I read through this build ,I was hoping to find new useful info.

and its all too obvious that the main goal was to list parts suppliers and name parts sources,I saw several areas, in engine build could be improved

but still theres bits of useful info included, so reading through is not a total waste of time, as an interesting build.

https://www.summitracing.com/parts/tfs-3241t001-c03/media/chartsandguides

looking at the listed parts ,Id think, to duplicate this build,

I think you could reasonably expect to be in the $20K-$22K expense range,

which in my opinion makes this ludicrous, as for similar cash ,

you could build a more impressive supercharged BBC.

when your spending that kind of cash , to build an engine too exceed 1000 HP,

I think starting with a 540-556 BBC makes more sense

https://www.shafiroff.com/Big-Block-Chevy.php

1,000 HP From a Broken-In 400-Inch Small-Block Chevy

F-1 Technology

Richard Holdener Aug 15, 2019

View Full Gallery

View Full Gallery

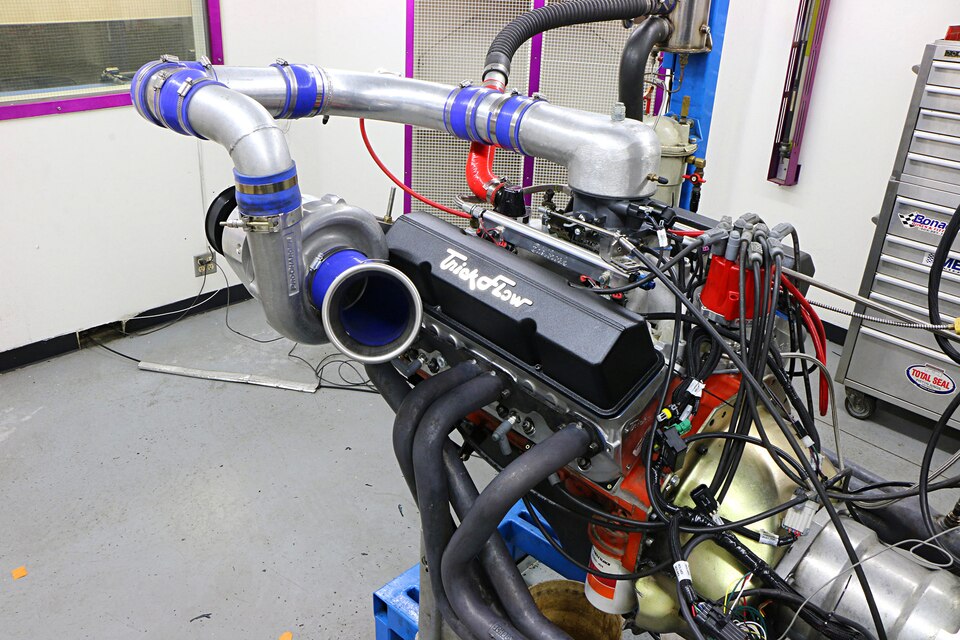

From the looks of the title you might think this is a story on some high-tech, modern energy regeneration system used by those fragile—but blindingly fast—F1 cars. Nothing could be further from the truth. The F-1 reference in the title does indeed deal with energy enhancement, but it's taken from the designation of a very capable ProCharger centrifugal supercharger. Rather than some high-strung, temperamental race engine, we applied the modern boost technology to an archaic, pushrod small-block Chevy.

In the Mouse motor's defense, it was fuel-injected, so there was at least a hint of sophistication and technology. But with open headers; a big, nasty cam; and a huffer at full song it was still definitely more anvil than advanced technology. Sometimes an anvil is the perfect tool for getting the job done. As a motivational source for coaxing our heavy Chevy station wagon down the quarter-mile, the small-block anvil was exactly what we needed.

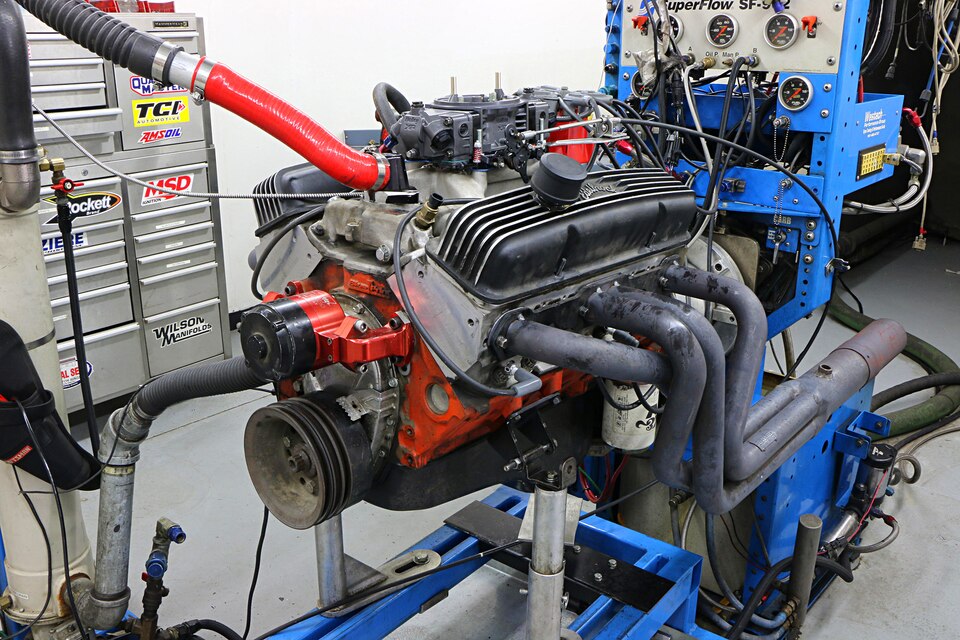

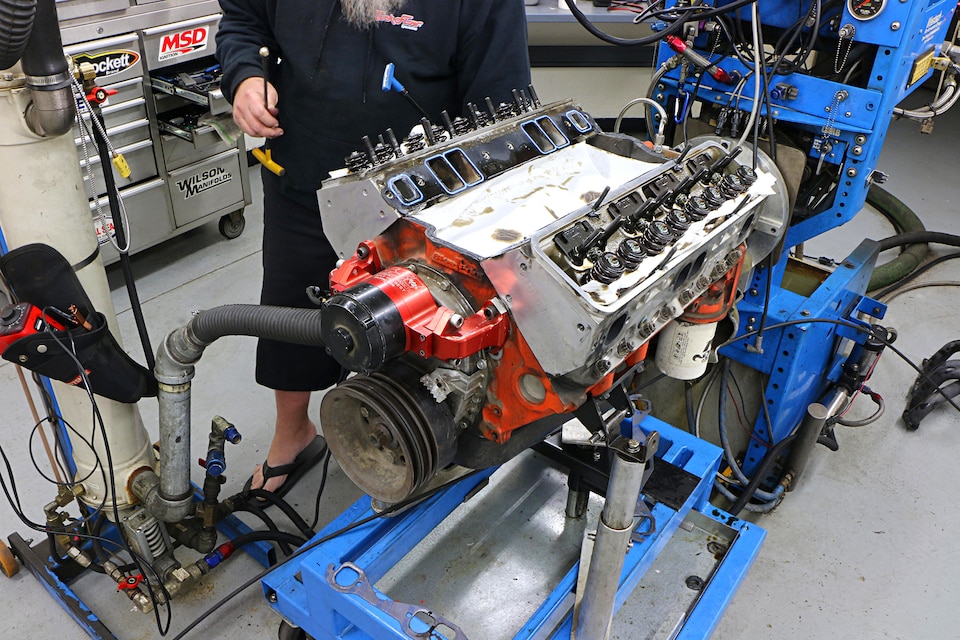

In truth, the test engine started out life heading in the right direction. The BluePrint Engines (BPE) small-block was designed specifically for use with power-adders and already included a displacement bump, forged internals, and low compression. The last of the three is often thought of as a detriment, but the low compression allowed us to safely crank up the boost to reach four-digit power levels. The engine sports 400 cubic inches thanks to a combination of a 4.125-inch bore and 3.750-inch stroke. Supplied as a long-block, the BPE four-bolt block was stuffed with forged internals that included the stroker crank, 6.000-inch H-beam rods, and dished pistons. The combo also included a set of as-cast aluminum heads (PN HP8103) with 220cc intake ports, 64cc chambers, and a 2.08/1.60 valve package. The healthy hydraulic roller cam checked in with a 0.555/0.577-inch lift split (with 1.6:1 roller rockers), 236/248-degree duration split, and 113-degree LSA. The long-block was finished up with valve and timing covers, and a complete oiling system.

Unlike many of our previous buildups, this crate engine was not fresh from the manufacturer. In fact, this small-block 400 had seen over 30,000 street and strip miles, including copious amounts of nitrous. The BPE engine was equipped with an Edelbrock RPM Air-Gap intake and Holley Terminator EFI throttle-body system. The EFI system was combined with multiple stages of NOS nitrous, feeding as much as 225 hp with both stages engaged. This helped push the 4,500-pound wagon deep into the 11s, but like most enthusiasts, the owner wanted more.

Rather than subject the BPE crate engine to a third nitrous stage, we decided to change direction and replace the nitrous with a single power-adder capable of doubling their 225hp gain, enter the ProCharger F-1A centrifugal supercharger.

Looking at the specs of the F-1A, we see the blower listed as being capable of supporting up to 1,100 hp. We know from experience that ProCharger's listed max power levels are conservative given the right engine combinations, so the F-1A was nearly perfect for our goal of reaching 1,000 hp with the small-block. While just cranking up the boost can certainly get you to your power goal, the preferred method is to get there at the lowest possible boost level. This way, the power added is done so with the smallest increase in the charge air temperature. Though we would be running the small-block with both an intercooler and on E85, we set out to maximize the power output of the engine in its naturally aspirated state before introducing boost.

While the BPE 400 was no slouch, we decided to replace the top end, including the as-cast heads, cam, and dual-plane intake manifold. Any gains made to the naturally aspirated combination would be multiplied under boost. For example, if we improved the power output of the naturally aspirated engine by 50 hp, we could see an extra 100 hp (or more) under boost. The gains really start to add up once you run elevated boost levels. This multiplication factor also allows you to reach any given power level at a lower boost level.

Before improving the power output of the BPE 400, we needed to see where we stood. The engine came out of the wagon and onto the dyno. Because we would be replacing the Terminator EFI throttle body with a multi-port EFI system, we elected to run the engine with a carburetor for the baseline. Equipped with a dual-plane intake, Holley carb, and MSD distributor, the low-compression BPE 400 produced 457 hp at 5,900 rpm and 473 lb-ft of torque at 4,300 rpm.

We then installed a set of Trick Flow Specialties Super 23 230cc heads that featured full CNC porting, a 2.08/1.60 valve package, and 70cc combustion chambers. The larger chambers reduced the static compression by 0.70 of a point, but the extra airflow and improved chamber design more than offset the drop in compression. The Super 23 heads were teamed with a Comp XR300HR cam that offered a 0.562/0.580-inch lift split, 248/254-degree duration split, and 110-degree LSA. Our original plan was to run a custom blower grind from the Billy the cam wizard over at Comp Cams, but an error on the author's part meant we received a retrofit cam and not one designed for the hydraulic roller block (sorry, Billy. ). The heads and cam were combined with an Edelbrock Victor Jr. EFI intake, and a carburetor. So equipped, the new combination produced 524 hp at 6,400 rpm and 486 lb-ft at 4,800 rpm. These peak numbers shifted slightly to 529 hp and 478 lb-ft once we replaced the carb with a Holley (4150) throttle body and 120-pound injectors.

With our low-compression, power-adder friendly 400-inch small-block easily exceeding 525 hp, it was time for some boost. And that's where things start to get very interesting.

2/22

2/22

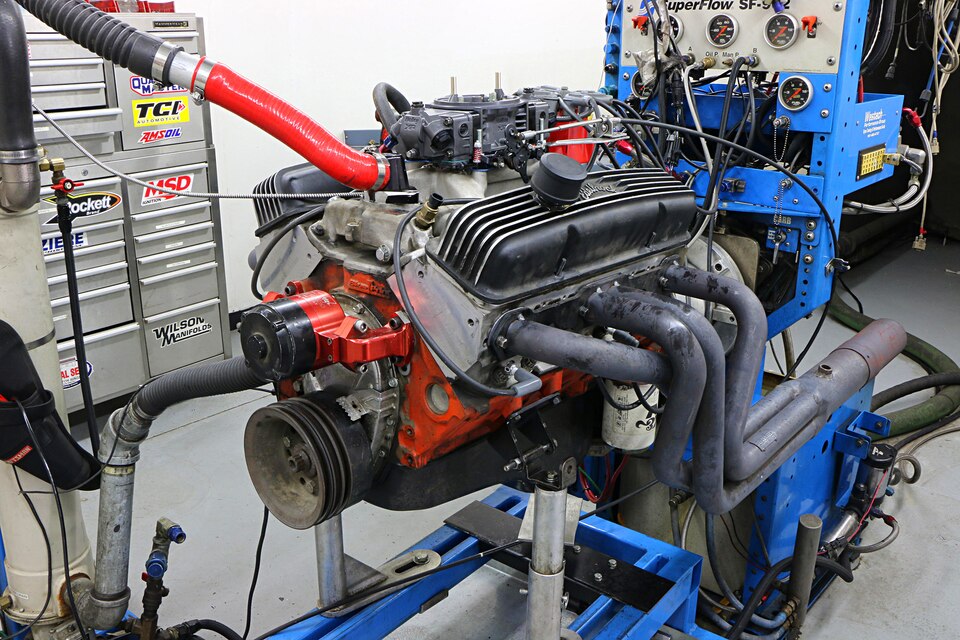

Supplied by BluePrint Engines (BPE), the crate long-block was designed for power-adder use and included forged internals, 9.0:1 compression, and as-cast aluminum heads. This particular engine has seen some 30K miles and endless hits of nitrous. The long-block had previously been equipped with an Edelbrock Performer RPM Air-Gap intake and Holley Terminator EFI. For our baseline dyno test we topped the intake with a Holley 750 XP carburetor. It pumped out 457 hp at 5,900 rpm and 473 lb-ft of torque at 4,300 rpm.

3/22

3/22

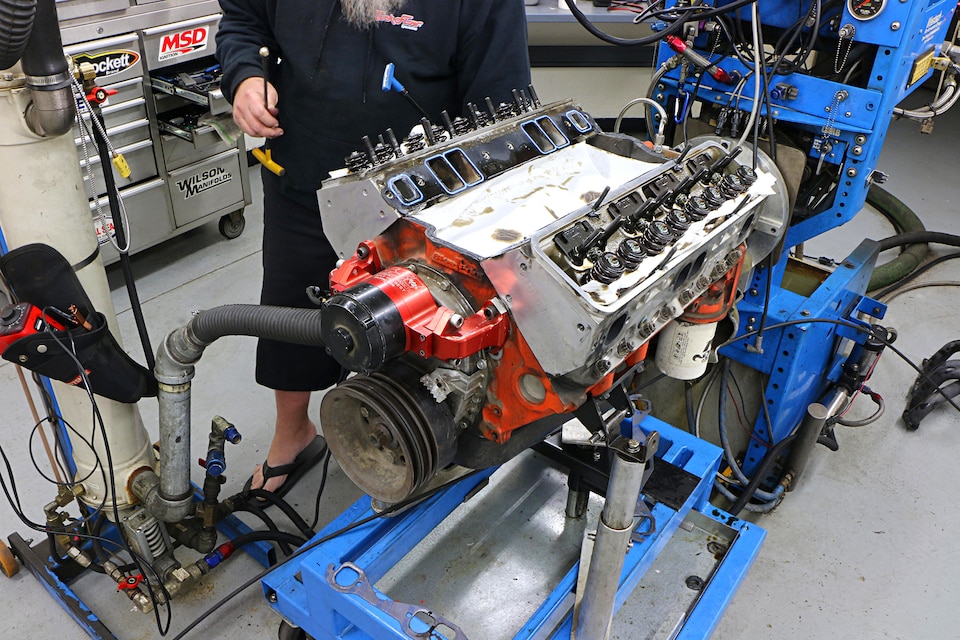

After the baseline, the engine was torn down in anticipation of the top-end upgrade.

4/22

4/22

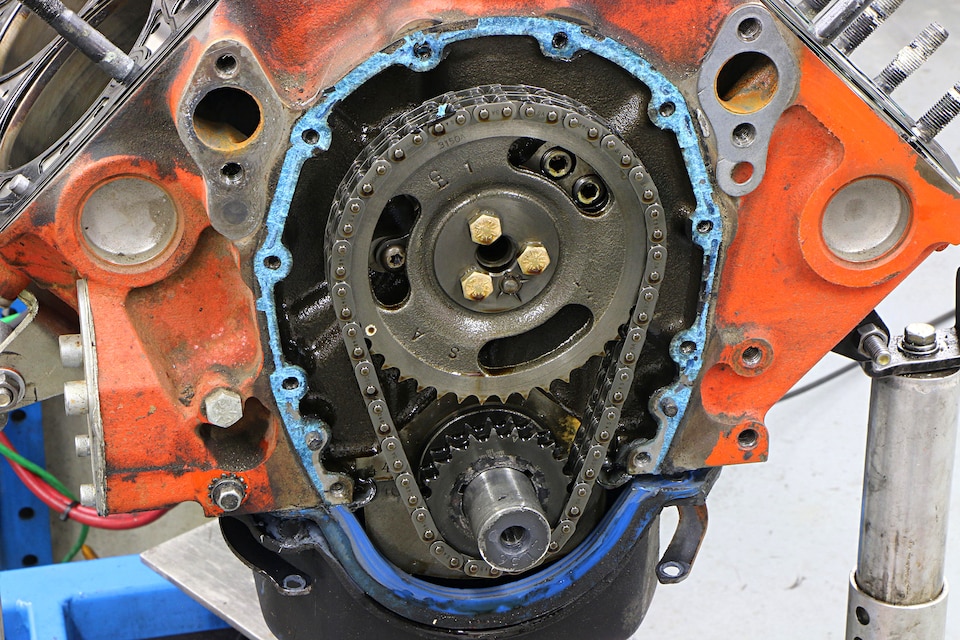

Off came the intake and cylinder heads, followed by the camshaft supplied with the crate engine.

5/22

5/22

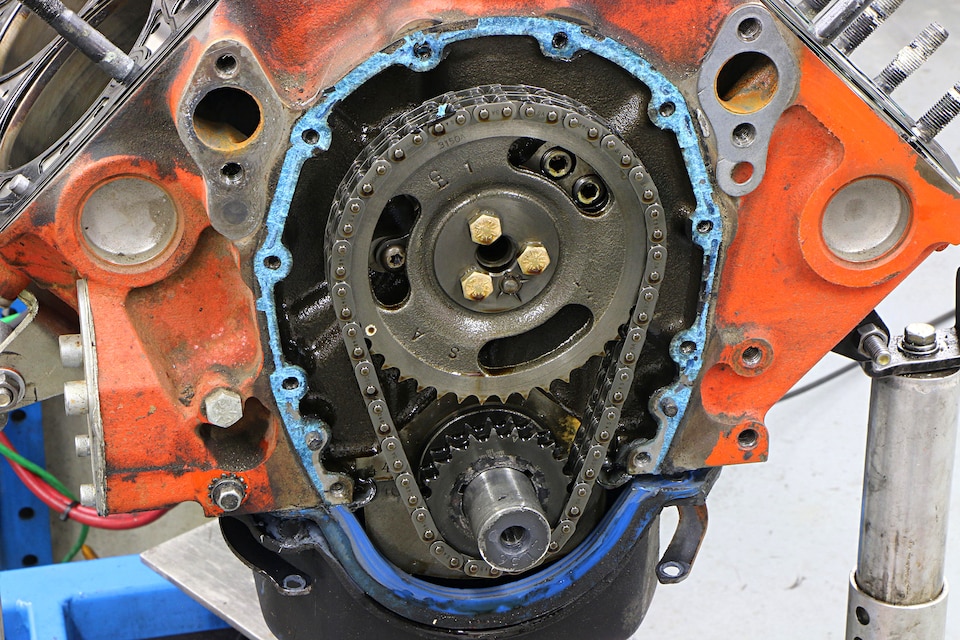

The mild cam was replaced with a much more aggressive off-the-shelf cam from Comp. The Xtreme Energy XR300HR cam offered a 0.562/0.580-inch lift split, 248/254-degree duration split, and 110-degree LSA. The cam was combined with a set of Trick Flow Specialties Super 23 230 heads. ARP head studs will keep everything secure.

6/22

6/22

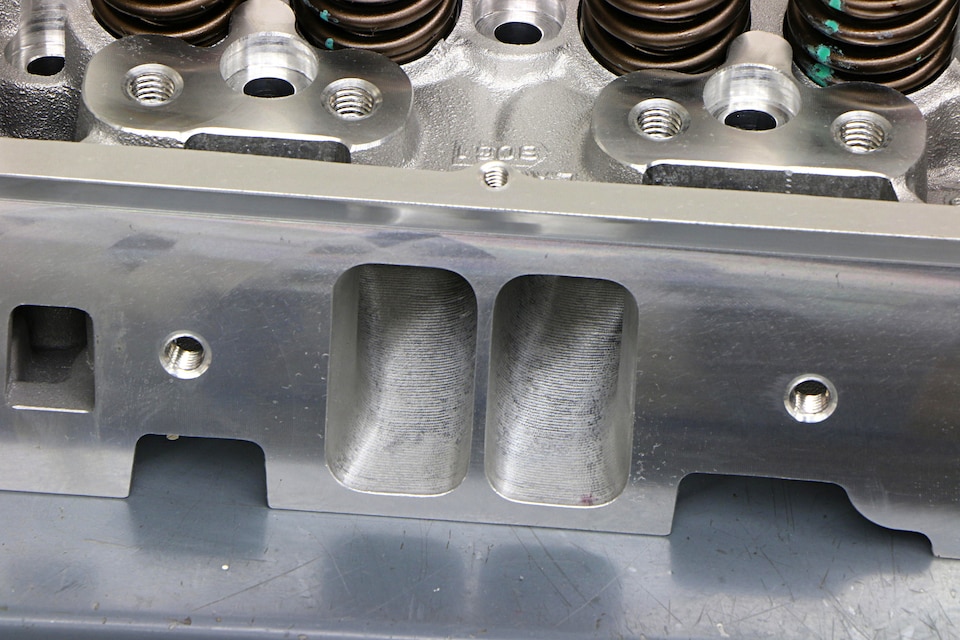

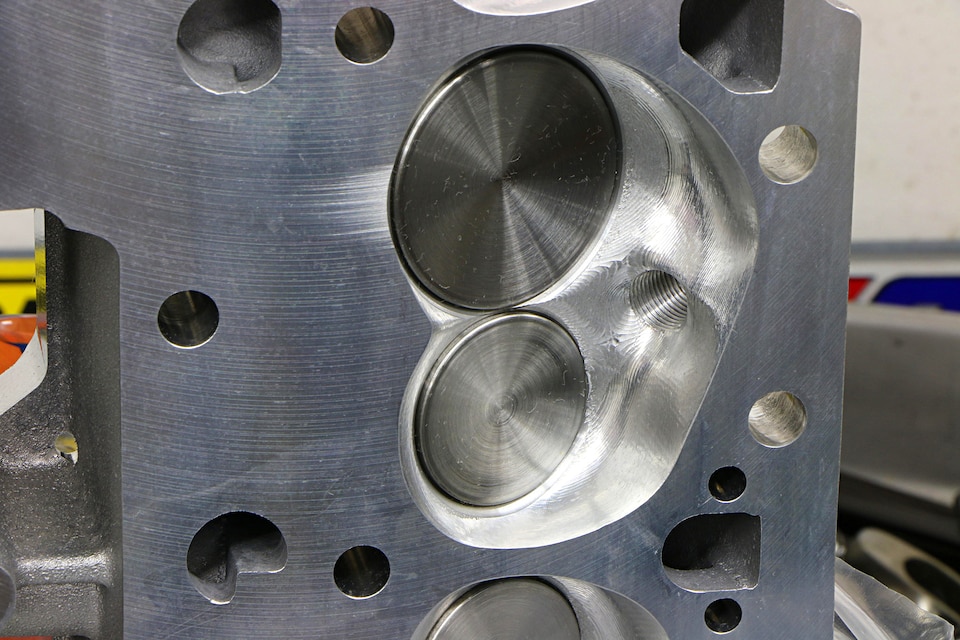

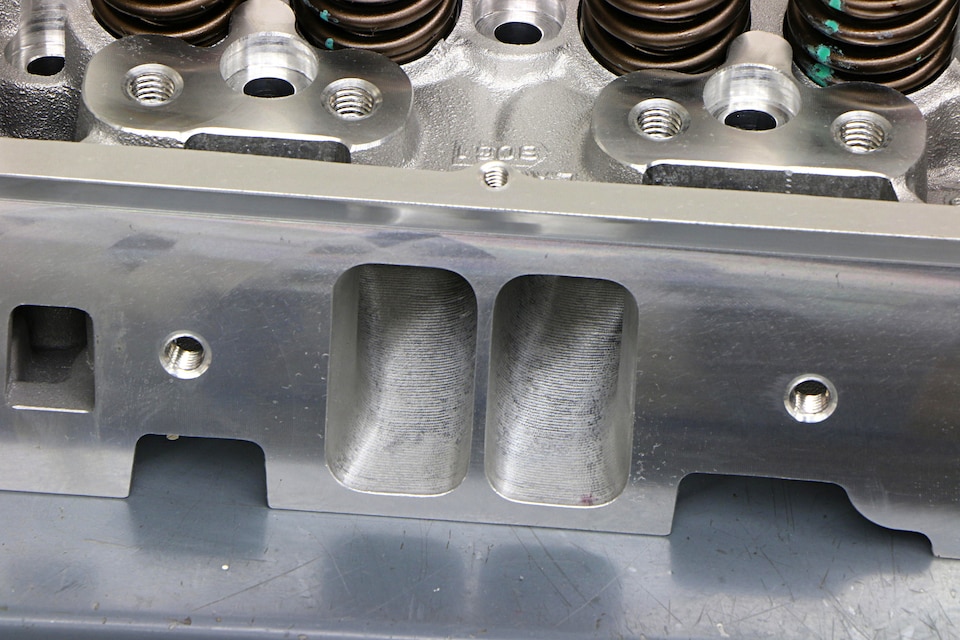

Thanks to CNC porting, the 230cc intake ports on the Super 23 heads flowed 310 cfm, enough to support well over 600 NA hp. The Super 23 230 heads featured a dual-spring package (with titanium retainers) that allowed up to 0.680-inch lift.

7/22

7/22

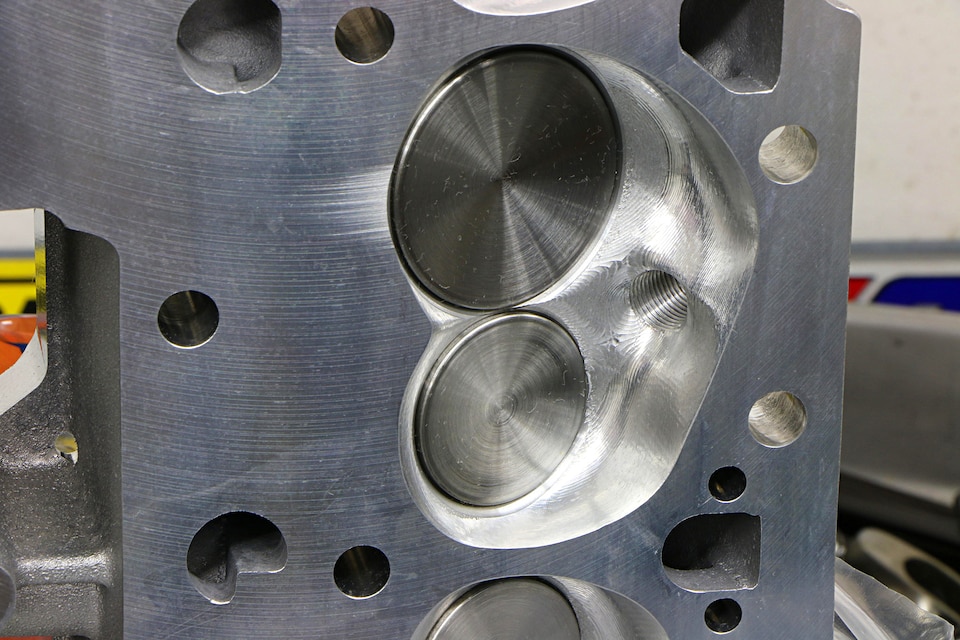

To maximize flow, the Super 23 heads featured a stainless 2.08/1.60 valve package and fully CNC-ported combustion chambers. The increase in chamber size from the BPE 64cc heads to the TFS Super 23 70cc heads lowered the static compression by roughly 0.70 of a point.

8/22

8/22

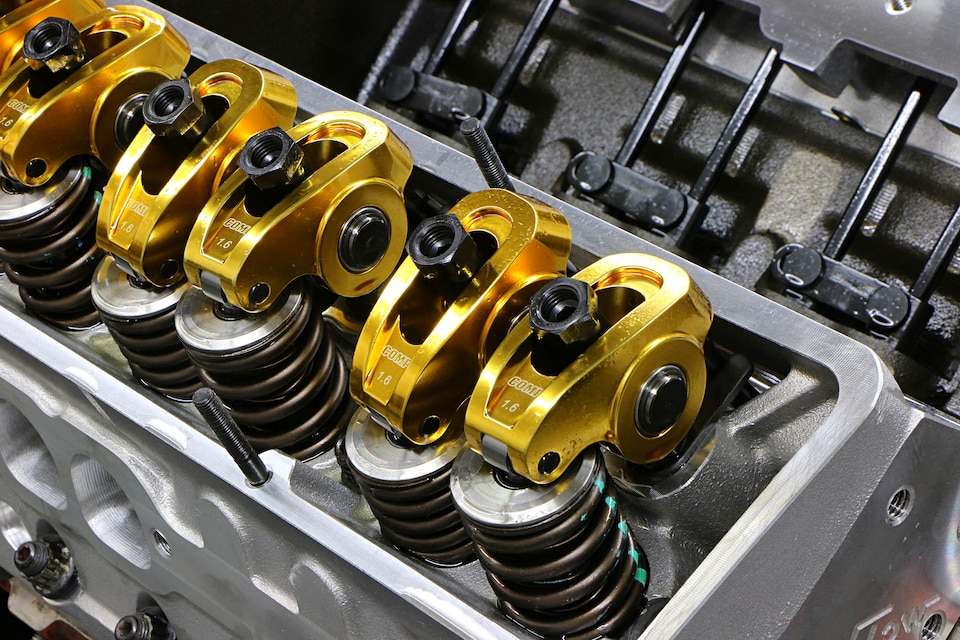

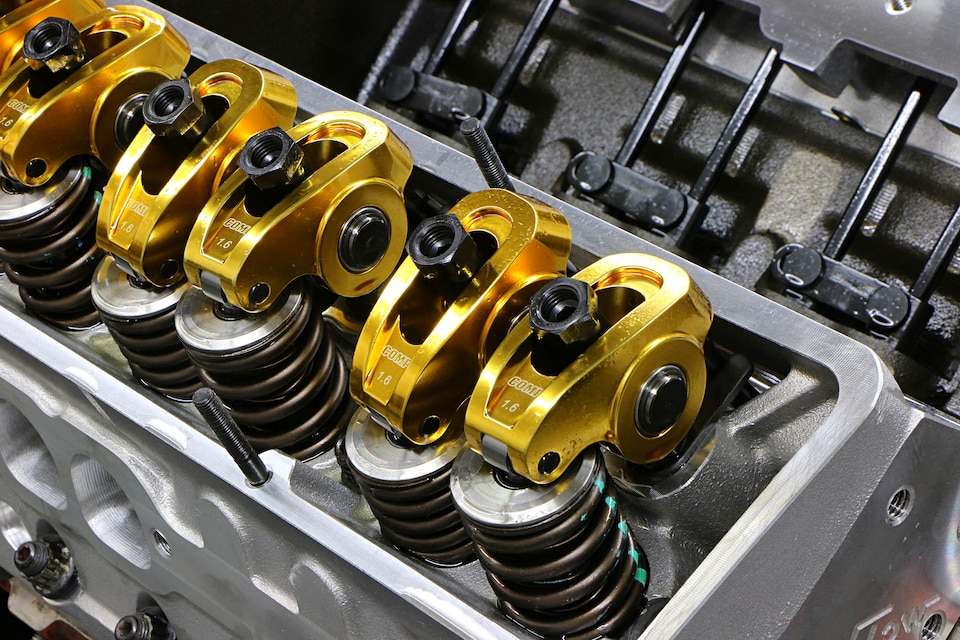

The Comp cam was combined with a set of hardened pushrods and Ultra Gold 1.6:1-ratio roller rockers.

