stepside

Well-Known Member

Hi

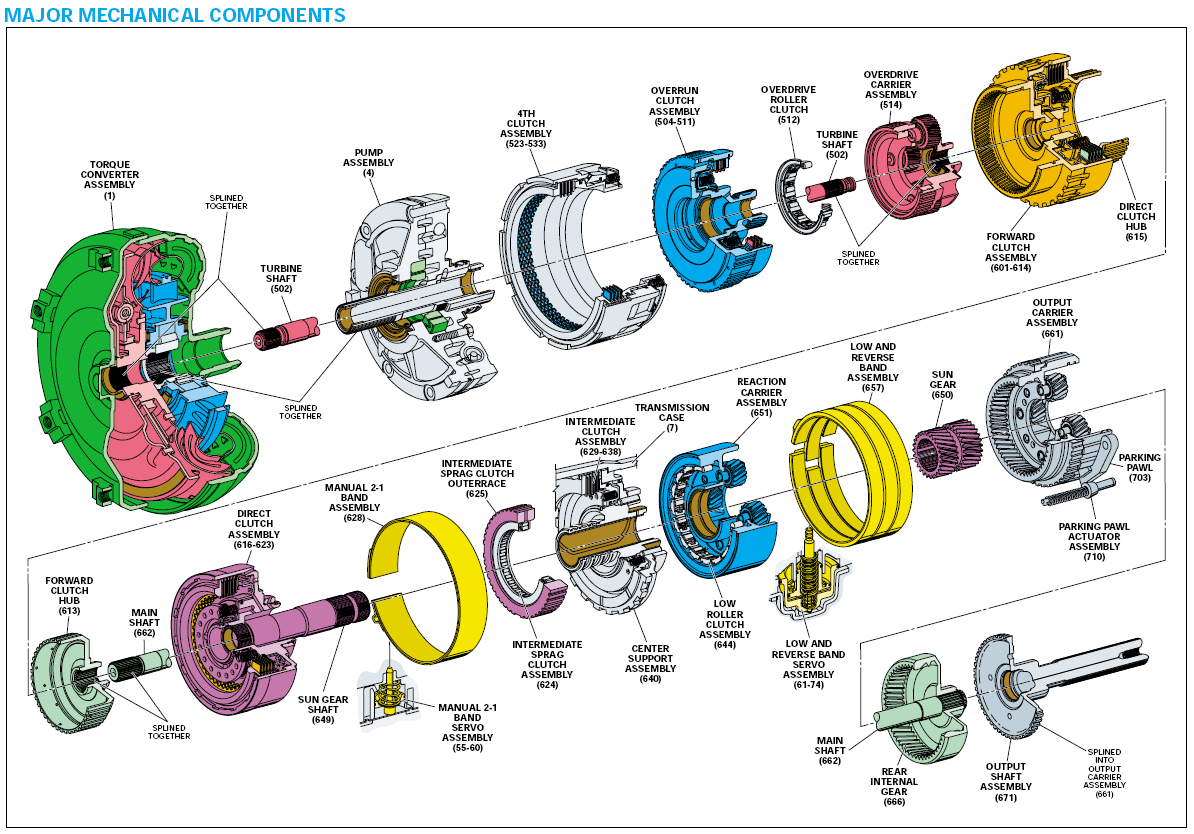

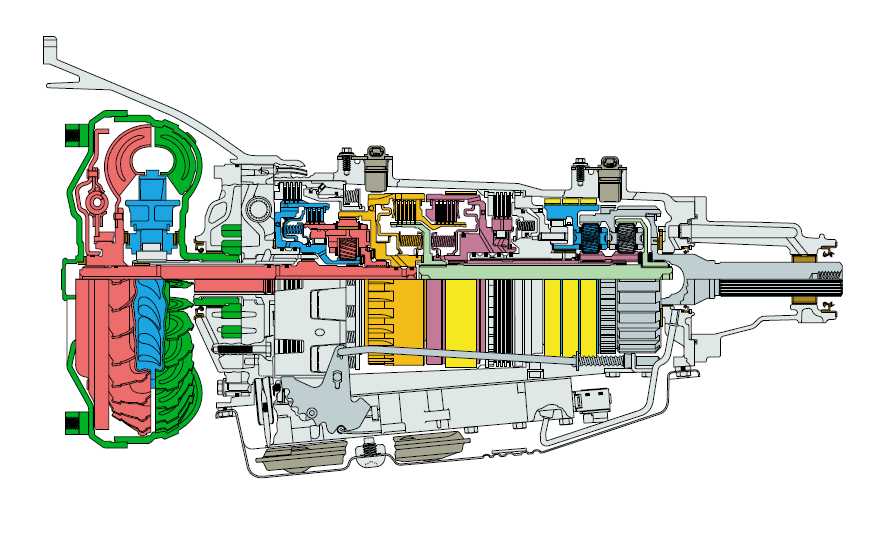

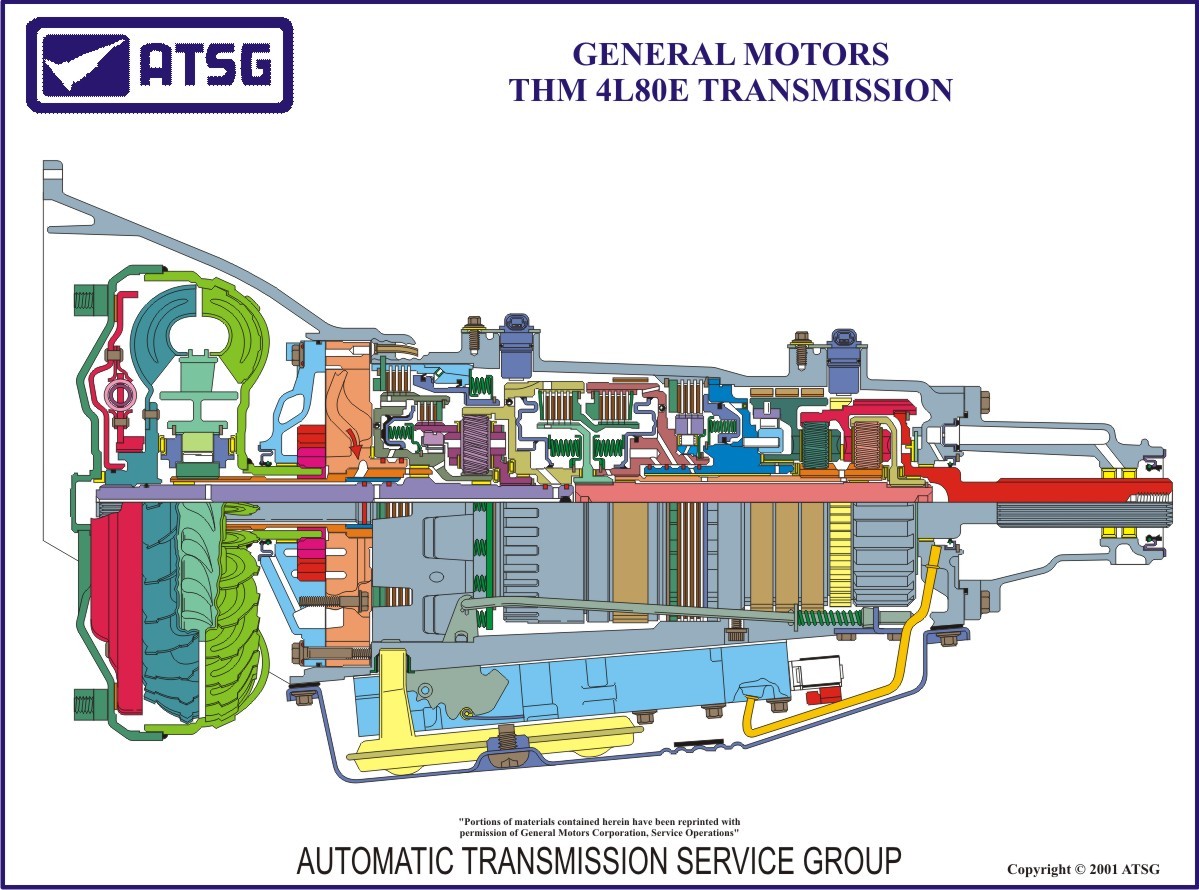

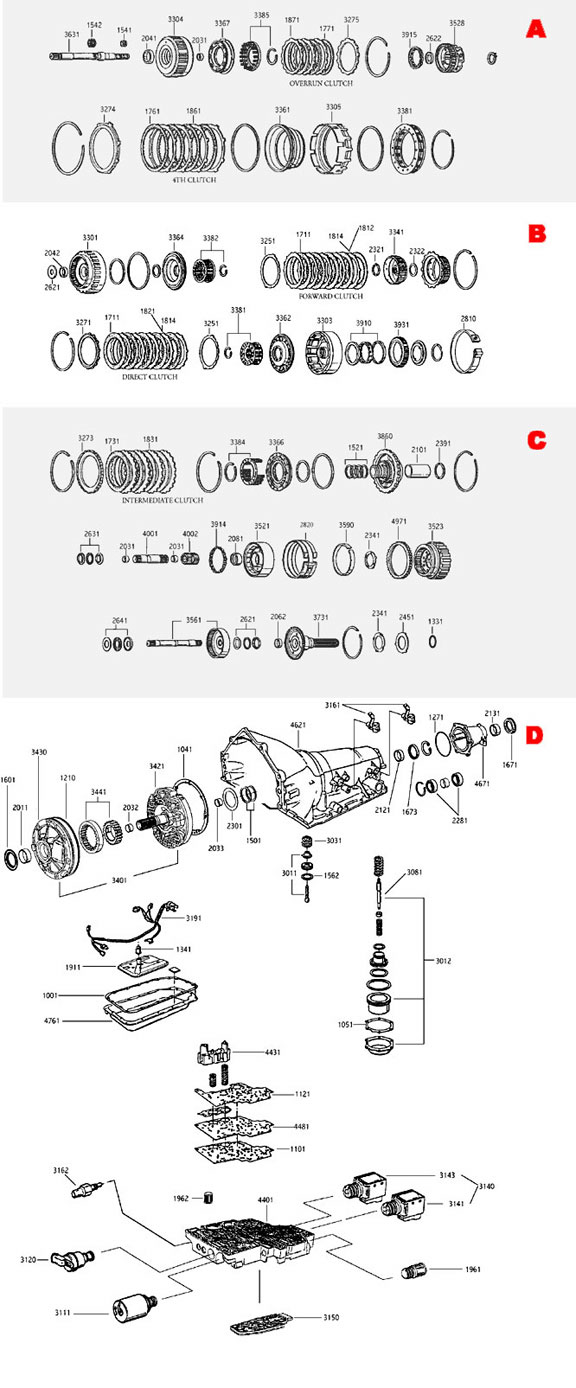

I started 4l80 transmission project

I did dual feed mod and drilled separator plate feed holes

Direct drum was broken so i replased it with cadillac t400 drum

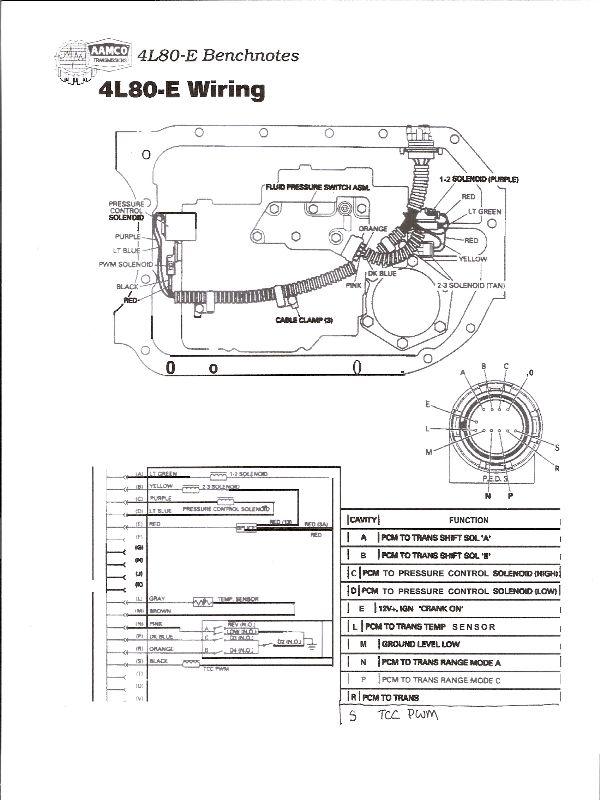

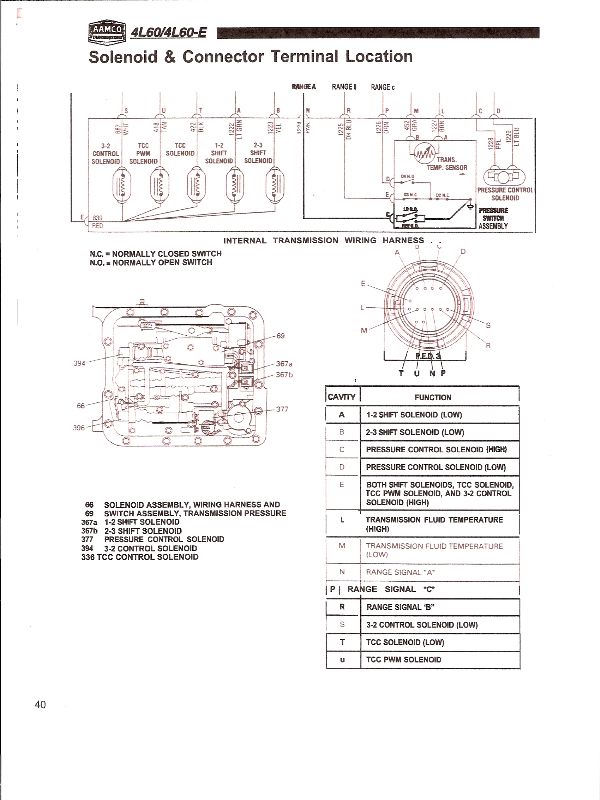

I bought megashift controller and wiring harness

Trans is ready now but torque converter makes me a

headache

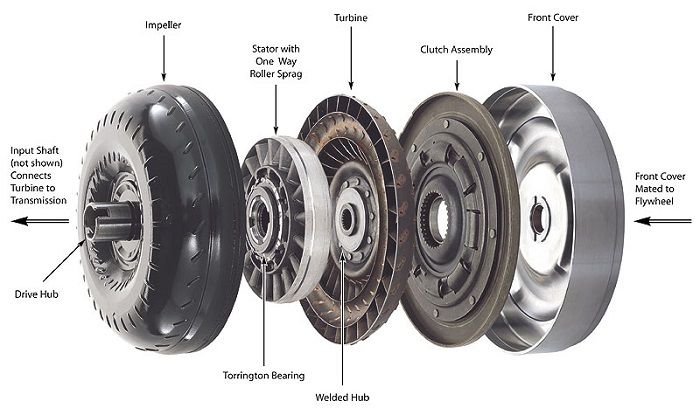

I found opel 245mm lock up torque converter and started modifying it to 4l80

Lots of machining and fitting but i get it to work

I've been really busy but i try to upload Some pictures

I started 4l80 transmission project

I did dual feed mod and drilled separator plate feed holes

Direct drum was broken so i replased it with cadillac t400 drum

I bought megashift controller and wiring harness

Trans is ready now but torque converter makes me a

headache

I found opel 245mm lock up torque converter and started modifying it to 4l80

Lots of machining and fitting but i get it to work

I've been really busy but i try to upload Some pictures