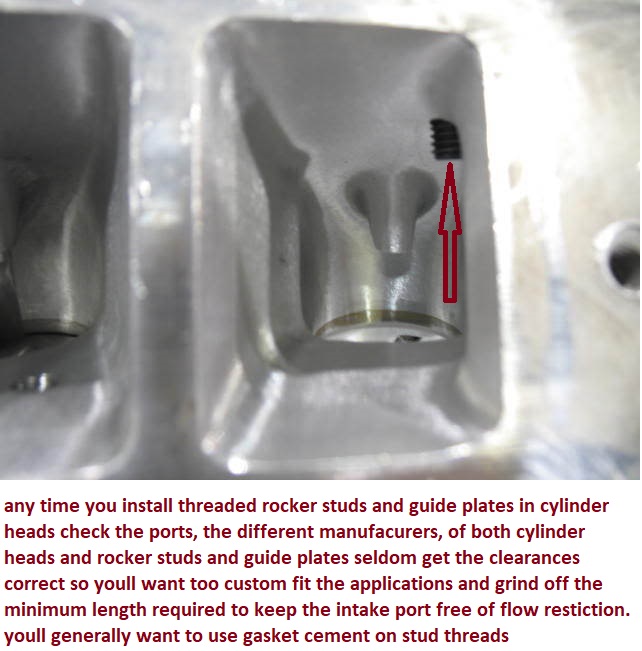

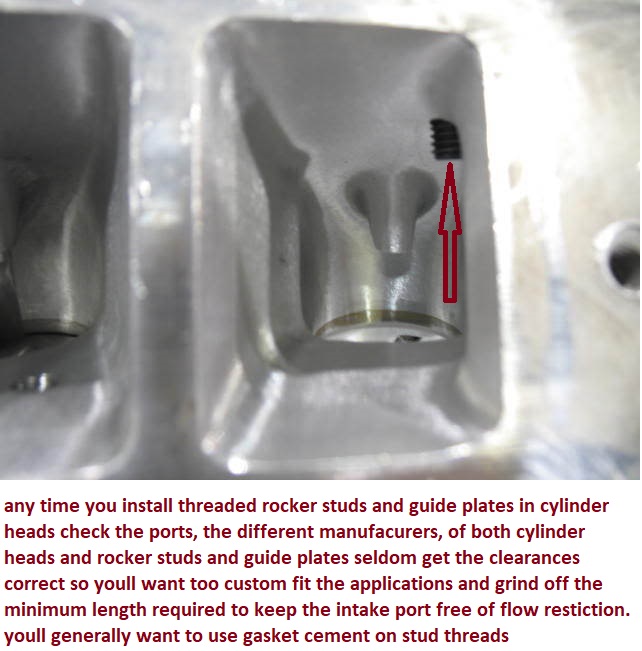

the loc-tie wont hurt anything unless you need to replace a broken stud, but its generally not required,

GREAT QUESTION!

anytime your not sure about something, or theres a defective link, ASK, don,t assume.

I try too keep current but theres always going to be people changing the linked info on different linked sights

either product pictured below works on head bolt or rocker stud threads, simply dip the threads and screw into place

check all valve train geometry and clearance on any engine you assemble or modify the valve train on.

read the threads

http://garage.grumpysperformance.co...venting-leaky-head-bolts-studs.50/#post-12558

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-45066

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/#post-19681

http://garage.grumpysperformance.com/index.php?threads/torque-to-yeild-head-bolts.2138/#post-5763

http://garage.grumpysperformance.com/index.php?threads/wrong-rocker.13987/#post-71250

http://garage.grumpysperformance.co...s-in-vs-threaded-rocker-studs.2746/#post-7475

GREAT QUESTION!

anytime your not sure about something, or theres a defective link, ASK, don,t assume.

I try too keep current but theres always going to be people changing the linked info on different linked sights

either product pictured below works on head bolt or rocker stud threads, simply dip the threads and screw into place

check all valve train geometry and clearance on any engine you assemble or modify the valve train on.

read the threads

http://garage.grumpysperformance.co...venting-leaky-head-bolts-studs.50/#post-12558

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-45066

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/#post-19681

http://garage.grumpysperformance.com/index.php?threads/torque-to-yeild-head-bolts.2138/#post-5763

http://garage.grumpysperformance.com/index.php?threads/wrong-rocker.13987/#post-71250

http://garage.grumpysperformance.co...s-in-vs-threaded-rocker-studs.2746/#post-7475

