I read through that build and the first thing that struck me was that why would anyone spend close to $1800 for a set of 2 those cast iron 308cc BIG BLOCK HEADS ($875 x 2)

theres dozens of other options both cast iron and aluminum

http://www.dragzine.com/tech-stories/engine/ultimate-guide-to-budget-bbc-cylinder-heads-under-2000/

http://garage.grumpysperformance.co...t-intake-on-oval-port-heads.13146/#post-69975

Ultimate Guide to Budget BBC Cylinder Heads Under $2,000

In general terms,

big engines make big power! It stands to reason that if you want earth shaking, ground pounding power, you probably want to build a big block engine. Power, however, comes at a price. The old adage of “there’s no replacement for displacement” still holds true, but cubic inches of power doesn’t have to cost you cubic dollars. The high performance aftermarket has seen an influx of big block Chevy cylinder heads, many of which can fit into the tightest of budgets and still bring thundering punishment to the pavement.

When you are putting together the big block puzzle, one of the worse things you can do is buy whatever part is on sale this week. Randomly buying parts because they look good or because they have good street cred may cost you more in the long run. Big Block Chevy cylinder heads are a perfect example of where money spent wisely can pay off with some decent power without spending your kid’s entire college fund. Power does come at a price, but you can make some wise choices that produce the power you are expecting by picking up affordable heads.

With some smart shopping techniques, like knowing what your overall goal is, you can purchase a set of cylinder heads without breaking the bank, and more importantly, without compromising on power. To help answer the question of “What cylinder head do I need for my big block Chevy?”we have assembled a guide that will help you get through the dense jungle growth of BBC cylinder head choices. Follow along as we go for a run through the jungle.

The Key to Finding the Right Cylinder Head

RHS’ Product Manager Kevin Feeney summed up the process of finding the right set of heads for your BBC, “The first step is to determine what you are trying to accomplish with the engine. Are you looking for torque or horsepower, or the best combination of them both? This and the size of the engine are vital to choosing the proper runner sizes, valve sizes and ports for the application.”

With so many variables, and so many choices, it’s easy to go down the wrong path or find a shortcut to less performance. “Too many times guys tend to buy cylinder heads based on high lift flow numbers that are easily achieved with large ports and valves, but do not necessarily provide them with the performance they are looking for,” added Feeney.

Cast Iron being poured into molds at the foundry. (Photo from CFM Corporation)

What this Guide Covers

Our comprehensive guide to budget-friendly big block cylinder heads is strictly limited to fully configured and assembled units that are sold as a set for under $2,000 and are perfect for street use. We limited the spectrum of head choices to engines that are designed to run 91 octane pump gas and are not trailer queens. If you’re building a car that you can’t drive to the track, you’re probably not looking for a budget friendly set of cylinder heads anyway and this guide won’t cover the range of cylinder heads that you are looking for.

Our Criteria for budget friendly:

- A fully configured and assembled set of cylinder heads

- Priced under $2,000

- Street or Street/Strip use

- Designed to run on pump gas

- Must be able to make more power than stock OEM cylinder heads

Take a look at the big picture before rushing out to buy the first set of BBC heads you see.

Factors To Consider

There are several factors to consider when selecting the right set of heads for your big block. Dart Machinery’s Advertising Director, Jack McInnis explained “The size of the engine, rpm range, camshaft, type of fuel, weight and gearing all factor in. Whether the car will be street driven 99% of the time, or if it will be primarily raced and driven on the street only occasionally will make a big difference in the choice as well.” Armed with McInnis’ warning to take a look at the whole picture, we have broken down some of the basic characteristics that you need to consider when selecting a budget big cube head.

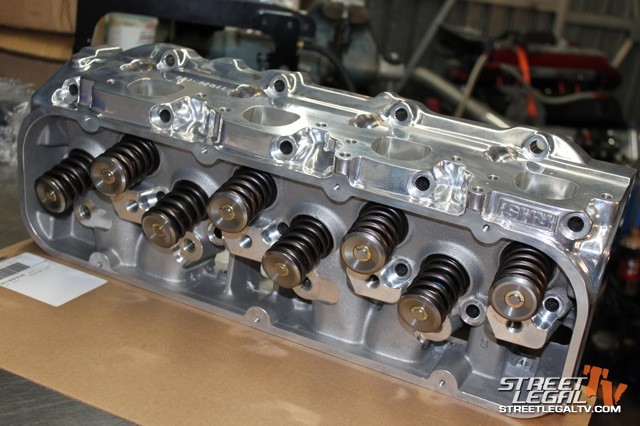

Aluminum heads look great and have a lot of good things going for them, but are they right for you?

Aluminum VS. Cast Iron

Cast iron is pretty common to most of us because it has been around the longest. Cast iron is inexpensive when compared to aluminum and is strong and durable. There are hundreds of different cast iron alloys but the kind that is typically used in cylinder heads is a gray cast iron. Gray cast iron is generally about 92-percent iron, 3.4 percent carbon, 2.5 percent silicon and 1.8 percent manganese. Rated at a tensile strength around 25,000 psi and a hardness somewhere near 180 on the Brinnell scale, cast iron heads are heavier than aluminum heads and can weigh as much as 30 percent more.

Aluminum’s main advantage is its light weight. Aluminum also dissipates heat very quickly, which may or may not be an advantage, depending on what you are trying to achieve. To make horsepower, you want some heat to be retained in the combustion chamber without detonation or preignition, which makes aluminum a great choice.

We talked to Billy Briggs of Briggs Performance about aluminum heads. “About the only drawback with aluminum is the simple fact that the aluminum alloy itself only has a life span of so long, but the pros are still huge. Ease of repair, ease of machining, heat dissipation and lighter weight are just a few,” said Briggs.

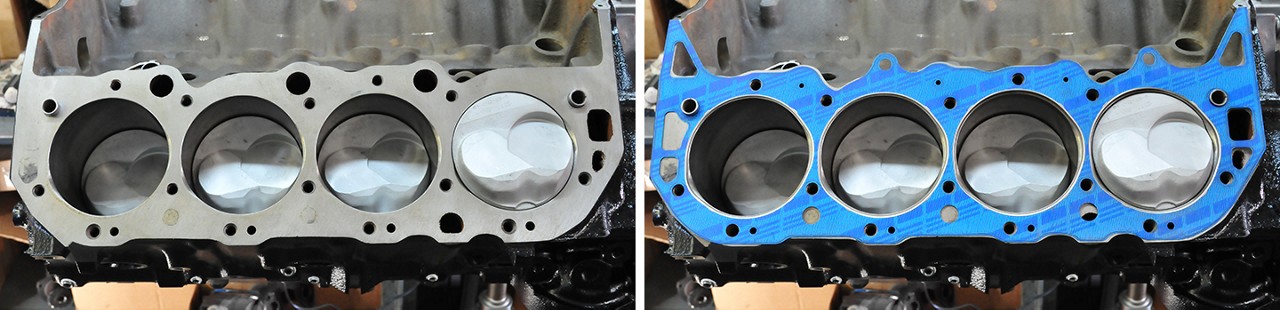

Aluminum alloys have become much better in recent years and the problems associated with heat warping aluminum heads in the early 1980s have been eliminated. There are some installation procedures that should be adhered to when installing aluminum cylinder heads for trouble free service.

Chad Golen of Golen Performance, a top notch GM LS engine builder, explained, “Aluminum has more expansion but doesn’t cause a problem with today’s head gaskets and high quality fasteners made by ARP. You just need to be careful bolting up accessories, like intakes and valve covers so you don’t damage the threads.”

Another company that specializes in big block Chevy heads is Livernois Motorsports in Michigan. Mike Schropp, Engine Department Supervisor at Livernois, confirmed that, “While aluminum heads do contract and expand at different rates than the cast iron block they may be bolted to, most modern day gaskets, bolts and heads require little to no maintenance after being installed.”

The key is using good quality gaskets and hardware. “New style gaskets do an excellent job of allowing the two surfaces to scrub on each other and still maintain a seal,” said Schropp. Using the professional guidance from Golen and Schropp, we recommend budget builders to plan on buying good quality gaskets and hardware with an aluminum cylinder head. Schropp also suggested “using an anode rod to try and prevent corrosion of the aluminum surfaces from the dissimilar metals if you are using an aluminum head and a cast iron block.”

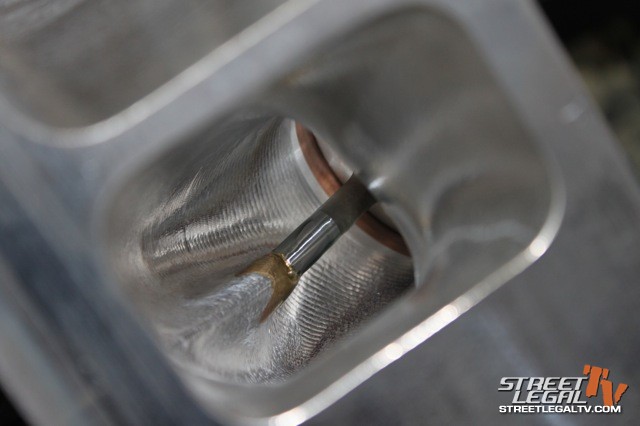

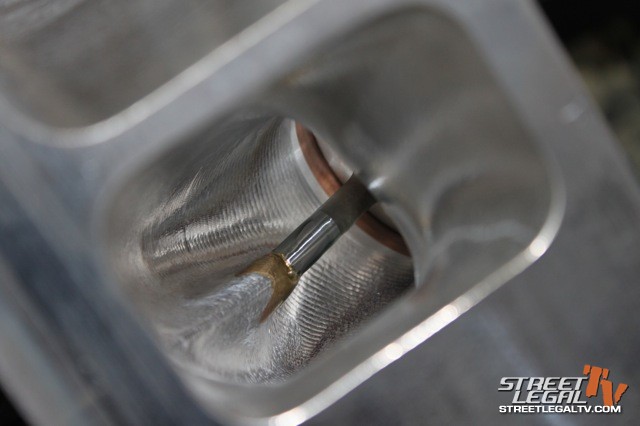

Combustion chamber design and volume are important in how the fuel is burnt.

Closed or Open Combustion Chamber?

These terms get thrown around casually without consideration for what they purpose is behind the design of these chambers. In respect to big block Chevy heads, these terms relate to the size of the combustion chamber. An open chamber will have a larger combustion chamber; typically the valves are not shrouded and the engine breathes better. An open chamber can be identified by the dome area of the chamber extending to the diameter of the cylinder bore.

A closed chamber typically has a diameter much smaller than the cylinder bore. The smaller combustion chamber results in the block’s deck surface extending into the combustion chamber area which forces the air/fuel mixture into the smaller combustion chamber when the piston is on the compression stroke.

When the piston nears the cylinder head and the flat area of the piston top and the flat area of the cylinder head get close, the air/fuel mixture is “squished” into the combustion chamber closer to the spark plug. This is where the term “squish area” comes from. The space between the flat area of the piston top and the cylinder head typically run cooler than the rest of the chamber and piston. This lower temperature is where the term “quench area” comes from.

Semi-open combustion chamber heads can flow extremely well and provide the right mix of turbulence and "squish".

While the terms “quench” and “squish” are often used interchangeably by many manufacturers, quench and squish are not the same thing, nor are they produced by the same set of conditions. The

Society of Automotive Engineers (SAE) has defined squish as the gases trapped between the piston dome and head that are ejected across the combustion chamber at high speed by the near-collision of the piston dome and head, causing turbulence and mixture homogenization. For our purposes, if the squish area is too close, there is a pumping loss and if the area is too far apart there will be lower squish velocity and less turbulence.

Quench on the other hand, is the ability to lower temperature of the end gases trapped between the piston dome and head by conduction. This prevents a second flame front from igniting the air/fuel mix prematurely. Members of the SAE acknowledge that for motors with 3.5” to 4.5” cylinder bores, a quench distance of 0.035” to 0.040” work well and result in near zero clearance due to thermal expansion, rod stretch and piston rock-over.

Properly designed quench areas have a dramatic effect on combustion quality and allow for higher compression ratios. For our budget friendly cylinder head guide, we can say in general terms, closed chambered heads can have an advantage in fuel efficiency and emissions by achieving a more complete burn, but valve shrouding can become an issue if the chamber is closed too much.

Combustion chamber size plays a significant role in compression (more is less and less is more). The smaller the combustion chamber, measured in cubic centimeters, the higher the compression will be.

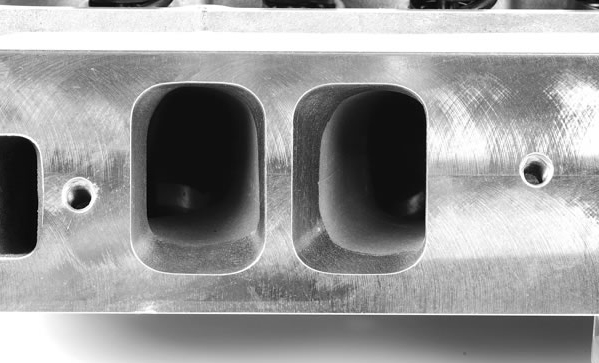

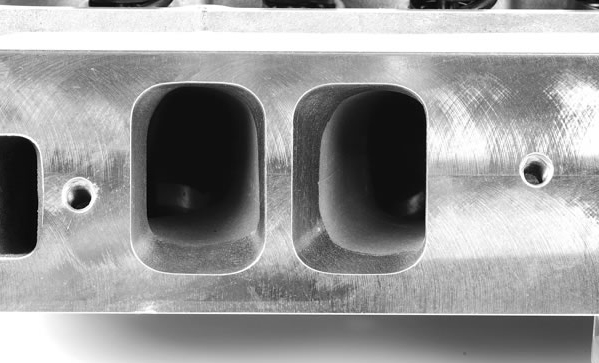

Intake Port Shape and Size

It doesn’t take a lot of imagination to understand that a larger port has the potential to flow more than a smaller port. How much flow your engine needs will vary based on how much the engine can use. Port size is a very important issue when it comes to head design. Simply speaking in terms of flow, the smaller the port diameter, the less air potential there is.

Runner volume (length) is also very important. As the runner gets longer, movement in the column of air will increase the flow at lower RPMs and decrease the flow at higher RPMs.

Intake port shape and size are important considerations in reaching your goal.

If you intend on doing a lot of low rpm street driving with a low-lift camshaft, performance will be less than optimal on cylinder heads with huge intake ports. The reverse is also true; high revving, big lift cammed engines with big displacement will not like smaller intake ports.

It’s true that a larger intake runner will allow more air and atomized fuel to flow through, but the larger area will also slow the velocity of the air and fuel flowing through it. Smaller runners speed up the flow, which improves throttle response and torque, but may not deliver the maximum amount of energy that your engine can use. The perfect combination of good flow and velocity is the challenge.

Common thought on port shapes is that oval shaped ports leave fewer opportunities for eddies and irregularities of flow in the corners because there are no corners, however, for budget friendly street heads running on pump gas, you should think of oval and rectangular ports as a function of size, not of shape.

RPMs are a big deal for street cars running on pump gas. Port shape is not as important as the cross sectional diameter and length of the runner matched to the RPMs. It’s highly unlikely that a street car is going to be spinning 7,000 RPM from stoplight to stoplight, thus a huge diameter, big volume oval port runner will probably under perform in the street RPM range.

Runner volume can make or break a daily driver.

Exhaust port shape and runner volume is even less important than the intake side, however, scavenging all the exhaust gasses from the combustion chamber means that you can refill the combustion chamber with more fuel and air. More fuel and air means more power, so there is some consideration in the exhaust runner size and exhaust port shape. Our best advice is to call the manufacturer’s tech lines or talk to your engine builder for guidance on runner size.

Comprehensive Guide to BBC Cylinder Heads by Application

For our guide, we chose to break down the “budget friendly” BBC cylinder heads into categories that include the entry level and work up to the street/strip category and up to the dedicated performance car level. We also include a breakdown on why we think the cylinder heads represented in each category are the best fit for the application. The cylinder heads are not listed in order of preference, simply by the company’s name in alphabetic order. Where applicable, we have included additional information on engine size as big block Chevy’s covered in this article range from engines manufactured from 1965 through 2006.

Budget Big Block Chevy Cylinder Heads For Entry Level Street

Looking for an entry level set of heads for street use goes beyond price. Given that GM factory production heads commonly had runner volumes of 230 to 270 cc. Larger volume runners were used in GM’s performance versions. Aftermarket cylinder heads have improved airflow but must be matched to the camshaft, intake and exhaust systems for the optimal results. The heads listed below are good choices for an application that is intended to be higher performing than stock and still used on the street for daily driving.

Smaller ports and runners will keep the mixture of air/fuel at a higher velocity making driving from stop light to stop light and idle quality a lot more steady. With too large of a runner volume, a basic stock type engine will lug at low RPMs until it gets to cruising speed. Entry level heads are designed for engine where there are not too many high performance upgrades already installed and the engine will be running on mid to high octane pump gas. Optimal runner volume for these conditions is somewhere in the range of 270 cc to 290 cc.

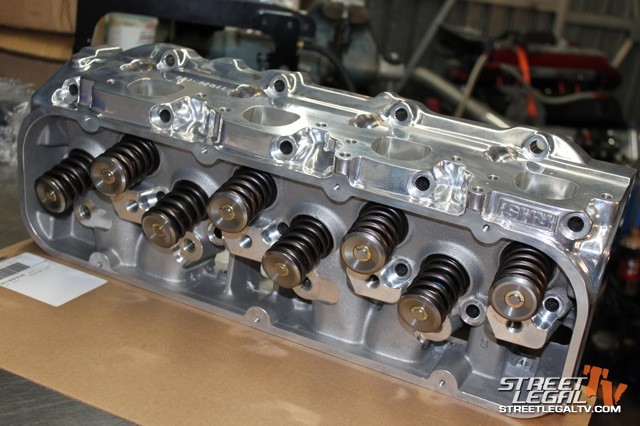

Dart 308cc Big Block Chevy Heads, Rectangular Port

Dart 308 cast iron cylinder head.

Perfect for: Entry Level Street or Street/Strip where front end weight is not an issue.

Material: Cast Iron Alloy

Cost: $1,700 per set

Intake Runner: 308cc

Combustion Chamber: Heart Shaped, 121 cc

- Additional Specs:

- Part Number: 15100111

- Intake Port Shape: Rectangular

- Intake Runner Volume: 308cc

- Exhaust Runner Volume: 129 cc

- Exhaust Port Shape: Round

- Intake Valve Diameter: 2.250″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.660″

- Springs Per Valve: Single

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1966-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV(1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

Edelbrock E Street 290 aluminum cylinder head.

Edelbrock E Street 290 (#50459)

Perfect for: Entry Level Street or Street/Strip

Material: Aluminum

Cost: $1,725 per set

Intake Runner: 290 cc

Combustion Chamber: Proprietary Semi Open Style, 110 cc

- Additional Specs:

- Part Number: 50459

- Intake Port Shape: Oval

- Intake Runner Volume: 290 cc

- Exhaust Runner Volume: 110 cc

- Exhaust Port Shape: D-Port

- Intake Valve Diameter: 2.190″

- Intake Valve Angle: 26°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 26°

- Maximum Valve Lift: 0.700″

- Springs Per Valve: Dual

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1965-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV(1963), 427 ci Mark IV(1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995)

Patriot Performance Freedom Series 2211 aluminum cylinder head.

Patriot Performance Freedom Series (#2211)

Perfect for: Entry Level Street or Street/Strip

Material: Aluminum

Cost: $1,400 per set

Intake Runner: 320 cc

Combustion Chamber: Proprietary, 119 cc

- Additional Specs:

- Part Number 2211

- Intake Port Shape: Rectangular

- Intake Runner Volume: 320 cc

- Exhaust Runner Volume: 125 cc

- Exhaust Port Shape: Round

- Intake Valve Diameter: 2.250″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.600″

- Springs Per Valve: hydraulic roller springs

- Retainer Locks: 7°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Priced around $1,400 per set

- Application: 396 ci Mark IV (1966-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV (1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

Summit Racing cast iron cylinder head.

Summit Racing Cast Iron (#SUM-152125)

Perfect for: Entry Level Street or Street/Strip

Material: Cast Iron

Cost: $1,500 per setIntake Runner: 308cc

Combustion Chamber: Heart shaped 119 cc

- Additional Specs:

- Part Number: SUM-152125

- Intake Port Shape: Rectangular

- Intake Runner Volume: 308cc

- Exhaust Runner Volume: 129 cc

- Exhaust Port Shape: Square

- Intake Valve Diameter: 2.250″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.660″

- Springs Per Valve: Single

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1965-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV (1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995)

Trick Flow Specialties PowerOval 280 aluminum cylinder heads.

Trick Flow Specialties PowerOval 280

Perfect for: Entry Level Street or Street/Strip

Material: Aluminum

Cost: $1,850 per set

Intake Runner: 280 cc

Combustion Chamber: Open Chamber 113 cc

- Additional Specs:

- Part Number: TFS-41300001 / TFS-41300002

- Intake Port Shape: Oval

- Exhaust Runner Volume: 137 cc

- Exhaust Port Shape: Round

- Intake Valve Diameter: 2.190″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.700″

- Springs Per Valve: Dual

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1966-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV (1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

World Products Merlin Oval Port Iron Heads

Perfect for: Entry Level Street or Street/Strip

Material: Cast Iron

Cost: $1,675 per set

Intake Runner: 269 cc

Combustion Chamber: Open Chamber 119 cc

World Products Merlin Oval Port Iron Heads.

- Additional Specs:

- Part Number: 030040-1 (Hydraulic Flat Tappet)/ 030040-2 (Solid Flat Tappet and Hydraulic Roller)

- Intake Port Shape: Oval

- Exhaust Port Shape: Round

- Intake Valve Diameter: 2.300″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.600″

- Springs Per Valve: 030040-1: Single. 030040-2: Dual

- Retainer Locks: 7°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1966-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV (1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

Street Performance & Muscle Car

Typically a bigger valve, port size and runner volume are desired in higher performance applications, however, knowing that this guide is for budget friendly, pump gas, street cruisers, we were looking for runner volumes in the range of 290 cc to 320 cc. On the smaller cubic inch big blocks, it’s probably still wise to stay down in the 290 cc to 305 cc range for drivability.

454 cubic inch big blocks are considered small by today’s standards where 502 ci and 572 ci engines are becoming more common. Obviously, a 454 ci engine will not have the same airflow demands as a 572 ci engine. The cylinder heads listed below still have good drivability in stop-and-go driving situations and low speed response while giving improved performance at the top end.

Dart 345 cast iron cylinder heads

Perfect for: Street Performance

Material: Cast Iron

Cost: $1,800 per set

Intake Runner: 345 cc

Combustion Chamber: Heart Shaped 121 cc

Dart 345 cast iron cylinder head.

- Additional Specs:

- Part Number: 15200132

- Intake Port Shape: Rectangular

- Exhaust Runner Volume: 129 cc

- Exhaust Port Shape: Round

- Intake Valve Diameter: 2.300″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.660″

- Springs Per Valve: Dual

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1966-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV(1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

Edelbrock Performer 454-O aluminum cylinder head.

Edelbrock Performer 454-O

Perfect for: Street Performance

Material: Aluminum

Cost: $1,900 per set

Intake Runner: 290 cc

Combustion Chamber: Proprietary Semi Open Style 110 cc

- Additional Specs:

- Part Number: 60479

- Intake Port Shape: Oval

- Exhaust Runner Volume: 110 cc

- Exhaust Port Shape: Square

- Intake Valve Diameter: 2.190″

- Intake Valve Angle: 26°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 26°

- Maximum Valve Lift: 0.700″

- Springs Per Valve: Single

- Retainer Locks: 7°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1966-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV (1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

Patriot Performance Freedom Series 2214 aluminum cylinder heads.

Patriot Performance Freedom Series (#2214)

Perfect for: Street Performance

Material: Aluminum

Cost: $1,600 per set

Intake Runner: 320 cc

Combustion Chamber: Proprietary 119 cc

- Additional Specs:

- Part Number: 2214

- Intake Port Shape: Rectangular

- Exhaust Runner Volume: 125 cc

- Exhaust Port Shape: Round

- Intake Valve Diameter: 2.250″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.700″

- Springs Per Valve: dual

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1966-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV (1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

RHS Pro Action 320 cc Hydraulic Roller

Perfect for: Street Performance

Material: Cast Iron

Cost: $1,575 per set

Intake Runner: 320 cc

Combustion Chamber: Proprietary Modified 119 cc

notice picture is in error a SBC

notice picture is in error a SBC

RHS Pro Action 320 Hydraulic Roller cast iron cylinder head.

- Additional Specs:

- Part Number: 11301-02

- Intake Port Shape: Rectangular

- Exhaust Runner Volume: 135 cc

- Exhaust Port Shape: Rectangular

- Intake Valve Diameter: 2.250″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.600″

- Springs Per Valve: Dual

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1965-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV(1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

World Products Merlin Rectangular Port Iron Heads.

World Products Merlin Rectangular Port Iron Heads

Perfect for: Street Performance

Material: Cast Iron

Cost: $1,675

Intake Runner: 320 cc

Combustion Chamber: Open Chamber 119 cc

- Additional Specs:

- Part Number: 030620-2 (Solid Flat Tappet & Hydraulic Roller)/ 030620-3 (Solid Roller)

- Intake Port Shape: Rectangular

- Exhaust Port Shape: Round

- Intake Valve Diameter: 2.300″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 030620-2: 0.650″ / 030620-3: 0.700″

- Springs Per Valve: Dual

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1966-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV (1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

Wild Street and Dedicated Performance

For an application where performance is desired over streetability comfort. The heads listed below are for larger cubic inch big blocks where the airflow demands are greater or highway driving where the engine does not have to lumber through the gears to get to cruising speed often. Once you get to cruising speed however, these heads should provide all the flow you need or want.

Cylinder heads in the dedicated performance category will do well with intake and exhaust upgrades that maximize the flow characteristics. Large port openings and runner volumes along with larger valves and valve train set up for higher lift are the standards of a wild street or dedicated performance head.

Edelbrock High Compression 454-O aluminum cylinder head.

Edelbrock High Compression 454-O (#60499) 50 state legal

Perfect for: Wild Street Performance or Dedicated Performance

Material: Aluminum

Cost: $1,900 per set

Intake Runner: 290 cc

Combustion Chamber: Proprietary Semi Open Style 100 cc

- Additional Specs:

- Part Number: 60499

- Intake Port Shape: Oval

- Exhaust Runner Volume: 110 cc

- Exhaust Port Shape: Square

- Intake Valve Diameter: 2.190″

- Intake Valve Angle: 26°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 26°

- Maximum Valve Lift: 0.700″

- Springs Per Valve: Single

- Retainer Locks: 7°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1966-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV (1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

Trick Flow Specialties PowerPort 320 aluminum cylinder heads.

Trick Flow Specialties PowerPort 320

Perfect for: Wild Street Performance or Dedicated Performance

Material: Aluminum

Cost: $1,950 per set

Intake Runner: 320 cc

Combustion Chamber: Open Chamber 122 cc

- Additional Specs:

- Part Number: TFS-41400001 or TFS-41400002

- Intake Port Shape: Rectangular

- Exhaust Runner Volume: 137 cc

- Exhaust Port Shape: Round

- Intake Valve Diameter: 2.250″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.700″

- Springs Per Valve: Dual

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1966-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV (1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

Patriot Performance Freedom Series (#2216)

Patriot Performance Freedom Series 2216 aluminum cylinder heads.

Perfect for: Wild Street Performance or Dedicated Performance

Material: Aluminum

Cost: $1,900 per set

Intake Runner: 320 cc

Combustion Chamber: Proprietary 119 cc

- Additional Specs:

- Intake Port Shape: Rectangular

- Exhaust Runner Volume: 125 cc

- Exhaust Port Shape: Round

- Intake Valve Diameter: 2.300″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.800″

- Springs Per Valve: Triple

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1966-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV (1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

RHS Pro Action 320 cc Solid Roller

notice picture is in error a SBC

notice picture is in error a SBC

RHS Pro Action 320 cc Solid Roller cast iron cylinder head.

Perfect for: Wild Street Performance or Dedicated Performance

Material: Aluminum

Cost: $1,780 per set

Intake Runner: 320 cc

Combustion Chamber: Proprietary 119 cc

- Additional Specs:

- Intake Port Shape: Rectangular

- Exhaust Runner Volume: 135 cc

- Exhaust Port Shape: Rectangular

- Intake Valve Diameter: 2.250″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.750″

- Springs Per Valve: Dual

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1965-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV(1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

RHS Pro Action 360 cc Solid Roller cast iron cylinder head.

RHS Pro Action 360 cc

Perfect for: Wild Street Performance or Dedicated Performance

Material: Cast Iron

Cost: $1,780 per set

Intake Runner: 360 cc

Combustion Chamber: Proprietary 119 cc

- Additional Specs:

- Part Number: 11302-02 (Hydraulic Roller)or 11302-03 (Solid Roller)

- Intake Port Shape: Rectangular

- Exhaust Runner Volume: 135 cc

- Exhaust Port Shape: Rectangular

- Intake Valve Diameter: 2.300″

- Intake Valve Angle: 24°

- Exhaust Valve Diameter: 1.880″

- Exhaust Valve Angle: 15°

- Maximum Valve Lift: 0.600″ (11302-02) / 0.750″ (11302-03)

- Springs Per Valve: Dual

- Retainer Locks: 10°

- Valve Train: Standard BBC 7/16” Stud Mount

- Guideplates: Hardened Steel, 3/8″ Pushrod size

- Application: 396 ci Mark IV (1965-1970), 402 ci Mark IV (1970-1972), 427 ci Mark IV(1966-1969), 454 ci Mark IV (1970-1990), 454 ci Gen V (1991-1995), 454 ci Gen VI (1996-2000)

The Final Word

It’s been said that the terms “budget” and “big block” don’t go together and qualify as an oxymoron when used together. However, the cylinder heads listed in our guide above are well within the range of what can be considered budget friendly. Nan Gelhard of Summit Racing Equipment emphasized that point by saying; “When you talk about dollars per horsepower you can see how it changes as you go from street to strip.”

Whether you have a stock big block that you salvaged from the wrecking yard and are looking for some modern technology heads to bolt on, or if you want to beef up your daily driver to take it to the drag strip occasionally, we’ve got you covered in one of the budget friendly categories listed above.

Billy Mitchell Jr. from World Products encourages enthusiasts to call the tech lines or work with your engine builder. “It’s important to marry the runner size and port shape to the cubic inch size of the engine,” says Mitchell. Chad Bowling of Patriot Performance also recommended working with your engine builder on the engine internals like camshaft before picking a set of assembled heads, “Most aftermarket head manufacturers offer cylinder heads in a variety of spring packages from hydraulic flat tappet to solid roller,” Bowling states. The final word is that it is OK to use this guide as you would any other guide, as a means of gathering information to talk with your engine builder about the best method of achieving your goals.

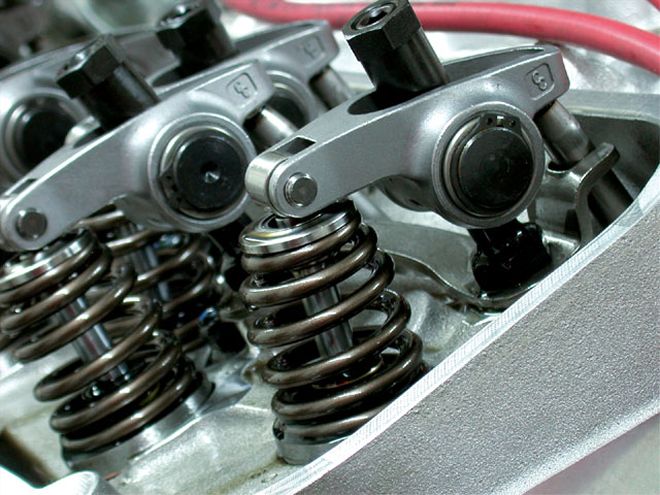

SOME ROLLER ROCKERS CAN AND DO BIND ON ROCKER STUDS, or rocker adjustment nuts, youll need to check carefully

some roller rocker too retainer combo clearance issues cause problems easily solved with beehive springs and smaller retainer diameters

BEEHIVE SPRINGS GIVE A GOOD DEAL MORE ROCKER TO RETAINER CLEARANCE

SOURCES

Dart Machinery

Phone:

248-362-1188

Edelbrock

Phone:

310-781-2222

Patriot Performance

Phone:

888-462-8276

RHS

Phone:

877-776-4323

Summit Racing

Phone:

330-630-0240

Trick Flow Specialties

Phone:

330-630-1555

World Products

Phone:

631-981-1918

http://www.jegs.com/p/World-Product...-III-Cast-Iron-Cylinder-Heads/746696/10002/-1

http://www.jegs.com/p/Dart/Dart-Big-Block-Chevy-Pro-1-Aluminum-Cylinder-Heads/744672/10002/-1

https://www.profilerperformance.com/174-bbc-24-degree-heads.html

http://www.jegs.com/p/ProMaxx-Perfo...hevy-Aluminum-Cylinder-Heads/2789044/10002/-1

https://www.summitracing.com/parts/pmx-2211

https://www.summitracing.com/parts/tfs-41410001-m22

https://www.summitracing.com/parts/tfs-4141t003-m22

https://www.summitracing.com/parts/edl-61559

https://www.summitracing.com/parts/rhs-11011

https://www.summitracing.com/parts/pfh-174-32-02

https://www.summitracing.com/parts/edl-60555 View Full Gallery

View Full Gallery

View Full Gallery

View Full Gallery

notice picture is in error a SBC

notice picture is in error a SBC