I got asked to suggest a bullet mold for a 44 mag revolver,

if limited to one the lee 310 grain or the 250 grain NEI,

certainly would be valid choices for most people, the 250 grain holds a very minor advantage,

in 100 yard accuracy , in my experience,

but it so slight I doubt most people shoot enough or consistently enough,

to see it .

notice ALL are gas check designs,

the plain base bullets in my experience,

have consistently proven to be easily proven LESS accurate and consistent.

https://www.sagesoutdoors.com/gas-checks/

https://www.midwayusa.com/s?userSearchQuery=gas+checks&userItemsPerPage=48

https://www.midsouthshooterssupply.com/search?SearchTerm=gas+checks

less than about 1/4" in the average 3" groups from either bullet mold,

at 100 yard targets, and thats seems consistently to be the case, in several revolvers and my marlin lever action.

the 44 caliber is about ideal for lower cost hard cast bullet use, and because I use the lee 310 for most hunting its a favorite

I've used a 44 mag revolver, or a 445 DWSM revolver ,

for 4-5 decades plus, almost exclusively with a selection of hard cast gas check bullet designs

powders like,

H110, blue dot, and herc 2400 are about ideal.

the 310 lee in the 44 mag and the 330 grain NEI in the DWSM are close to ideal for hunting,

but the twist rate in the 44 mag generally won,t stabilize the 330 gain NEI,

the lighter weight NEI mold designs are generally good for target use,

but certainly will work for hunting anything like hogs or deer,

lethality is not a problem, nut consistently getting exit wounds can be with the

235 grain hard cast bullets

I use the 330 grain almost exclusively in the 445 DWSM,

as it takes up excessive internal powder space, in my opinion,

in the shorter 44 mag case and I try hard to maintain at least 1200 fps,

in hunting revolvers

the 250 and 260 grain bullets from NEI molds are exceptionally accurate, and theres zero issue hunting hogs or deer,

but I occasionally won,t get exits so I use the lyman and lee 300-310 grain bullet molds,

on elk hunts with the 44 mag

https://leeprecision.com/mold-6-cav-c430-310-rf.html

https://www.midwayusa.com/product/5...0-diameter-300-grain-semi-wadcutter-gas-check

http://www.neihandtools.com/catalog/index.html

btw the three

most accurate powders I found for use in a 44 mag revolver during decades of testing

are

blue dot

2400

h110

https://www.shootingtimes.com/editorial/reloading-the-44-magnum/99155

https://load-data.nosler.com/load-data/44-remington-magnum-hg/

http://garage.grumpysperformance.com/index.php?threads/44-mag.7500/

http://garage.grumpysperformance.com/index.php?threads/445-dan-wesson-revolvers.1992/

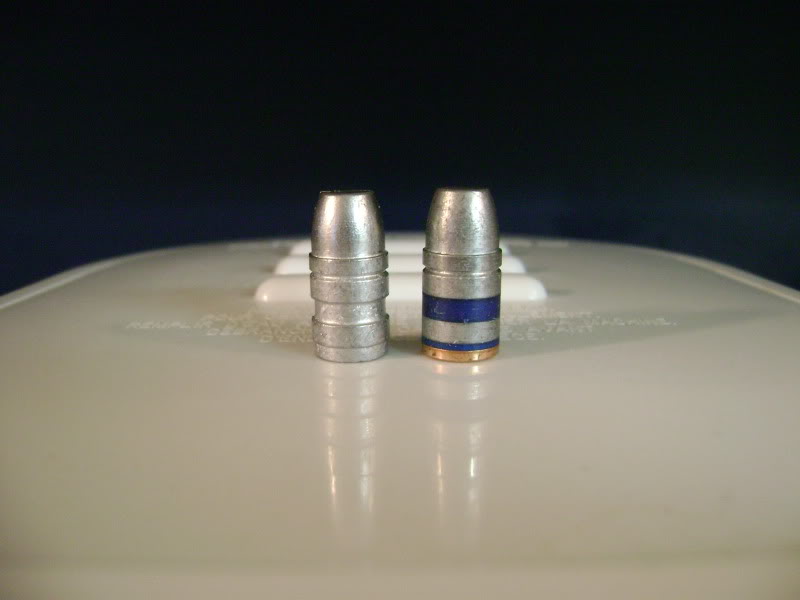

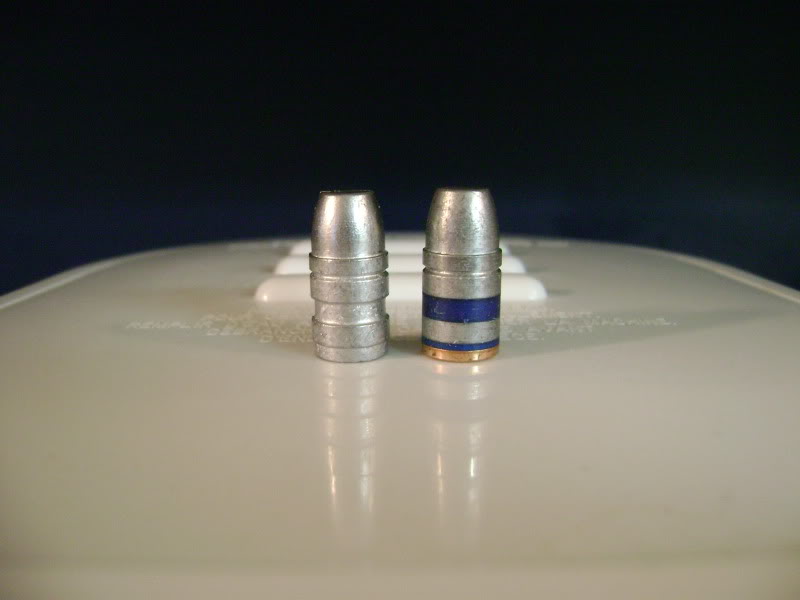

the mild frosted appearance has ZERO negative effect on performance and in fact its tends to indicate a more consistent mold fill

the alloy change allowed the tin and antimony crystallizes content to more effectively fill the voids but results in a slightly more frosted appearance

heavy frosting generally tends to result in a slightly under sized bullet, shiney, has no benefit, other than aesthetics,

want to prove it?

get your best looking ten of each shiney and mildly or even completely frosted bullets , load each group exactly the same, now shoot both in separated groups

chances are very good little difference or the frosted group is marginally tighter,

set the first shiney bullets you cast aside and then weigh and measure them for comparison to the frosted ones.

740F-760F is generally fine, obviously cast at a rate that does not over heat the mold, if you get finning your generally casting too fast or theres debris in the mold

heres a picture I found someplace of mildly frosted and perfectly cast bullets

btw if your going to cast bullets wait till the molds clean and hot then lightly spray the mold interior surface with moly spray, as it helps the cast bullets fall easily from the mold and makes casting process faster and more consistent. (yes the first couple will suck, but after a couple fills the micro moly on the mold surface helps noticeably)

btw if your going to cast bullets wait till the molds clean and hot then lightly spray the mold interior surface with moly spray, as it helps the cast bullets fall easily from the mold and makes casting process faster and more consistent. (yes the first couple will suck, but after a couple fills the micro moly on the mold surface helps noticeably)

if limited to one the lee 310 grain or the 250 grain NEI,

certainly would be valid choices for most people, the 250 grain holds a very minor advantage,

in 100 yard accuracy , in my experience,

but it so slight I doubt most people shoot enough or consistently enough,

to see it .

notice ALL are gas check designs,

the plain base bullets in my experience,

have consistently proven to be easily proven LESS accurate and consistent.

https://www.sagesoutdoors.com/gas-checks/

https://www.midwayusa.com/s?userSearchQuery=gas+checks&userItemsPerPage=48

https://www.midsouthshooterssupply.com/search?SearchTerm=gas+checks

less than about 1/4" in the average 3" groups from either bullet mold,

at 100 yard targets, and thats seems consistently to be the case, in several revolvers and my marlin lever action.

the 44 caliber is about ideal for lower cost hard cast bullet use, and because I use the lee 310 for most hunting its a favorite

I've used a 44 mag revolver, or a 445 DWSM revolver ,

for 4-5 decades plus, almost exclusively with a selection of hard cast gas check bullet designs

powders like,

H110, blue dot, and herc 2400 are about ideal.

the 310 lee in the 44 mag and the 330 grain NEI in the DWSM are close to ideal for hunting,

but the twist rate in the 44 mag generally won,t stabilize the 330 gain NEI,

the lighter weight NEI mold designs are generally good for target use,

but certainly will work for hunting anything like hogs or deer,

lethality is not a problem, nut consistently getting exit wounds can be with the

235 grain hard cast bullets

I use the 330 grain almost exclusively in the 445 DWSM,

as it takes up excessive internal powder space, in my opinion,

in the shorter 44 mag case and I try hard to maintain at least 1200 fps,

in hunting revolvers

the 250 and 260 grain bullets from NEI molds are exceptionally accurate, and theres zero issue hunting hogs or deer,

but I occasionally won,t get exits so I use the lyman and lee 300-310 grain bullet molds,

on elk hunts with the 44 mag

https://leeprecision.com/mold-6-cav-c430-310-rf.html

https://www.midwayusa.com/product/5...0-diameter-300-grain-semi-wadcutter-gas-check

http://www.neihandtools.com/catalog/index.html

btw the three

most accurate powders I found for use in a 44 mag revolver during decades of testing

are

blue dot

2400

h110

https://www.shootingtimes.com/editorial/reloading-the-44-magnum/99155

https://load-data.nosler.com/load-data/44-remington-magnum-hg/

http://garage.grumpysperformance.com/index.php?threads/44-mag.7500/

http://garage.grumpysperformance.com/index.php?threads/445-dan-wesson-revolvers.1992/

the mild frosted appearance has ZERO negative effect on performance and in fact its tends to indicate a more consistent mold fill

the alloy change allowed the tin and antimony crystallizes content to more effectively fill the voids but results in a slightly more frosted appearance

heavy frosting generally tends to result in a slightly under sized bullet, shiney, has no benefit, other than aesthetics,

want to prove it?

get your best looking ten of each shiney and mildly or even completely frosted bullets , load each group exactly the same, now shoot both in separated groups

chances are very good little difference or the frosted group is marginally tighter,

set the first shiney bullets you cast aside and then weigh and measure them for comparison to the frosted ones.

740F-760F is generally fine, obviously cast at a rate that does not over heat the mold, if you get finning your generally casting too fast or theres debris in the mold

heres a picture I found someplace of mildly frosted and perfectly cast bullets

Last edited: