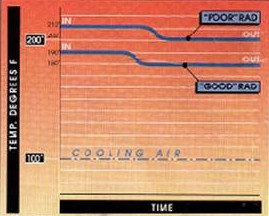

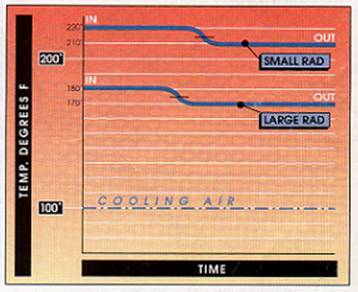

that, need for the coolant traveling through the engine,to take time to absorb and release heat, is

a complete myth, as long as the radiator has at least the minimum surface area that will cool the engine to about 200 f

with minimal air flow like the car sees sitting still only using the fans to supply air flow,the faster the coolant flows the more effective the cooling system becomes

the larger the surface area of the radiator, and number of fins per inch of surface area around the coolant transfer tubes,

and the higher the coolant volume in relation to the total percentage of coolant in the engine ,

the greater the volume of outside air mass passing over the fins and tube surface area,

the more effective the radiator can become, but remember OIL does much of the initial heat absorption and heat transfer ,

so adding an effective oil cooler with its own fan, significantly improves engine cooling efficiency

ample

lets assume you really want this $180 ,

trans fluid or oil cooler,

you'll want too stop and think things carefully and measure accurately

https://www.summitracing.com/parts/flx-45908

Summit Racing Part Number:FLX-45908

Overall Height (in):10.500 in.

Overall Width (in):15.000 in.

Overall Thickness (in):4.000 in.

Flex-a-lite's fan-equipped, heavy-duty remote coolers offer a great combination of cooling power and freedom of mounting location, all at down-to-earth prices. Their tube-and-fin design is made up of efficient aluminum fins and multi-pass copper tubing. With their attached 800 cfm electric fans, they don't have to be mounted in direct airflow to work. They make their own breeze. So you can put them in just about any convenient, reasonable place and they'll still get the job done. There also are dual-circuit versions that accommodate two different fluids--such as engine oil and automatic-transmission fluid--in the same-size cooler. That's especially good for applications where space is limited or cooling needs for the fluids concerned aren't extreme. A manual control switch, air-conditioning override switch, and GatorClip mounting clips are available separately.

in this case you would make a test styra-foam block

10.75" tall

17.25"-to-17.5" wide

4.25" thick

if that fits where you intend to fit the fluid cooler you have a great indicator it will fit

obviously the cooler needs to mount to something sturdy so ideally the mount stand or brackets you custom fabricate will have it firmly and solidly located where you intended it to be!

(you'll want to order a GAUGE an ADJUSTABLE FAN CONTROL RELAY/CONTROLLER

SEPARATELY, and once you've verified clearances you order the components then measure and get custom lines fabricated

some of my least favorite myths

(1) you need to slow the coolant flow thru the radiator to allow time to cool the fluid moving thru it

(2) swapping from a 190F to a 160F T-stat will significantly reduce an engines tendency to over heat.

(3) removing the t-stat will cure over heating

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/how-the-cooling-system-works-basics.853/