You definitely need a tubing cutter. If you plan on doing a double flare, you need a perfect cut.

If your cut is less than perfect you will bang your head trying to get a nice flare.

The first step in your flare will be crooked causing your hole to be off center, ultimately causing a poor seal and a dreaded leak.

This is the cutter I already had Rigid Model # 31622

http://www.homedepot.com/p/RIDGID-150-Tubing-Cutter-31622/100018866

I would suggest a big one like this because it has a tool attached in the side to clean the inside of your cut.

You could use a rat tail file if all you have is a small cutter that does not have the attached tool.

Just make sure you blow out your line really well after cutting and cleaning.

I would suggest getting a decent set of files if you don't have any. They sure are handy for a lot of things.

I used this tubing bender from Napa. Part Number: BK 7769001

http://www.napaonline.com/Catalog/CatalogItemDetail.aspx/Tubing-Bender/_/R-BK_7769001_0006393011

Not the best bender, but it worked great for me, and after using a spring bender on a prior truck, this bender was a huge

upgrade for me. I've worked with angles my whole life so I am really accurate at guessing degrees of angles. This bender is perfect for me.

Honestly, if you only ever bend one tube, I still wouldn't use the spring bender. Spend the $8 it will be worth your time.

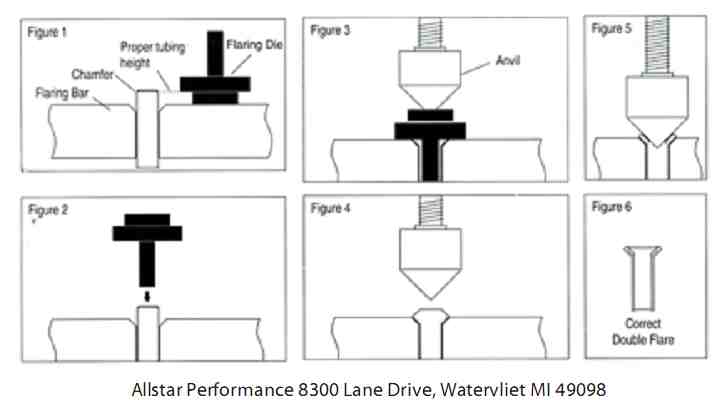

I used the double flare kit from Harbor Freight... Pittsburgh Automotive - Item#66534

http://www.harborfreight.com/double-tube-flaring-tool-kit-66534.html

While this did get the job done... I would actually recommend spending more money on one of these.

I had to use my bench vise and clamp this one down so tight I thought my vice was going to break.

If you use this one (don't say you weren't warned), you better have a good vice or your tubing will just keep slipping when you put pressure on the end.

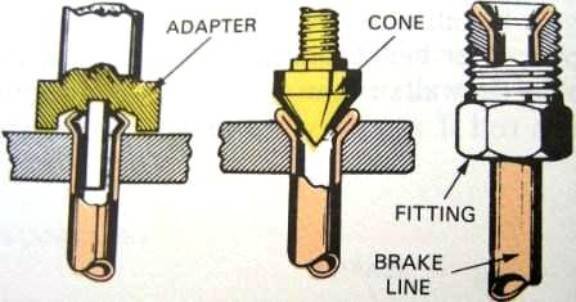

This may not be necessary, but I used a bastard cut flat mill file to chamfer the outside edge of my tube before flaring.

I did transmission lines so I used a touch of transmission fluid on the end of the line and cone before flaring to keep the friction down;

and I feel like it prolongs the life of the tool a bit. I will be doing a lot more line, so this thing will probably end up in the dumpster.

I hear good things about the rigid Grumpy posted above.

This is what I ended up with...

A CLEAN DRIVEWAY!

One thing I would definitely recommend if you're new to flaring. Make sure you get enough tubing to practice your flares.

I messed up 2-3 flares before I slowed down and prepped everything correctly. After that is was a breeze.