9/22

9/22

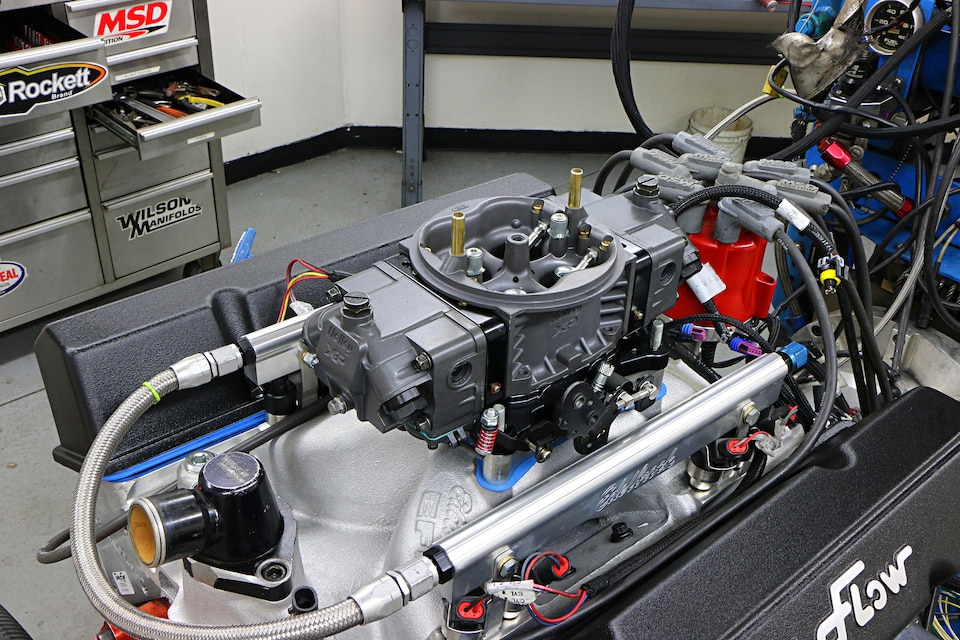

The dual-plane, carbureted intake was replaced by this single-plane, EFI intake from Edelbrock.

10/22

10/22

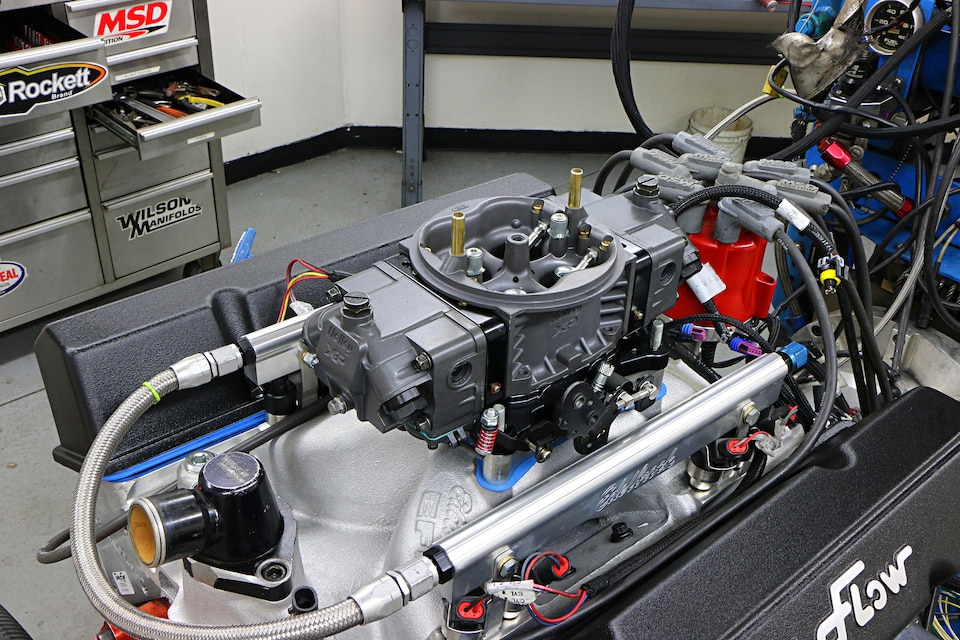

We initially topped the single-plane, EFI intake with a carburetor. Ensuring plenty of spark was an MSD billet distributor and 6AL ignition amplifier.

11/22

11/22

Run on the dyno in carbureted trim, the modified 400-inch small-block produced 524 hp at 6,400 rpm and 486 lb-ft of torque at 4,800 rpm.

12/22

12/22

After running the carburetor, we replaced the Holley XP with a 4150 throttle body. The airflow supplied by the high-flow throttle body was combined with fuel from a set of 120-pound Holley injectors. Everything was controlled with a Holley HP ECU.

13/22

13/22

The EFI system allowed us to optimize the air/fuel curve (something not possible with the carbureted combination). Equipped with the EFI system, the injected small-block produced 529 hp and 478 lb-ft of torque.

14/22

14/22

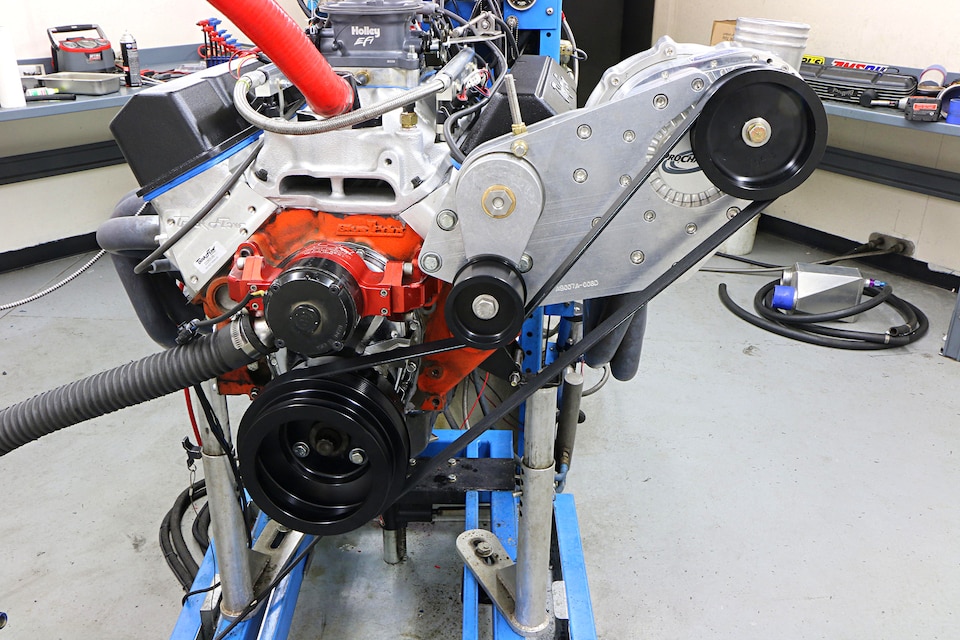

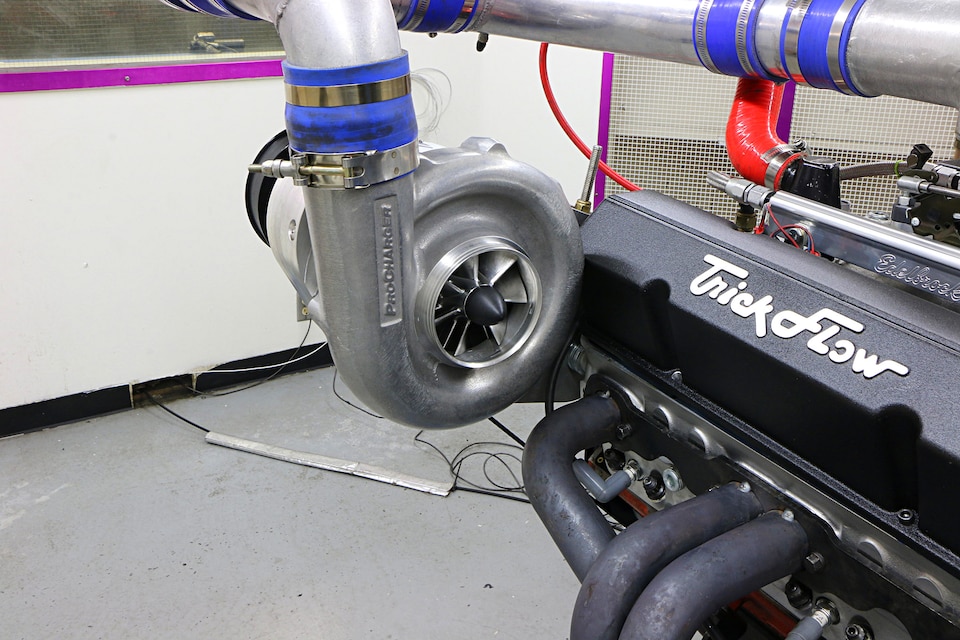

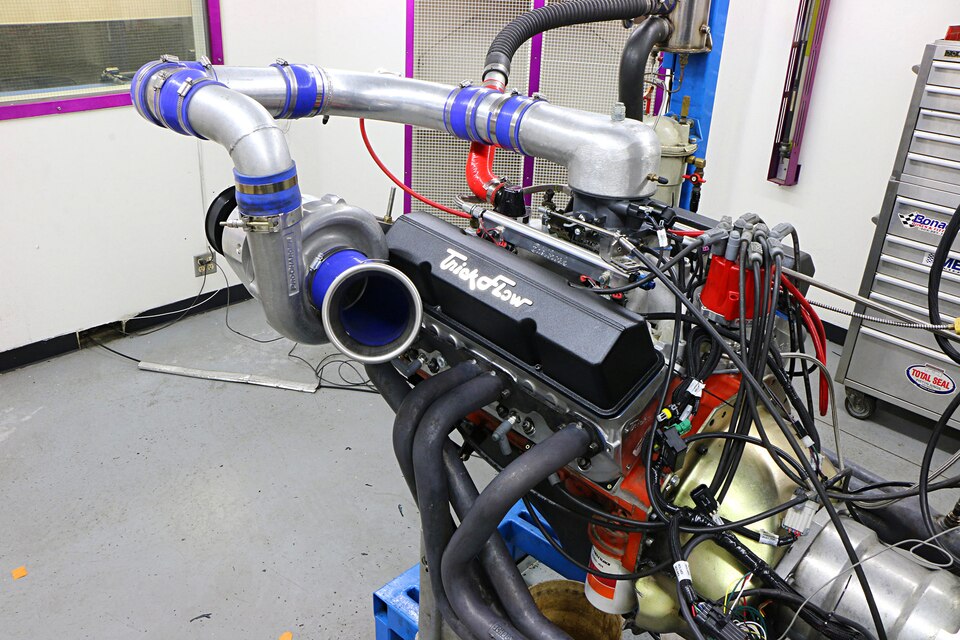

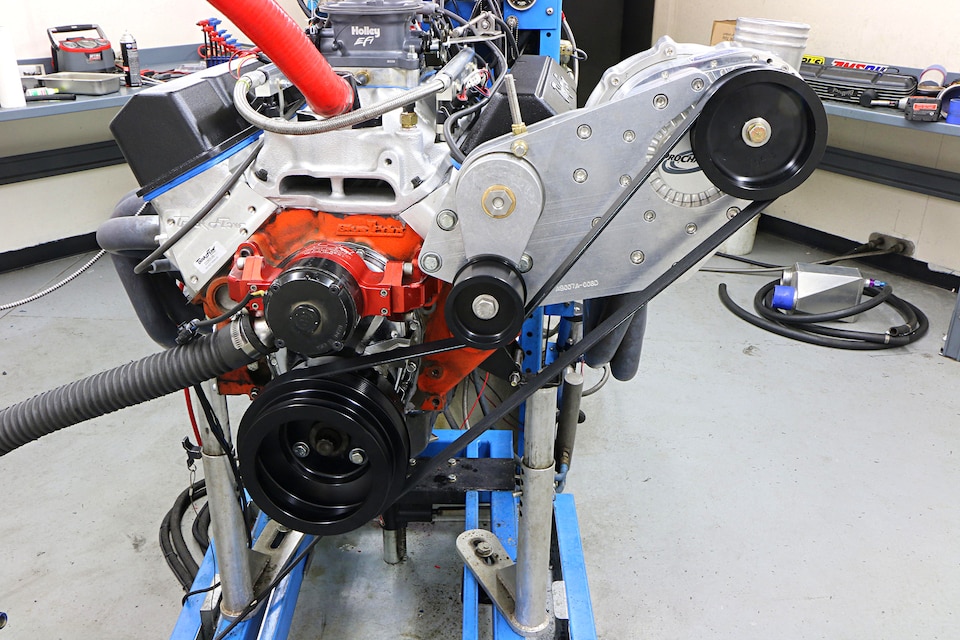

After running the fuel injection, it was time to employ the ProCharger F-1A supercharger. The supercharger was equipped with the largest (4.5-inch) blower pulley we had available, meaning the lowest boost we could run. The crank pulley was an eight-rib, eight-inch unit. Ideally, we'd like to see a cog belt at power levels above 1,000 hp, but this system worked well once we had the system tensioned properly.

15/22

15/22

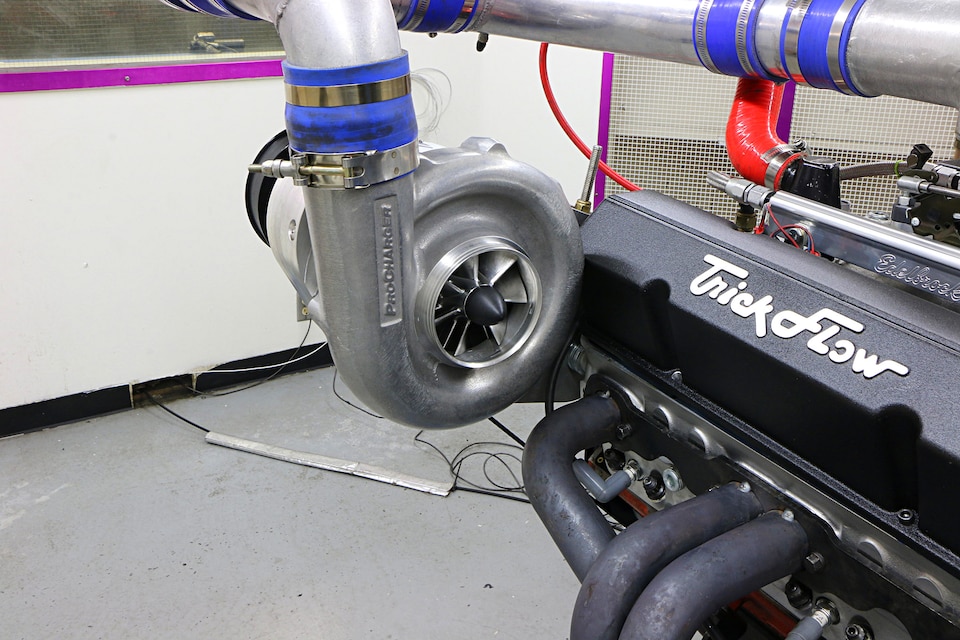

The F-1A featured an efficient impeller design that was easily capable of supporting our four-digit power level goal.

16/22

16/22

To improve airflow and keep the blower from sucking hot air near the header, we installed a silicone coupler and radiused air entry from Summit Racing. Run on the dyno without an intercooler and with E85 fuel, the supercharged 400-inch BPE small-block produced 952 hp and 828 lb-ft of torque at a peak boost level of 17.3 psi.

17/22

17/22

Next, we added this air-to-water intercooler (from ProCharger) to the mix, and then ran on both race fuel and E85. Run with 114-octane Rockett Brand race fuel, the engine produced 966 hp and 846 lb-ft of torque, though the belt started to slip slightly near the power peak. After tightening the belt and switching to E85, we were rewarded with 1,008 hp at 6,300 rpm and 874 lb-ft of torque. The combination of bolt-ons and boost sure had a positive effect on the power output of our crate engine.

18/22

18/22

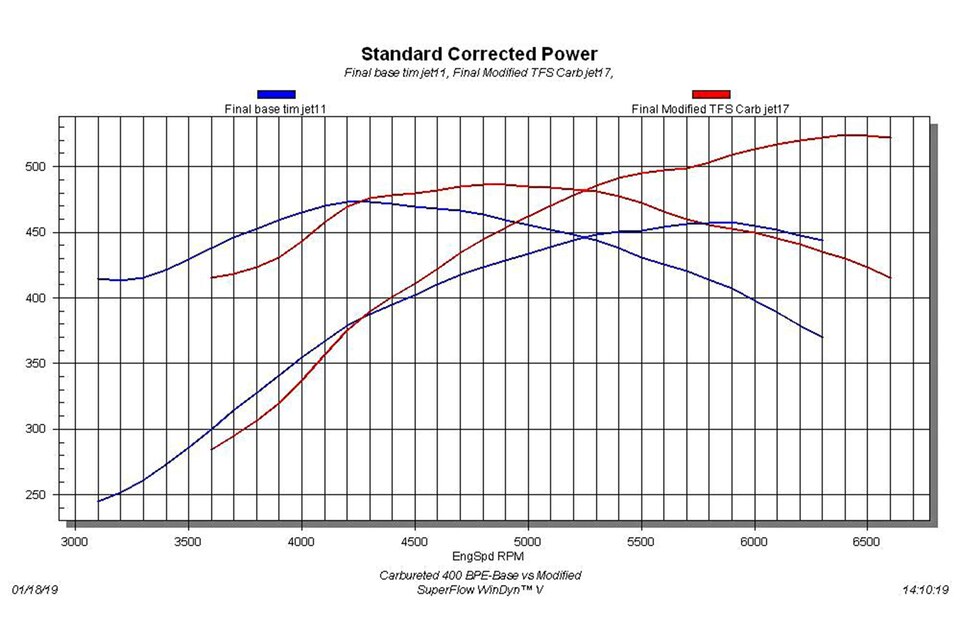

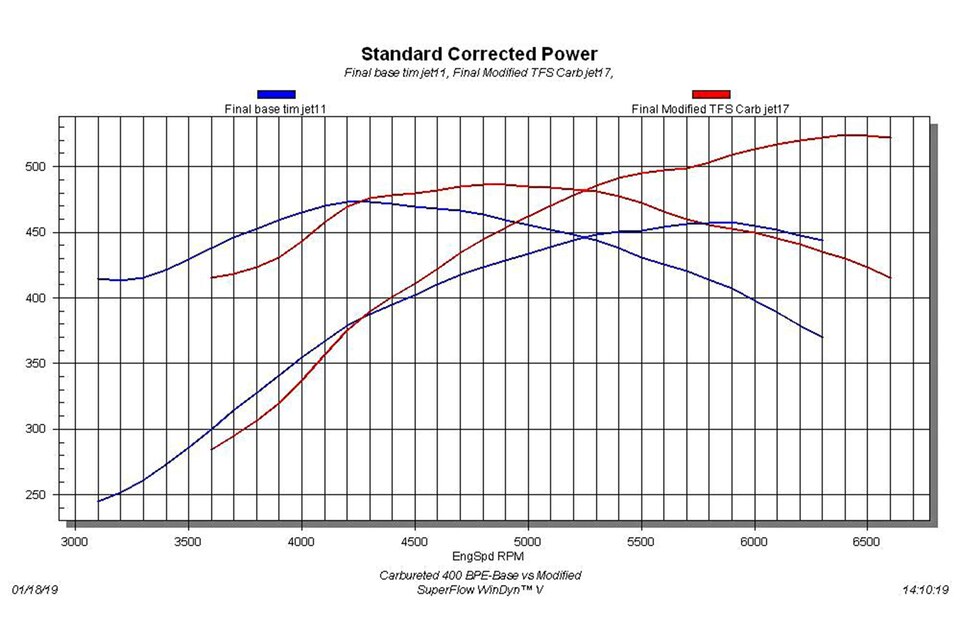

Carbureted BPE 400 SBC — Base vs. Top-End Combo Despite dropping the compression by over half a point, the modifications to the (low-compression, power-adder ready) BPE 400 small-block had a positive effect on power. Replacing the as-cast heads, mild cam, and Edelbrock Performer RPM Air-Gap intake with TFS Super 23 230 heads, Comp XR300HR cam, and single-plane intake resulted in a jump in power from 457 hp and 473 lb-ft of torque to 524 hp and 486 lb-ft of torque.

19/22

19/22

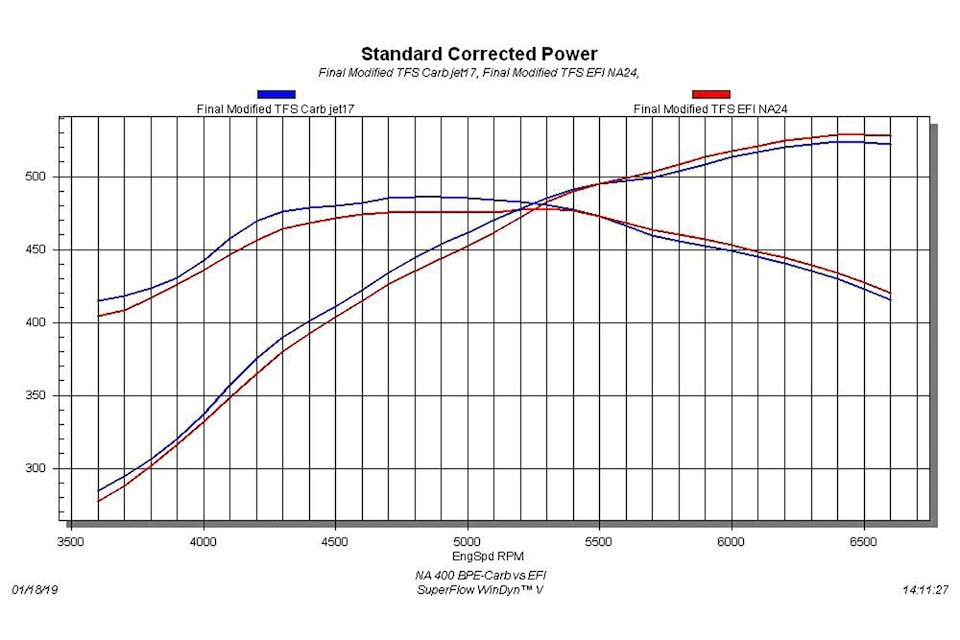

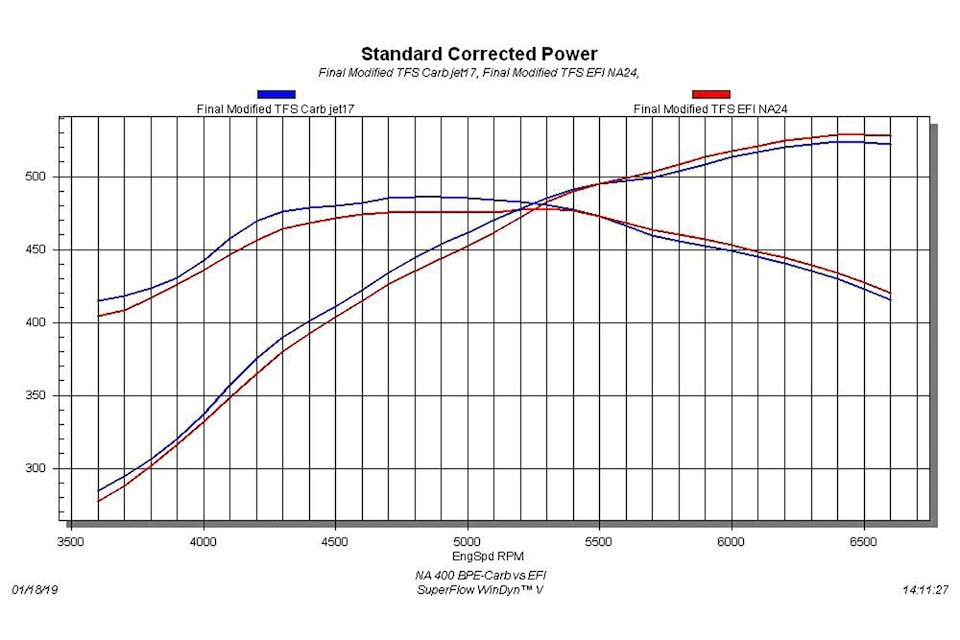

NA Modified BPE 400 SBC — Carb vs. EFI Part of the upgrade performed on the small-block 400 was the installation of a single-plane, EFI intake from Edelbrock. Prior to hooking up the electronics, we ran the EFI intake with a carburetor. Run with the carb, the modified engine produced 524 hp and 486 lb-ft of torque. After the installation of the 4150 throttle body and dialing in the A/F ratio and timing with the Holley HP management system, the injected small-block produced 529 hp and 478 lb-ft of torque. The introduction of the fuel-injection system allowed us to dial in the A/F ratio over the entire curve, something not always possible with a carburetor. The improved air/fuel mixture resulted in more peak power, but the fuel cooling offered by the carb showed its worth by offering more peak torque.

20/22

20/22

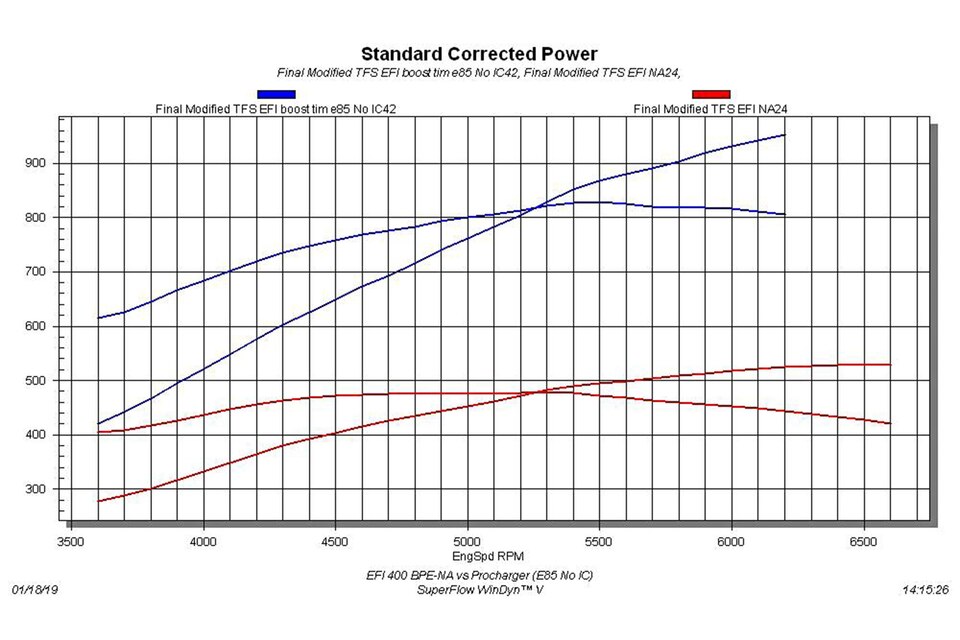

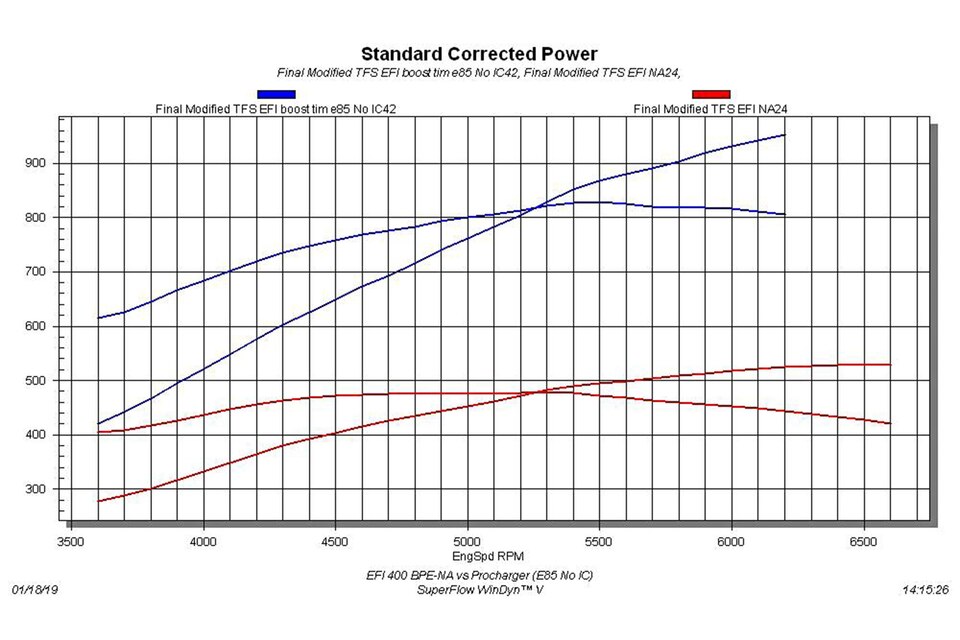

Modified BPE 400 SBC — NA vs. ProCharger F-1A, E85 (non IC) Our first test with boost was to install the ProCharger F-1A supercharger and run it on the injected small-block using E85 and no intercooler. The F-1A was equipped with the supplied 8-inch crank pulley and the largest (4.5-inch) blower pulley. This combination resulted in the lowest possible boost pressure available to us. Equipped with no intercooler and run with Rockett Brand E85 fuel, the supercharged BPE 400 produced 952 hp and 828 lb-ft of torque at a peak boost reading of 17.3 psi. The F-1A improved the power output of the small-block by an impressive 423 hp.

21/22

21/22

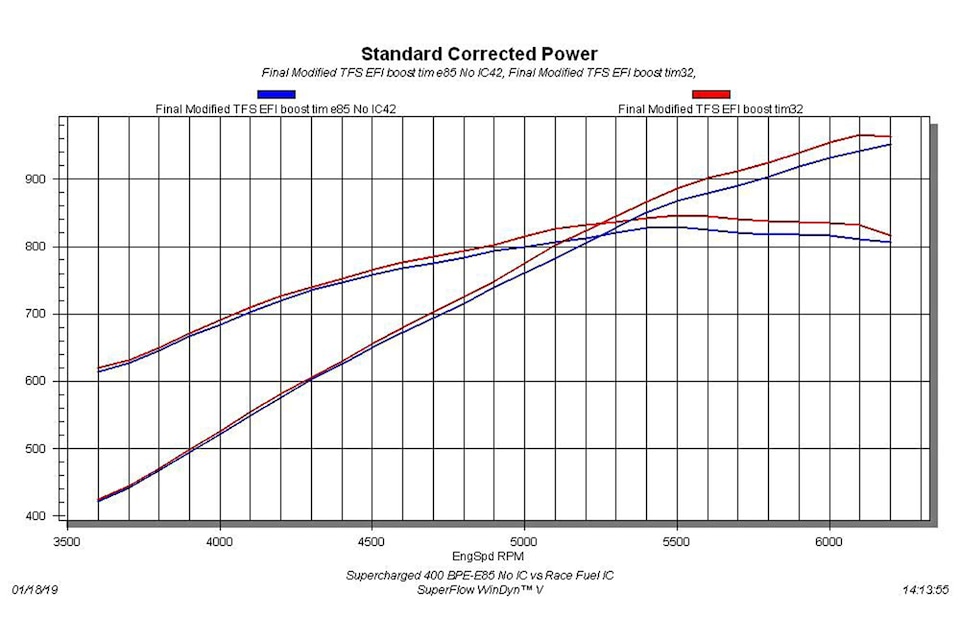

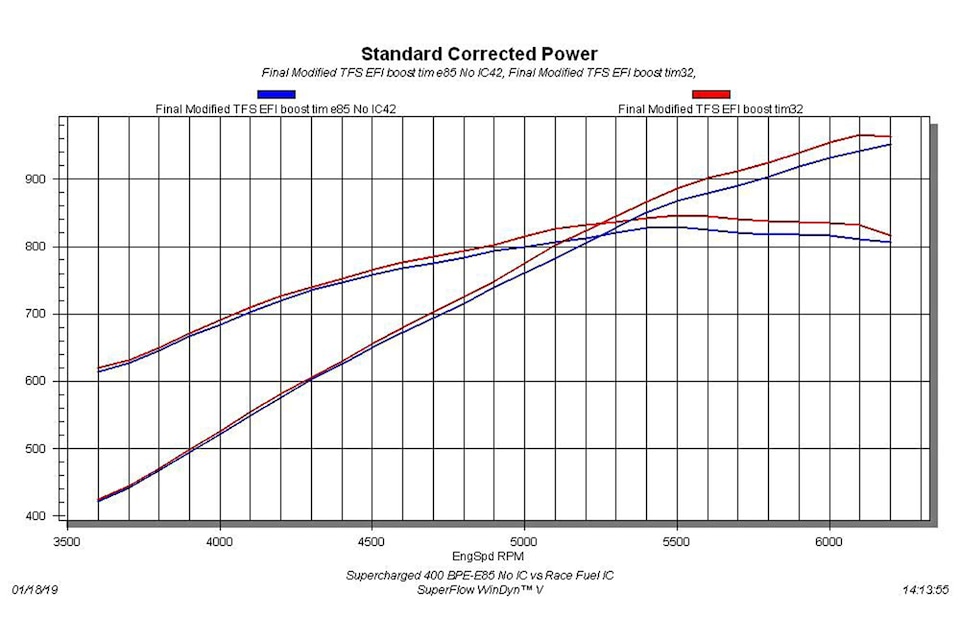

Supercharged BPE 400 SBC — E85 (Non IC) vs. Race Fuel (IC) After adding the ProCharger F-1A supercharger to the mix, we decided to do some more testing. Run non-intercooled with E85 fuel, the supercharged engine produced 952 hp and 828 lb-ft of torque. We replaced the E85 with 114-octane Rockett Brand race fuel (making no changes to timing) and added an air-to-water intercooler. Equipped with the race fuel and intercooler, the power output improved to 966 hp and 846 lb-ft of torque, despite a slight drop in boost pressure through the intercooler.

22/22

22/22

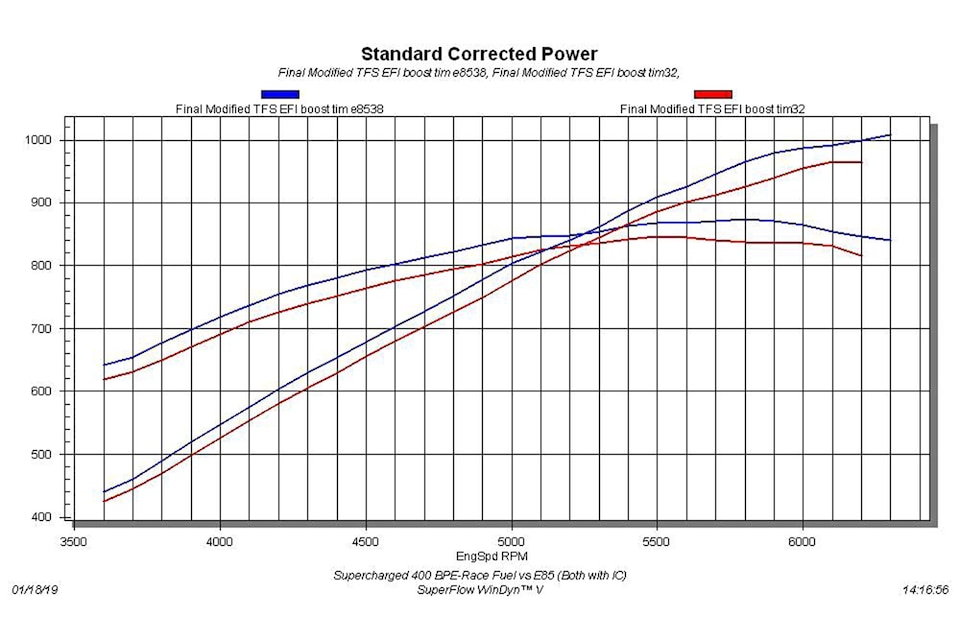

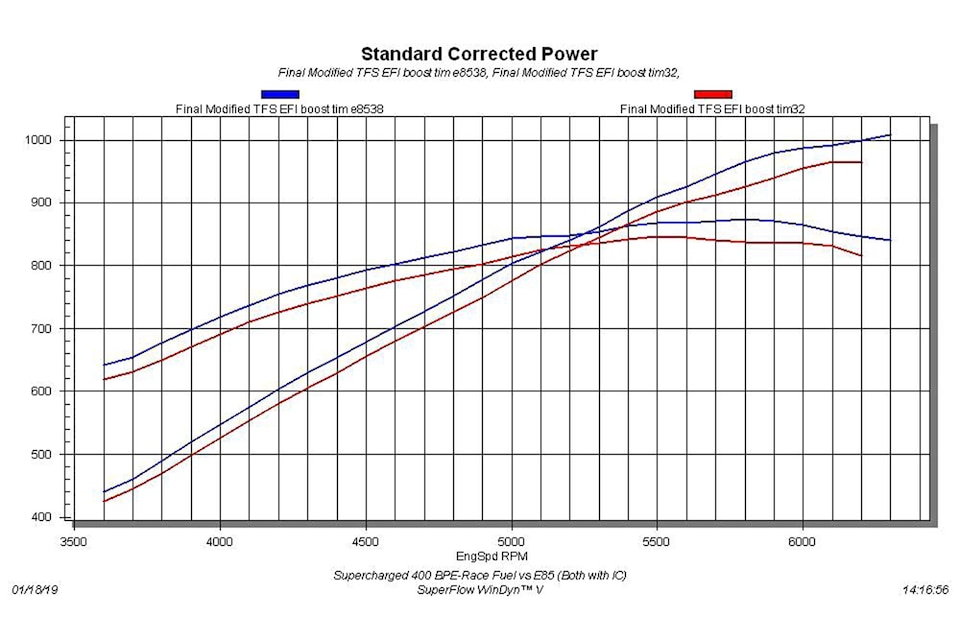

Intercooled, Supercharged BPE 400 SBC — Race Fuel vs. E85 Having tested the engine with E85 and no intercooler versus race gas with an intercooler, there was only one test left to do. We had to see how much power was available with E85 and the air-to-water intercooler. After equipping the small-block with both E85 and the intercooler, the power output jumped to 1,008 hp and 874 lb-ft of torque. Remember, this was with the least amount of boost we could run with our giant 4.5-inch blower pulley. We are constantly amazed at how easy it is to make over 1,000 hp these days.

Sources:

ARP

800.826.3045

arp-bolts.com

BluePrint Engines

800.483.4263

blueprintengines.com

Comp Cams

901.795.2400

compcams.com

Holley/Hooker

270.782.2900

holley.com

ProCharger

913.338.2886

procharger.com

Rockett Brand Racing Fuel

847.795.8400

rockettbrand.com

Summit Racing

888.939.7497

summitracing.com

Trick Flow Specialties

888.841.6556

trickflow.com

and its all too obvious that the main goal was to list parts suppliers and name parts sources,I saw several areas, in engine build could be improved

but still theres bits of useful info included, so reading through is not a total waste of time, as an interesting build.

https://www.summitracing.com/parts/tfs-3241t001-c03/media/chartsandguides

looking at the listed parts ,Id think, to duplicate this build,

I think you could reasonably expect to be in the $20K-$22K expense range,

which in my opinion makes this ludicrous, as for similar cash ,

you could build a more impressive supercharged BBC.

when your spending that kind of cash , to build an engine too exceed 1000 HP,

I think starting with a 540-556 BBC makes more sense

https://www.shafiroff.com/Big-Block-Chevy.php

1,000 HP From a Broken-In 400-Inch Small-Block Chevy

F-1 Technology

Richard Holdener Aug 15, 2019

View Full Gallery

View Full GalleryFrom the looks of the title you might think this is a story on some high-tech, modern energy regeneration system used by those fragile—but blindingly fast—F1 cars. Nothing could be further from the truth. The F-1 reference in the title does indeed deal with energy enhancement, but it's taken from the designation of a very capable ProCharger centrifugal supercharger. Rather than some high-strung, temperamental race engine, we applied the modern boost technology to an archaic, pushrod small-block Chevy.

In the Mouse motor's defense, it was fuel-injected, so there was at least a hint of sophistication and technology. But with open headers; a big, nasty cam; and a huffer at full song it was still definitely more anvil than advanced technology. Sometimes an anvil is the perfect tool for getting the job done. As a motivational source for coaxing our heavy Chevy station wagon down the quarter-mile, the small-block anvil was exactly what we needed.

