8

87vette81big

Guest

I sent pictures of your Mohawk Lift Richard.

Ed is thinking .

Ed is thinking .

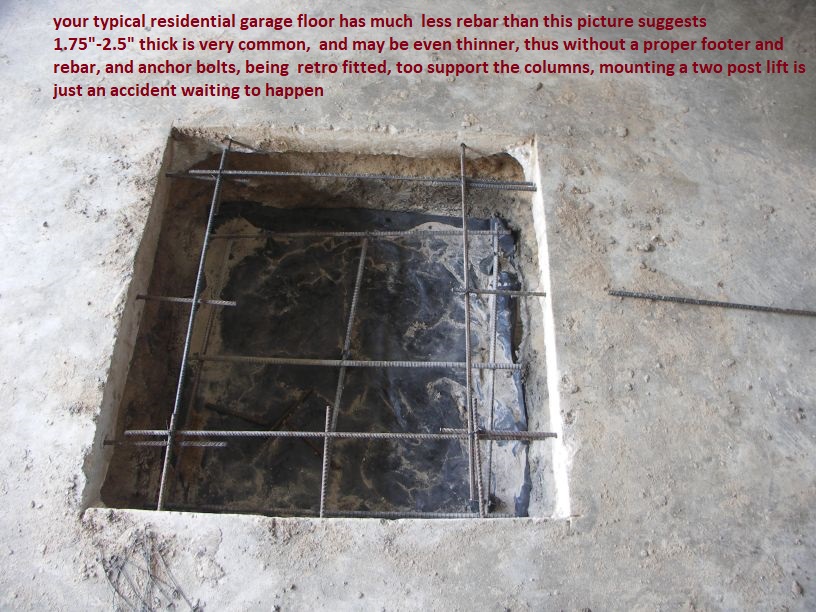

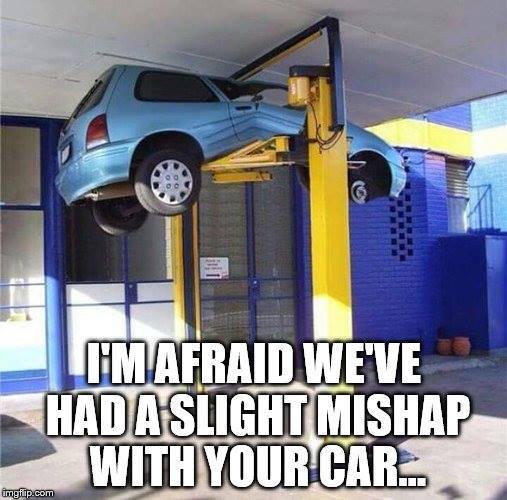

here is a great example of multi level, compound, stupidity and negligence

first

the guy operating the lift should have seen what was happening to the van well before the damage went that far!

second

look at the picture carefully, that YELLOW bar,

just below the upper beam, that is keeping the vans roof from going higher,

is supposed to be an emergency power contact switch that stops the lift the second its lifted a 1/4" from its hanging location

A friend and I went to an estate sale Saturday.

We got a truck(and car) load of parts at a great price.

Part of the sale includes an old 4 post lift.I have no pictures and haven't seen it working.

I can get it very cheap.

There was no brand name on it that we could find.It looks to be in good condition though.

Each post has a large threaded rod from top to bottom to do the lifting.There's a shallow beam between each set of posts at each end with ramps between them.I'm guessing there's a cable or chain drive system inside this part of the lift to connect all 4 posts.It is about 11' wide and 15'long.8'tall where the motor is mounted.Other 3 posts are about 7'tall.

Does anyone recognize this lift?

Hoping to find some info on dis-assembly to move it.

We had a few thousand used,new and nos parts to go thru and spent hours there is why I didn't spend more time on the lift.

It's a good ways from me,so when I do go back I'll get pics of it,but hoping to try to get it then.

Again,I'm hoping someone has any info.I've looked at a lot of them on-line but nothing is it.

Thanks,Mike.

hey Grumpy, I purchased a used four post lift at a local estate sale ,

and it was simply standing in the previous owners two car garage,

not even fastened to the floor, he, had obviously wanted to move it occasionally.

I just disassembled it enough for transport and brought it home and re-assembled it,

but it scares the hell out of me because if I put the car up on it you can move the lift noticeably,

just giving it a mild shove, I'm certain it could be made to drop the car if anyone gave it a serious shove.

so how do I stabilize this fairly easily?