Speedlink1973

Well-Known Member

Speedlink1973

Well-Known Member

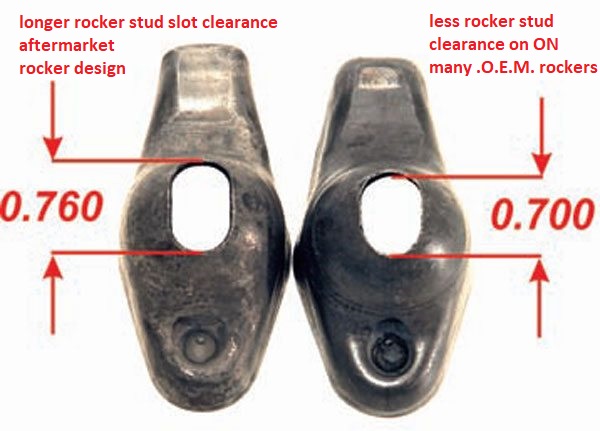

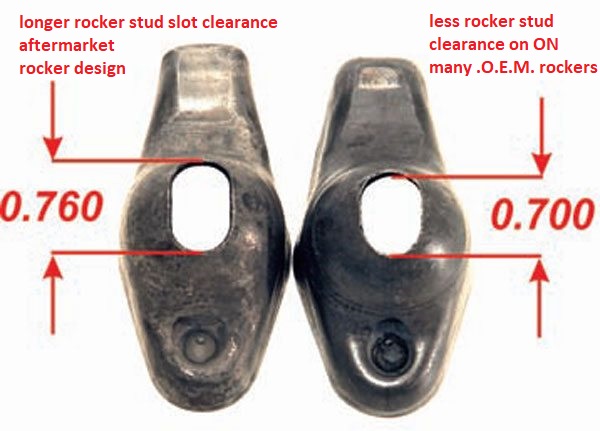

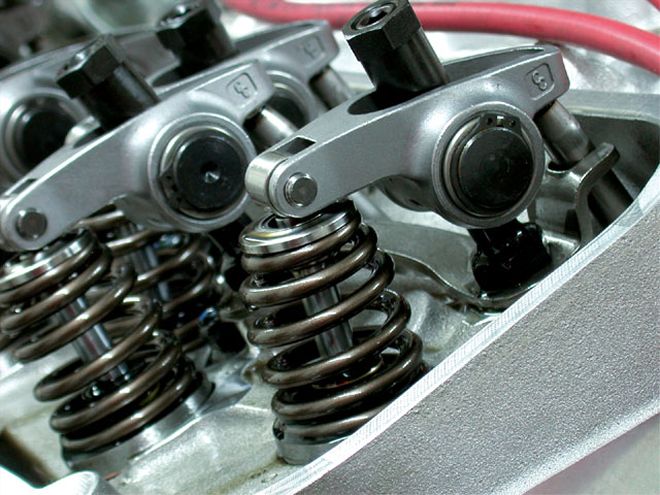

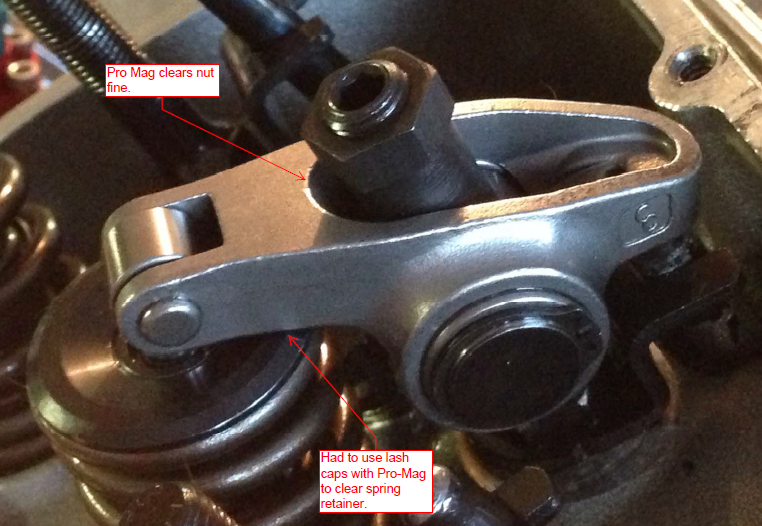

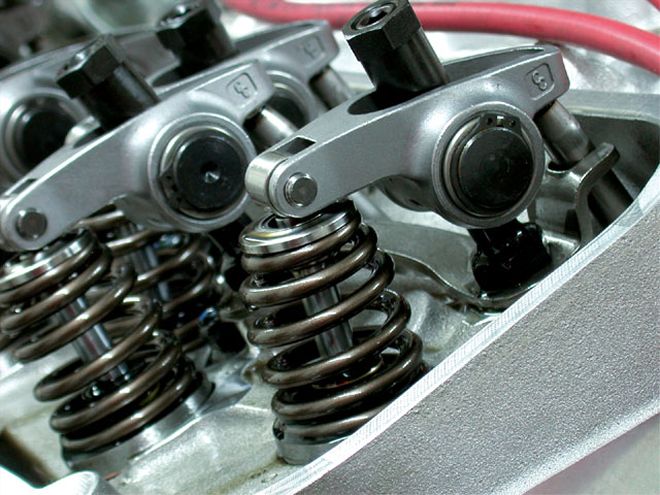

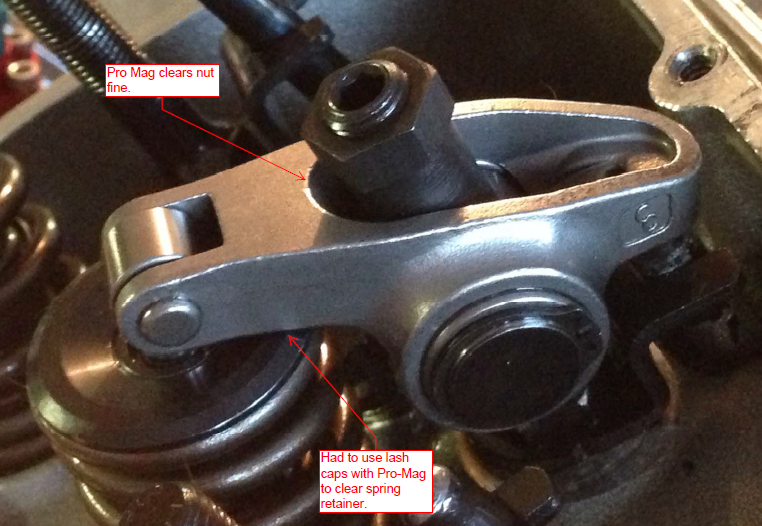

due too the design of most rocker stud girdles and the locking nut designs in many cases your choices will be limited ,

but I prefer to keep the lower rocker girdle surface a minimum of about .060 from any portion of the roller rocker in its arc if I can manage that

http://garage.grumpysperformance.com/index.php?threads/valve-spring-cooling-via-engine-oil.6491/

SOME ROLLER ROCKERS CAN AND DO BIND ON ROCKER STUDS, or rocker adjustment nuts, youll need to check carefully

some roller rocker too retainer combo clearance issues cause problems easily solved with beehive springs and smaller retainer diameters

BEEHIVE SPRINGS GIVE A GOOD DEAL MORE ROCKER TO RETAINER CLEARANCE

the POLY LOCKS that are used with most roller rockers AND ROLLER ROCKER SIZES, (come in a variety of lengths AND DIAMETERS AND THREAD SIZES) so you might find you need tall valve covers to allow clearance BUT in most cases swapping to shorter poly locks reduced that problem from mandating taller valve covers, be aware that the outside diameter of the locks is a darn important factor in allowing the rocker to reach full potential lift!

it should be obvious that youll need to carefully check clearances over the full rotation and lift in several areas if you chance valve train components and retainer to rocker and internal rocker clearance slot to poly lock are two of many potential places the valve train may bind if theres not the correct clearance

but I prefer to keep the lower rocker girdle surface a minimum of about .060 from any portion of the roller rocker in its arc if I can manage that

http://garage.grumpysperformance.com/index.php?threads/valve-spring-cooling-via-engine-oil.6491/

SOME ROLLER ROCKERS CAN AND DO BIND ON ROCKER STUDS, or rocker adjustment nuts, youll need to check carefully

some roller rocker too retainer combo clearance issues cause problems easily solved with beehive springs and smaller retainer diameters

BEEHIVE SPRINGS GIVE A GOOD DEAL MORE ROCKER TO RETAINER CLEARANCE

the POLY LOCKS that are used with most roller rockers AND ROLLER ROCKER SIZES, (come in a variety of lengths AND DIAMETERS AND THREAD SIZES) so you might find you need tall valve covers to allow clearance BUT in most cases swapping to shorter poly locks reduced that problem from mandating taller valve covers, be aware that the outside diameter of the locks is a darn important factor in allowing the rocker to reach full potential lift!

it should be obvious that youll need to carefully check clearances over the full rotation and lift in several areas if you chance valve train components and retainer to rocker and internal rocker clearance slot to poly lock are two of many potential places the valve train may bind if theres not the correct clearance

Last edited:

Speedlink1973

Well-Known Member

This is how I checked push rod length

And rocker arm geometry

I set 3/4 turn preload on lifters

7/16"-20= .050 per turn Howard's

Wants hydraulic lifters at max .060 and minimum at .020

I put stud girdles on then adjusted locked the set screw lock per this video.

Attachments

Last edited by a moderator: