You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

496ci revamped

- Thread starter Speedlink1973

- Start date

Speedlink1973

Well-Known Member

Speedlink1973

Well-Known Member

Got piston dome compression numbers Grumpy

24.4 cc was supposed to be 25cc

At a depth of .569 and a diameter of 4.310

It was 112cc

Calculator said it should be 136.4 cc

- 112cc = 24.4cc

Oh I used 91% alcohol and a few drops of

Red food coloring.

When I was done I tipped block upside down wiped it out and wiped down bore with WD-40

Then put my quick set powder on it again.

24.4 cc was supposed to be 25cc

At a depth of .569 and a diameter of 4.310

It was 112cc

Calculator said it should be 136.4 cc

- 112cc = 24.4cc

Oh I used 91% alcohol and a few drops of

Red food coloring.

When I was done I tipped block upside down wiped it out and wiped down bore with WD-40

Then put my quick set powder on it again.

Attachments

Last edited:

Speedlink1973

Well-Known Member

I gapped the rings at .024 just in case I want Nos later on that gap per total sealLooks good to me!

Is good up to 150hp shot

Maniacmechanic1

solid fixture here in the forum

One area I have found with Power adders working in a Race Shop last year Building engines from bare block to turn key is large piston ring gaps do not matter at all.I gapped the rings at .024 just in case I want Nos later on that gap per total seal

Is good up to 150hp shot

I gapped all piston rings for 400 + Hp on Top of base HP N/A.

To cover my Butt.

Every car was Turbo Boosted.

Some had 44 psi Boost.

None blew up.

Speedlink1973

Well-Known Member

I wasn't too worried about a bigger gapOne area I have found with Power adders working in a Race Shop last year Building engines from bare block to turn key is large piston ring gaps do not matter at all.

I gapped all piston rings for 400 + Hp on Top of base HP N/A.

To cover my Butt.

Every car was Turbo Boosted.

Some had 44 psi Boost.

None blew up.

Just for the fact it's a gapless ring.

I almost took them bigger, but I doubt I go with Nos,

If anything I will jerk the pistons out put flat tops in drop compression to 8.5 to 9:1

And put a under the hood low profile supercharger on it and run 6 to 8 psi of boost

I'm kinda a mad scientist, it's my tinker toy.

Maniacmechanic1

solid fixture here in the forum

It takes a Large or Huge Supercharger to feed a 496 ci BBC.I wasn't too worried about a bigger gap

Just for the fact it's a gapless ring.

I almost took them bigger, but I doubt I go with Nos,

If anything I will jerk the pistons out put flat tops in drop compression to 8.5 to 9:1

And put a under the hood low profile supercharger on it and run 6 to 8 psi of boost

Gets expensive.

But 1000+ Hp easily done in theory.

Figure $8,000 cash more to Supercharge.

Maniacmechanic1

solid fixture here in the forum

Math always looked good on Grumpy 496.

Build it.

Tune it.

Get the car dialed in.

See What it does.

So much torque just impossible to put down all on street tires.

Build it.

Tune it.

Get the car dialed in.

See What it does.

So much torque just impossible to put down all on street tires.

Speedlink1973

Well-Known Member

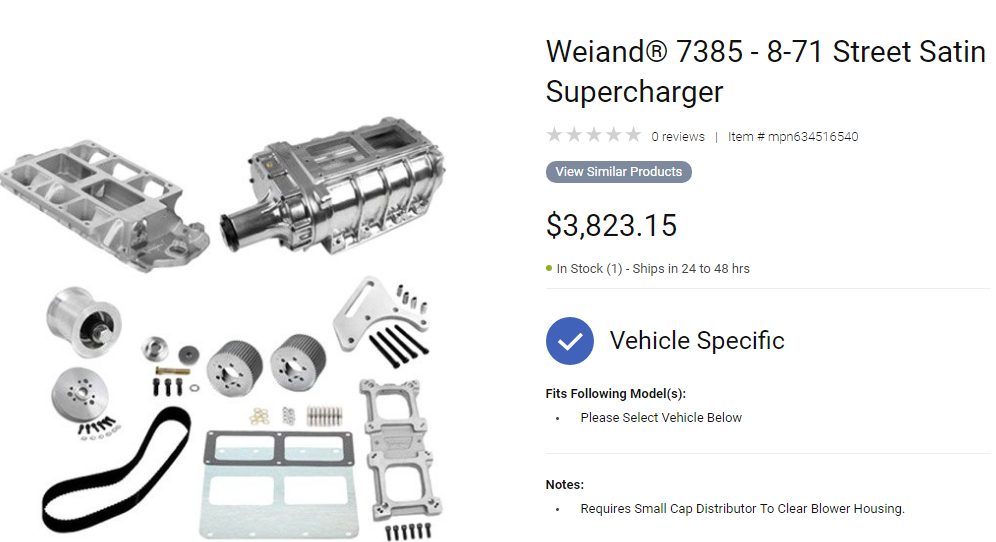

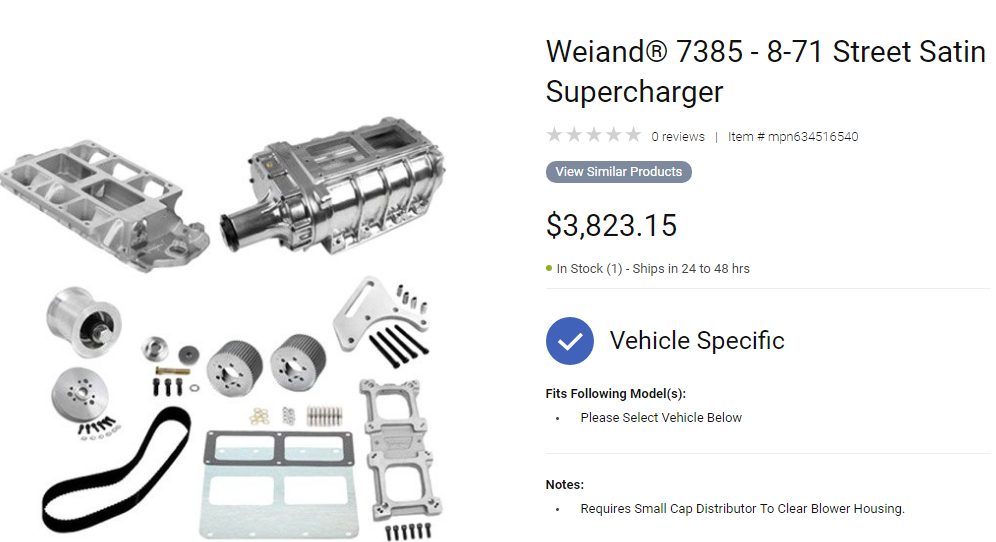

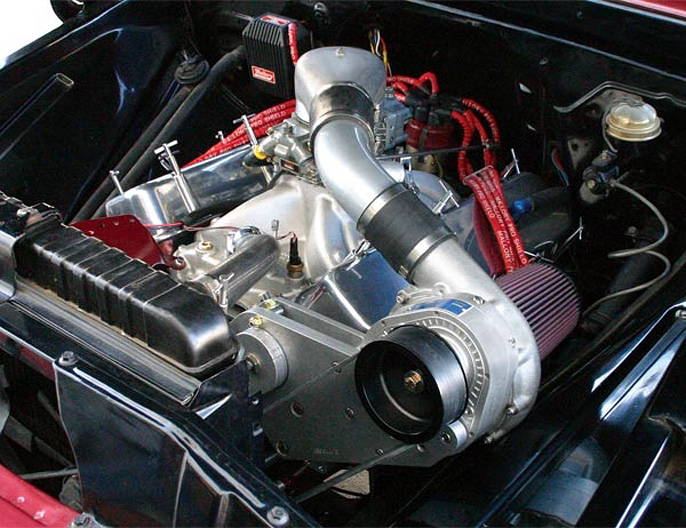

I actually bought this, but sent it backIt takes a Large or Huge Supercharger to feed a 496 ci BBC.

Gets expensive.

But 1000+ Hp easily done in theory.

Figure $8,000 cash more to Supercharge.

Because I didn't want to change pistons,

But ended up changing pistons anyway

Attachments

Maniacmechanic1

solid fixture here in the forum

Little guy for a Big 496.I actually bought this, but sent it back

Because I didn't want to change pistons,

But ended up changing pistons anyway

Should deliver nice Normal Aspirated.

Speedlink1973

Well-Known Member

At that time I didn't know much,Little guy for a Big 496.

Should deliver nice Normal Aspirated.

I'm a bit more educated than I was then thanks to mostly you guys.

Think my N/A motor will do just fine

Last edited:

a 177 on a 496 bbc is good for visual effect but its going to be not only nearly useless once you exceed about 5000 rpm,for providing significant boost levels, regardless of pullie ratio selected,

\its probably going to offer minimal or no gain at all over a properly built N/A high compression 496 bbc simply because it can,t keep up with the the engines air flow demand,

and still produce any worth while boost volume.

roots superchargers can be driven to over engine rpm,

with changes in the drive vs driven belt pullies, rather easily but as the rpms increase so does heat and a loss of efficiency.

Im certainly not saying a 177 supercharger won,t boost average power,

but the gains will be nothing close to what you could expect from a properly sized super charger like an 871 or better yet a centrifugal supercharger with a properly sized inter-cooler.

much better match to a 496 BBC

https://www.carid.com/weiand/8-71-s...MIhuaYkZ2m3AIVC7XACh0IKA_UEAQYBSABEgK_kPD_BwE

https://www.procharger.com/automoti...eted/gm-carbureted-aftermarket-efi/sbbb-chevy

https://www.procharger.com/automoti...t-efi/sbbb-chevy#/p-1x-and-d-1x-superchargers

https://www.holley.com/products/int...MIgbncx6Cm3AIVFrbACh13kQbIEAQYBCABEgJwy_D_BwE

https://www.powerperformancenews.com/tech/grade-on-a-curve-choosing-the-right-supercharger/

http://www.superchargersonline.com/index.php?main_page=page&id=53

https://www.jegs.com/s/tech-article...chargers+-+Blowers+-+Roots+Type+-+Centrifugal

http://www.superchevy.com/how-to/engines-drivetrain/0610ch-superchargers/

https://www.carthrottle.com/post/what-do-supercharger-capacity-ratings-actually-mean/

\its probably going to offer minimal or no gain at all over a properly built N/A high compression 496 bbc simply because it can,t keep up with the the engines air flow demand,

and still produce any worth while boost volume.

roots superchargers can be driven to over engine rpm,

with changes in the drive vs driven belt pullies, rather easily but as the rpms increase so does heat and a loss of efficiency.

Im certainly not saying a 177 supercharger won,t boost average power,

but the gains will be nothing close to what you could expect from a properly sized super charger like an 871 or better yet a centrifugal supercharger with a properly sized inter-cooler.

much better match to a 496 BBC

https://www.carid.com/weiand/8-71-s...MIhuaYkZ2m3AIVC7XACh0IKA_UEAQYBSABEgK_kPD_BwE

https://www.procharger.com/automoti...eted/gm-carbureted-aftermarket-efi/sbbb-chevy

https://www.procharger.com/automoti...t-efi/sbbb-chevy#/p-1x-and-d-1x-superchargers

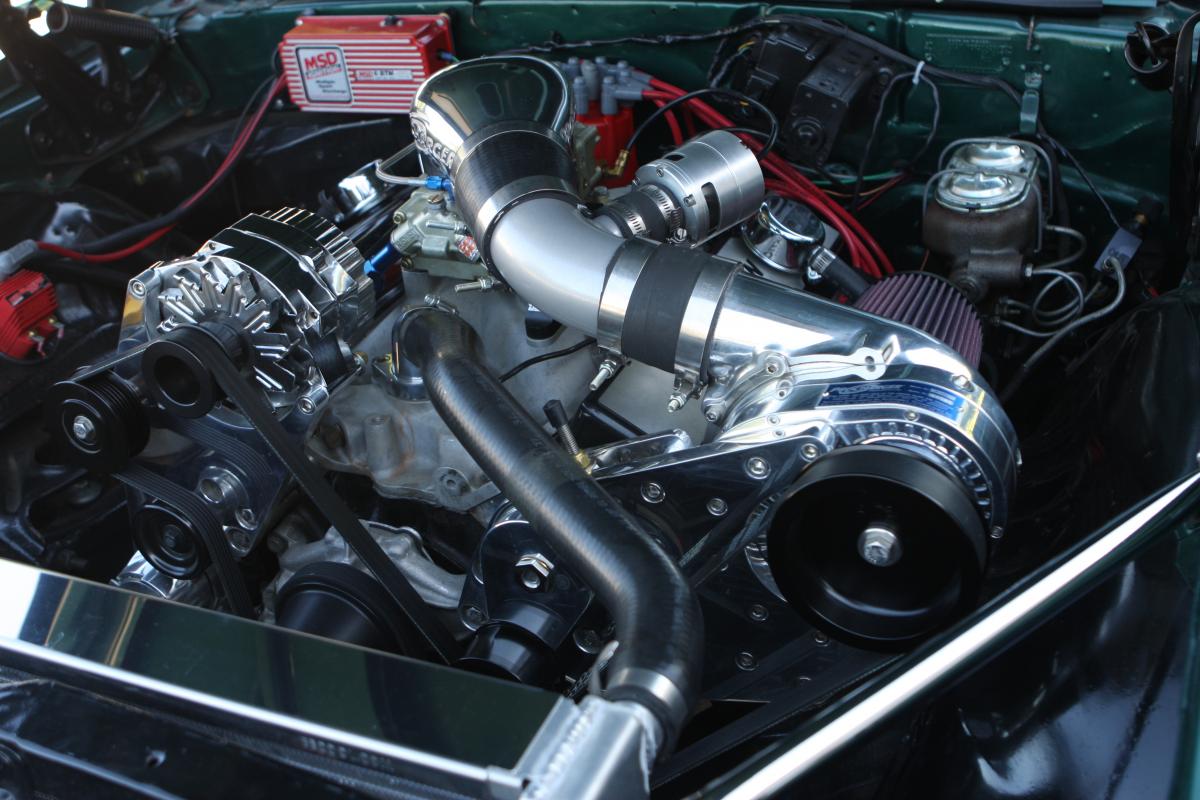

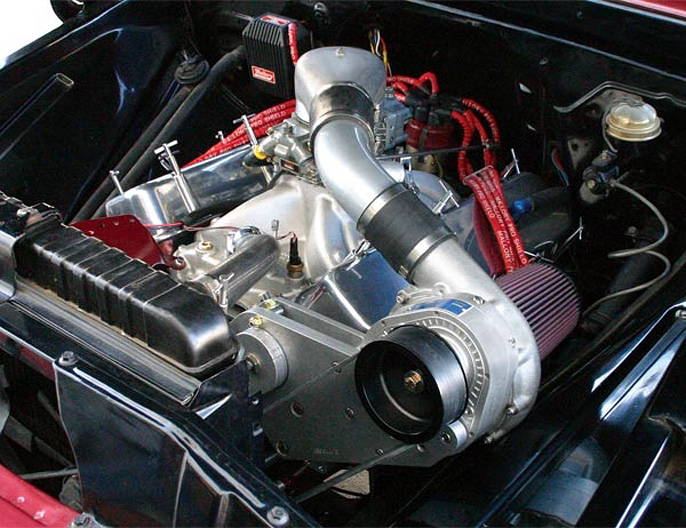

an even better option in my opinion , requiring less hood clearance, would be a centrifugal supercharger with inter-cooler ( inter-cooler not shown in this picture) and a throttle body and direct port injection is also an option.The numbers related to these blower sizes, such as 142, 177, and 256, relate to the amount of air in cubic inches that is pumped by the blower in one blower revolution. The 6-71 and 8-71 designations refer to the original GMC diesel engines. Table 2 shows the amount of air per blower revolution the Weiand blowers pump.

TABLE 2: Supercharger Volumes

Supercharger Type Approximate CID or

Air Per Revolution

Pro-Street 142 142

Pro-Street 177 177

Pro-Street 256 256

Weiand 6-71 411

Weiand 8-71 436

Weiand 10-71 469

Weiand 12-71 497

Weiand 14-71 522

In selecting the proper supercharger for your application, you also need to take into consideration how you plan to drive your vehicle and the approximate boost level desired. How you plan to drive your vehicle is important because you can set up your blower to be more efficient at high engine speeds or more efficient at low engine speeds, or you can arrange for the best compromise for the full engine rpm range.

To run boost levels from 6 to 10 pounds we recommend the following:

Forged blower pistons with a static compression ratio of 7.5:1

For maximum boost and horsepower applications (12 pounds or more), we recommend the following engine specifications:

- Steel crankshaft

- Four bolt main caps

- Steel harmonic dampener

- Stainless steel valves

- Three angle valve job

- More aggressive camshaft

- Roller rockers

- Ported and polished heads

- Steel rods with good rod bolts

- Chromoly push rods

- High output ignition

- Weiand high flow water pump (cast iron or aluminum available - see our complete water pump section for applications)

- Minimum of a 2-1/2" diameter dual exhaust with headers. Recommended primary tube diameters and collector sizes are:

- Small Blocks: 1-5/8" to 1-3/4" with 3" collectors

- Big Blocks: 1-7/8" to 2' with 3-1/2" collectors

- High quality forged or billet crankshaft

- Four bolt main caps with quality bolts or studs

- Steel harmonic balancer or crank hub

- High quality steel rods (H or I beam)

- Forged blower pistons

- O-ringing the block (mandatory)

- Severe duty stainless steel valves or iconel

- Fully ported and polished heads

- Solid or roller cam designed for high boost

- Roller rockers

- Chromoly push rods

- High output ignition management system or magneto

- Blueprinted carburetors or fuel injection

- High octane race fuel (112+ rating)

- Minimum of a 3" diameter dual exhaust with free flowing street/race mufflers and large tube headers.

- Recommended primary tube diameters and collector sizes are:

- Small Blocks: 1-7/8" to 2" with 3-1/2" collectors Big Blocks: 2-1/8" to 2-1/4", with 4" collectors

- Maximum effective compression ratio on gas not to exceed 24:1

- It's important to realize that there are no hard and fast rules and the suggestions made here are general in nature.

https://www.holley.com/products/int...MIgbncx6Cm3AIVFrbACh13kQbIEAQYBCABEgJwy_D_BwE

https://www.powerperformancenews.com/tech/grade-on-a-curve-choosing-the-right-supercharger/

http://www.superchargersonline.com/index.php?main_page=page&id=53

https://www.jegs.com/s/tech-article...chargers+-+Blowers+-+Roots+Type+-+Centrifugal

http://www.superchevy.com/how-to/engines-drivetrain/0610ch-superchargers/

https://www.carthrottle.com/post/what-do-supercharger-capacity-ratings-actually-mean/

Last edited:

Speedlink1973

Well-Known Member

Yep that's why I sent that 177 back

Because I didn't know what I was doing

Or getting into with it, and stuck to N/A

I've been eyeing that Holley EFI

One reason why is you can polish the hell out of it just above the injectors.

Because I didn't know what I was doing

Or getting into with it, and stuck to N/A

I've been eyeing that Holley EFI

One reason why is you can polish the hell out of it just above the injectors.

Speedlink1973

Well-Known Member

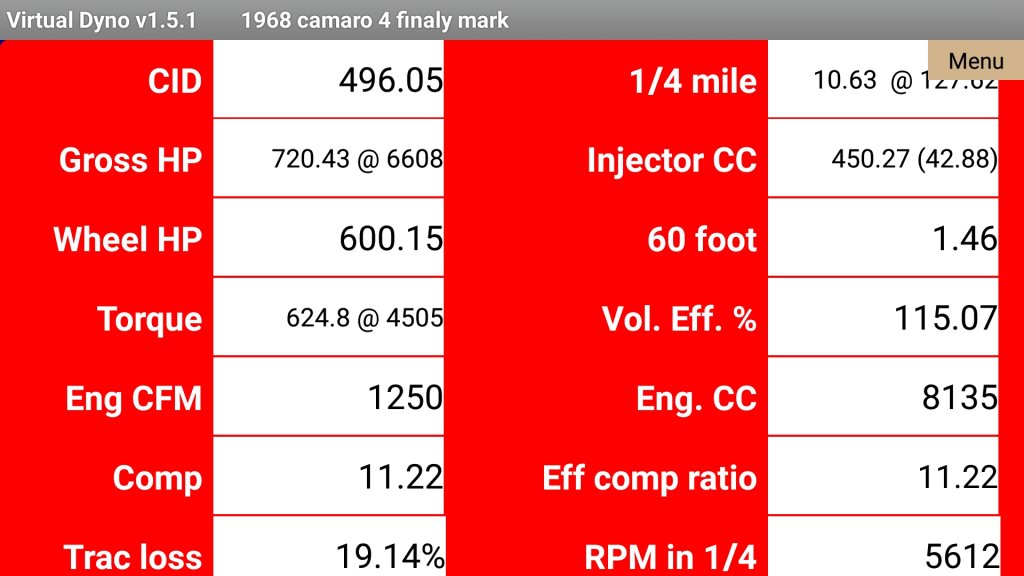

I know this guy was mentionedMath always looked good on Grumpy 496.

Build it.

Tune it.

Get the car dialed in.

See What it does.

So much torque just impossible to put down all on street tires.

On here as a engine builder Mark Jones

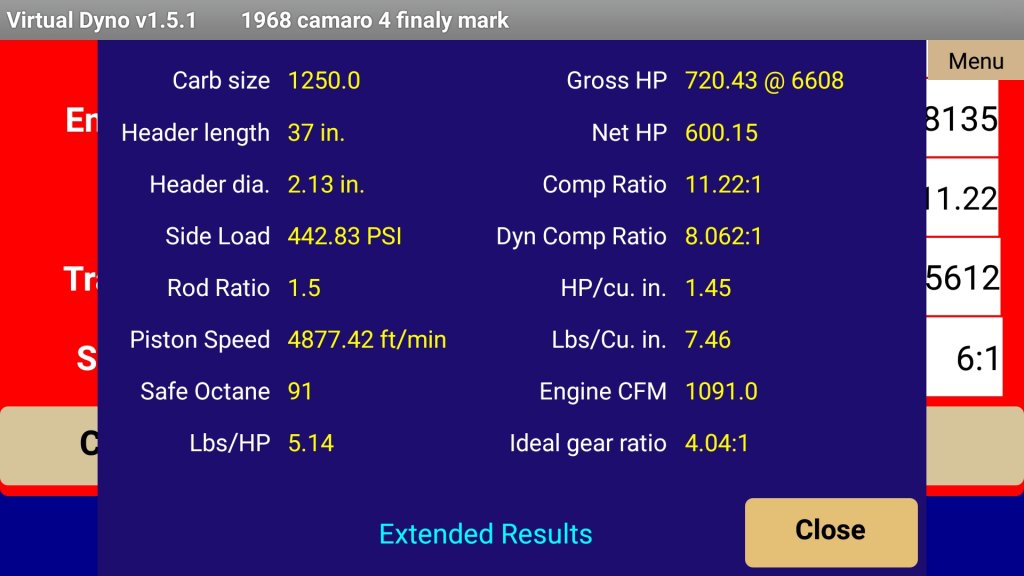

I think my N/A motor will be in this area

Wish I had a good calculator to to see a curve.

Attachments

Last edited by a moderator:

If you are willing to supply the input data, then I can run several simulations with DynoSim5.Wish I had a good calculator to to see a curve.

Not the cheapest or most expensive software.

DynoSim5 Input Variables

Bore & Stroke:

Rod Length:

Heads with flow numbers:

Combustion Chamber Size in CC’s:

Dome Volume: For a domed piston use a (-) negative number. For a piston with valve reliefs use a + positive number.

Valve Reliefs Volume:

Deck Clearance:

Head Gasket Bore:

Head Gasket Thichness:

Valve Sizes I/E:

Intake Manifold Model Type [Single or Dual Plane]

Model #:

Carburetor Size (CFM):

SCR & DCR:Header Tube Diameter: Small, Medium, Large (1-5/8", or , or)

Cam Card:

Cam Installed per Cam Card, or Retarded or Advanced:

Rocker Ratio:

.

Speedlink1973

Well-Known Member

Oh I have another question for you guy's

I seen some of the blocks screens in lifter valley, I noticed some are screwed down and some that appear to have epoxy

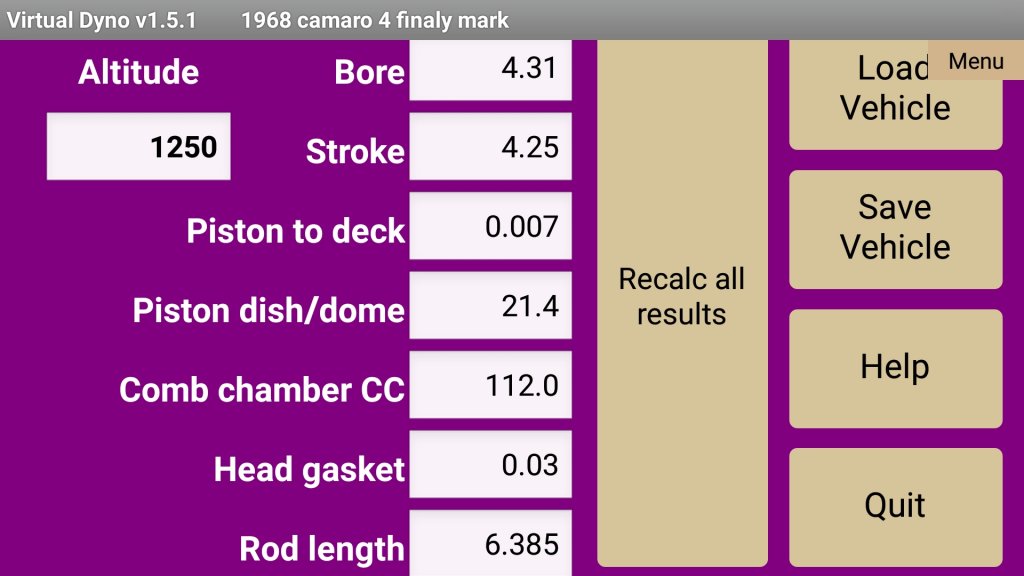

2" diameter tubes 37" long

The pistons are 25cc dome piston

But cc them in cylinder came to 24.4cc

But to take in account of big bore gasket diameter I lose 3cc so it's 21.4 cc as picture shows

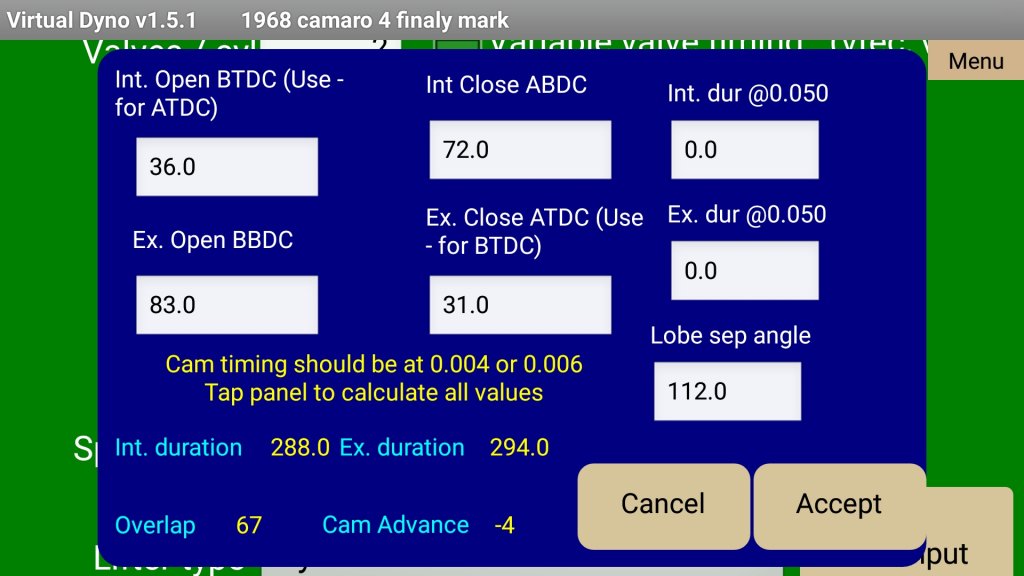

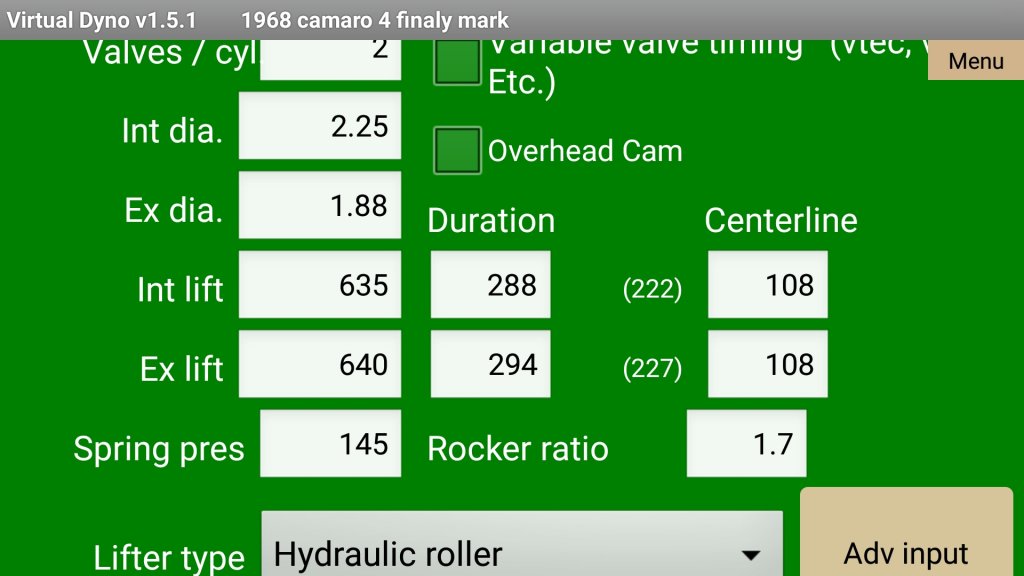

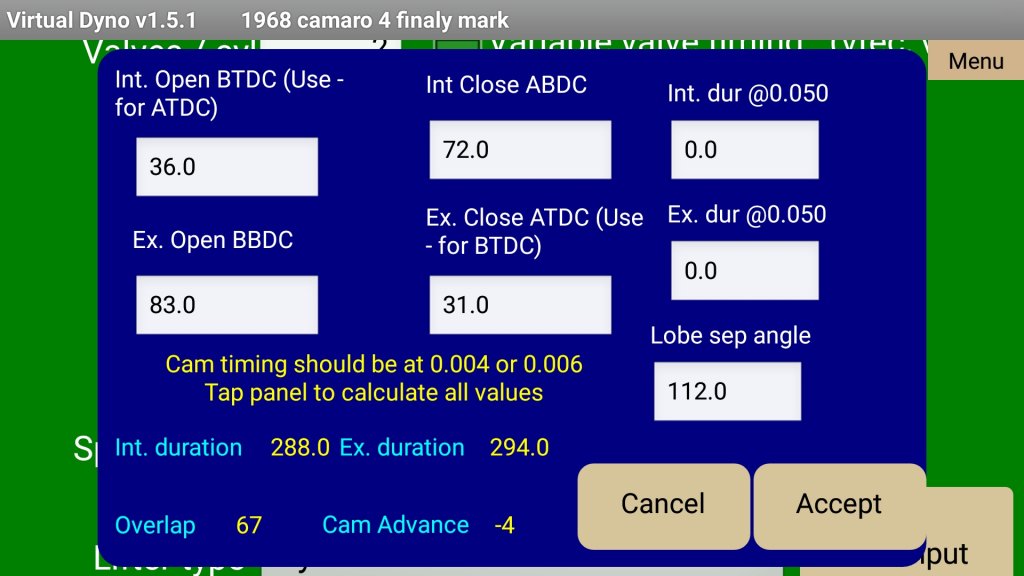

Cam in at 108 center line retarded-4 degrees

Oh head gasket diameter is 4.540

Thanks

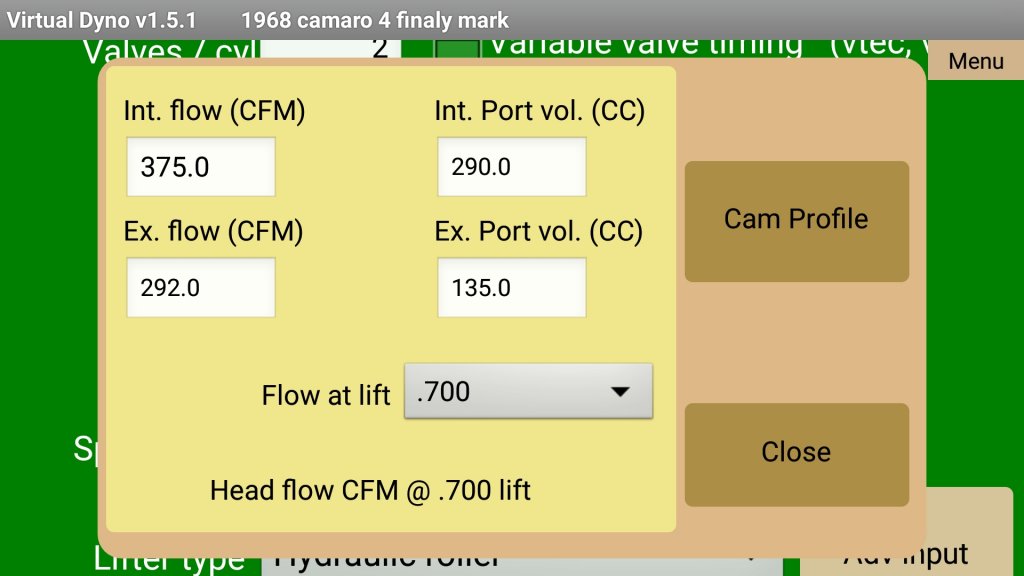

Injectors are 62lbs an hour 8 injectors total.

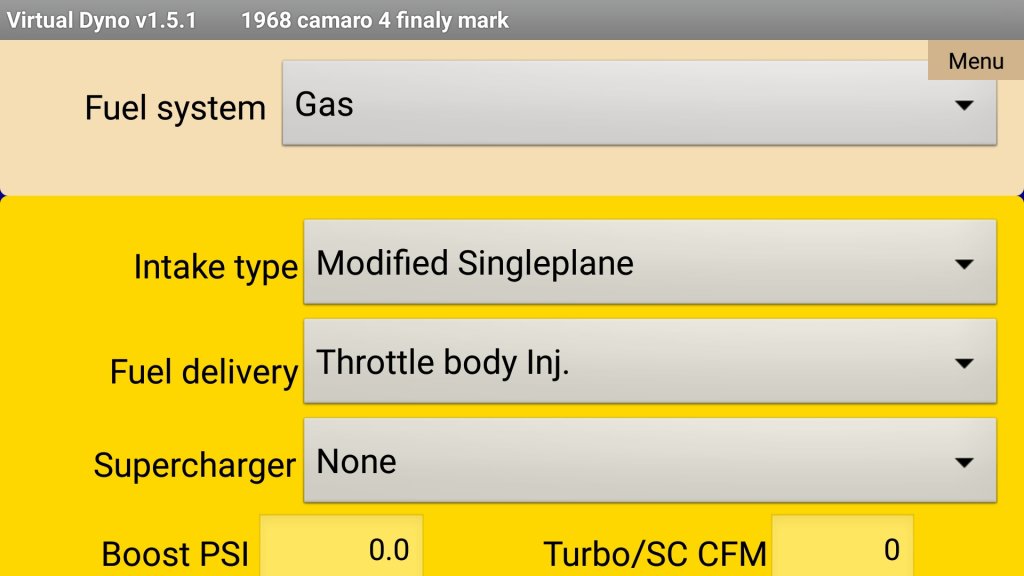

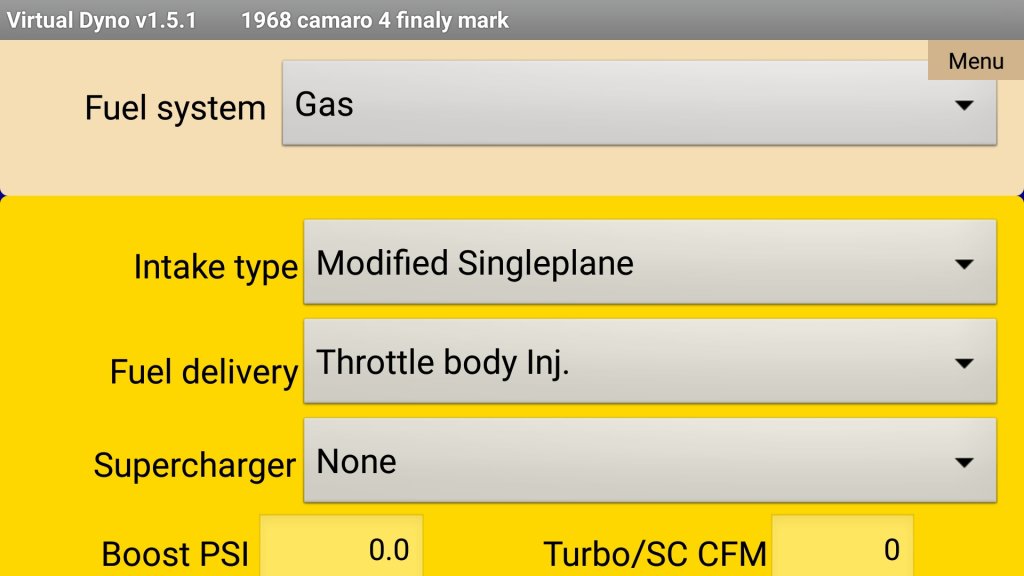

The throttle body injection works differently then a carburetor as far as cfm

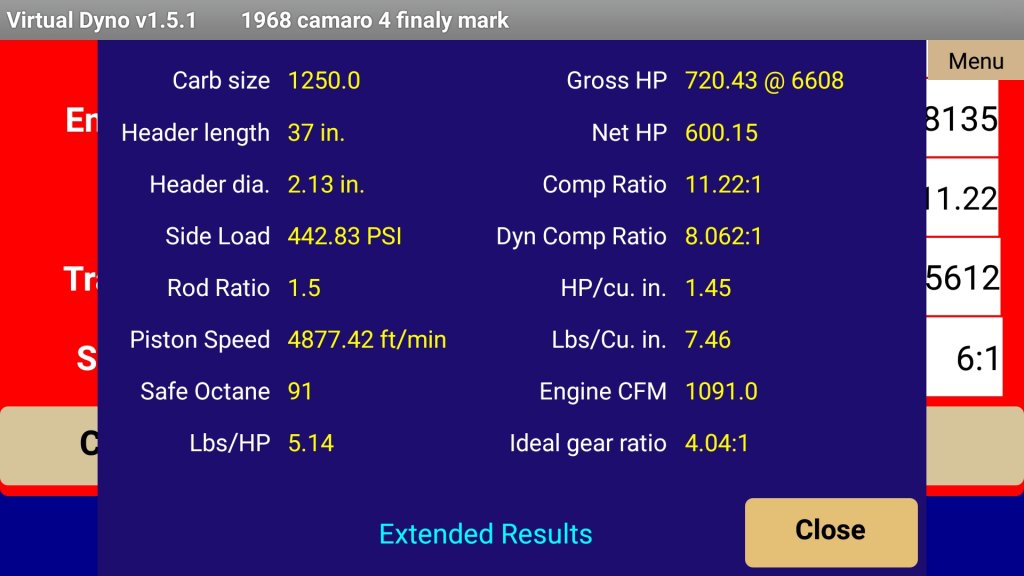

Goes it's 850cfm but this will support up to 800 hp when I talked to Fitech about injectors at 62lbs an hour should support 950 hp or better, they told me the software is the limiting factor 850hp max

On pump gas , throttle body cfm is exactly the same as the 1200hp unit they sell

Not sure if your calculator can decipher

It or not if not I would use the recommended 1250cfm.

It would be interesting to see a couple of different curves being I'm using a adjustable belt drive and can adjust on the fly this app has me retarding it 4 degrees

I'm running a MSD digital 6AL MSD Pro-Billet Distributor

Not sure if you need that information or not.

I seen some of the blocks screens in lifter valley, I noticed some are screwed down and some that appear to have epoxy

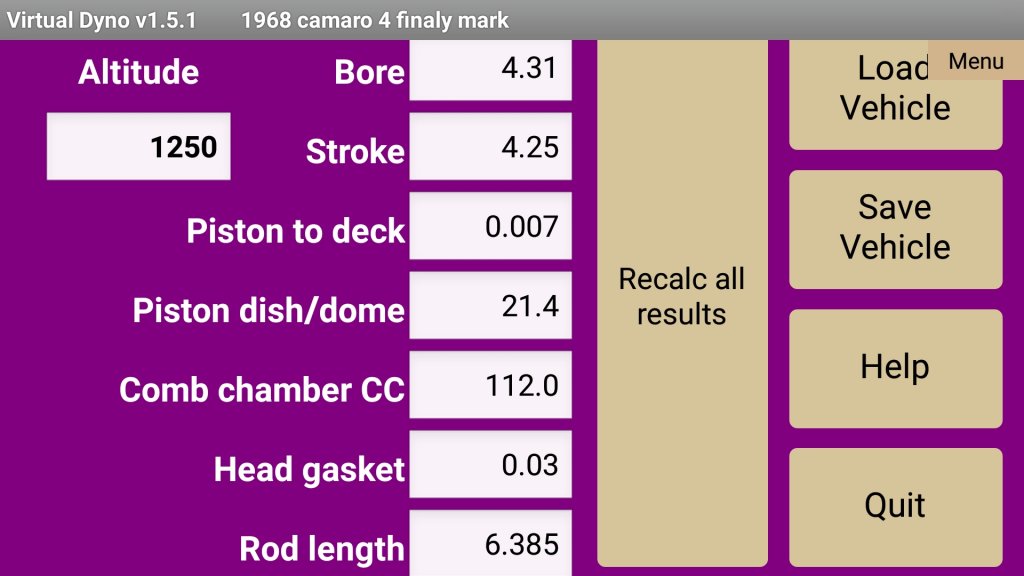

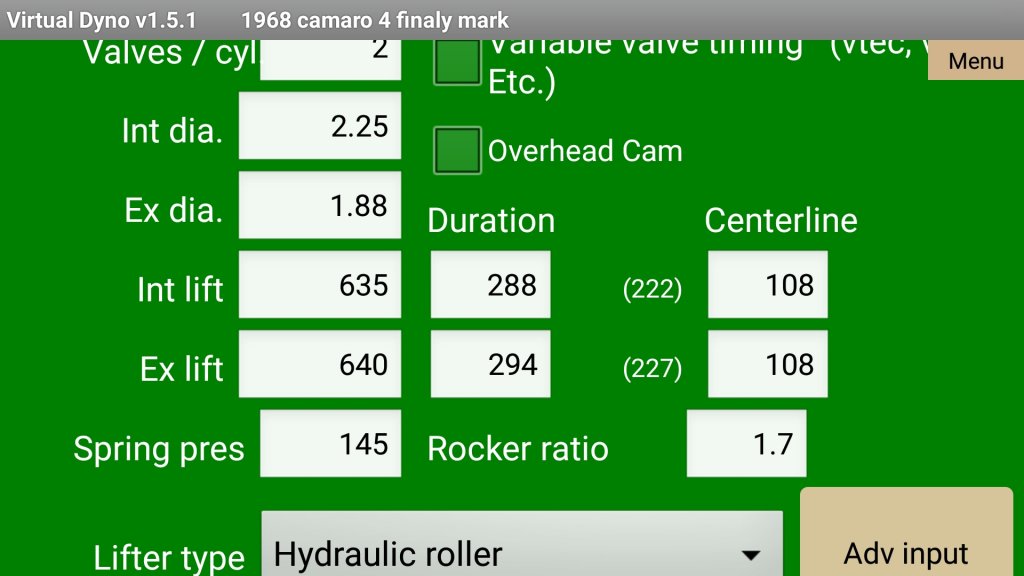

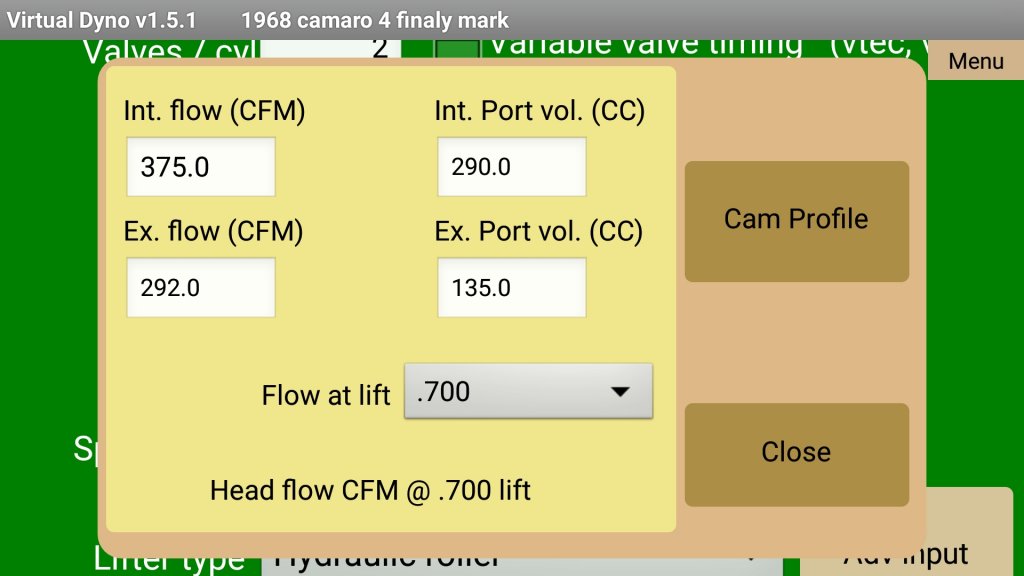

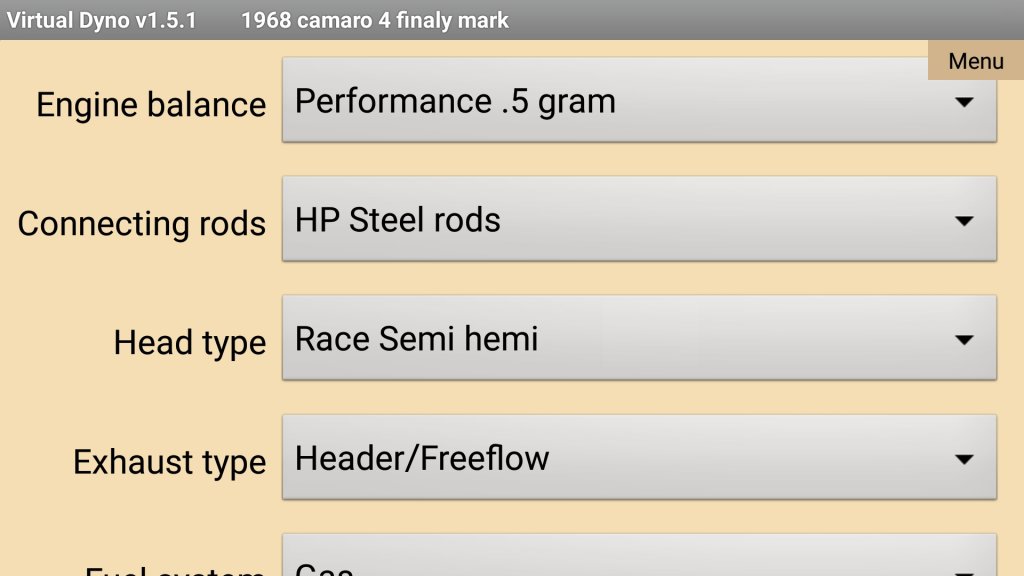

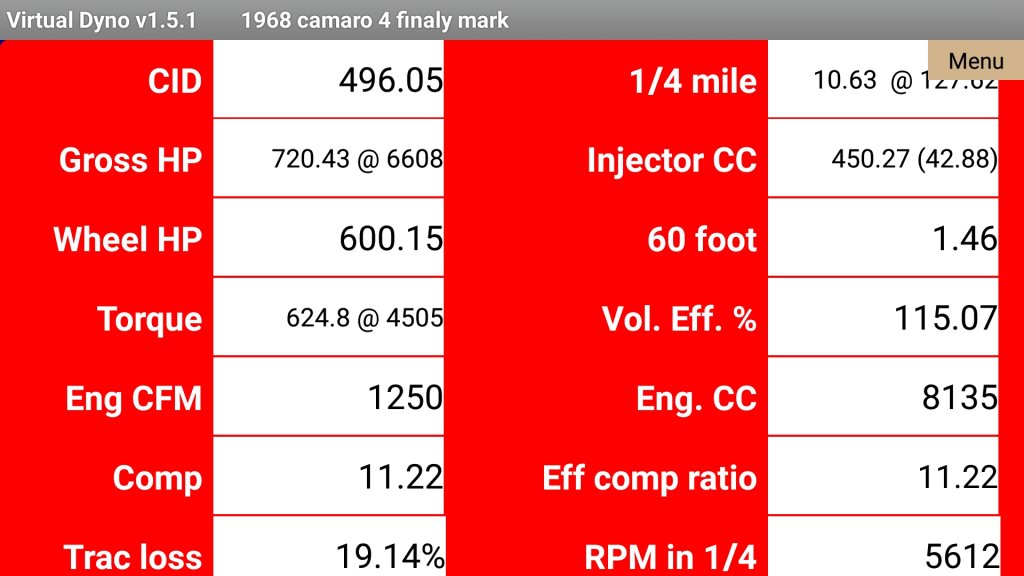

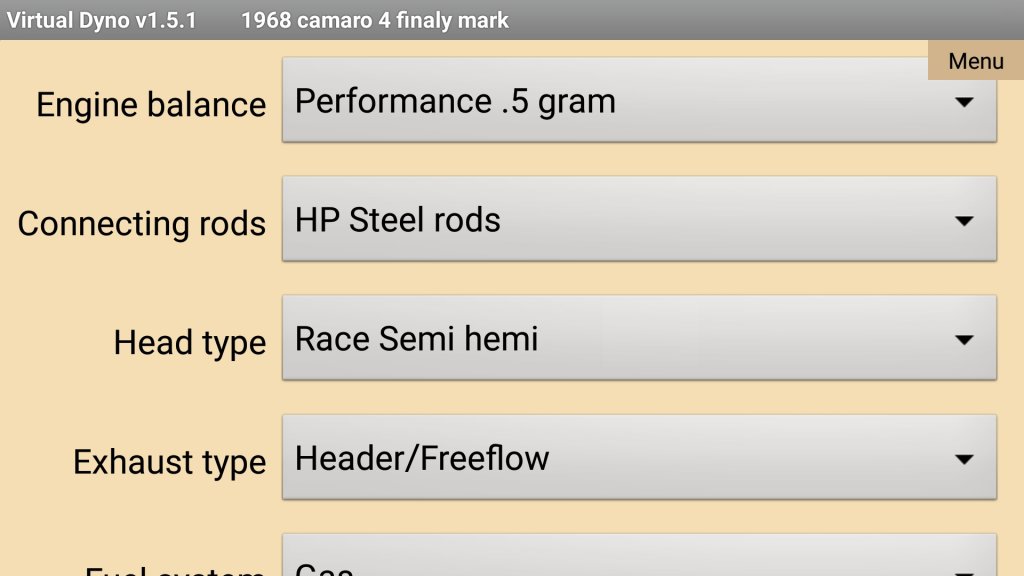

This is what my virtual dyno pro app came up withIf you are willing to supply the input data, then I can run several simulations with DynoSim5.

Not the cheapest or most expensive software.

DynoSim5 Input Variables

Bore & Stroke:

Rod Length:

Heads with flow numbers:

Combustion Chamber Size in CC’s:

Dome Volume: For a domed piston use a (-) negative number. For a piston with valve reliefs use a + positive number.

Valve Reliefs Volume:

Deck Clearance:

Head Gasket Bore:

Head Gasket Thichness:

Valve Sizes I/E:

Intake Manifold Model Type [Single or Dual Plane]

Model #:

Carburetor Size (CFM):

SCR & DCR:Header Tube Diameter: Small, Medium, Large (1-5/8", or , or)

Cam Card:

Cam Installed per Cam Card, or Retarded or Advanced:

Rocker Ratio:

.

2" diameter tubes 37" long

The pistons are 25cc dome piston

But cc them in cylinder came to 24.4cc

But to take in account of big bore gasket diameter I lose 3cc so it's 21.4 cc as picture shows

Cam in at 108 center line retarded-4 degrees

Oh head gasket diameter is 4.540

Thanks

Injectors are 62lbs an hour 8 injectors total.

The throttle body injection works differently then a carburetor as far as cfm

Goes it's 850cfm but this will support up to 800 hp when I talked to Fitech about injectors at 62lbs an hour should support 950 hp or better, they told me the software is the limiting factor 850hp max

On pump gas , throttle body cfm is exactly the same as the 1200hp unit they sell

Not sure if your calculator can decipher

It or not if not I would use the recommended 1250cfm.

It would be interesting to see a couple of different curves being I'm using a adjustable belt drive and can adjust on the fly this app has me retarding it 4 degrees

I'm running a MSD digital 6AL MSD Pro-Billet Distributor

Not sure if you need that information or not.

Attachments

-

Screenshot_20180717-191855.jpg74.8 KB · Views: 4

Screenshot_20180717-191855.jpg74.8 KB · Views: 4 -

Screenshot_20180717-191936.jpg72.1 KB · Views: 4

Screenshot_20180717-191936.jpg72.1 KB · Views: 4 -

Screenshot_20180717-191944.jpg64.9 KB · Views: 4

Screenshot_20180717-191944.jpg64.9 KB · Views: 4 -

Screenshot_20180717-192001.jpg86.7 KB · Views: 4

Screenshot_20180717-192001.jpg86.7 KB · Views: 4 -

Screenshot_20180717-192027.jpg74.9 KB · Views: 4

Screenshot_20180717-192027.jpg74.9 KB · Views: 4 -

Screenshot_20180717-192353.jpg65.3 KB · Views: 4

Screenshot_20180717-192353.jpg65.3 KB · Views: 4 -

Screenshot_20180717-192405.jpg59.1 KB · Views: 4

Screenshot_20180717-192405.jpg59.1 KB · Views: 4 -

Screenshot_20180717-192331.jpg80.6 KB · Views: 4

Screenshot_20180717-192331.jpg80.6 KB · Views: 4

Last edited:

Speedlink1973

Well-Known Member

Hey Grumpy, epoxied

A 13 lbs pull neodymium rare earth magnets in pan as suggested to pick up trash.

I hope you bought thee correct high heat versions?

the next time you pull the engine down youll see all the crap they collected

http://garage.grumpysperformance.com/index.php?threads/magnets.120/#post-76617

Maniacmechanic1

solid fixture here in the forum

Cam specs are mild for such a Big Ci. Engine.Oh I have another question for you guy's

I seen some of the blocks screens in lifter valley, I noticed some are screwed down and some that appear to have epoxy

This is what my virtual dyno pro app came up with

2" diameter tubes 37" long

The pistons are 25cc dome piston

But cc them in cylinder came to 24.4cc

But to take in account of big bore gasket diameter I lose 3cc so it's 21.4 cc as picture shows

Cam in at 108 center line retarded-4 degrees

Thanks

Will make Superb torque.

Not a Supercharger cam . Lobe centers too tight.

Ok for Nitrous a small shot 125-150 .

What I see.