In truth, the test engine started out life heading in the right direction. The BluePrint Engines (BPE) small-block was designed specifically for use with power-adders and already included a displacement bump, forged internals, and low compression. The last of the three is often thought of as a detriment, but the low compression allowed us to safely crank up the boost to reach four-digit power levels. The engine sports 400 cubic inches thanks to a combination of a 4.125-inch bore and 3.750-inch stroke. Supplied as a long-block, the BPE four-bolt block was stuffed with forged internals that included the stroker crank, 6.000-inch H-beam rods, and dished pistons. The combo also included a set of as-cast aluminum heads (PN HP8103) with 220cc intake ports, 64cc chambers, and a 2.08/1.60 valve package. The healthy hydraulic roller cam checked in with a 0.555/0.577-inch lift split (with 1.6:1 roller rockers), 236/248-degree duration split, and 113-degree LSA. The long-block was finished up with valve and timing covers, and a complete oiling system.

Unlike many of our previous buildups, this crate engine was not fresh from the manufacturer. In fact, this small-block 400 had seen over 30,000 street and strip miles, including copious amounts of nitrous. The BPE engine was equipped with an Edelbrock RPM Air-Gap intake and Holley Terminator EFI throttle-body system. The EFI system was combined with multiple stages of NOS nitrous, feeding as much as 225 hp with both stages engaged. This helped push the 4,500-pound wagon deep into the 11s, but like most enthusiasts, the owner wanted more.

Rather than subject the BPE crate engine to a third nitrous stage, we decided to change direction and replace the nitrous with a single power-adder capable of doubling their 225hp gain, enter the ProCharger F-1A centrifugal supercharger.

Looking at the specs of the F-1A, we see the blower listed as being capable of supporting up to 1,100 hp. We know from experience that ProCharger's listed max power levels are conservative given the right engine combinations, so the F-1A was nearly perfect for our goal of reaching 1,000 hp with the small-block. While just cranking up the boost can certainly get you to your power goal, the preferred method is to get there at the lowest possible boost level. This way, the power added is done so with the smallest increase in the charge air temperature. Though we would be running the small-block with both an intercooler and on E85, we set out to maximize the power output of the engine in its naturally aspirated state before introducing boost.

While the BPE 400 was no slouch, we decided to replace the top end, including the as-cast heads, cam, and dual-plane intake manifold. Any gains made to the naturally aspirated combination would be multiplied under boost. For example, if we improved the power output of the naturally aspirated engine by 50 hp, we could see an extra 100 hp (or more) under boost. The gains really start to add up once you run elevated boost levels. This multiplication factor also allows you to reach any given power level at a lower boost level.

Before improving the power output of the BPE 400, we needed to see where we stood. The engine came out of the wagon and onto the dyno. Because we would be replacing the Terminator EFI throttle body with a multi-port EFI system, we elected to run the engine with a carburetor for the baseline. Equipped with a dual-plane intake, Holley carb, and MSD distributor, the low-compression BPE 400 produced 457 hp at 5,900 rpm and 473 lb-ft of torque at 4,300 rpm.

We then installed a set of Trick Flow Specialties Super 23 230cc heads that featured full CNC porting, a 2.08/1.60 valve package, and 70cc combustion chambers. The larger chambers reduced the static compression by 0.70 of a point, but the extra airflow and improved chamber design more than offset the drop in compression. The Super 23 heads were teamed with a Comp XR300HR cam that offered a 0.562/0.580-inch lift split, 248/254-degree duration split, and 110-degree LSA. Our original plan was to run a custom blower grind from the Billy the cam wizard over at Comp Cams, but an error on the author's part meant we received a retrofit cam and not one designed for the hydraulic roller block (sorry, Billy. ). The heads and cam were combined with an Edelbrock Victor Jr. EFI intake, and a carburetor. So equipped, the new combination produced 524 hp at 6,400 rpm and 486 lb-ft at 4,800 rpm. These peak numbers shifted slightly to 529 hp and 478 lb-ft once we replaced the carb with a Holley (4150) throttle body and 120-pound injectors.

With our low-compression, power-adder friendly 400-inch small-block easily exceeding 525 hp, it was time for some boost. And that's where things start to get very interesting.

Supplied by BluePrint Engines (BPE), the crate long-block was designed for power-adder use and included forged internals, 9.0:1 compression, and as-cast aluminum heads. This particular engine has seen some 30K miles and endless hits of nitrous. The long-block had previously been equipped with an Edelbrock Performer RPM Air-Gap intake and Holley Terminator EFI. For our baseline dyno test we topped the intake with a Holley 750 XP carburetor. It pumped out 457 hp at 5,900 rpm and 473 lb-ft of torque at 4,300 rpm.

After the baseline, the engine was torn down in anticipation of the top-end upgrade.

Off came the intake and cylinder heads, followed by the camshaft supplied with the crate engine.

The mild cam was replaced with a much more aggressive off-the-shelf cam from Comp. The Xtreme Energy XR300HR cam offered a 0.562/0.580-inch lift split, 248/254-degree duration split, and 110-degree LSA. The cam was combined with a set of Trick Flow Specialties Super 23 230 heads. ARP head studs will keep everything secure.

Thanks to CNC porting, the 230cc intake ports on the Super 23 heads flowed 310 cfm, enough to support well over 600 NA hp. The Super 23 230 heads featured a dual-spring package (with titanium retainers) that allowed up to 0.680-inch lift.

To maximize flow, the Super 23 heads featured a stainless 2.08/1.60 valve package and fully CNC-ported combustion chambers. The increase in chamber size from the BPE 64cc heads to the TFS Super 23 70cc heads lowered the static compression by roughly 0.70 of a point.

The Comp cam was combined with a set of hardened pushrods and Ultra Gold 1.6:1-ratio roller rockers.

The dual-plane, carbureted intake was replaced by this single-plane, EFI intake from Edelbrock.

We initially topped the single-plane, EFI intake with a carburetor. Ensuring plenty of spark was an MSD billet distributor and 6AL ignition amplifier.

Run on the dyno in carbureted trim, the modified 400-inch small-block produced 524 hp at 6,400 rpm and 486 lb-ft of torque at 4,800 rpm.

After running the carburetor, we replaced the Holley XP with a 4150 throttle body. The airflow supplied by the high-flow throttle body was combined with fuel from a set of 120-pound Holley injectors. Everything was controlled with a Holley HP ECU.

The EFI system allowed us to optimize the air/fuel curve (something not possible with the carbureted combination). Equipped with the EFI system, the injected small-block produced 529 hp and 478 lb-ft of torque.

After running the fuel injection, it was time to employ the ProCharger F-1A supercharger. The supercharger was equipped with the largest (4.5-inch) blower pulley we had available, meaning the lowest boost we could run. The crank pulley was an eight-rib, eight-inch unit. Ideally, we'd like to see a cog belt at power levels above 1,000 hp, but this system worked well once we had the system tensioned properly.

The F-1A featured an efficient impeller design that was easily capable of supporting our four-digit power level goal.

To improve airflow and keep the blower from sucking hot air near the header, we installed a silicone coupler and radiused air entry from Summit Racing. Run on the dyno without an intercooler and with E85 fuel, the supercharged 400-inch BPE small-block produced 952 hp and 828 lb-ft of torque at a peak boost level of 17.3 psi.

Next, we added this air-to-water intercooler (from ProCharger) to the mix, and then ran on both race fuel and E85. Run with 114-octane Rockett Brand race fuel, the engine produced 966 hp and 846 lb-ft of torque, though the belt started to slip slightly near the power peak. After tightening the belt and switching to E85, we were rewarded with 1,008 hp at 6,300 rpm and 874 lb-ft of torque. The combination of bolt-ons and boost sure had a positive effect on the power output of our crate engine.

Carbureted BPE 400 SBC — Base vs. Top-End Combo Despite dropping the compression by over half a point, the modifications to the (low-compression, power-adder ready) BPE 400 small-block had a positive effect on power. Replacing the as-cast heads, mild cam, and Edelbrock Performer RPM Air-Gap intake with TFS Super 23 230 heads, Comp XR300HR cam, and single-plane intake resulted in a jump in power from 457 hp and 473 lb-ft of torque to 524 hp and 486 lb-ft of torque.

NA Modified BPE 400 SBC — Carb vs. EFI Part of the upgrade performed on the small-block 400 was the installation of a single-plane, EFI intake from Edelbrock. Prior to hooking up the electronics, we ran the EFI intake with a carburetor. Run with the carb, the modified engine produced 524 hp and 486 lb-ft of torque. After the installation of the 4150 throttle body and dialing in the A/F ratio and timing with the Holley HP management system, the injected small-block produced 529 hp and 478 lb-ft of torque. The introduction of the fuel-injection system allowed us to dial in the A/F ratio over the entire curve, something not always possible with a carburetor. The improved air/fuel mixture resulted in more peak power, but the fuel cooling offered by the carb showed its worth by offering more peak torque.

Modified BPE 400 SBC — NA vs. ProCharger F-1A, E85 (non IC) Our first test with boost was to install the ProCharger F-1A supercharger and run it on the injected small-block using E85 and no intercooler. The F-1A was equipped with the supplied 8-inch crank pulley and the largest (4.5-inch) blower pulley. This combination resulted in the lowest possible boost pressure available to us. Equipped with no intercooler and run with Rockett Brand E85 fuel, the supercharged BPE 400 produced 952 hp and 828 lb-ft of torque at a peak boost reading of 17.3 psi. The F-1A improved the power output of the small-block by an impressive 423 hp.

Supercharged BPE 400 SBC — E85 (Non IC) vs. Race Fuel (IC) After adding the ProCharger F-1A supercharger to the mix, we decided to do some more testing. Run non-intercooled with E85 fuel, the supercharged engine produced 952 hp and 828 lb-ft of torque. We replaced the E85 with 114-octane Rockett Brand race fuel (making no changes to timing) and added an air-to-water intercooler. Equipped with the race fuel and intercooler, the power output improved to 966 hp and 846 lb-ft of torque, despite a slight drop in boost pressure through the intercooler.

Intercooled, Supercharged BPE 400 SBC — Race Fuel vs. E85 Having tested the engine with E85 and no intercooler versus race gas with an intercooler, there was only one test left to do. We had to see how much power was available with E85 and the air-to-water intercooler. After equipping the small-block with both E85 and the intercooler, the power output jumped to 1,008 hp and 874 lb-ft of torque. Remember, this was with the least amount of boost we could run with our giant 4.5-inch blower pulley. We are constantly amazed at how easy it is to make over 1,000 hp these days.

Sources:

ARP

800.826.3045

arp-bolts.com

BluePrint Engines

800.483.4263

blueprintengines.com

Comp Cams

901.795.2400

compcams.com

Holley/Hooker

270.782.2900

holley.com

ProCharger

913.338.2886

procharger.com

Rockett Brand Racing Fuel

847.795.8400

rockettbrand.com

Summit Racing

888.939.7497

summitracing.com

Trick Flow Specialties

888.841.6556

trickflow.com

Last edited: