You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

61 c10 Build

- Thread starter BetsyRed63

- Start date

BetsyRed63

Well-Known Member

I'm not sure what to tell you now, other than maybe you need to pull the heads and check valve

guide clearance and replace the seals if the clearance is good.

I guess it's as good of time as any to upgrade the heads on this thing. I can check everything when I pull this set off.

keep in mind if you hear air under pressure escaping from the cylinders it has to be coming past the rings into the lower engine OR

escaping past the valve sealing area on the valves.

worn valves are not necessarily round nor are worn valve seats

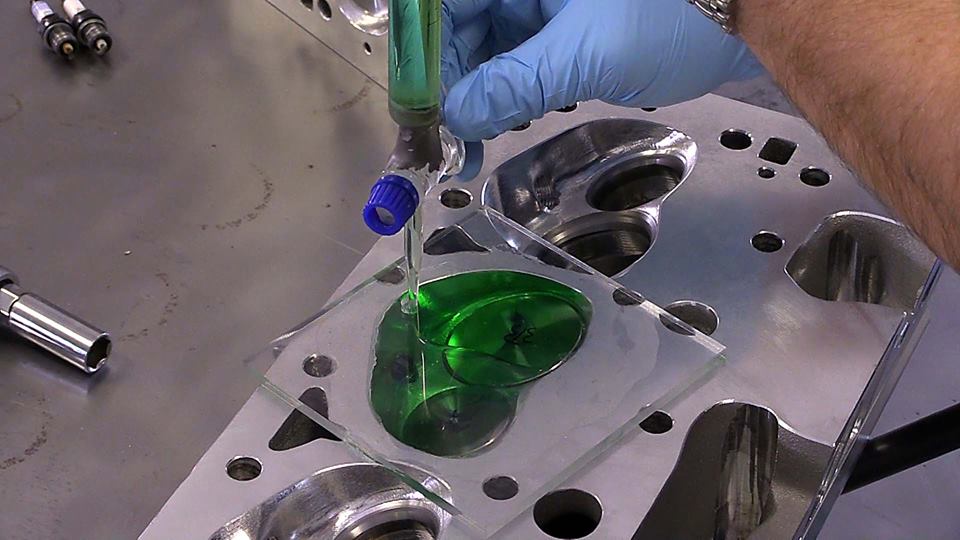

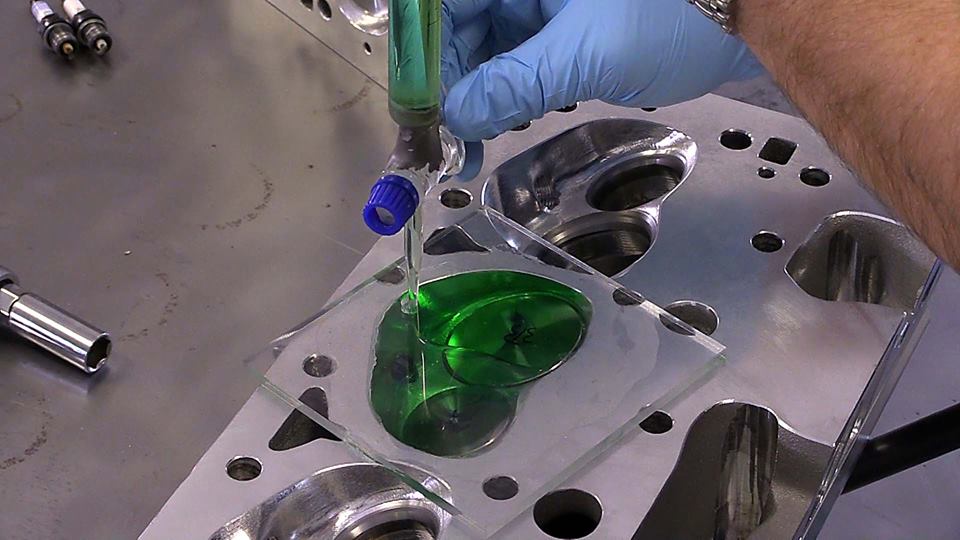

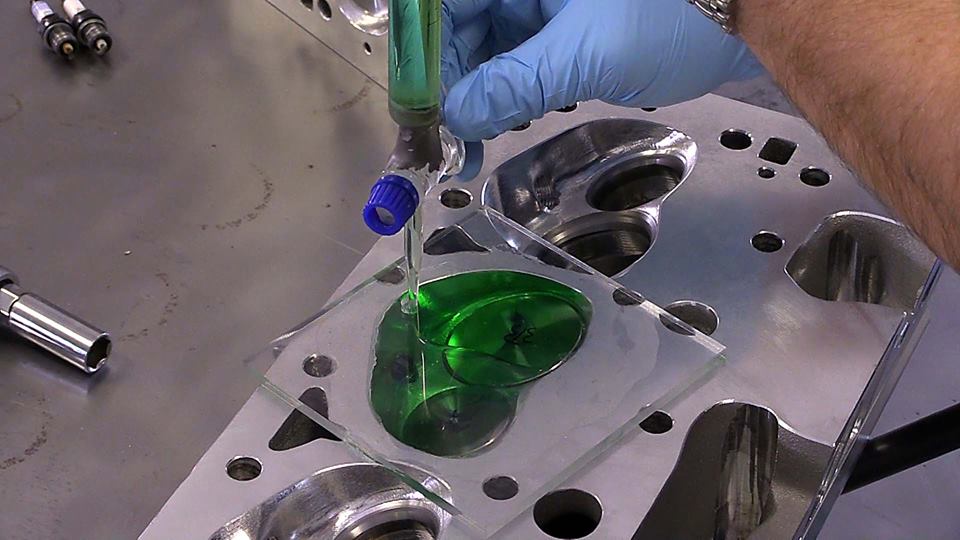

obviously testing the valve to seat seal and checking combustion chamber consistency in size helps (ccing head chambers and doing a consistent multi angle valve job)

but of course everything, in this hobby, costs you cash and time to do correctly

http://garage.grumpysperformance.com/index.php?threads/valve-seat-runout.15104/#post-86003

http://garage.grumpysperformance.co...ng-combustion-chambers.2630/page-3#post-77963

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/#post-71989

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50247

http://garage.grumpysperformance.co...gree-valve-seats-tpi-motors.14662/#post-78724

http://garage.grumpysperformance.com/index.php?threads/how-to-lap-valve-seats.1159/#post-2362

http://garage.grumpysperformance.co...at-angles-and-air-flow.8460/page-2#post-32923

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/

http://garage.grumpysperformance.co...lve-seat-angles-and-air-flow.8460/#post-29682

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/#post-8387

escaping past the valve sealing area on the valves.

worn valves are not necessarily round nor are worn valve seats

obviously testing the valve to seat seal and checking combustion chamber consistency in size helps (ccing head chambers and doing a consistent multi angle valve job)

but of course everything, in this hobby, costs you cash and time to do correctly

http://garage.grumpysperformance.com/index.php?threads/valve-seat-runout.15104/#post-86003

http://garage.grumpysperformance.co...ng-combustion-chambers.2630/page-3#post-77963

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/#post-71989

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50247

http://garage.grumpysperformance.co...gree-valve-seats-tpi-motors.14662/#post-78724

http://garage.grumpysperformance.com/index.php?threads/how-to-lap-valve-seats.1159/#post-2362

http://garage.grumpysperformance.co...at-angles-and-air-flow.8460/page-2#post-32923

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/

http://garage.grumpysperformance.co...lve-seat-angles-and-air-flow.8460/#post-29682

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/#post-8387

BetsyRed63

Well-Known Member

keep in mind if you hear air under pressure escaping from the cylinders it has to be coming past the rings into the lower engine OR

escaping past the valve sealing area on the valves.

worn valves are not necessarily round nor are worn valve seats

obviously testing the valve to seat seal and checking combustion chamber consistency in size helps (ccing head chambers and doing a consistent multi angle valve job)

but of course everything, in this hobby, costs you cash and time to do correctly

http://garage.grumpysperformance.com/index.php?threads/valve-seat-runout.15104/#post-86003

http://garage.grumpysperformance.co...ng-combustion-chambers.2630/page-3#post-77963

http://garage.grumpysperformance.com/index.php?threads/ccing-my-heads.14187/#post-71989

http://garage.grumpysperformance.co...olishing-combustion-chambers.2630/#post-50247

http://garage.grumpysperformance.co...gree-valve-seats-tpi-motors.14662/#post-78724

http://garage.grumpysperformance.com/index.php?threads/how-to-lap-valve-seats.1159/#post-2362

http://garage.grumpysperformance.co...at-angles-and-air-flow.8460/page-2#post-32923

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/

http://garage.grumpysperformance.co...lve-seat-angles-and-air-flow.8460/#post-29682

http://garage.grumpysperformance.com/index.php?threads/multi-angle-valve-job-related.3143/#post-8387

I could hear air coming from the carb, as well as the dip stick tube on every cylinder. Won't there be a little escaping even on a near perfect motor? Or should you not hear it at all?

The heads had a valve job, new seals, springs, studs & keepers. I thought they had a triple angle valve job, but I can't find that on the build specs from the builder. I must be remembering that wrong.

I'd honestly rather get a decent set of heads, rather than rebuild these. But, if the whole bottom end needs a rebuild, I'll have to really consider all options.

BetsyRed63

Well-Known Member

Appreciate all of the info again. I'll dig into all of this tonight, and over the weekend.

I've actually been looking at the Brodix IK series.

Last edited:

BetsyRed63

Well-Known Member

Was taking a look at the valve springs, and noticed the umbrella valve seals. They don't all seem to be consistent. Most are all the way at the top of the valve, and Some are a little further down. I assume umbrella style are suppose to float?

Last edited:

the quality and design, varies , but some umbrella valve seals are not ideal,

what many are is they are cheap, and just slip on the valve, stem, thus easy to install,

the correct and better valve seals require the valve guide be machined to have them installed

related info.. check links for pictures an added info

http://garage.grumpysperformance.co...anging-valve-springs-on-the-car.404/#post-496

http://garage.grumpysperformance.com/index.php?threads/removing-valve-seals.4283/#post-96765

http://garage.grumpysperformance.co...mpressors-and-checking-springs.903/#post-1465

http://garage.grumpysperformance.co...eplacing-oil-seals-in-heads.14660/#post-78667

http://garage.grumpysperformance.co...gree-valve-seats-tpi-motors.14662/#post-98674

http://garage.grumpysperformance.co...ting-up-the-valve-train.181/page-2#post-96257

what many are is they are cheap, and just slip on the valve, stem, thus easy to install,

the correct and better valve seals require the valve guide be machined to have them installed

related info.. check links for pictures an added info

http://garage.grumpysperformance.co...anging-valve-springs-on-the-car.404/#post-496

http://garage.grumpysperformance.com/index.php?threads/removing-valve-seals.4283/#post-96765

http://garage.grumpysperformance.co...mpressors-and-checking-springs.903/#post-1465

http://garage.grumpysperformance.co...eplacing-oil-seals-in-heads.14660/#post-78667

http://garage.grumpysperformance.co...gree-valve-seats-tpi-motors.14662/#post-98674

http://garage.grumpysperformance.co...ting-up-the-valve-train.181/page-2#post-96257

BetsyRed63

Well-Known Member

the quality and design, varies , but some umbrella valve seals are not ideal,

what many are is they are cheap, and just slip on the valve, stem, thus easy to install,

the correct and better valve seals require the valve guide be machined to have them installed

related info.. check links for pictures an added info

http://garage.grumpysperformance.co...anging-valve-springs-on-the-car.404/#post-496

http://garage.grumpysperformance.com/index.php?threads/removing-valve-seals.4283/#post-96765

http://garage.grumpysperformance.co...mpressors-and-checking-springs.903/#post-1465

http://garage.grumpysperformance.co...eplacing-oil-seals-in-heads.14660/#post-78667

http://garage.grumpysperformance.co...gree-valve-seats-tpi-motors.14662/#post-98674

http://garage.grumpysperformance.co...ting-up-the-valve-train.181/page-2#post-96257

Gotcha.

I studied a lot of these links, and videos you sent over the weekend, and noticed the positive stop seal is a much better option for the intake. Not sure I want to have these heads machined for those seals.

Last edited:

BetsyRed63

Well-Known Member

Found a complete LQ4 with a solid bottom end for $750, just needs a valve job. Tempting, but I'm not sure I'm up for that type of swap. I've worked physical labor since I was 10 or 12, and I guess I'm at the age where anything more than minor repairs feels like a job.

BetsyRed63

Well-Known Member

Thanks, I actually read that same article the other night, and a lot of related on this site. I basically have to consider everything, unless I keep it naturally aspirated, then I'd only have 99 other things to consider instead of 100.

Last edited:

BetsyRed63

Well-Known Member

Worked On the truck this weekend. Adjusted the valves, and got even better compression numbers, leakdown improved on #7. Went from the Accel 576s to a comparable NGK shorty, and they are burning much better.

Oil pressure is great, vacuum is still low, around 14.

I think the oil pan gasket may be leaking. Guess that will be my next task. Hoping the valve adjustment, and oil pan gasket will take care of the oil consumption.

Compression/Leakdown

1 - 175 / 100/96

3 - 170 / 100/96

5 - 178 / 100/95

7 - 170 / 100/93

2 - 175 / 100/96

4 - 172 / 100/94

6 - 170 / 100/93

8 - 175 / 100/94

Oil pressure is great, vacuum is still low, around 14.

I think the oil pan gasket may be leaking. Guess that will be my next task. Hoping the valve adjustment, and oil pan gasket will take care of the oil consumption.

Compression/Leakdown

1 - 175 / 100/96

3 - 170 / 100/96

5 - 178 / 100/95

7 - 170 / 100/93

2 - 175 / 100/96

4 - 172 / 100/94

6 - 170 / 100/93

8 - 175 / 100/94

Do you know if they were too tight ? But hydraulic lifters would have to be more than justAdjusted the valves

alittle too tight to change compression numbers. Atmospheric pressure changes could effect

the cylinder pressures from one day to the next, but not the leak down numbers.

If you change the pan gasket look for a One Piece Gasket. But there other places where oil

can find it's way from inside to the outside in the pan area.

BetsyRed63

Well-Known Member

The compression was just slightly improved, maybe the weather.Do you know if they were too tight ? But hydraulic lifters would have to be more than just

alittle too tight to change compression numbers. Atmospheric pressure changes could effect

the cylinder pressures from one day to the next, but not the leak down numbers.

If you change the pan gasket look for a One Piece Gasket. But there other places where oil

can find it's way from inside to the outside in the pan area.

But, #2 was down about 142 or so, and it jumped up about 30 after the valve adjustment.

I was planning to get the thick felpro one piece rubber and steel gasket.

The motor is pretty clean, and I can see if any oil leaks from the top.

It only leaks when I run it, and it almost seems like it is coming from several bolts on the oil pan. Looks like it may be getting through the gasket, and over the edge of the pan.

I cleaned everything, and then let it idle for a while until I saw a drop.

I checked the torque on the bolts, they were a little loose.

BetsyRed63

Well-Known Member

Maybe a stuck valve came loose in #2 for a swing that big?Do you know if they were too tight ? But hydraulic lifters would have to be more than just

alittle too tight to change compression numbers. Atmospheric pressure changes could effect

the cylinder pressures from one day to the next, but not the leak down numbers.

If you change the pan gasket look for a One Piece Gasket. But there other places where oil

can find it's way from inside to the outside in the pan area.

Possible I suppose.Maybe a stuck valve came loose in #2 for a swing that big?

BetsyRed63

Well-Known Member

Changed the oil pan gasket Friday night. Used the thick one piece rubber with steel (Fel-Pro OS34510T). It replaced the 4 piece cork and rubber set.

Pain in the rear, but it stopped the leaking.

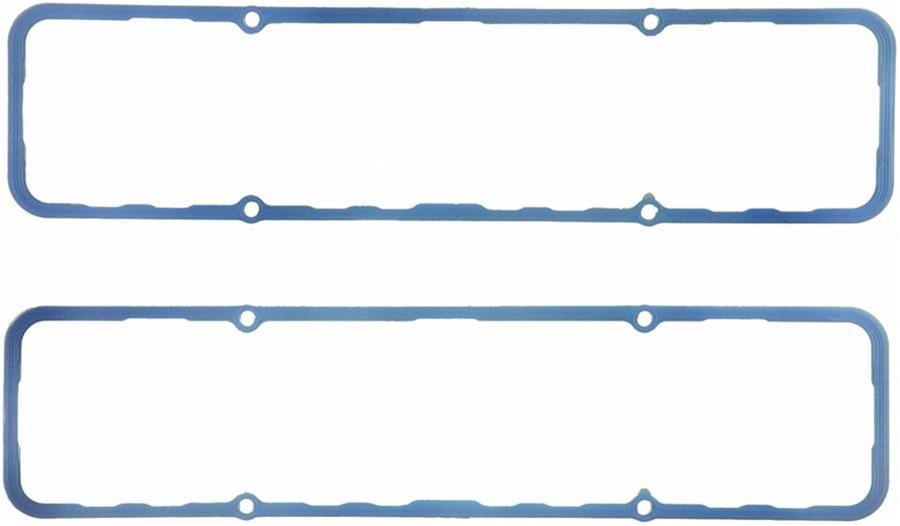

Anyone have luck with rubber valve cover gaskets? I tried a set a few years ago, and the back corner always leaked. I have aftermarket aluminum covers that have really thick rails, and they are dead flat.

Cork works the best so far, but they always seem to bleed after awhile.

Hate those rounded edge on stock heads.

Pain in the rear, but it stopped the leaking.

Anyone have luck with rubber valve cover gaskets? I tried a set a few years ago, and the back corner always leaked. I have aftermarket aluminum covers that have really thick rails, and they are dead flat.

Cork works the best so far, but they always seem to bleed after awhile.

Hate those rounded edge on stock heads.

These work well, but your not going to like the price !

You will not have to work about how tight you make them since they have compression limiters.

www.summitracing.com

Steel core gaskets may not fit valve covers with a gasket retaining lip. Silicone molded rubber with steel core construction and steel compression limiters. Will also fit applications using Chevy 18 degree or Brodix 12 heads.

www.summitracing.com

Steel core gaskets may not fit valve covers with a gasket retaining lip. Silicone molded rubber with steel core construction and steel compression limiters. Will also fit applications using Chevy 18 degree or Brodix 12 heads.

You will not have to work about how tight you make them since they have compression limiters.

Fel-Pro 1628 Fel-Pro Performance Valve Cover Gaskets | Summit Racing

Free Shipping - Fel-Pro Performance Valve Cover Gaskets with qualifying orders of $109. Shop Valve Cover Gaskets at Summit Racing.

BetsyRed63

Well-Known Member

I almost bought that set when I got my last set of gaskets. I don't mind the price as long as they seal well.These work well, but your not going to like the price !

You will not have to work about how tight you make them since they have compression limiters.

Steel core gaskets may not fit valve covers with a gasket retaining lip. Silicone molded rubber with steel core construction and steel compression limiters. Will also fit applications using Chevy 18 degree or Brodix 12 heads.

Fel-Pro 1628 Fel-Pro Performance Valve Cover Gaskets | Summit Racing

Free Shipping - Fel-Pro Performance Valve Cover Gaskets with qualifying orders of $109. Shop Valve Cover Gaskets at Summit Racing.www.summitracing.com

My valve covers don't have a lip at all, they look just like these. https://www.cvfracing.com/chevy-sma...400/?msclkid=d1ef0dce422c132366696cb1502ced4f

The passenger side sucks to take off.