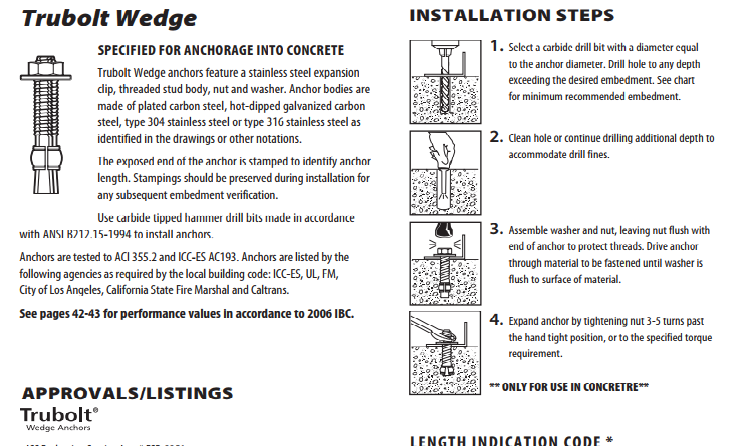

Grumpy I read all the way through your thread on lifts and decided on the purchase of a quality two post lift design.

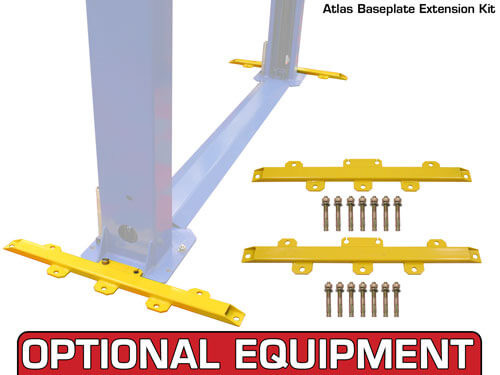

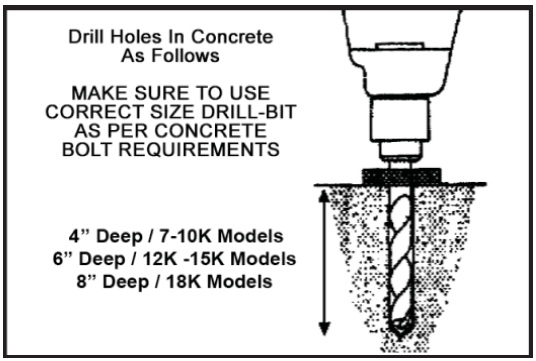

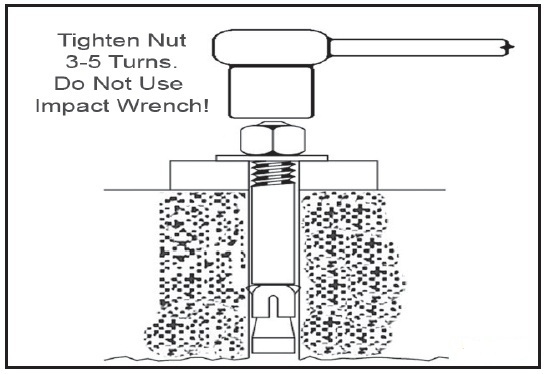

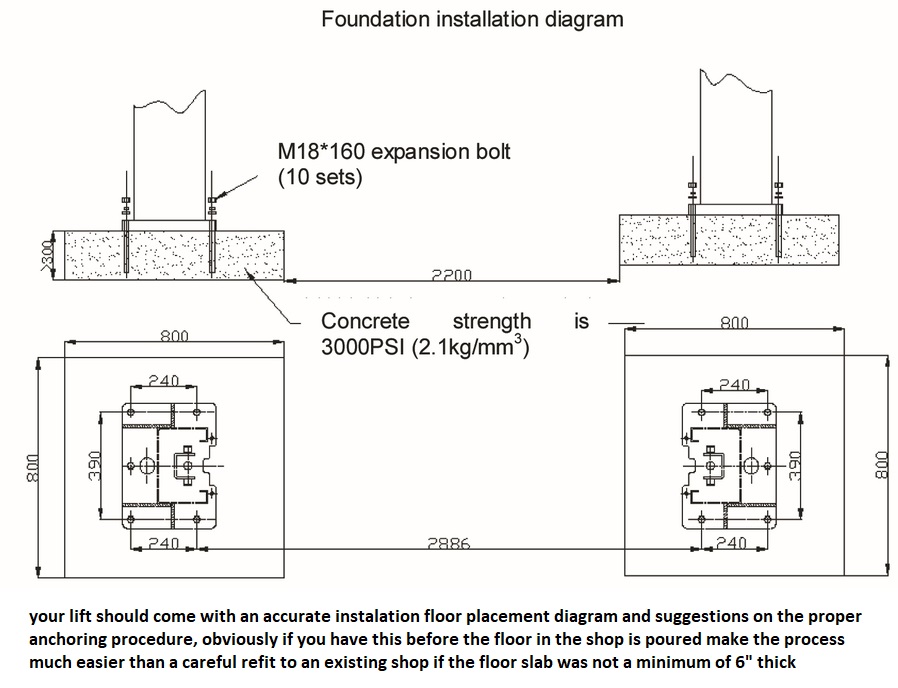

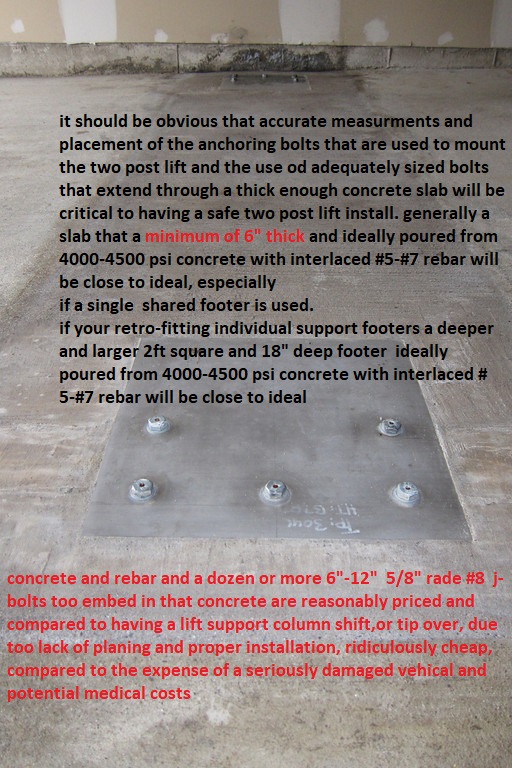

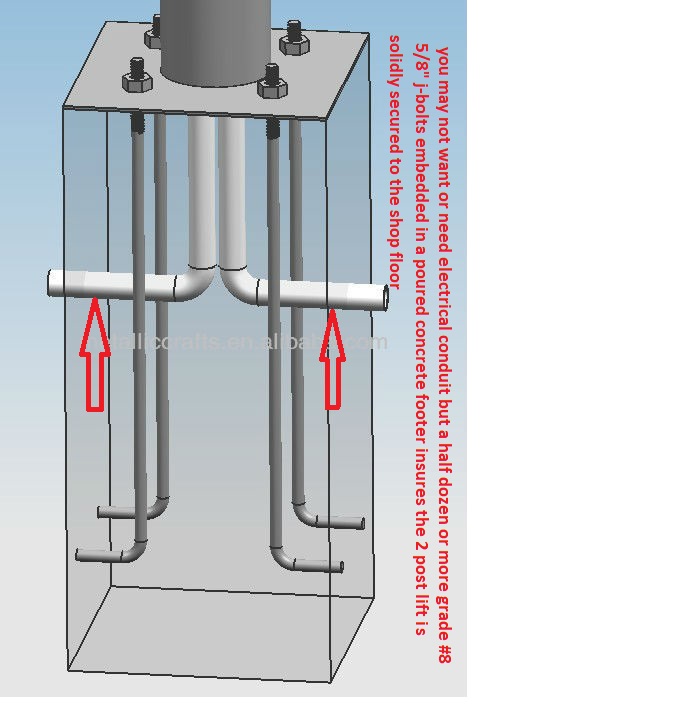

the manufacturer states its strongly suggested that a 4" minimum slab concrete floor be used to securely fasten the lift base.

I test drilled my floor slab in several places and as you mentioned I have a 2 3/4" to 3.0" slab.... now what?