I wouldn't think crankcase pressure would go up unless you had really crappy

Valve guides and seals, I would think with gapless rings you would have less,

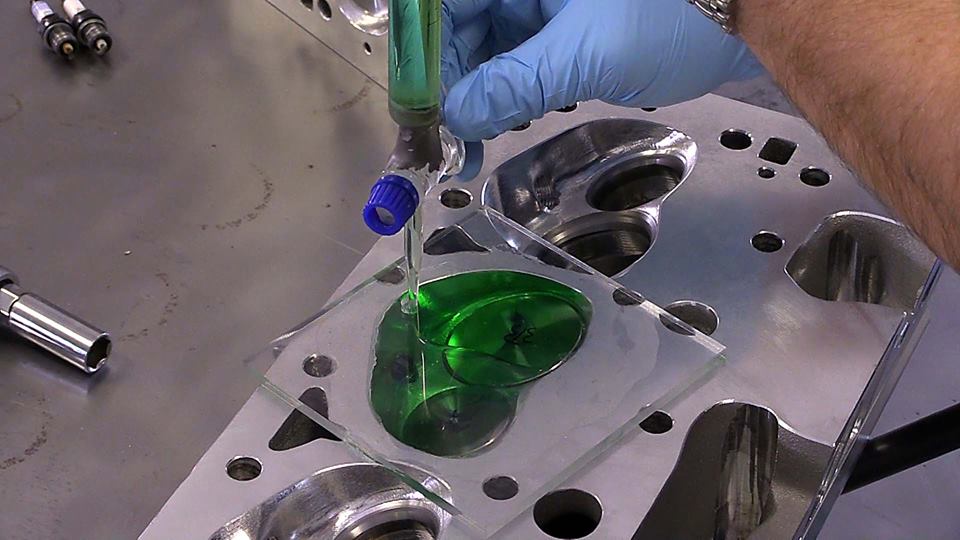

I know total seal asked what heads I was running because I guess certain valve guide seal won't work.

They pull alot more Vacuum Total Seal Gapless Rings.

Mystery oil consumption problems are what I fought.

No smoke ever.

People following behind my 1970 Trans Am said no oil smoke WOT.

3 inch tail pipes, full 3 inch dual back.

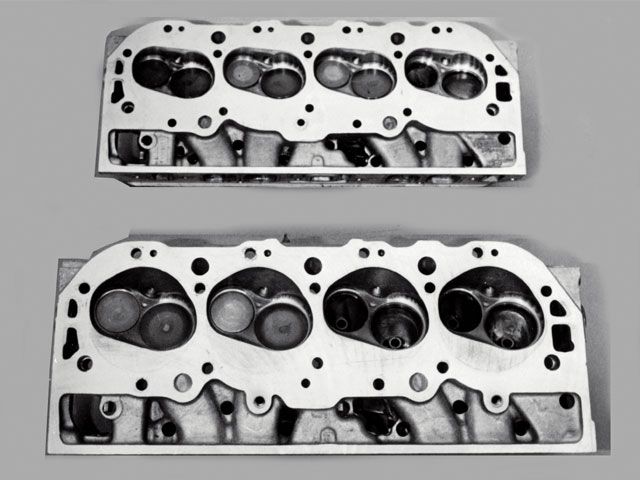

I had to close up running Valveguide to valvestem clearances.

To do that K-Liner Bronze Guides.

Bought a Sunnen Valveguide Hone, Known as the Sunnen P30.

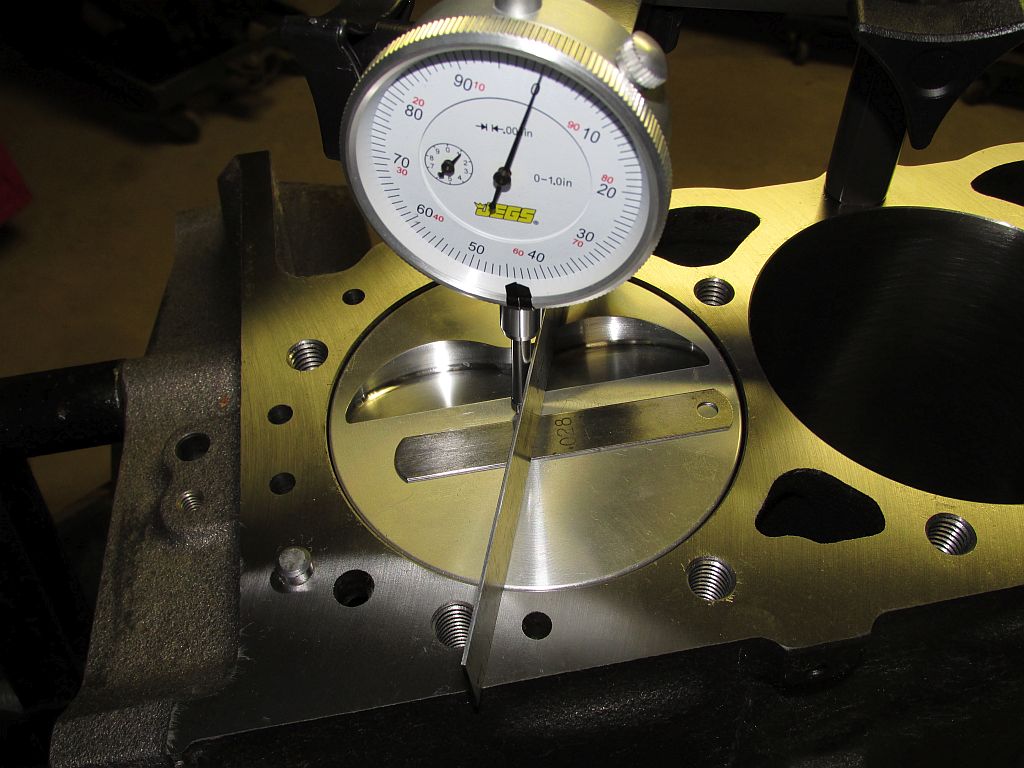

Bought a small dial bore gauge set measures down to .0001".

Could not find a machinist that would Hone running clearances I wanted & Total Seal recommended to me.

Machined the Valveguide seal bosses myself with the Crower Tool.

Viton Valvestem seals.

I know Machine work. Worked in a machine shop when younger.

Not a Pro Tool & Die Maker like you though. You guys are the best of the best.

Oil consumption issues went away.

They pull that much more vacuum.

They are not for everyone Total Seal Gapless Rings.

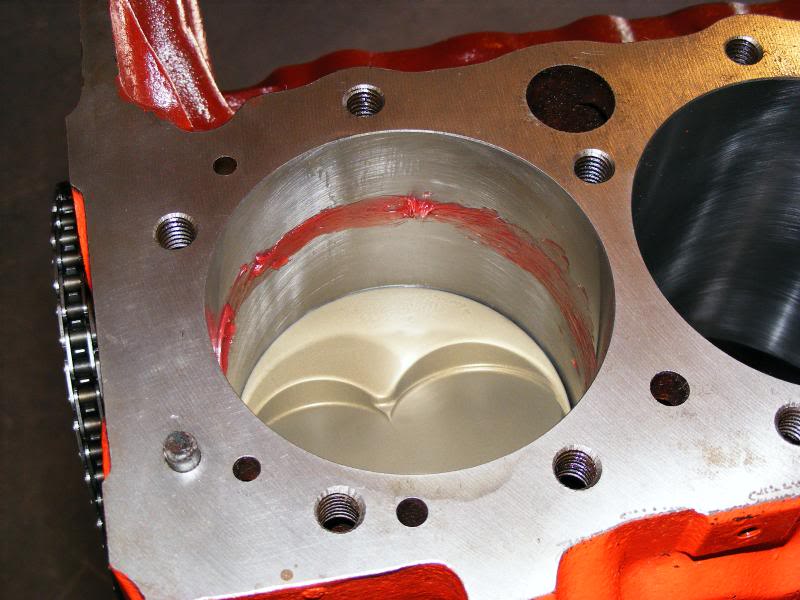

Any less than perfection will likely have issues.

But they do work.

Won Many Races uses Gapless Rings.

Much as I love the Gapless Rings.

With today's guys slap parts on and go, I steer away and conventional rings a better fit for them.

They have no inclination understanding of Tight tolerance 1/10,000 ths inch tolerances.

Just did not have the education.