http://www.powerblocktv.com/episode/HP2 ... MZz5y7O2PI part #1

http://www.powerblocktv.com/episode/HP2 ... MZ0fy7O2PI part #2

theres enough useful info and a few simple tips on engine assembly,

here in the linked video, to warrant the time spent to watch it to the end,

yeah the ADDS are a real P.I.T.A. but the info is worth putting up with the annoying adds

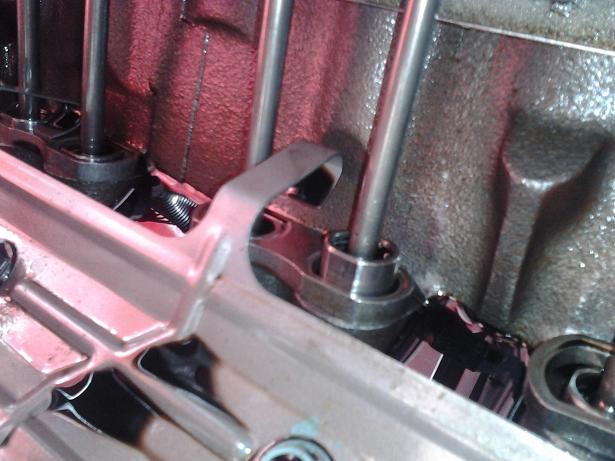

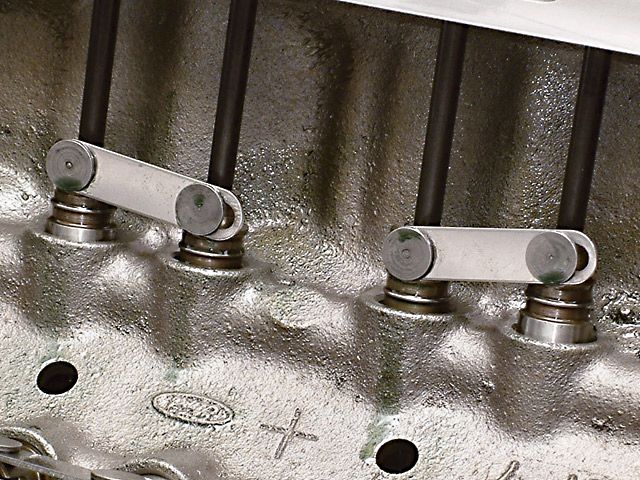

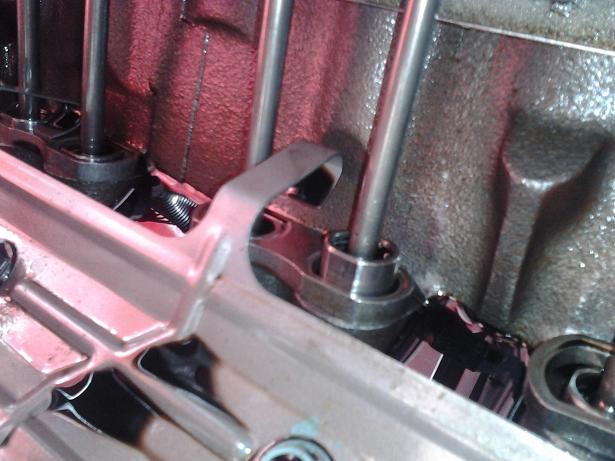

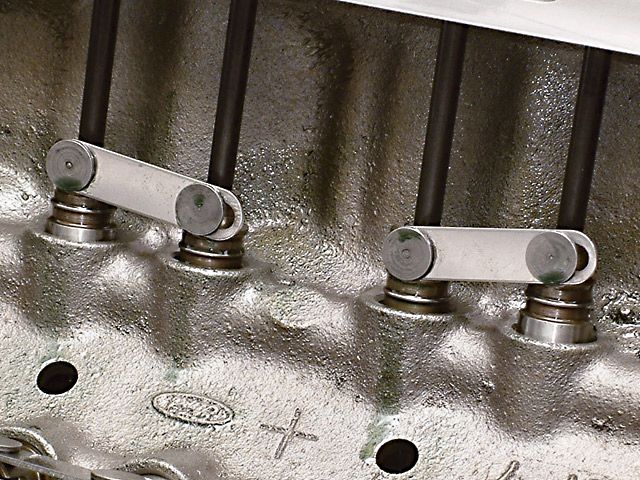

btw the dog bone links on the roller lifters are best avoided theres far more durable ways to maintain roller alignment

you may or may not have SCAT provide an internally balanced, 383 sbc ,

I would certainly suggest , 6" connecting rods with 7/16" ARP rod bolts,

but thats not mandatory

but Id suggest you buy the flywheel and damper separately as you have more control on the QUALITY of the components,

a billet flywheel is a huge step up in strength over a cast OEM flywheel.

http://garage.grumpysperformance.com/index.php?threads/selecting-a-flywheel.1042/#post-1969

http://garage.grumpysperformance.co...e-a-clutch-in-a-c3-corvette.15034/#post-85152

and of course, by now you might realize I post related info for the hundreds of members,

that may read through the thread in months or years yet to come

read through all links and sub-links

be aware that a 168 tooth flywheel will not fit in every bell housing design,

but it allows a much better choice in clutches and in many cases better quality clutches.

always ask questions before spending cash

http://garage.grumpysperformance.com/index.php?threads/harmonic-balancer.3554/#post-53706

http://garage.grumpysperformance.com/index.php?threads/168-or-153-flywheels.3951/#post-67681

http://garage.grumpysperformance.co...pes-of-crankshaft-steel.204/page-2#post-46231

http://garage.grumpysperformance.co...ing-rod-strength-h-vs-i-beam.1168/#post-40253

http://garage.grumpysperformance.co...nk-durring-short-blk-assembly.852/#post-39417

http://garage.grumpysperformance.com/index.php?threads/what-damper-flywheel.6026/#post-21582

http://garage.grumpysperformance.com/index.php?threads/selecting-a-flywheel.1042/#post-1969

http://garage.grumpysperformance.com/index.php?threads/don-t-beat-that-damper.83/#post-14101

http://garage.grumpysperformance.com/index.php?threads/damper-honing.4975/#post-13912

http://garage.grumpysperformance.com/index.php?threads/damper-tool.223/#post-8024

https://www.dieselarmy.com/engine-tech/engine/how-it-works-viscous-dampers-a-k-a-harmonic-balancers/

https://www.dragzine.com/tech-stori...ers-are-crucial-to-the-health-of-your-engine/

http://www.laskeyracing.com/shop/harmonics.htm

https://fluidampr.com/how-a-fluidampr-works/

http://garage.grumpysperformance.co...r-seal-crank-in-1-piece-block.301/#post-31934

http://www.dieseltechmag.com/2009/02/dt-tested-fluidampr-performance-damper

https://motoiq.com/project-golf-r-mkvii-fluidampr-test/3/

http://garage.grumpysperformance.com/index.php?threads/cheap-damper-ballancer-source.279/#post-1673

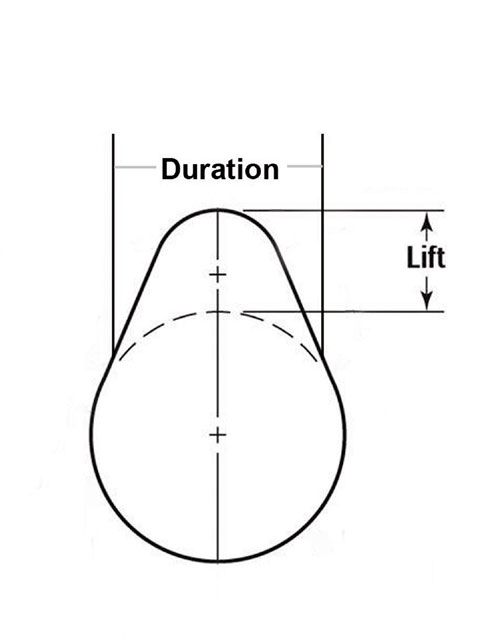

the stock Chevy hydraulic roller lifters , dog bone and spider springs don,t always work reliably, ALL THE TIME with engines having over .500 lift or when spun over 6000rpm, its not all that rare for the lifter ,retainer to bend the retainer spring allowing the lifter to spin sideways, in the lifter bore, resulting in a destroyed cam, thats why Ive suggested BRAND NAME ,AFTERMARKET RETRO FIT CAM COMPONENTS BE USED

ID also point out that SCAT CRANKS AND RODS are in my opinion a better, made, and a more durable product, made to more consistent tolerances that either stock OEM or several other popular aftermarket suppliers of cranks and rods Ive measured

http://scatcrankshafts.com/

Its been my experience that properly matched linked bar roller lifters are FAR MORE TROUBLE FREE AND DURABLE

especially if your lift exceeds .550 or your spinning the engine over 6000rpm occasionally

viewtopic.php?f=52&t=5522&p=16620&hilit=roller+lifter#p16620

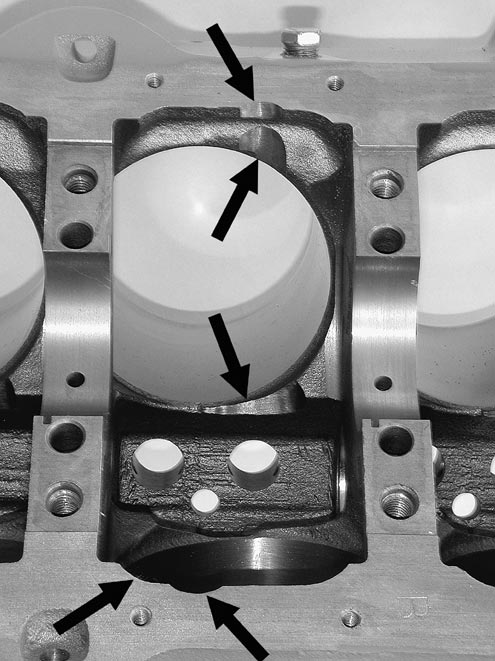

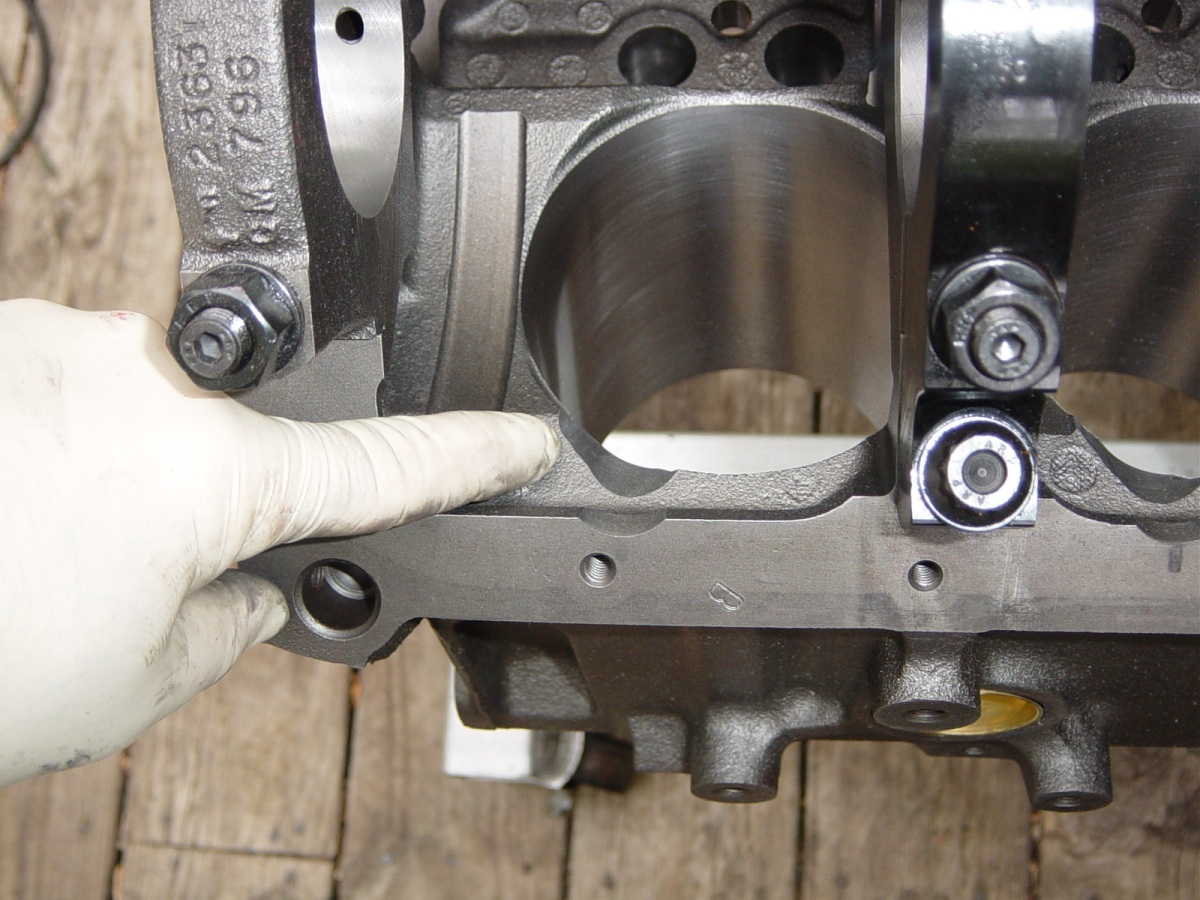

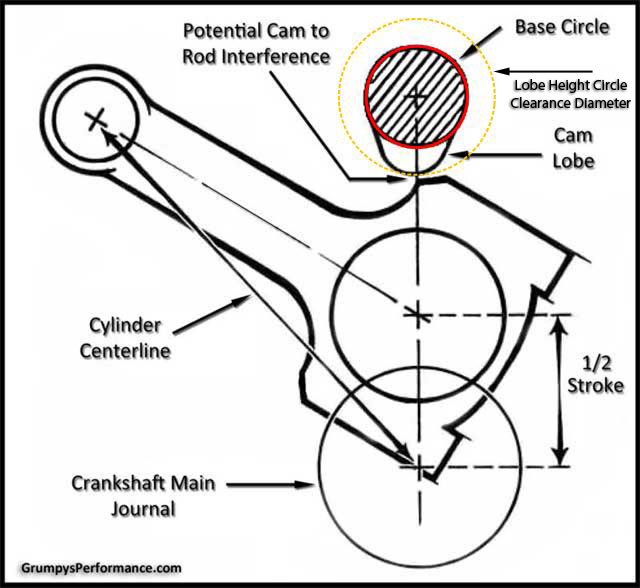

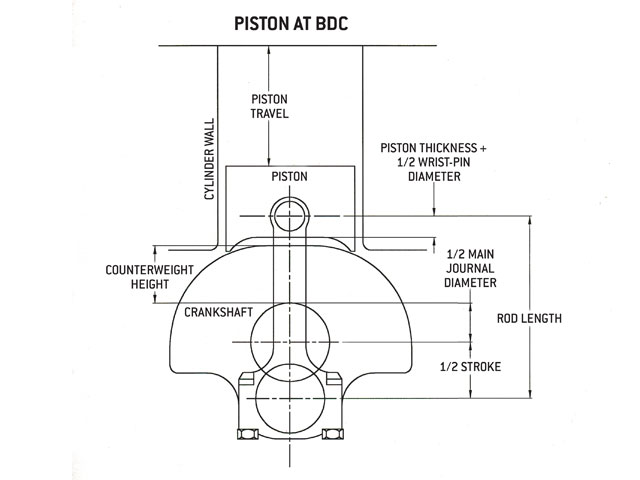

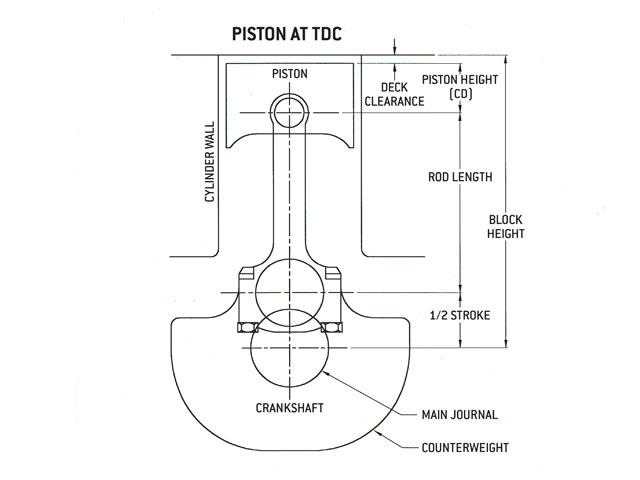

yes you'll ALWAYS NEED to verify clearances carefully when assembling any engine and no, you can,t assume everything will fit just because its part of a component list thats suppose to fit correctly, simply because manufacturing is an imprecise process and mistake do get made occasionally!

RELATED INFO

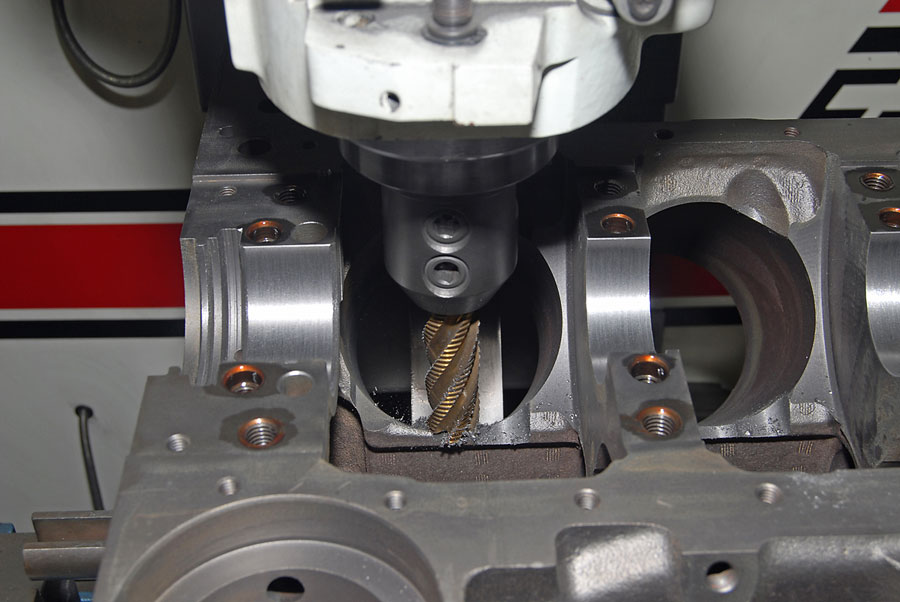

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/tips-on-building-a-383-sbc-stroker.428/

http://garage.grumpysperformance.com/index.php?threads/stroker-tips-by-len-emanuelson.1249/

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-52466

http://garage.grumpysperformance.com/index.php?threads/what-con-rods-would-you-buy.942/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

http://www.hotrod.com/how-to/engine/ccrp-0808-383-stroker-small-block-chevy/

viewtopic.php?f=44&t=38&p=26432&hilit=+known+engine+combo#p26432

viewtopic.php?f=52&t=181

viewtopic.php?f=53&t=8310&p=28891&hilit=+books+video#p28891

viewtopic.php?f=69&t=3814

read thru these threads and sub links, theres a great deal of useful info in those links and sub links, take the effort youll save yourself months of work and thousands of dollars if you understand ALL the info before you start buying parts

http://www.powerblocktv.com/episode/HP2 ... MZ0fy7O2PI part #2

theres enough useful info and a few simple tips on engine assembly,

here in the linked video, to warrant the time spent to watch it to the end,

yeah the ADDS are a real P.I.T.A. but the info is worth putting up with the annoying adds

btw the dog bone links on the roller lifters are best avoided theres far more durable ways to maintain roller alignment

you may or may not have SCAT provide an internally balanced, 383 sbc ,

I would certainly suggest , 6" connecting rods with 7/16" ARP rod bolts,

but thats not mandatory

but Id suggest you buy the flywheel and damper separately as you have more control on the QUALITY of the components,

a billet flywheel is a huge step up in strength over a cast OEM flywheel.

http://garage.grumpysperformance.com/index.php?threads/selecting-a-flywheel.1042/#post-1969

http://garage.grumpysperformance.co...e-a-clutch-in-a-c3-corvette.15034/#post-85152

and of course, by now you might realize I post related info for the hundreds of members,

that may read through the thread in months or years yet to come

read through all links and sub-links

be aware that a 168 tooth flywheel will not fit in every bell housing design,

but it allows a much better choice in clutches and in many cases better quality clutches.

always ask questions before spending cash

http://garage.grumpysperformance.com/index.php?threads/harmonic-balancer.3554/#post-53706

http://garage.grumpysperformance.com/index.php?threads/168-or-153-flywheels.3951/#post-67681

http://garage.grumpysperformance.co...pes-of-crankshaft-steel.204/page-2#post-46231

http://garage.grumpysperformance.co...ing-rod-strength-h-vs-i-beam.1168/#post-40253

http://garage.grumpysperformance.co...nk-durring-short-blk-assembly.852/#post-39417

http://garage.grumpysperformance.com/index.php?threads/what-damper-flywheel.6026/#post-21582

http://garage.grumpysperformance.com/index.php?threads/selecting-a-flywheel.1042/#post-1969

http://garage.grumpysperformance.com/index.php?threads/don-t-beat-that-damper.83/#post-14101

http://garage.grumpysperformance.com/index.php?threads/damper-honing.4975/#post-13912

http://garage.grumpysperformance.com/index.php?threads/damper-tool.223/#post-8024

https://www.dieselarmy.com/engine-tech/engine/how-it-works-viscous-dampers-a-k-a-harmonic-balancers/

https://www.dragzine.com/tech-stori...ers-are-crucial-to-the-health-of-your-engine/

http://www.laskeyracing.com/shop/harmonics.htm

https://fluidampr.com/how-a-fluidampr-works/

http://garage.grumpysperformance.co...r-seal-crank-in-1-piece-block.301/#post-31934

http://www.dieseltechmag.com/2009/02/dt-tested-fluidampr-performance-damper

383 Stealthram

My 383 motor for my 88 trans am is Scat Stroker with AFR 195 Eliminator 72 cc heads, flat pistons. The càm is Comp Cams Nitrous cam 227/236, .502/.520 lift, 113 lsa. I have Stealthram and TRI-y jet hot coated headers. I will get a Crane Gm small cap distributor and Crane Gold Race narrow body...

garage.grumpysperformance.com

https://motoiq.com/project-golf-r-mkvii-fluidampr-test/3/

383 Stealthram

My 383 motor for my 88 trans am is Scat Stroker with AFR 195 Eliminator 72 cc heads, flat pistons. The càm is Comp Cams Nitrous cam 227/236, .502/.520 lift, 113 lsa. I have Stealthram and TRI-y jet hot coated headers. I will get a Crane Gm small cap distributor and Crane Gold Race narrow body...

garage.grumpysperformance.com

http://garage.grumpysperformance.com/index.php?threads/cheap-damper-ballancer-source.279/#post-1673

the stock Chevy hydraulic roller lifters , dog bone and spider springs don,t always work reliably, ALL THE TIME with engines having over .500 lift or when spun over 6000rpm, its not all that rare for the lifter ,retainer to bend the retainer spring allowing the lifter to spin sideways, in the lifter bore, resulting in a destroyed cam, thats why Ive suggested BRAND NAME ,AFTERMARKET RETRO FIT CAM COMPONENTS BE USED

ID also point out that SCAT CRANKS AND RODS are in my opinion a better, made, and a more durable product, made to more consistent tolerances that either stock OEM or several other popular aftermarket suppliers of cranks and rods Ive measured

http://scatcrankshafts.com/

especially if your lift exceeds .550 or your spinning the engine over 6000rpm occasionally

viewtopic.php?f=52&t=5522&p=16620&hilit=roller+lifter#p16620

yes you'll ALWAYS NEED to verify clearances carefully when assembling any engine and no, you can,t assume everything will fit just because its part of a component list thats suppose to fit correctly, simply because manufacturing is an imprecise process and mistake do get made occasionally!

RELATED INFO

http://garage.grumpysperformance.com/index.php?threads/block-prep.125/

http://garage.grumpysperformance.co...k-after-a-cam-lobe-rod-or-bearings-fail.2919/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.com/index.php?threads/tips-on-building-a-383-sbc-stroker.428/

http://garage.grumpysperformance.com/index.php?threads/stroker-tips-by-len-emanuelson.1249/

http://garage.grumpysperformance.com/index.php?threads/parts-prep-cleaning.6255/

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-52466

http://garage.grumpysperformance.com/index.php?threads/what-con-rods-would-you-buy.942/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

http://www.hotrod.com/how-to/engine/ccrp-0808-383-stroker-small-block-chevy/

viewtopic.php?f=44&t=38&p=26432&hilit=+known+engine+combo#p26432

viewtopic.php?f=52&t=181

viewtopic.php?f=53&t=8310&p=28891&hilit=+books+video#p28891

viewtopic.php?f=69&t=3814

read thru these threads and sub links, theres a great deal of useful info in those links and sub links, take the effort youll save yourself months of work and thousands of dollars if you understand ALL the info before you start buying parts

Last edited by a moderator: