good,the components listed certainly should keep the engine coolant reasonably cool,

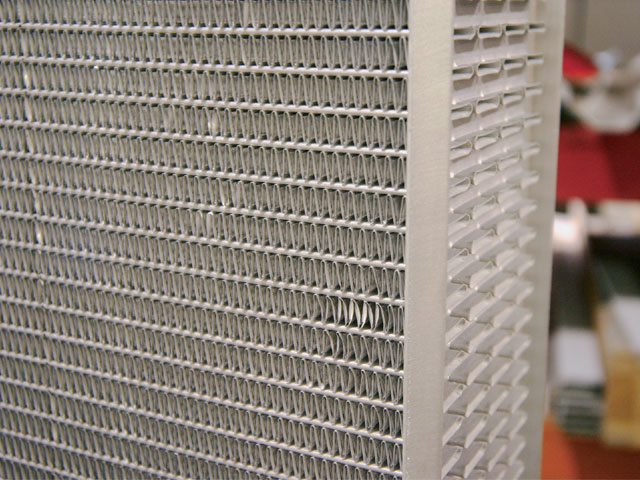

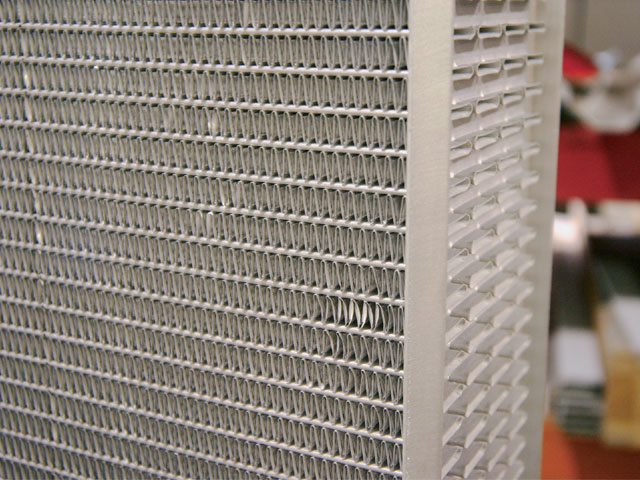

total surface area of the radiator should ideally be at or more than about 1.5-2 sq inches per cubic inch of engine displacement.

in theory that requires about a 24 inch tall x 32 inch wide

496 x 1.5=744

24 x 32=768

obviously clearance issues fitting that large a radiator become a problem so multi tube radiator designs are rather common on performance applications

total surface area of the radiator should ideally be at or more than about 1.5-2 sq inches per cubic inch of engine displacement.

in theory that requires about a 24 inch tall x 32 inch wide

496 x 1.5=744

24 x 32=768

obviously clearance issues fitting that large a radiator become a problem so multi tube radiator designs are rather common on performance applications

Last edited: