http://www.powerperformancenews.com/tech-articles/presto-change-o-bbc-oval-port-magic/#prettyPhoto

Words And Photos: Richard Holdener

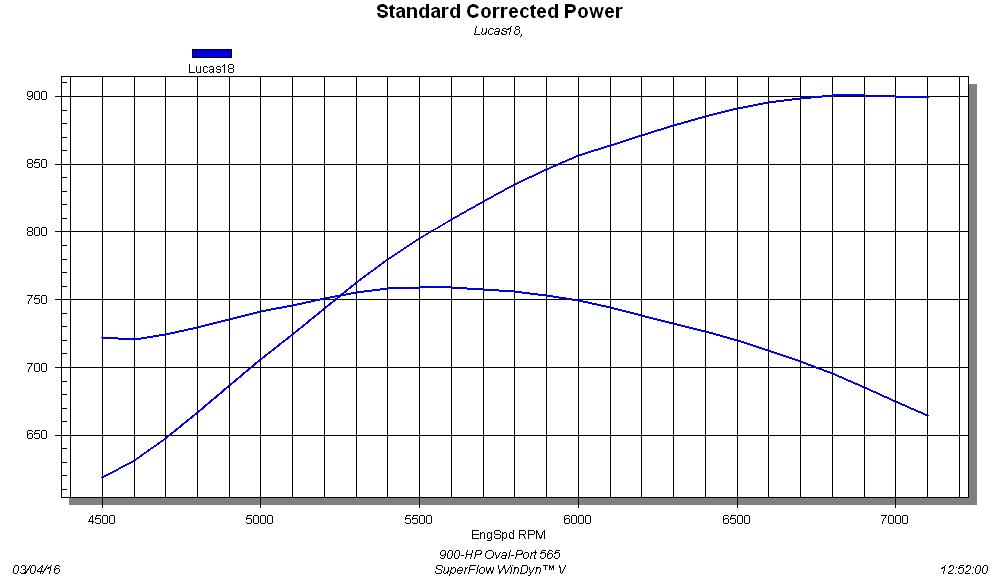

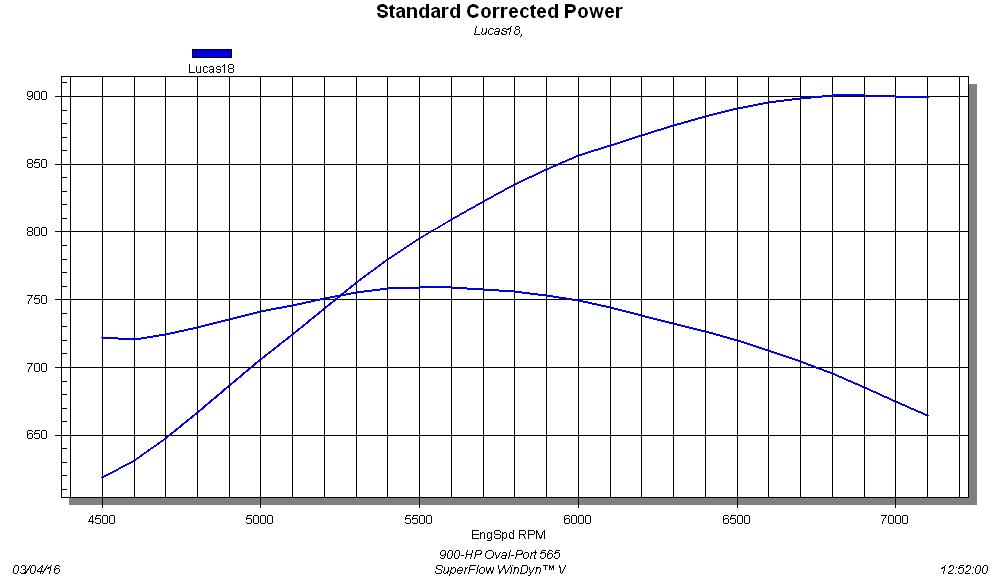

If you are a Chevy guy and heading out to the performance super market for parts to build your 900-hp big-block, what stuff might we find in your cart? Oh sure, there will be the usual suspects, like high-compression pistons, roller cam, and a single-plane intake. But, what if we told you they were having a sale on oval-port cylinder heads?

Most big blockers would walk right by said sale items and head over to the isle with rectangular port heads, right? Conventional wisdom suggests big power requires big cylinder heads, but don’t count out a set of AFR oval port heads, especially after they have been given the once over by Merlin the (flow) magician at Mamo Motorsports. If this 565 BBC is any indication, there are a great many big blocks sporting the wrong shape intake ports.

The Mamo Motorsports heads started out life as (already impressive) AFR oval-port castings.

After a wave of the magic porting wand, the AFR heads receive the Mamo Motorsports logo. These heads also received a PAC spring package designed for use with the solid roller cam profile.

Truth be told, even the magician himself, Tony Mamo from Mamo Motorsports, was hesitant about using oval-port heads on a build-up looking for 900 hp. At the insistence of Dan Ledbetter, Merlin stepped up to the challenge to create a 900-hp big-block using oval-port heads, and like any good magician, he had a trick (or two) up his sleeve.

It would take impressive oval-port heads to support the desired power level, so the easiest way to make great heads is to start with good ones, meaning something from Air Flow Research. Starting the project with the 300cc Magnum oval port heads, Mamo Motorsports was able apply some magic to coax even more flow and power from the impressive castings. According to the magician, head flow topped the 400cfm mark after all the wand waving. Of course, the heads were only part of the program, and the rest of the motor needed to be up to the task as well.

The Mamo heads featured a 2.30/1.88-inch valve package and detailed 111cc combustion chambers.

The oval-port heads may not have the port volume of a conventional rec-port heads, but boy howdy did they flow!

Once the head flow was taken care of, the rest of the big-block required attention. Starting with a Dart Big M block, the first three weapons in the arsenal of power were cubes, cam, and compression. It is always easier to reach a given power goal with a bigger motor, so Dan and Tony stepped the build-up to a full 565c.i. Next on the performance to-do list was cam timing. The big-block received a solid roller profile that offered a .779/.750 lift split, a 280/282-degree duration split, and 112-degree lsa. Rounding out the three Cs was a static compression ratio of 14.0:1, thanks to domed Ross (4.60-inch bore) pistons (with Total Seal Rings) and small (111cc) combustion chambers.

The power level and rpm dictated forged internals, so the 565 also received a Callies 4.25-inch Magnum series stroker crank and Ultra rods. Also included in the short block were a Moroso oil pan and windage tray, Mellings oil pump and vacuum pump from Jones Racing Products. Rounding out the build were an ATI damper and Edelbrock mechanical water pump.

Words And Photos: Richard Holdener

If you are a Chevy guy and heading out to the performance super market for parts to build your 900-hp big-block, what stuff might we find in your cart? Oh sure, there will be the usual suspects, like high-compression pistons, roller cam, and a single-plane intake. But, what if we told you they were having a sale on oval-port cylinder heads?

Most big blockers would walk right by said sale items and head over to the isle with rectangular port heads, right? Conventional wisdom suggests big power requires big cylinder heads, but don’t count out a set of AFR oval port heads, especially after they have been given the once over by Merlin the (flow) magician at Mamo Motorsports. If this 565 BBC is any indication, there are a great many big blocks sporting the wrong shape intake ports.

The Mamo Motorsports heads started out life as (already impressive) AFR oval-port castings.

After a wave of the magic porting wand, the AFR heads receive the Mamo Motorsports logo. These heads also received a PAC spring package designed for use with the solid roller cam profile.

Truth be told, even the magician himself, Tony Mamo from Mamo Motorsports, was hesitant about using oval-port heads on a build-up looking for 900 hp. At the insistence of Dan Ledbetter, Merlin stepped up to the challenge to create a 900-hp big-block using oval-port heads, and like any good magician, he had a trick (or two) up his sleeve.

It would take impressive oval-port heads to support the desired power level, so the easiest way to make great heads is to start with good ones, meaning something from Air Flow Research. Starting the project with the 300cc Magnum oval port heads, Mamo Motorsports was able apply some magic to coax even more flow and power from the impressive castings. According to the magician, head flow topped the 400cfm mark after all the wand waving. Of course, the heads were only part of the program, and the rest of the motor needed to be up to the task as well.

The Mamo heads featured a 2.30/1.88-inch valve package and detailed 111cc combustion chambers.

The oval-port heads may not have the port volume of a conventional rec-port heads, but boy howdy did they flow!

Once the head flow was taken care of, the rest of the big-block required attention. Starting with a Dart Big M block, the first three weapons in the arsenal of power were cubes, cam, and compression. It is always easier to reach a given power goal with a bigger motor, so Dan and Tony stepped the build-up to a full 565c.i. Next on the performance to-do list was cam timing. The big-block received a solid roller profile that offered a .779/.750 lift split, a 280/282-degree duration split, and 112-degree lsa. Rounding out the three Cs was a static compression ratio of 14.0:1, thanks to domed Ross (4.60-inch bore) pistons (with Total Seal Rings) and small (111cc) combustion chambers.

The power level and rpm dictated forged internals, so the 565 also received a Callies 4.25-inch Magnum series stroker crank and Ultra rods. Also included in the short block were a Moroso oil pan and windage tray, Mellings oil pump and vacuum pump from Jones Racing Products. Rounding out the build were an ATI damper and Edelbrock mechanical water pump.